Patents

Literature

32results about How to "Precise control of dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

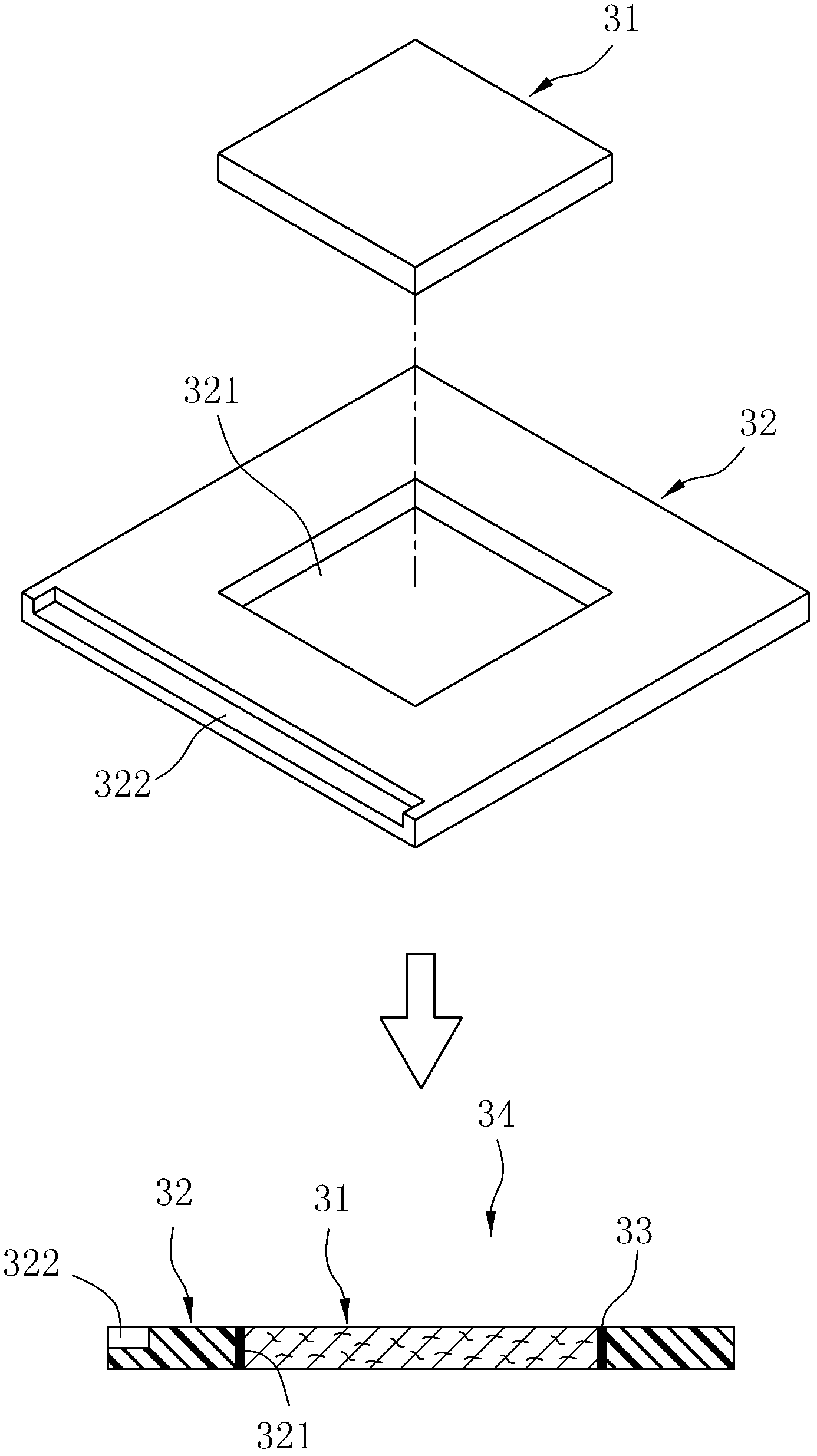

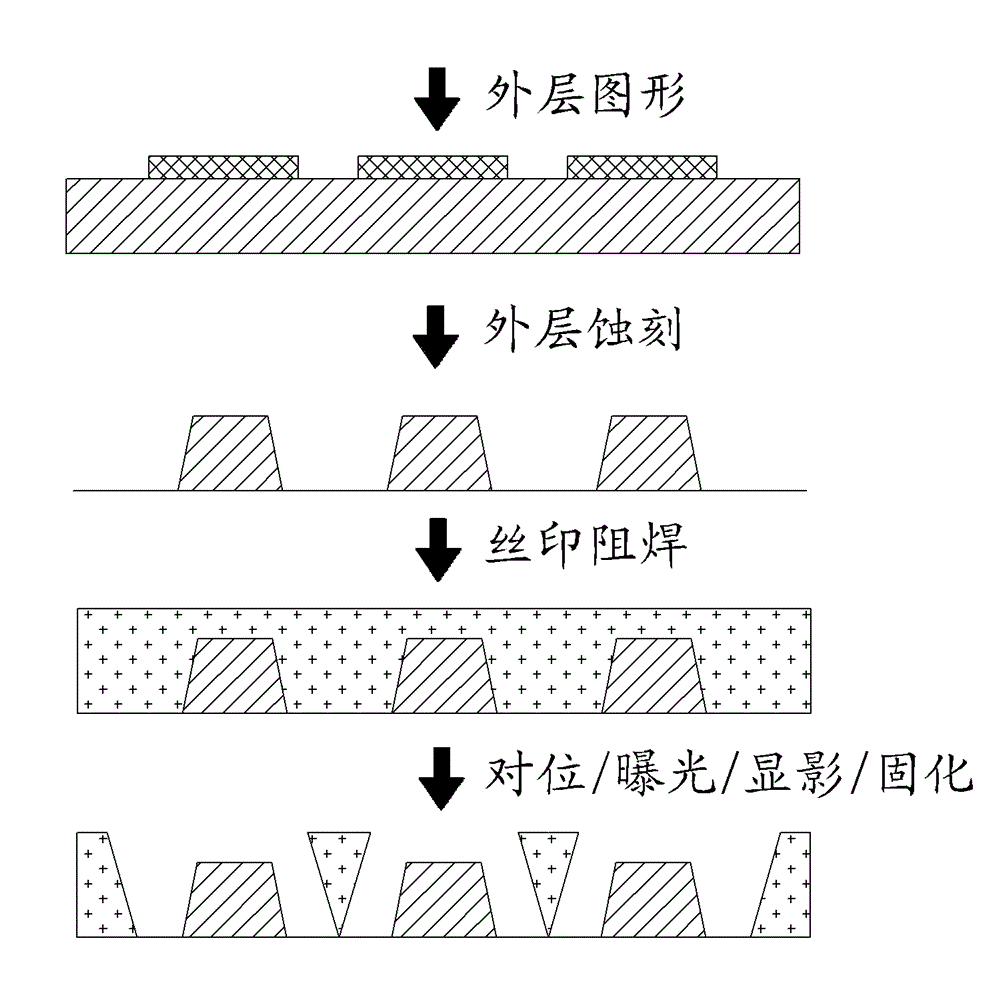

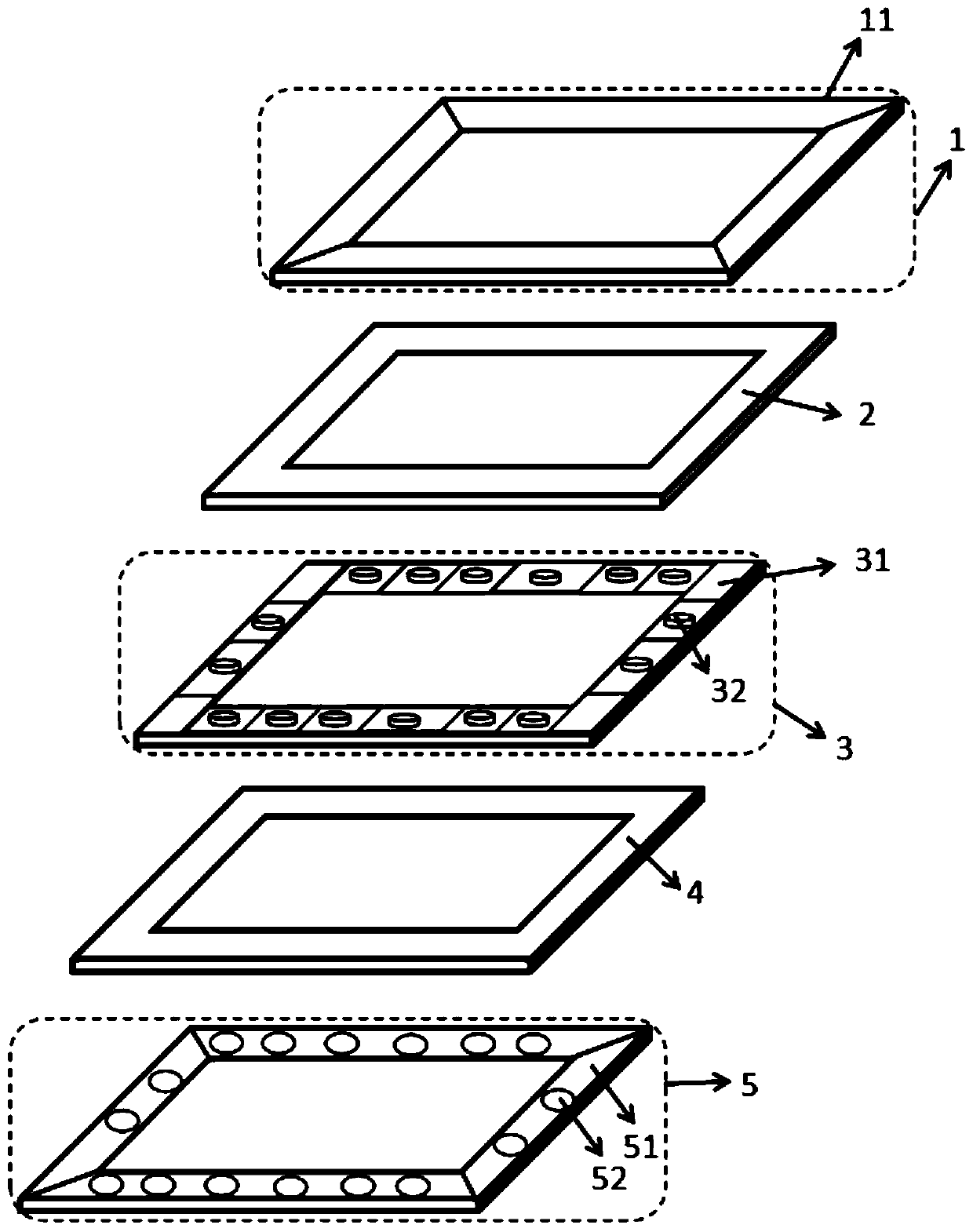

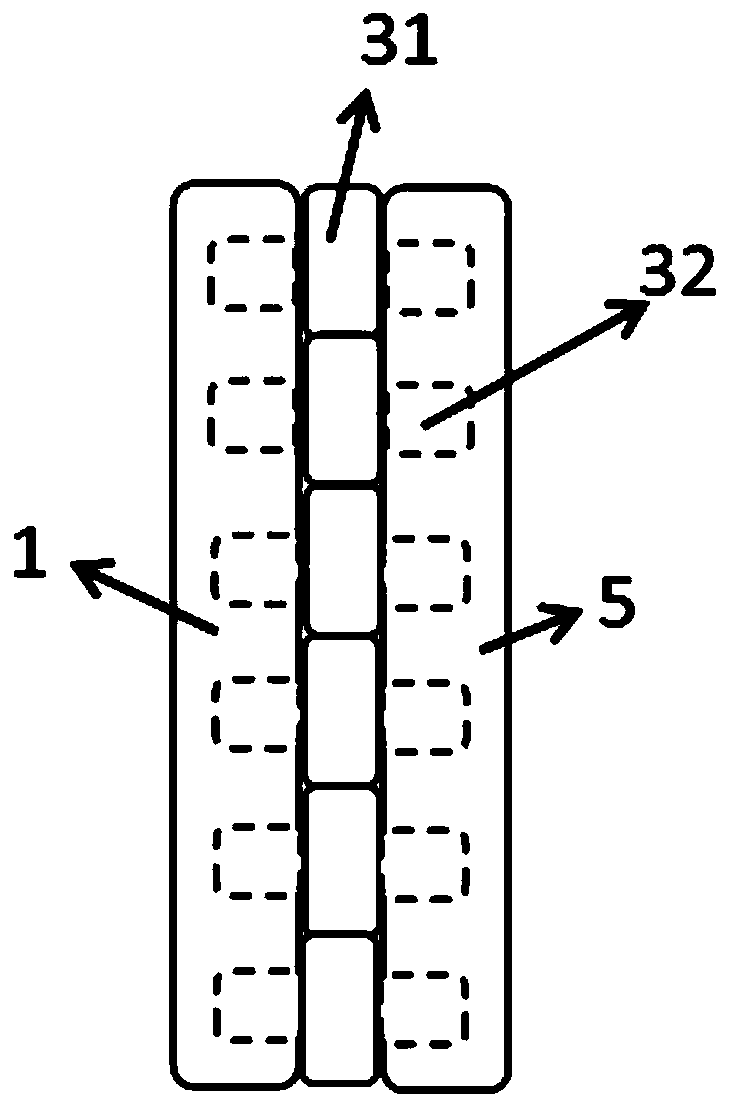

Processing method of surface-mounted pads on thick copper circuit board

ActiveCN102244985ABig sizeMeet the design size requirementsConductive material chemical/electrolytical removalSolder maskCopper

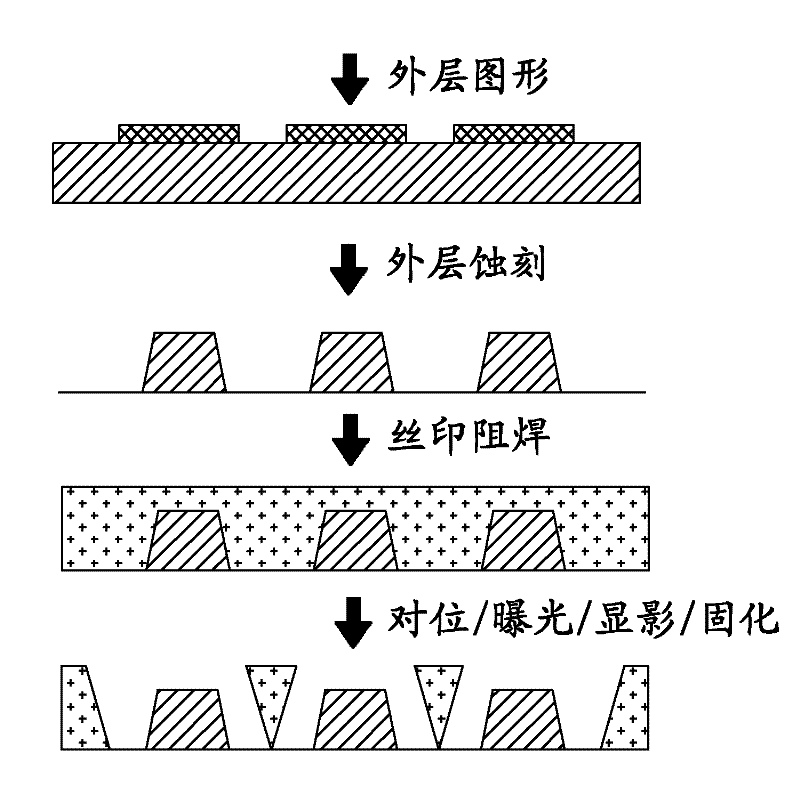

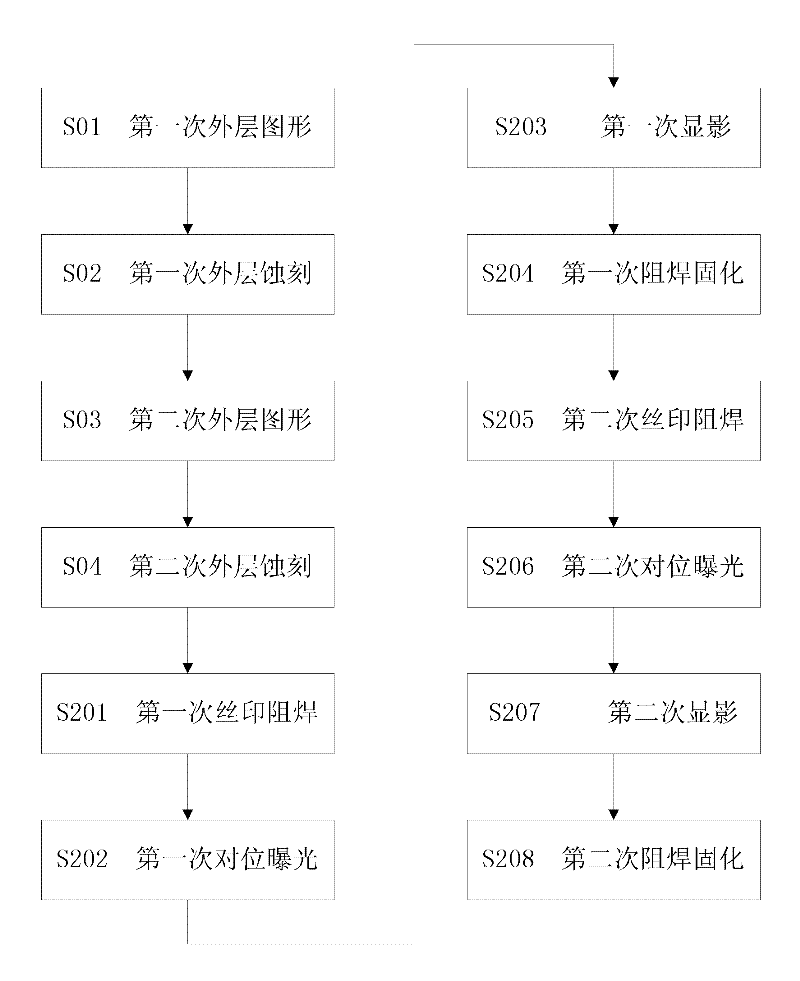

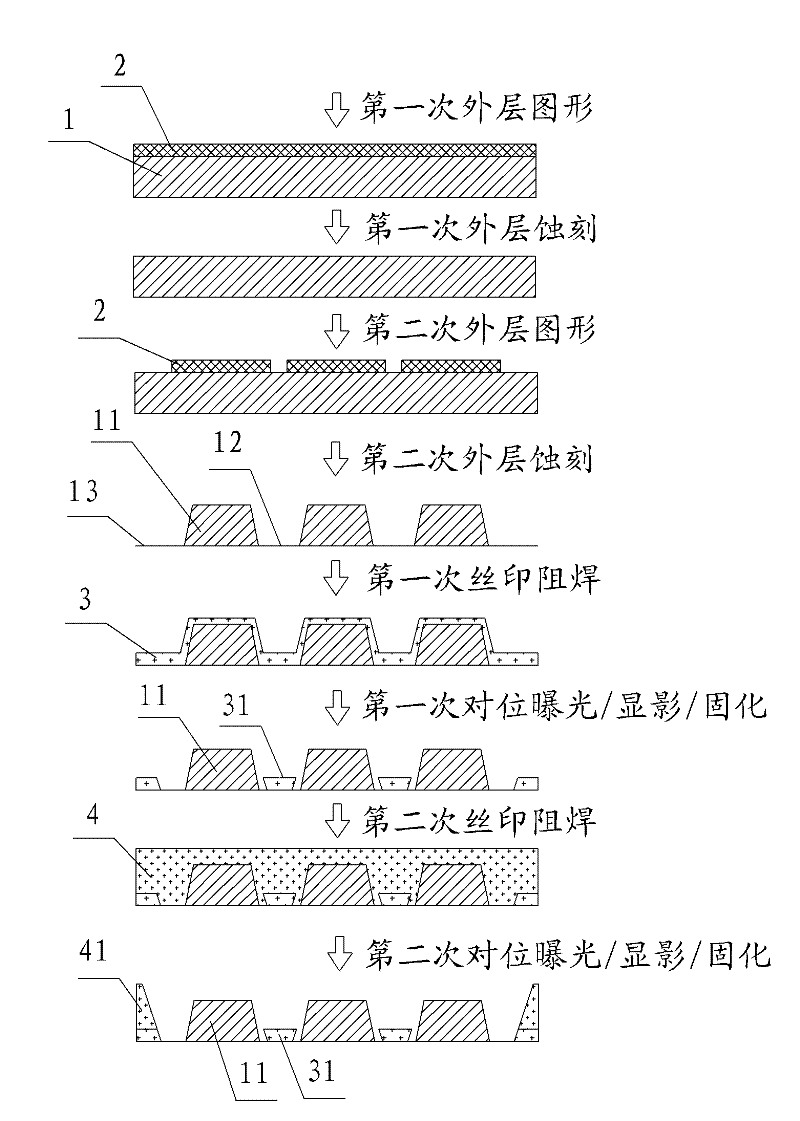

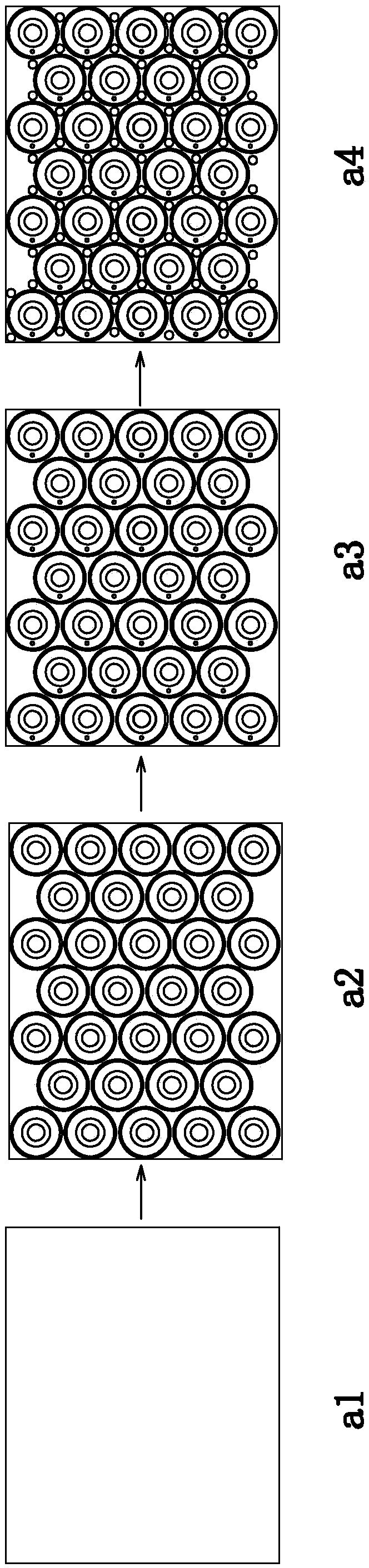

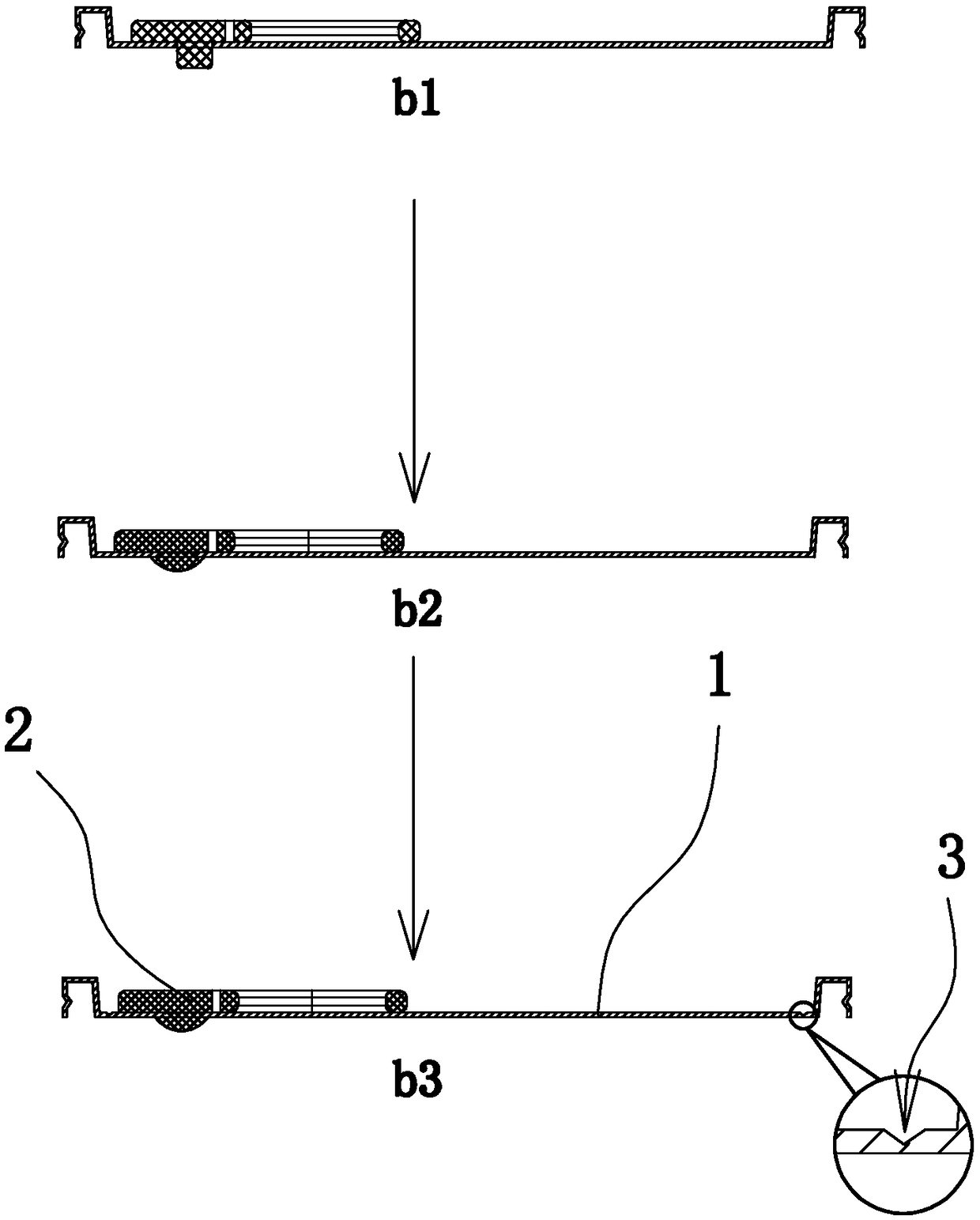

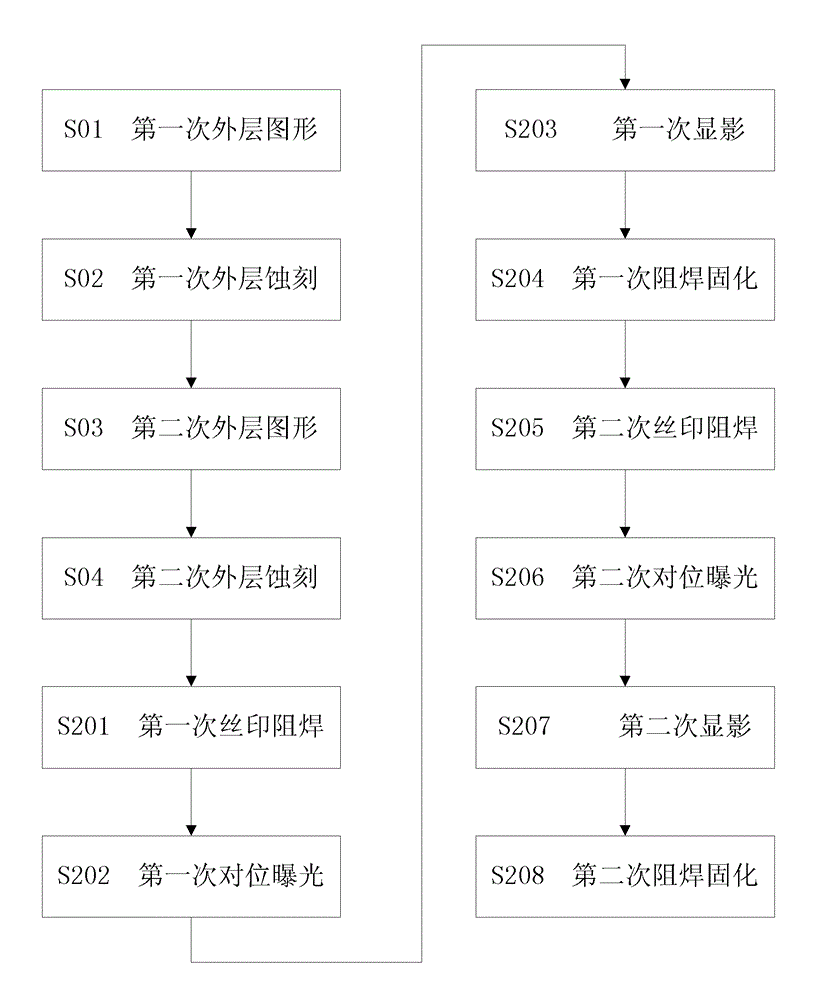

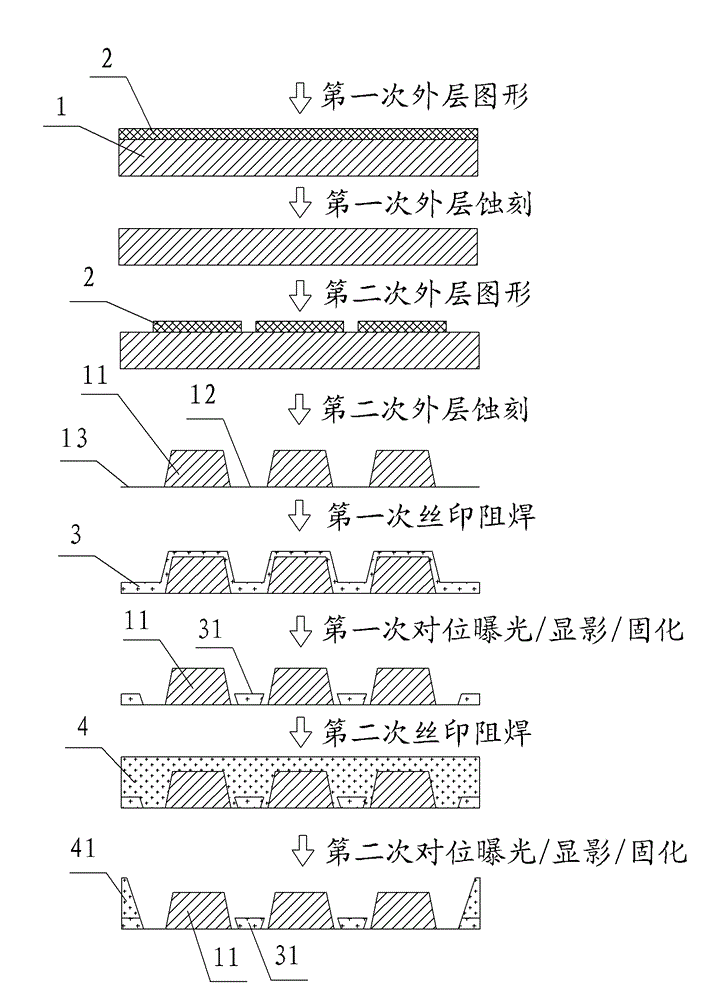

The invention discloses a processing method of surface-mounted pads on a thick copper circuit board. The processing method comprises the following steps: S01. patterning an external layer for the first time; 2. etching the external layer for the first time; 3. patterning the external layer for the second time; 4. etching the external layer for the second time; and 5. manufacturing a solder mask bridge among the surface-mounted pads by a fractional solder resisting method. The processing method has the beneficial effects that the surface-mounted pads are manufactured by a partitioned etching method, which strengthens size control of the surface-mounted pads and meets the design requirements; and the solder mask bridge among the surface-mounted pads are manufactured by utilizing the fractional solder resisting method so that the solder mask bridge and the circuit board are firmly connected together and are not easily separated from each other.

Owner:WUXI SHENNAN CIRCUITS CO LTD

Rolled part temperature obtaining method and device for plate-strip hot-rolling production line

ActiveCN111079275APrecise control of dimensional accuracyClear principleDesign optimisation/simulationHeat conservationThermal contact conductance

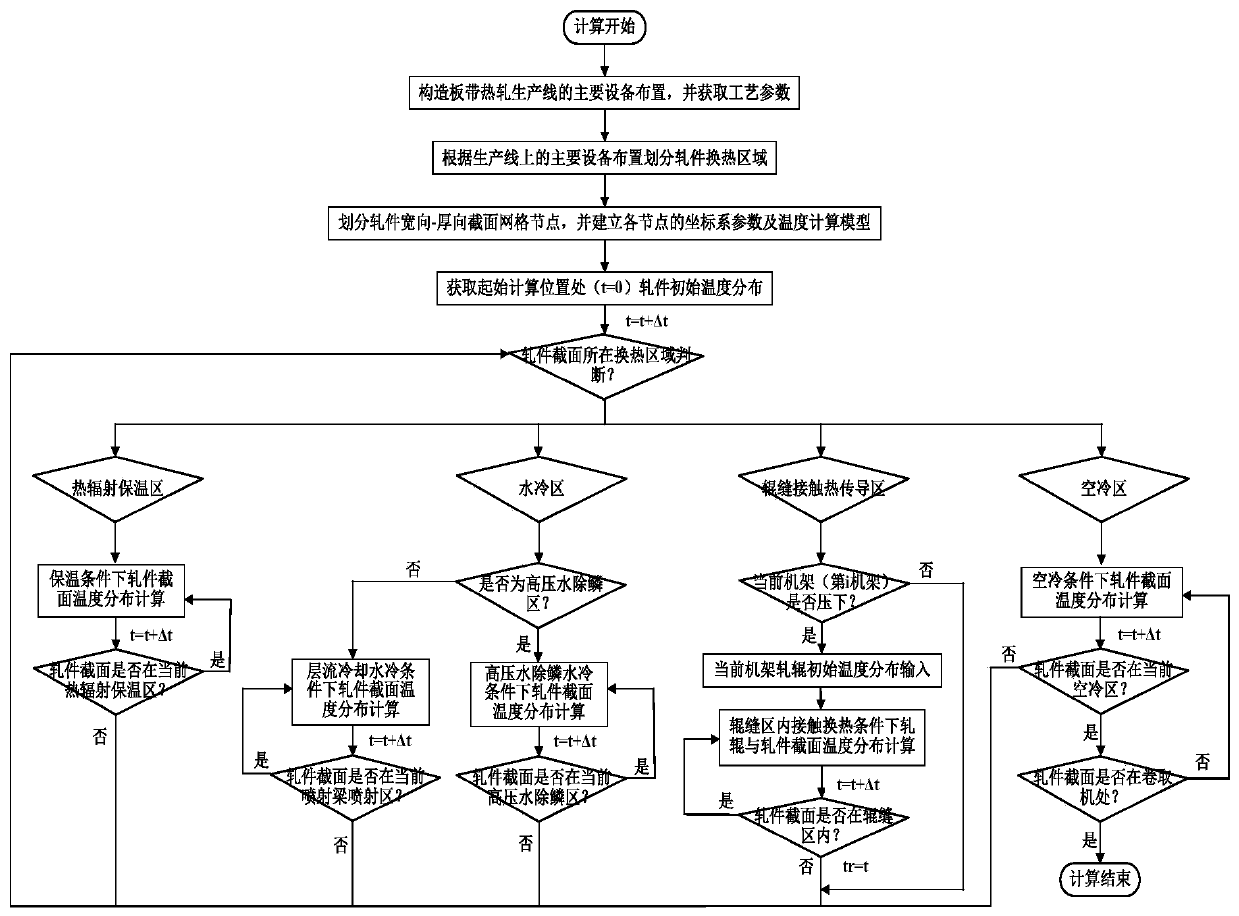

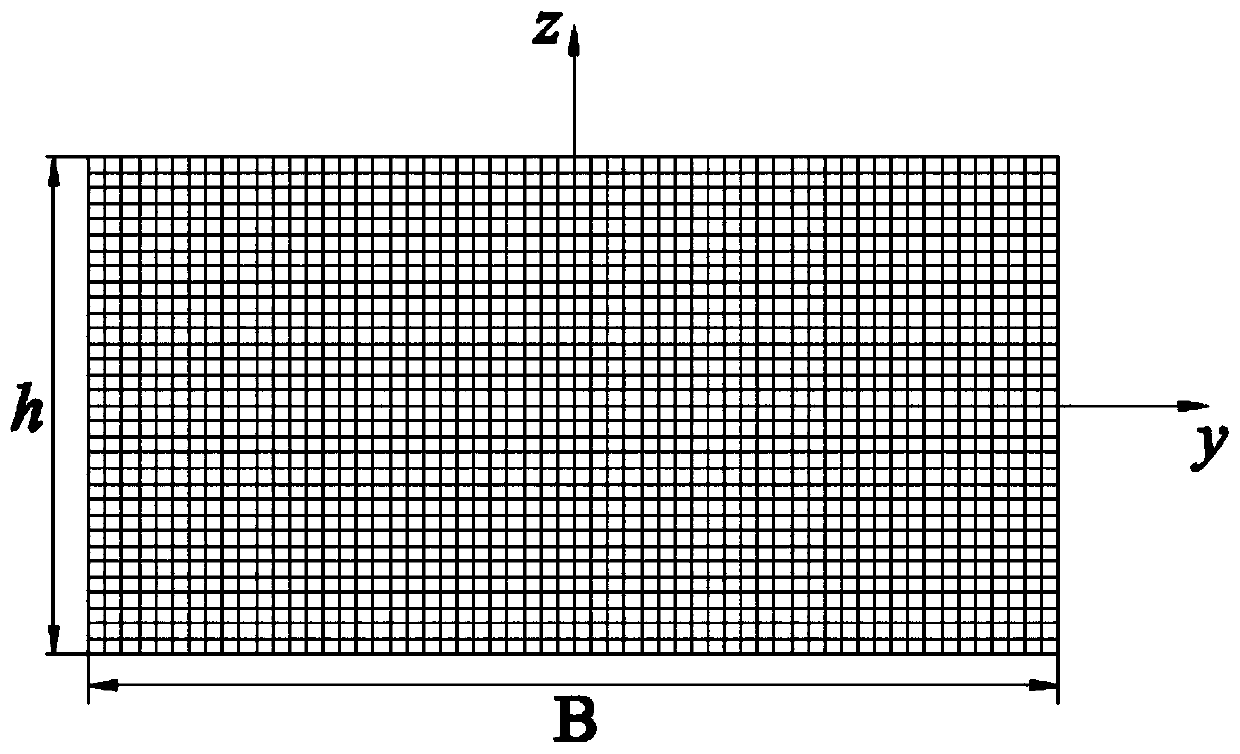

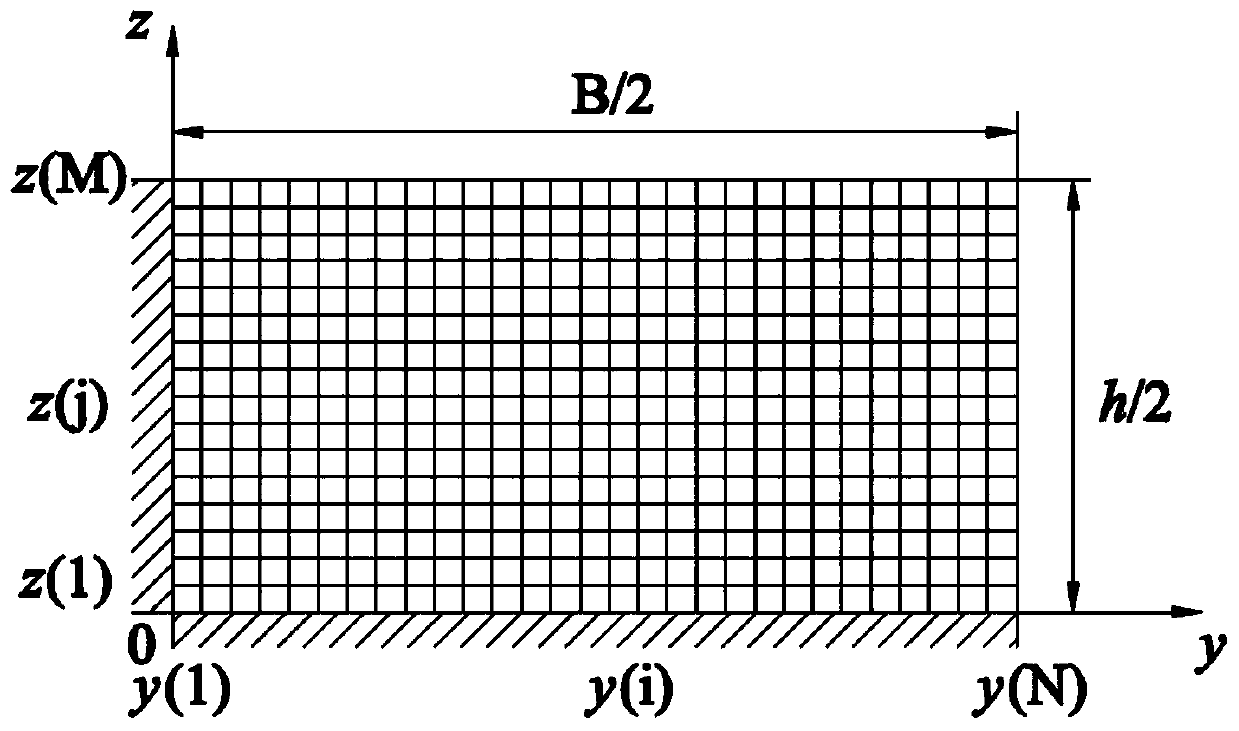

The invention discloses a rolled part temperature collection method for a plate and strip hot rolling production line, which comprises the following steps of: constructing equipment arrangement of theplate and strip hot rolling production line, and obtaining related process parameters; dividing a rolled part heat exchange area according to equipment arrangement on the production line, wherein theheat exchange area comprises an air cooling area, a water cooling area, a roll gap contact heat conduction area and a heat radiation heat preservation area; dividing width-thickness section grid nodes of the rolled part, and establishing coordinate system parameters and a temperature calculation model of each node; obtaining initial temperature distribution of the rolled part at the initial calculation position; from the initial calculation position to the final calculation position, the heat exchange area where the rolled part section is located is judged firstly when calculation is conducted every time, and then the temperature distribution of the rolled part section at the position is calculated through a corresponding rolled part temperature model. The method has the beneficial effects that the principle is clear and definite, assumption and simplification conditions are few, the temperature field change of the rolled part on the given hot rolling production line can be accuratelyforecasted, and the calculation precision is higher than that of an analytical method.

Owner:WISDRI ENG & RES INC LTD

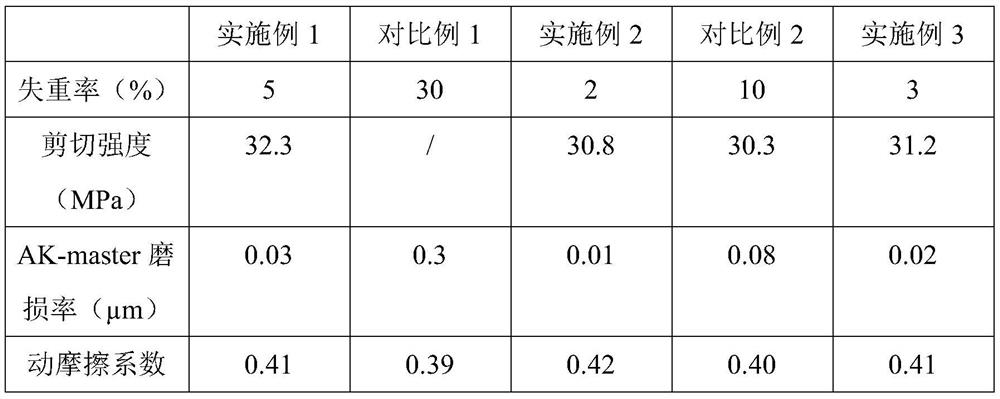

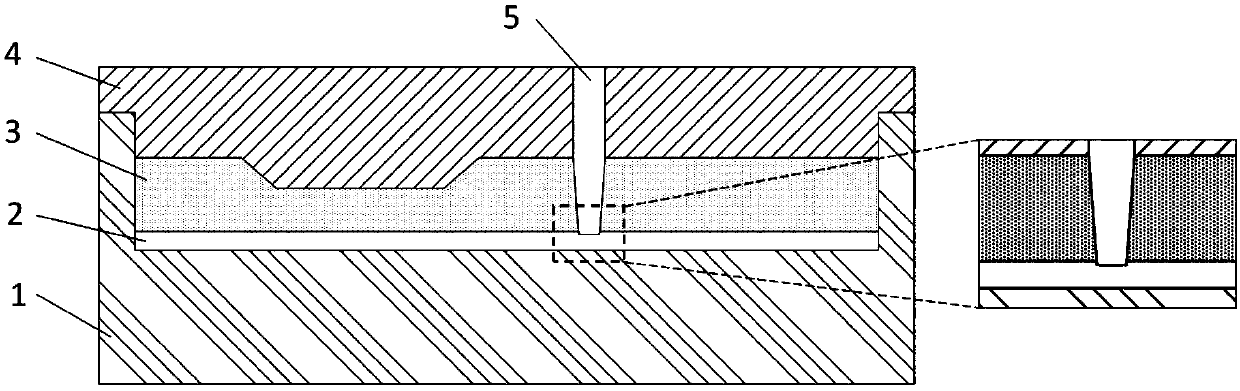

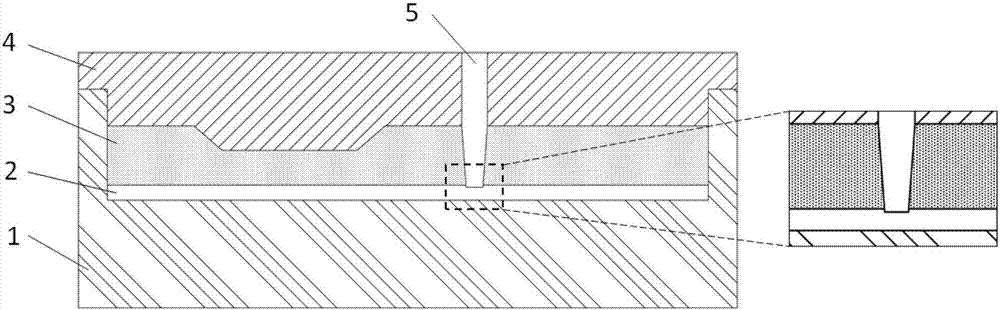

Carbon-ceramic brake disc with wear-resistant and anti-oxidation coating and preparation method of carbon-ceramic brake disc

ActiveCN113277869AHigh bonding strengthUniform compositionBraking discsFriction liningOxidation resistantCarbon composites

The invention discloses a carbon-ceramic brake disc with a wear-resistant and anti-oxidation coating and a preparation method of the carbon-ceramic brake disc. The preparation method comprises the following steps that grooving treatment is conducted on the upper surface and the lower surface of a carbon / carbon composite material disc body, then coating slurry is brushed in a groove in the upper surface till the groove in the upper surface is filled with the coating slurry, and then the carbon / carbon composite material disc body is turned over, the groove in the lower surface is coated with the coating slurry till the groove in the lower surface is filled with the coating slurry, thus the carbon / carbon composite material disc body containing the coating slurry is obtained, curing, carbonization and ceramization treatment are sequentially conducted, and the carbon-ceramic brake disc is obtained. The preparation process of the wear-resistant and oxidation-resistant coating is simple, large-scale industrial mass production is easy to realize, the coating is bright and smooth in appearance, the bonding strength between the coating and the disc body is high, the size precision is easy to accurately control, and the problem that the size is easy to control inaccurately when the ceramic brake disc is subjected to machining treatment can be effectively solved.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

An injection molding device and injection molding method

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

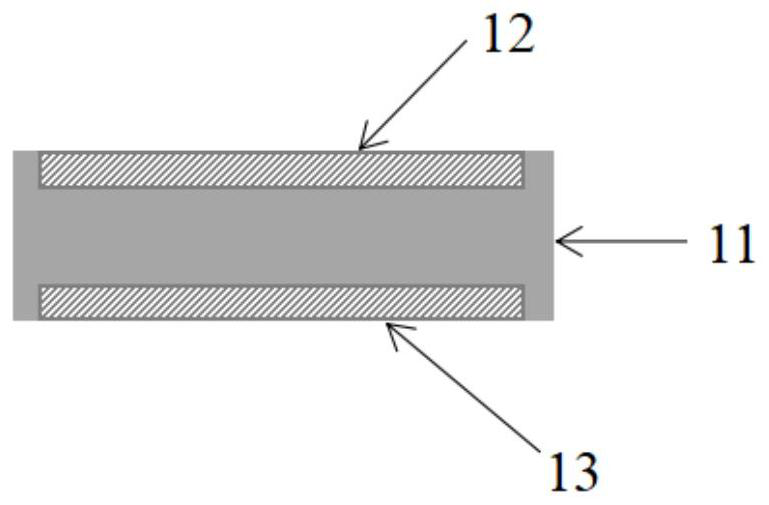

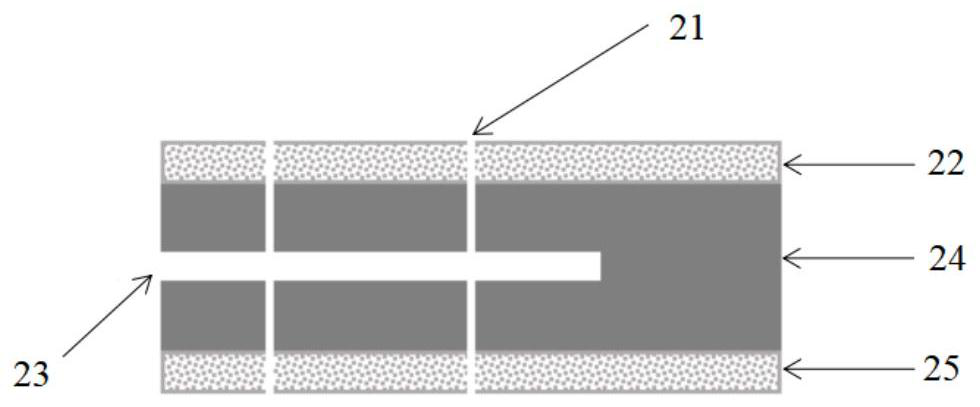

Injection molding device and injection molding method

ActiveCN107053579ASmall sizePrecise control of dimensional accuracyCoatingsMicron scaleInjection moulding

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

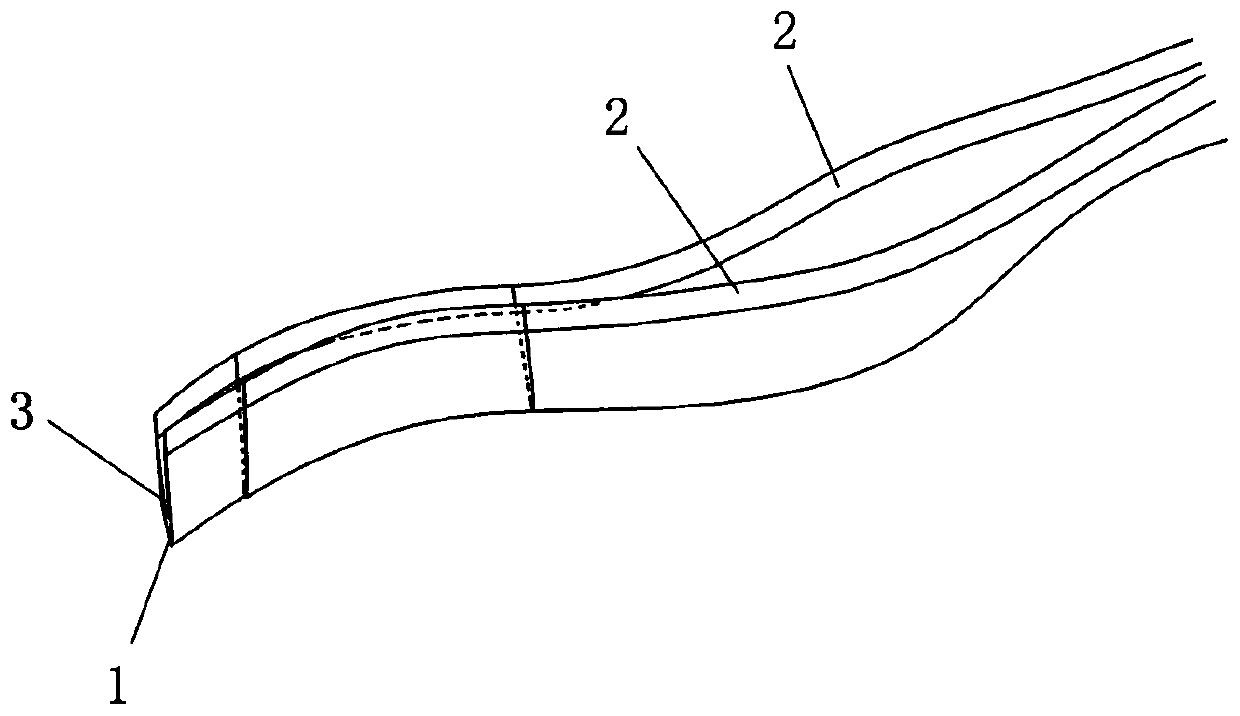

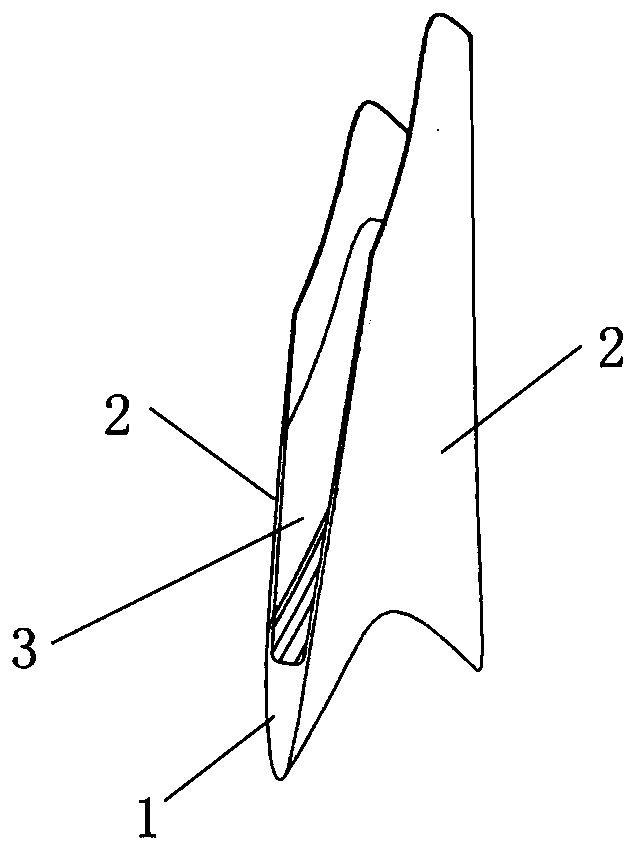

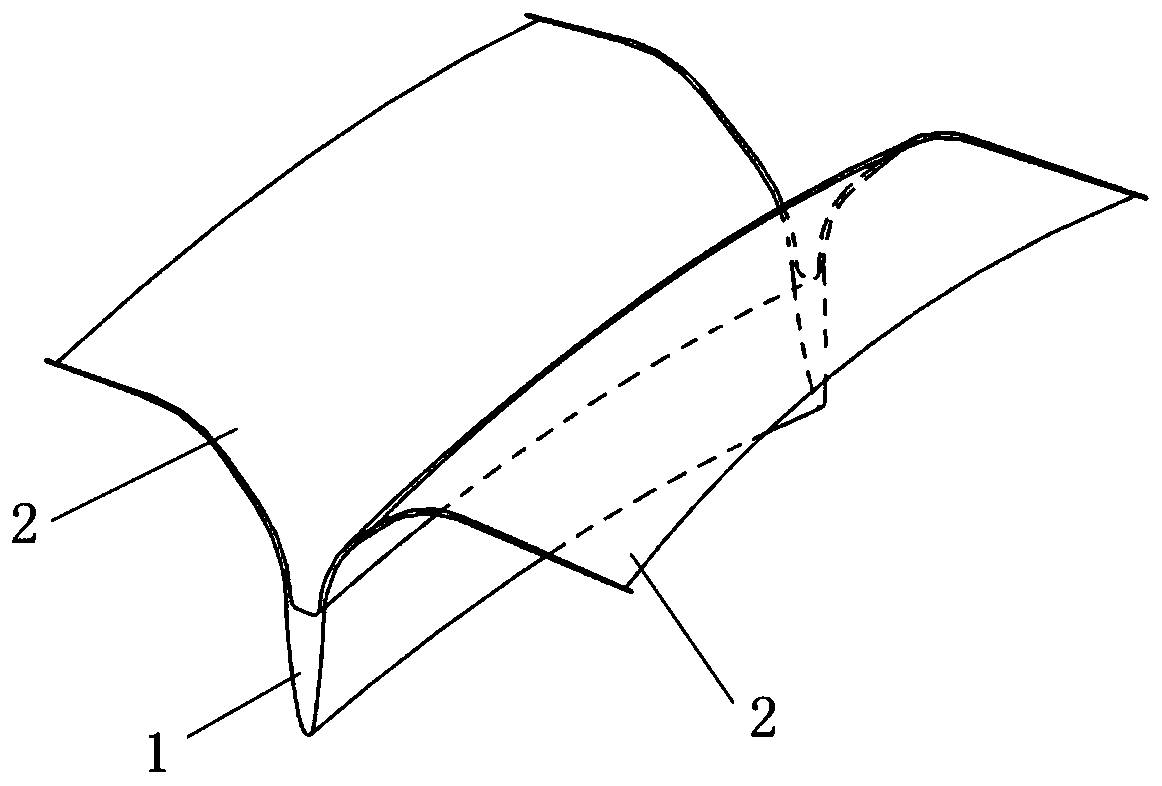

Composite forming method of component with large-angle thin-wall twisted narrow-depth cavity feature

ActiveCN110421077AEliminate featuresEliminate structureShaping toolsMachine partsModel reconstruction

The invention relates to a composite forming method of a component with a large-angle thin-wall twisted narrow-depth cavity feature. The composite forming method comprises the steps of model reconstruction, mold manufacturing as well as processing and forming; the model reconstruction comprises the steps that a three-dimensional model of the component is reconstructed in software, two side wing thin walls of the component three-dimensional model are unfolded outwards towards the two sides to form the three-dimensional model of a pre-machined part; mold manufacturing comprises the steps that acorrecting mold comprising a plurality of mold components is manufactured according to the outline design of the component; and processing and forming comprise the steps that production and processingof the pre-machined parts of a plate part is performed, then, the two side wing thin walls which are unfolded outwards of the pre-machined part are heated and folded inwards by using the correcting mold, and component processing is completed. Compared with the prior art, the component is reconstructed into the pre-processing part with no deep-cavity features, the side wing sheets on the two sidescan be recovered to form the large-angle twisted narrow-depth cavity during heating and folding, the defect that the narrow-depth cavity is damaged or lost due to the fact that the cutting processingis directly adopted can be overcome, and the product precision and the finished product rate are guaranteed to the maximum degree.

Owner:SHANGHAI JIAO TONG UNIV +1

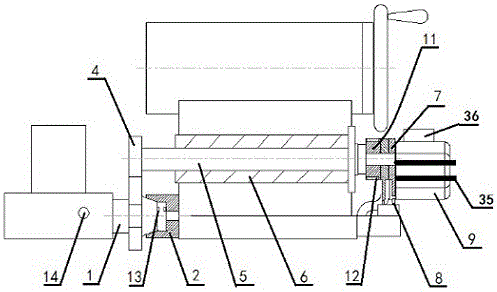

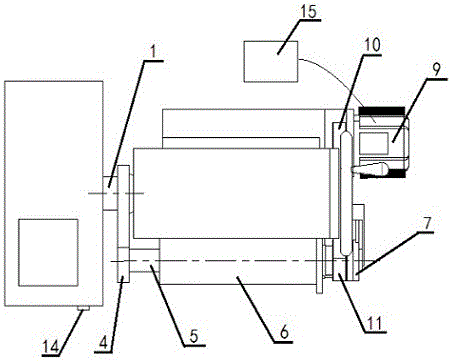

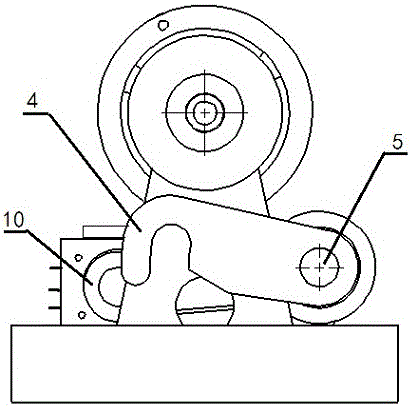

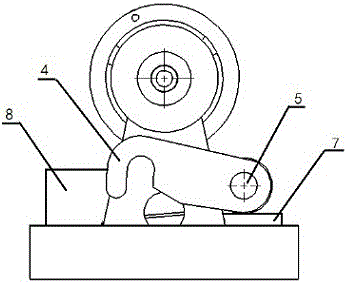

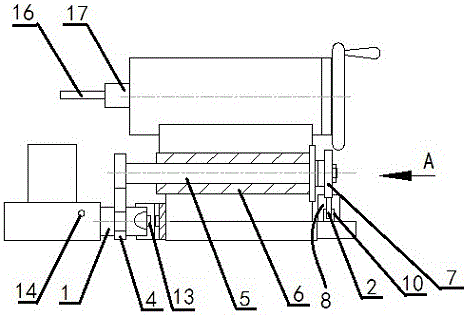

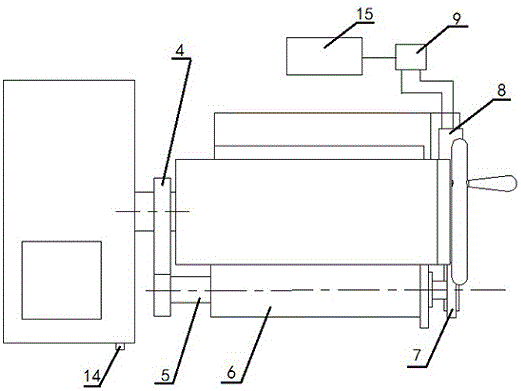

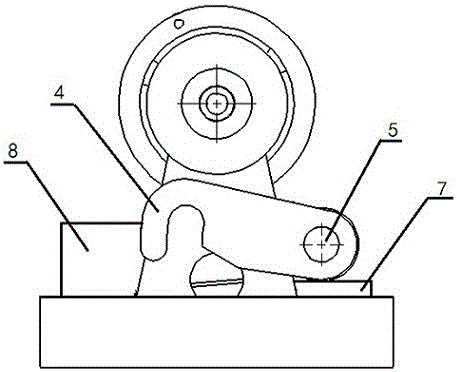

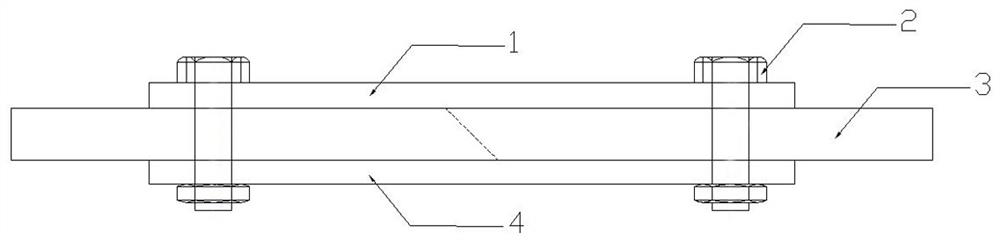

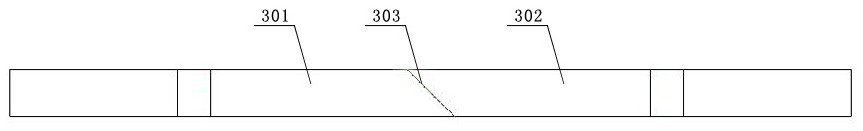

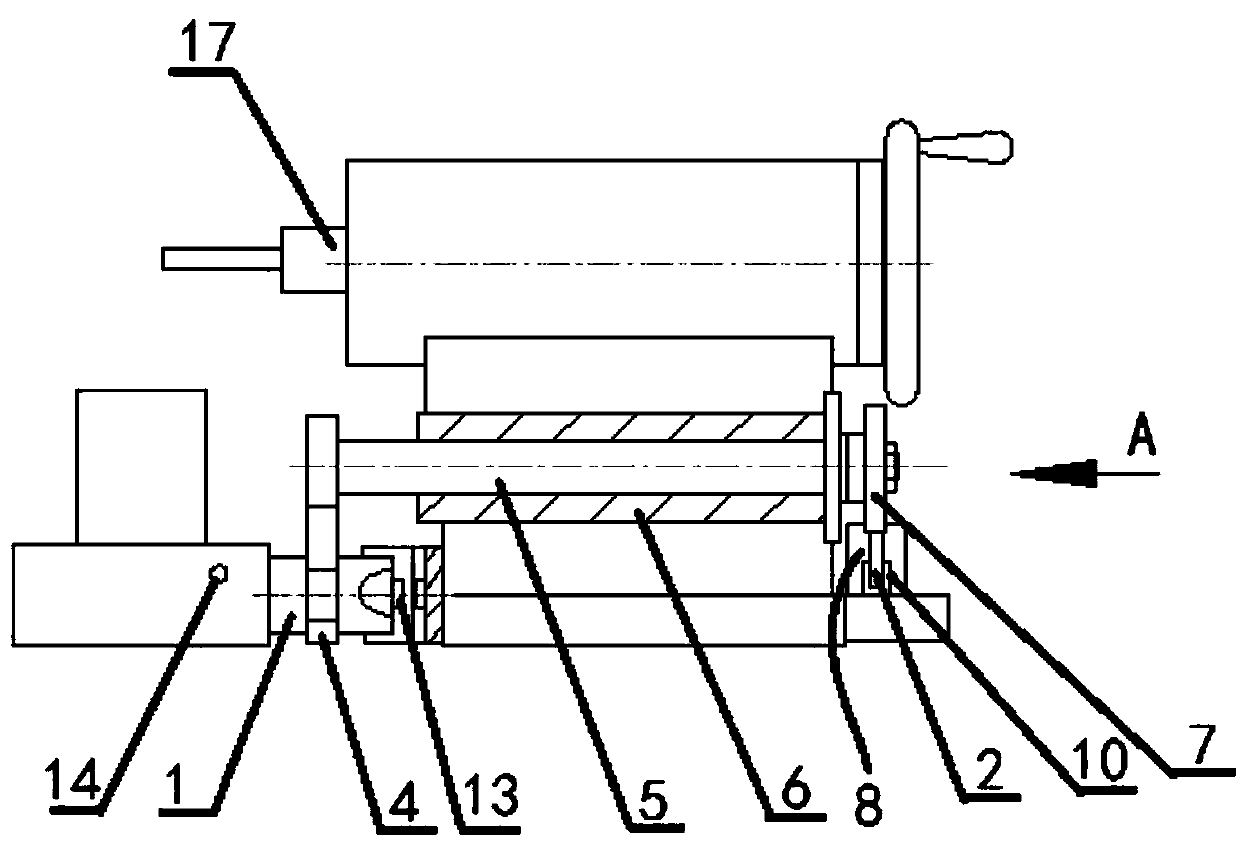

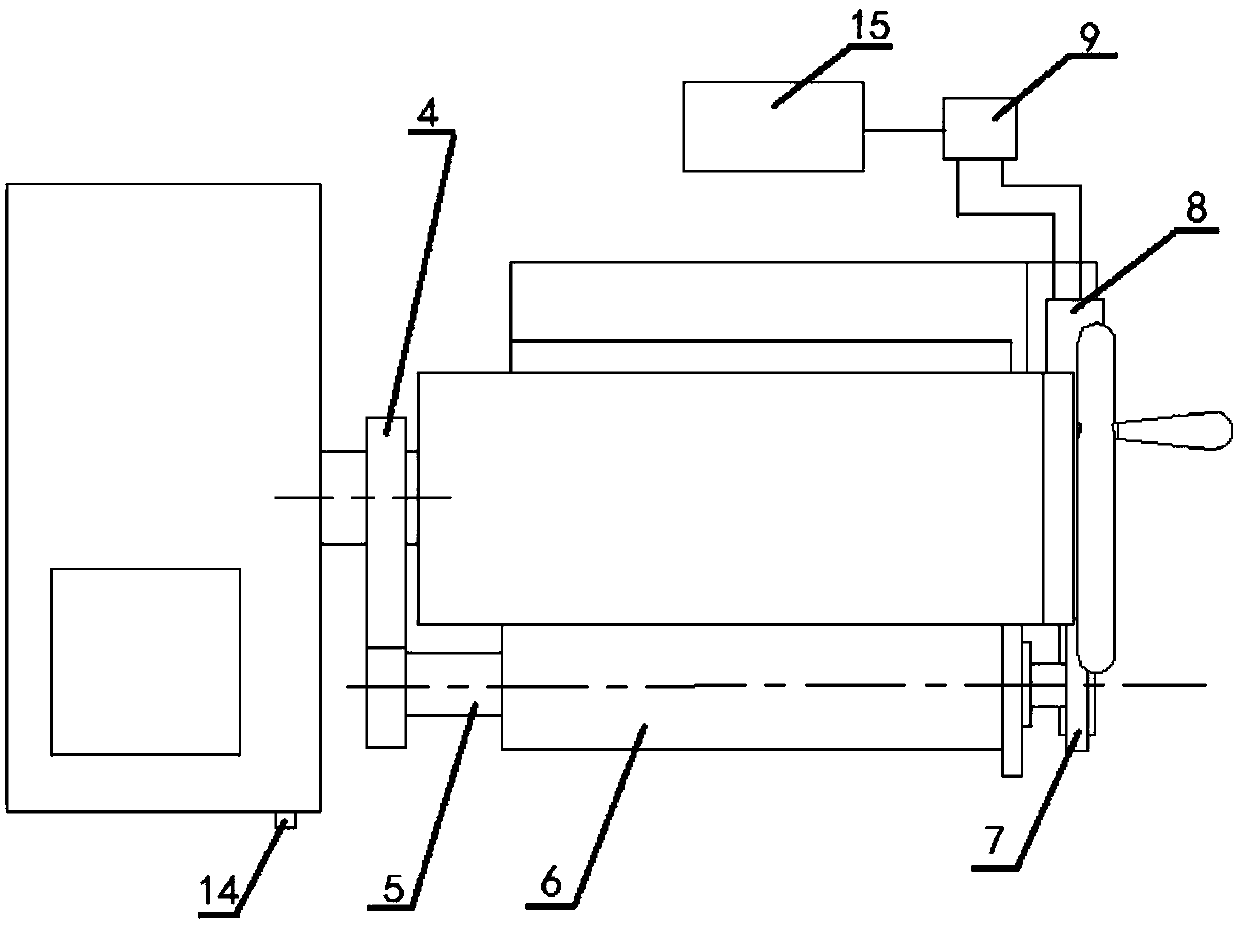

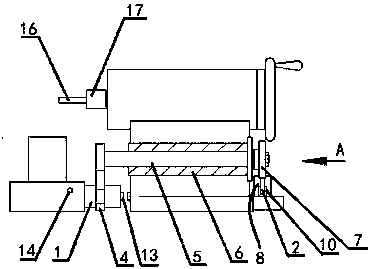

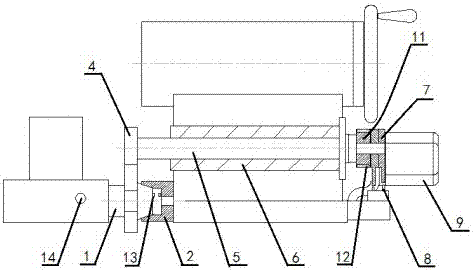

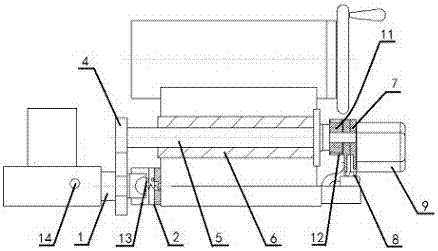

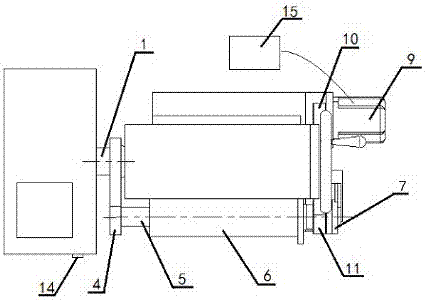

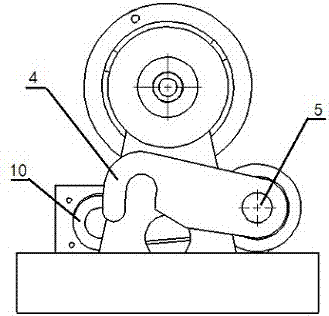

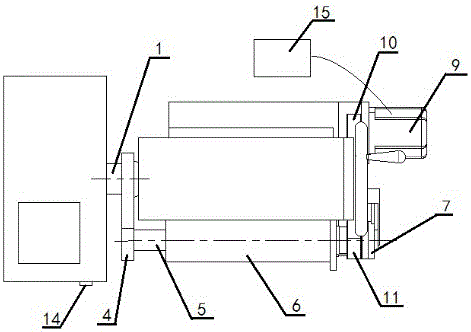

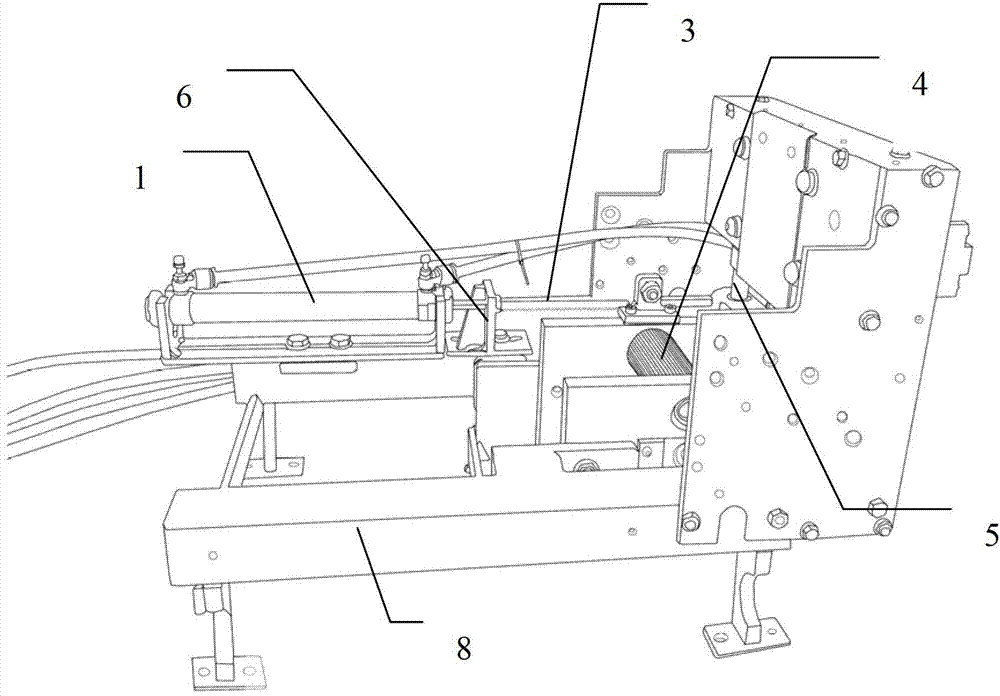

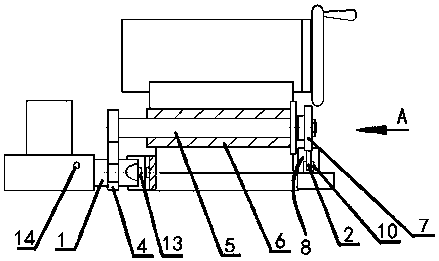

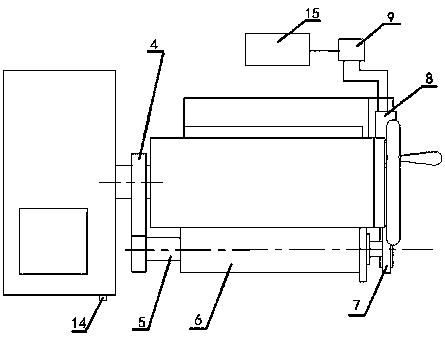

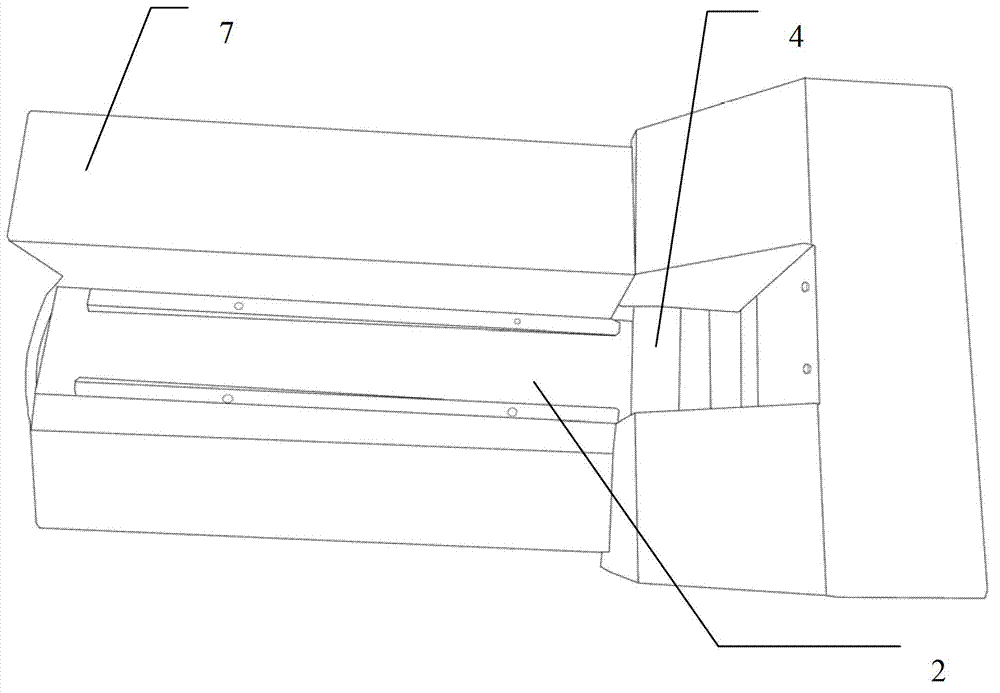

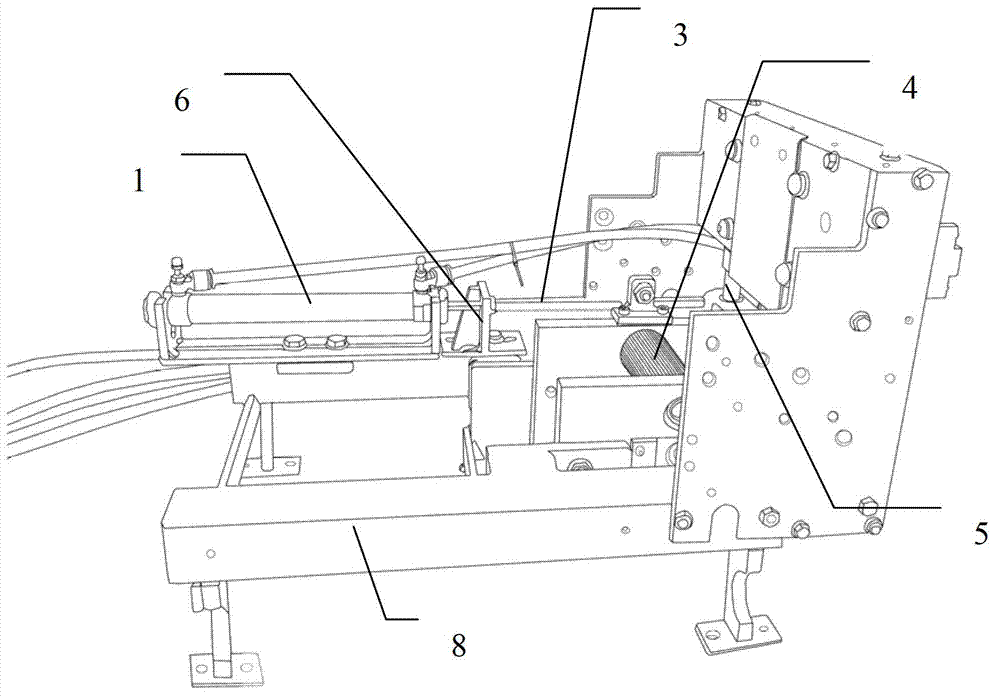

Automatically-controlled numerically controlled lathe tailstock feeding method

ActiveCN105965306ARealize synchronized movementHigh degree of automationTailstocks/centresFeeding apparatusNumerical controlAutomatic control

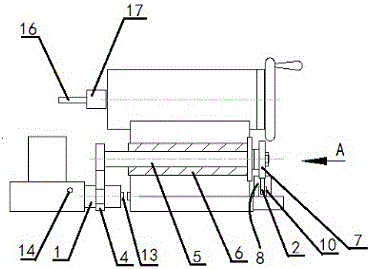

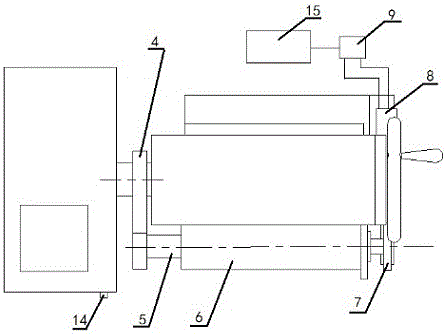

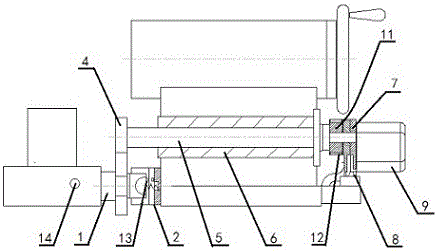

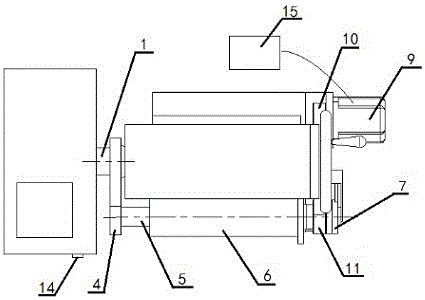

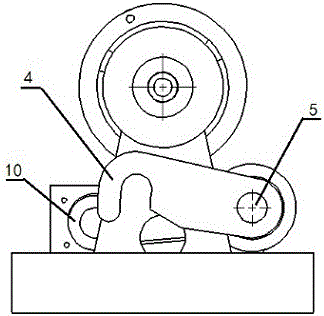

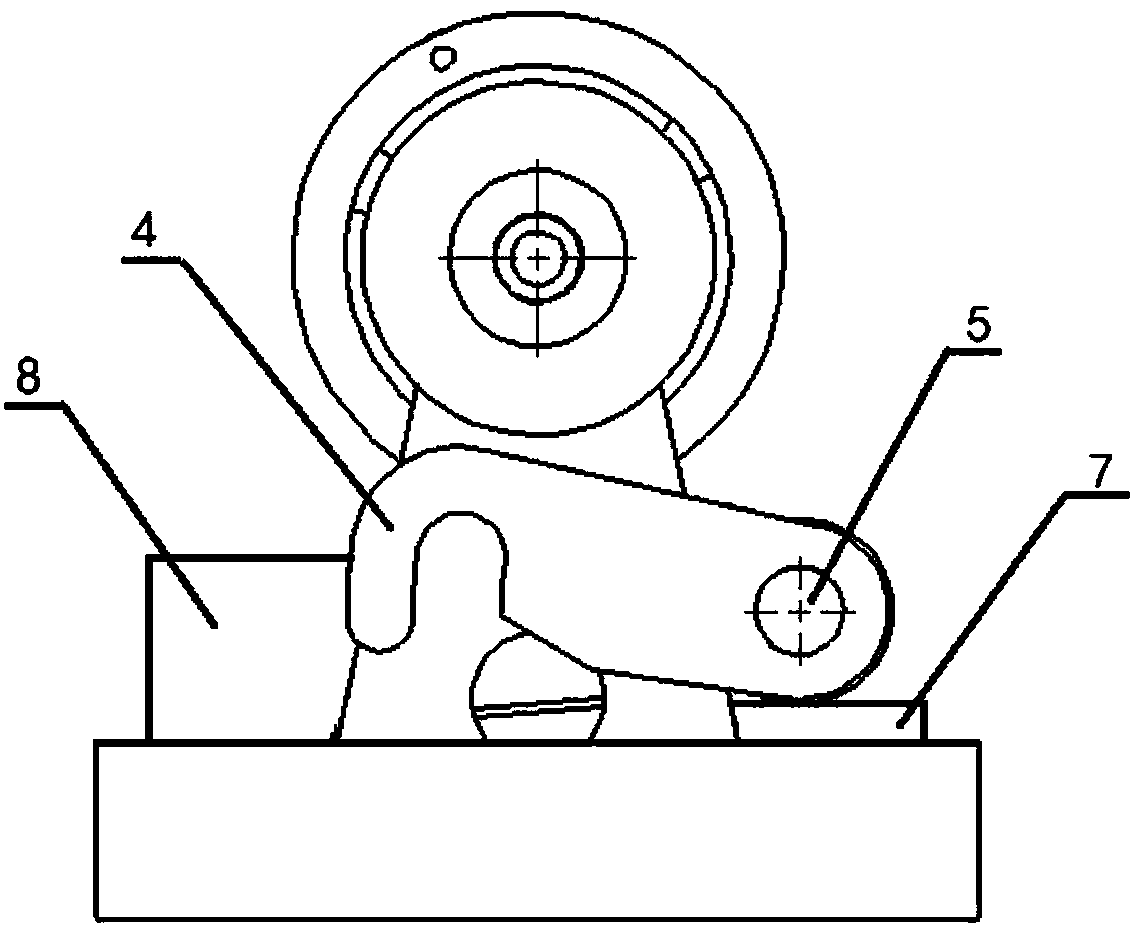

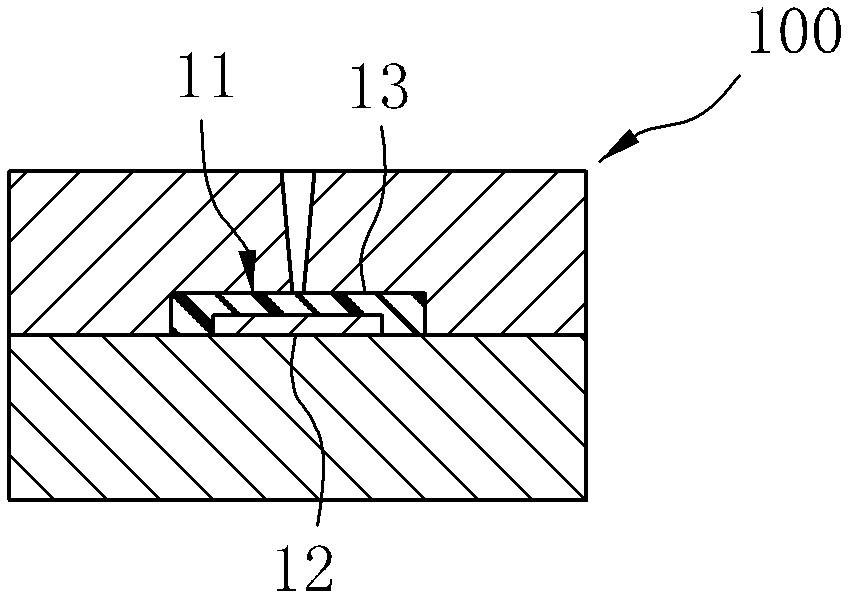

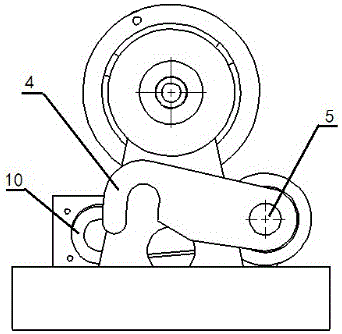

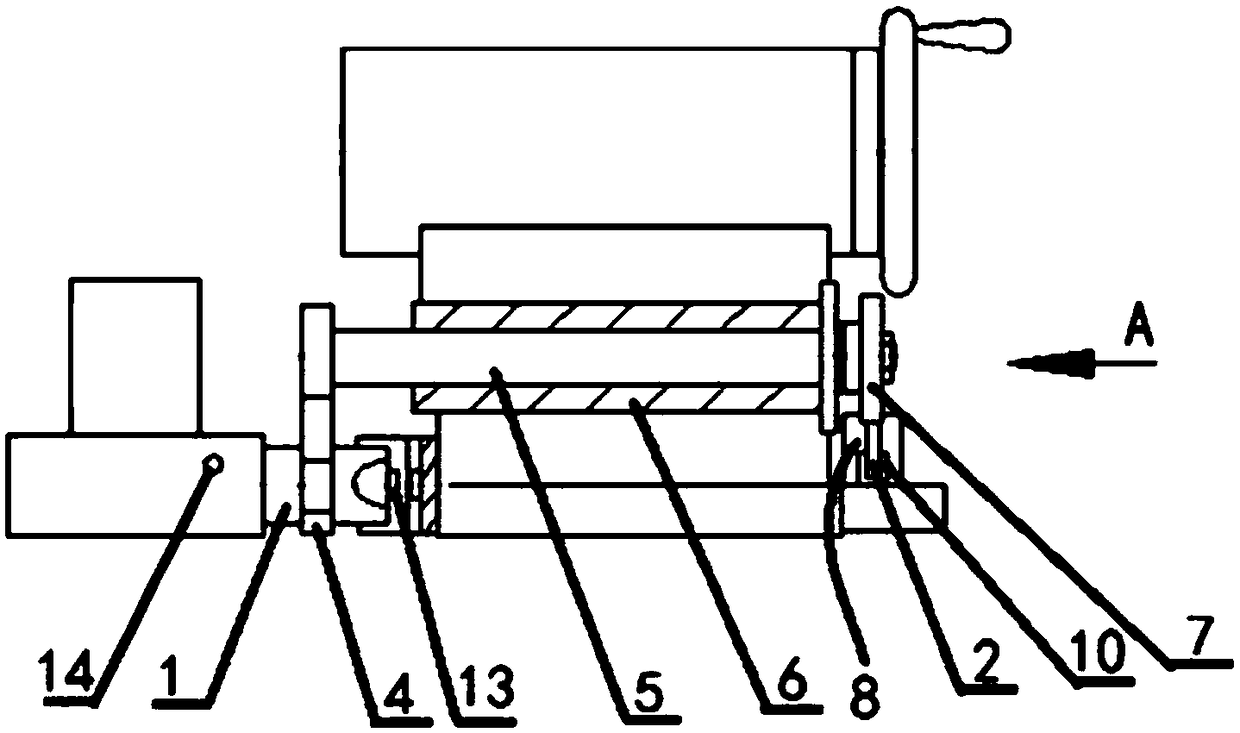

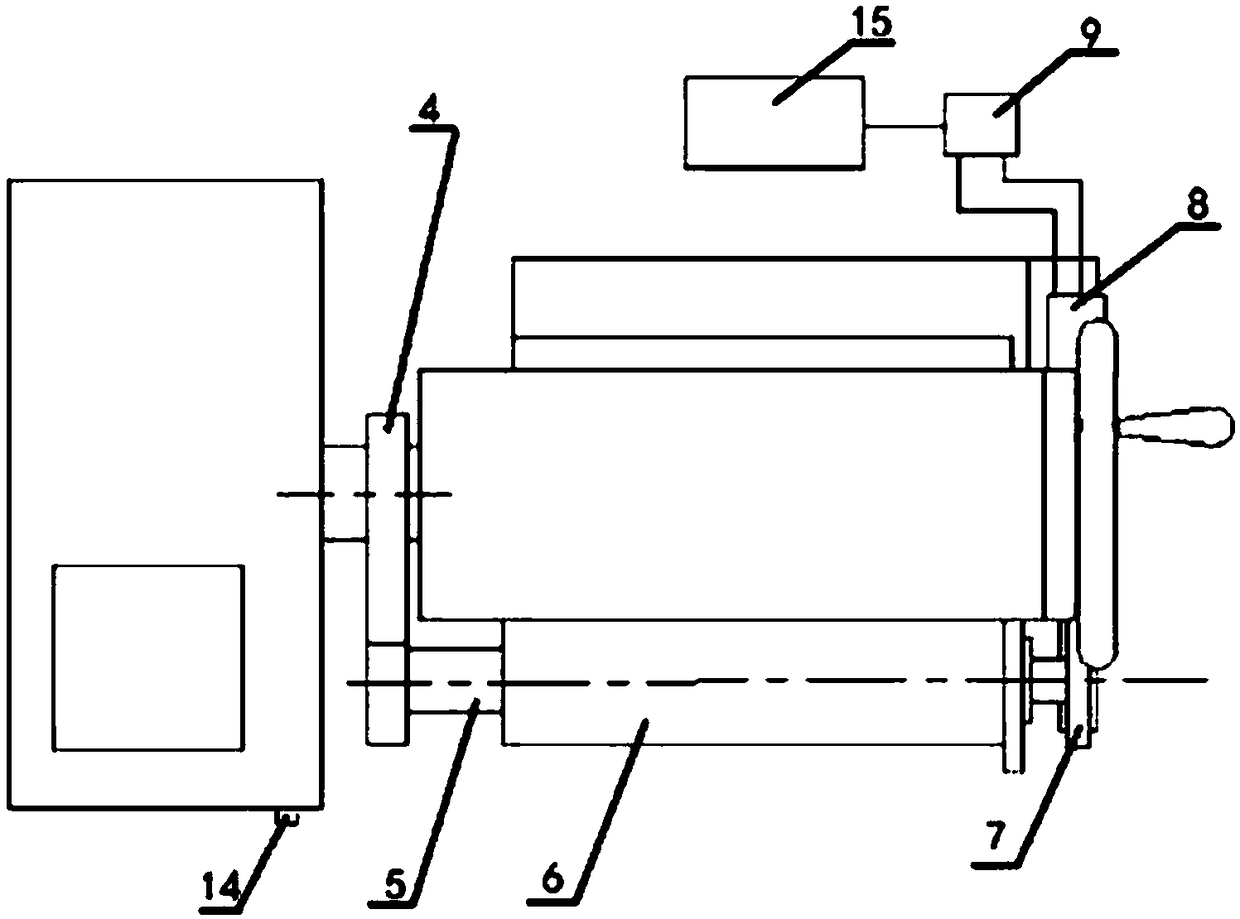

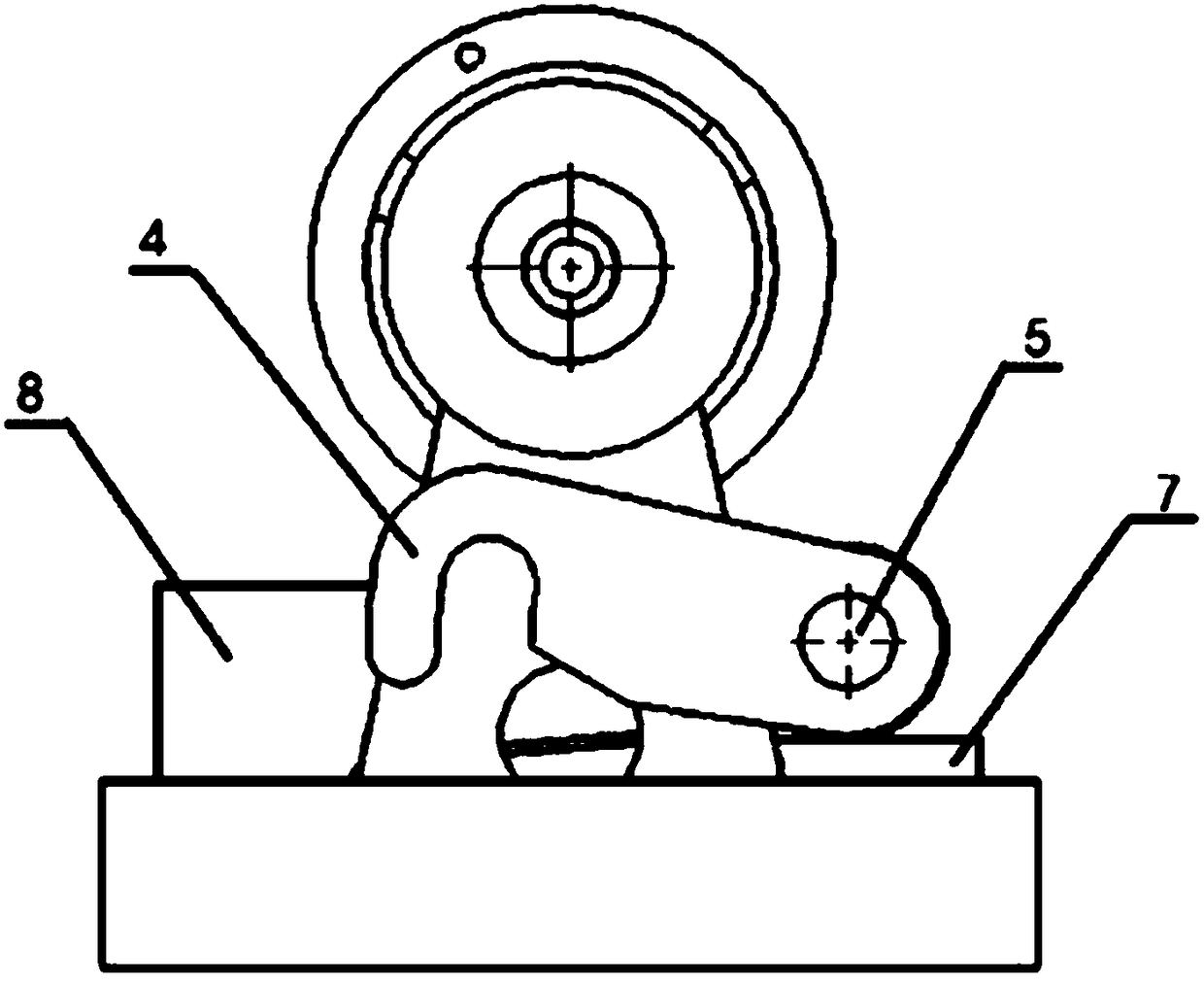

The invention provides an automatically-controlled numerically controlled lathe tailstock feeding method. A connecting device which combines a numerically controlled lathe saddle and a tailstock and disengages the numerically controlled lathe saddle from the tailstock is adopted. The connecting device comprises an alignment assembly, a rotating arm assembly and a driving assembly; the alignment assembly comprises an alignment shaft (1) and an alignment sleeve (2) with an inner cone hole, a sensor (13) is arranged at the shaft end of the alignment shaft (1) and at the bottom of the cone hole of the alignment sleeve (2); the rotating arm assembly comprises a rotating arm (4), a rotating shaft (5), a shaft sleeve (6) and two limiting pressing blocks (7); the driving assembly comprises a pair of belt drives, a driving motor (9), a reset switch (14) and a controller (15); the controller (15) is installed in a machine tool power distribution cabinet, the reset switch (14) is installed in front of the numerically controlled lathe saddle and electrically connected with the controller, the driving motor (9) is fixedly connected with the tailstock of the numerically controlled lathe and electrically connected with the controller (15), and a vibration reduction backing plate is arranged between the driving motor (9) and the tailstock of the numerically controlled lathe and used for reducing vibratory force generated when the driving motor (9) operates.

Owner:惠州合友五金制品有限公司

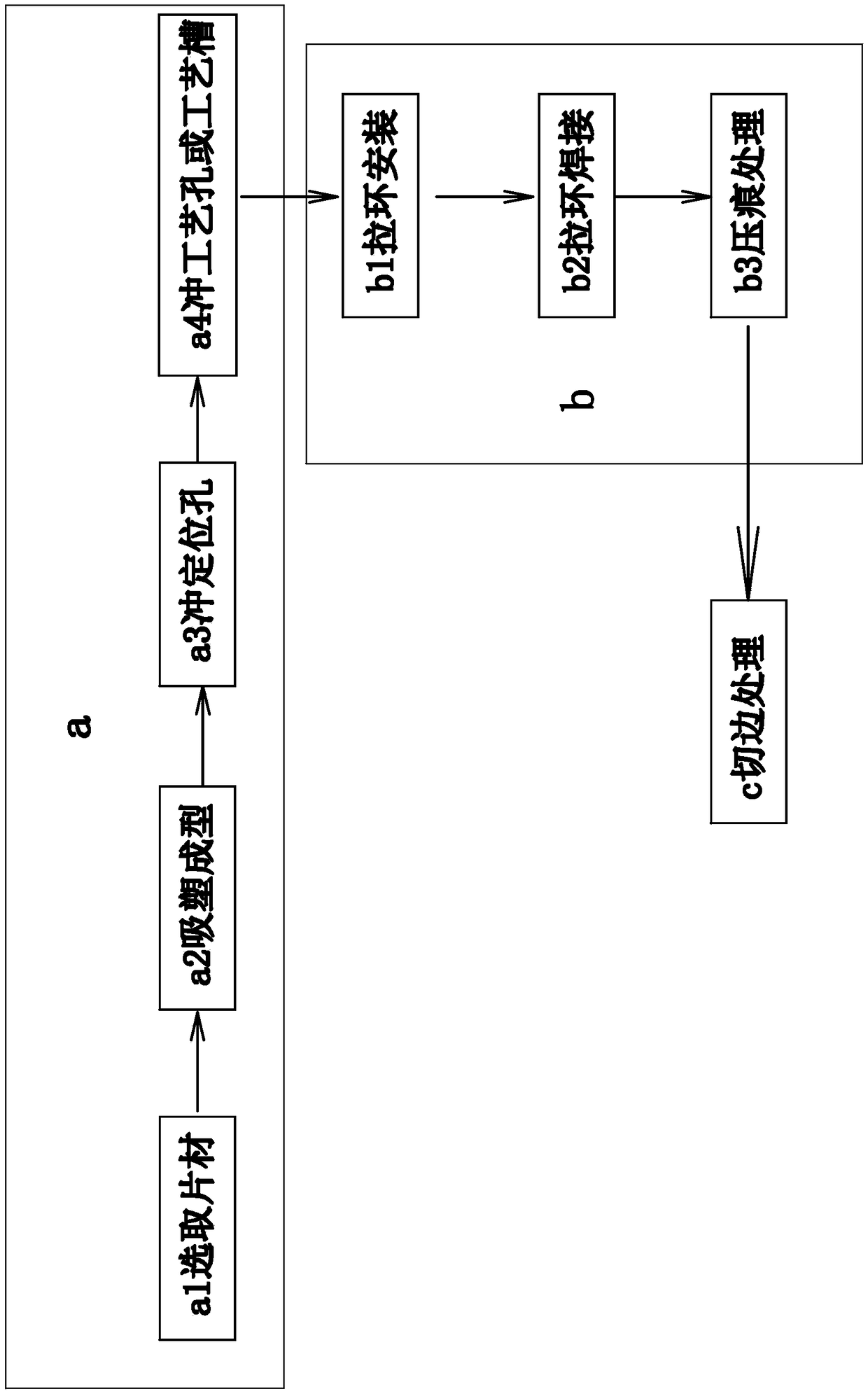

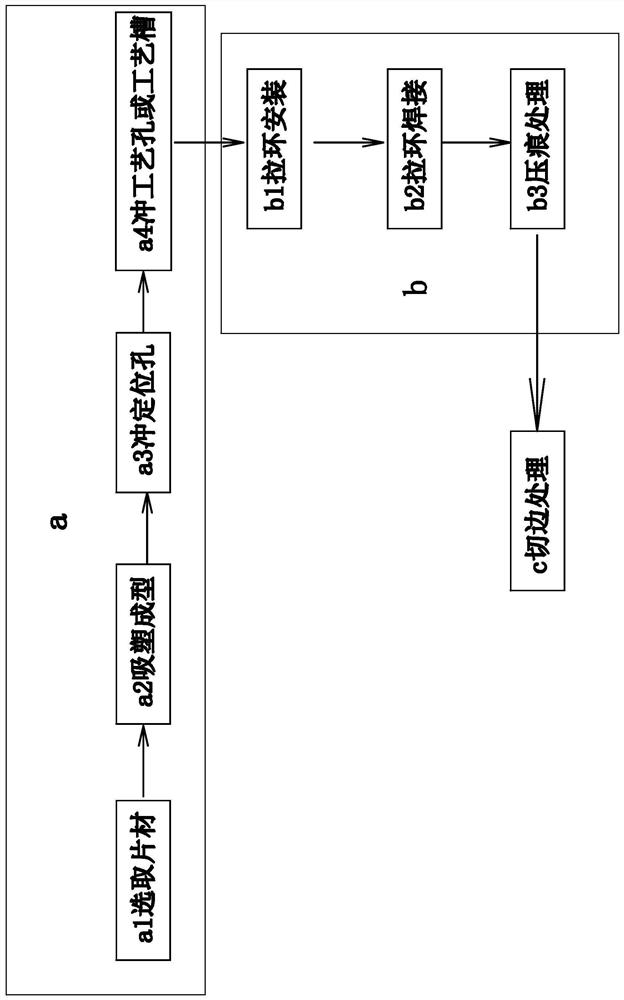

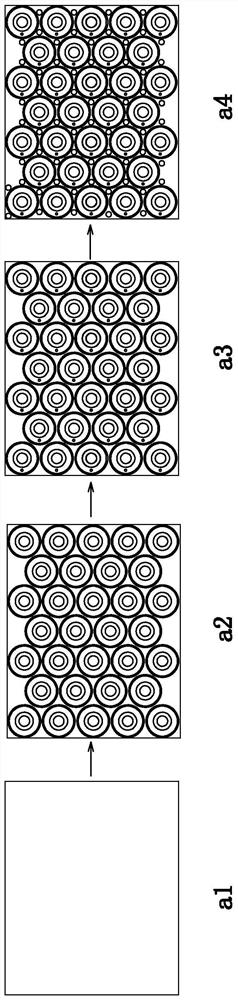

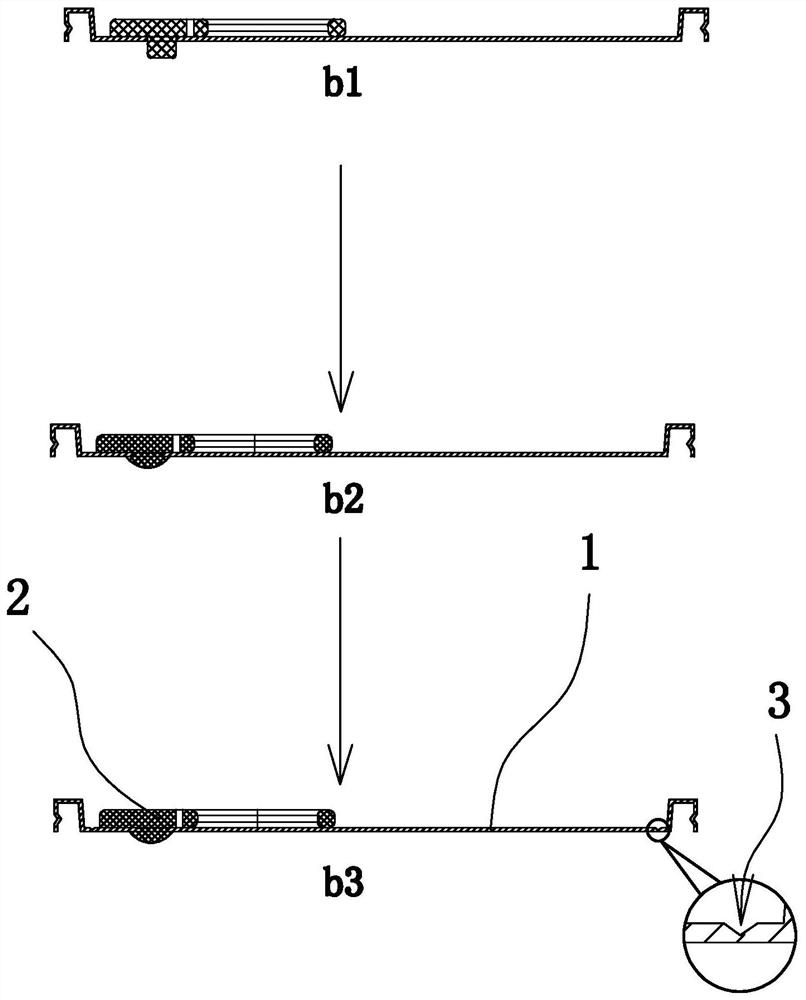

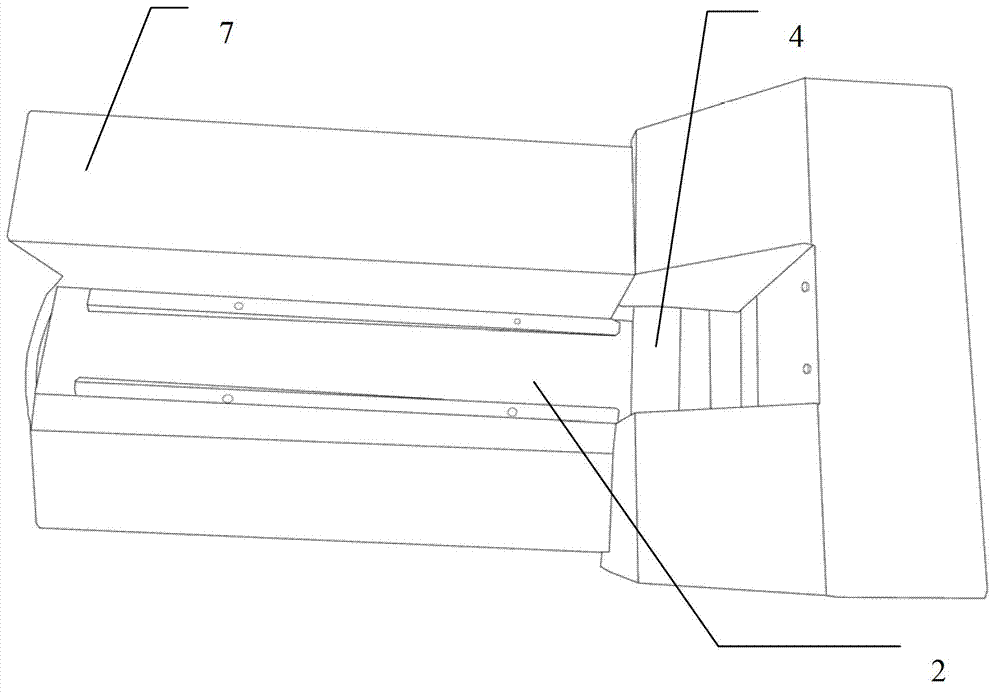

Snap lid manufacturing process and snap lid

The invention provides a snap lid manufacturing process and a snap lid, and belongs to the technical field of machinery. The process solves the problem that an existing snap lid has poor toughness andeasy crushing. The snap lid comprises a thermoforming snap lid body, the snap lid body is stamped with a pre-break mark, and a pull ring is thermally fused with the snap lid body. The manufacturing process comprises the steps of step a, selecting a sheet made of a plastic material and performing thermoforming to form the snap lid body on the sheet; step b, pressing the corresponding snap lid bodyon the sheet, and installing, hot-melting and connecting the pull ring to form a snap lid blank with the pre-break mark; step c, trimming the corresponding snap lid blank on the sheet and separatingthe sheet to form the snap lid. The snap lid is made by the thermoforming, molecules are arranged in strip-shaped line segments, the tightness between the molecules is good, so that the overall toughness of the lid body is good, the crushing is not easy, the yield is high, crushing is not easy in the tearing process, and operation is convenient.

Owner:张仁贵

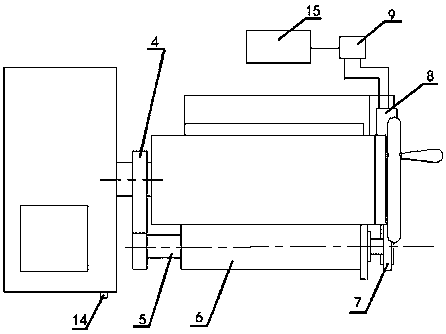

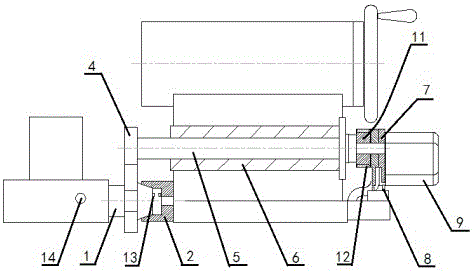

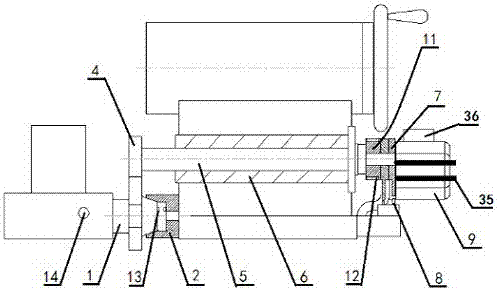

Automatic numerical control lathe tailstock control method

ActiveCN106001633ARealize synchronized movementRealize finishingTailstocks/centresAuxillary equipmentMagnetic exchangeAutomatic control

The invention provides an automatic numerical control lathe tailstock control method. A connection device for achieving automatic connection and disconnection between a lathe saddle and a tailstock of a numerical control lathe through an air cylinder is utilized. The connection device comprises a connection pillar, a rotating arm assembly, a drive assembly and a drill bit assembly, the middle of the connection pillar is provided with an annular groove, the shaft end of the connection pillar and the side face of the tailstock are provided with a pair of sensors, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and a big gear, the shaft sleeve is fixed to the front side face of the tailstock of the numerical control lathe, the rotating shaft penetrates through the shaft sleeve, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the big gear, the front end of the rotating arm is provided with a hook portion capable of being clamped into an annular groove, the drive assembly comprises a rack, an air cylinder, a magnetic exchange valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the magnetic exchange valve, and the rest switch is mounted in front of the lathe saddle of the numerical control lathe and electrically connected with the controller.

Owner:三星智能科技盐城有限公司

Numerically-controlled lathe tailstock automatic feeding control method capable of controlling finishing of hole bottoms

ActiveCN106112024ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

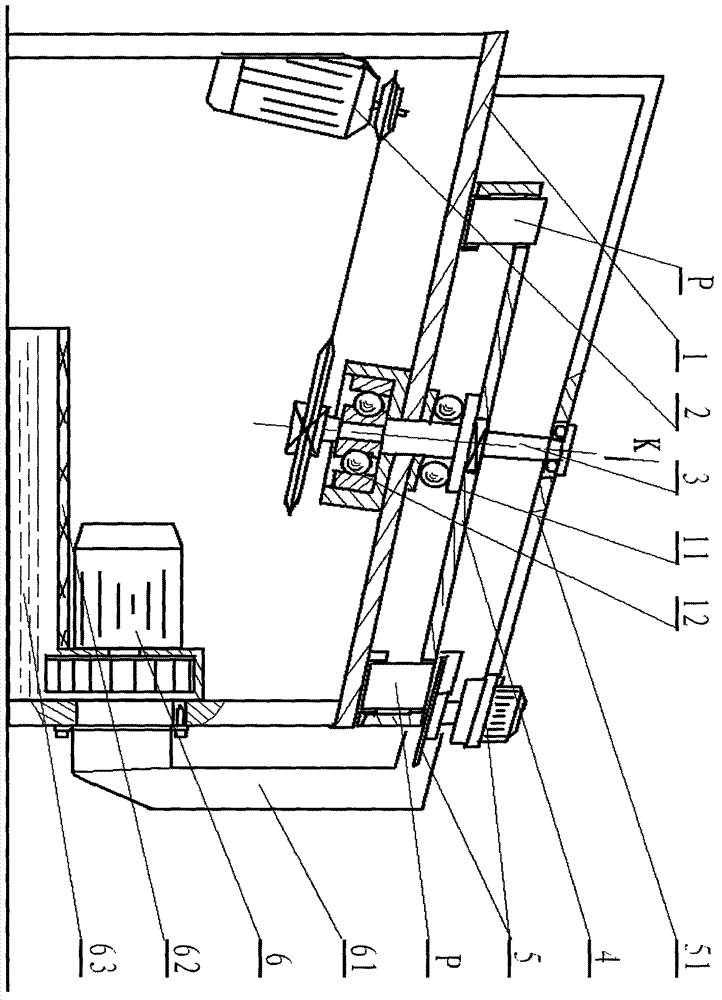

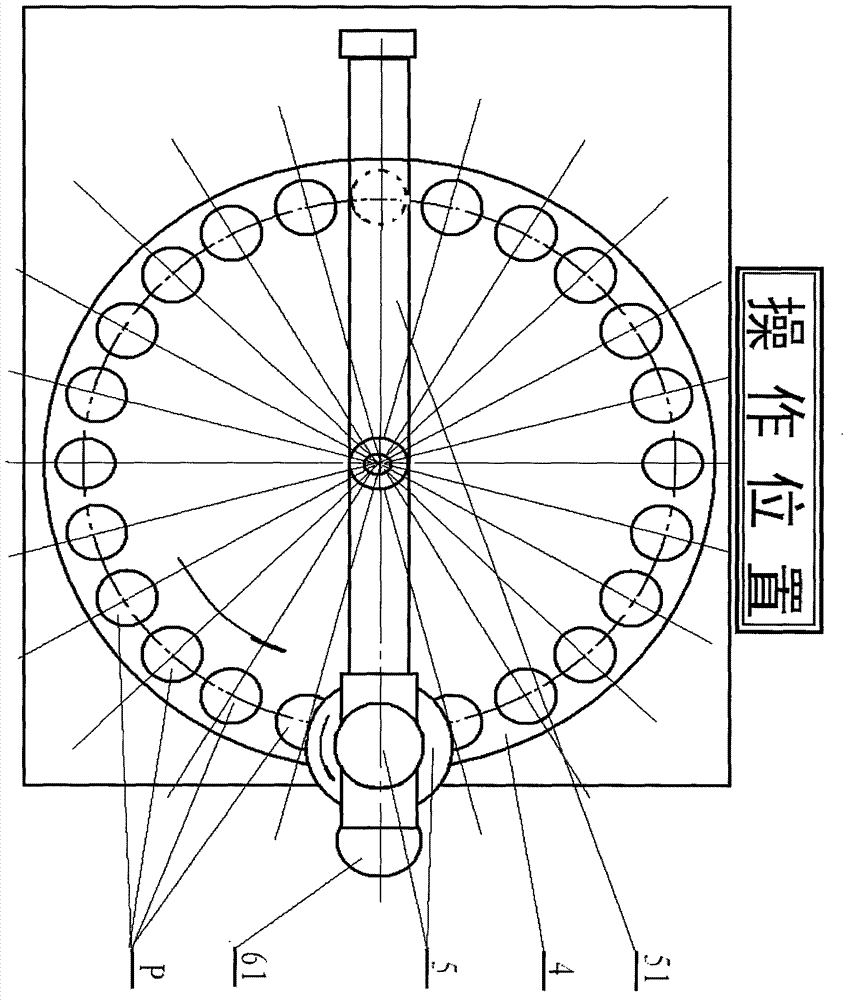

Flat head cutting device for end faces of barrel products

InactiveCN103112090APrecise control of dimensional accuracySimple structureWorking accessoriesStone-like material working toolsActivated carbonDimensional precision

The invention discloses a flat head cutting device for end faces of barrel products and belongs to the technical field of machine manufacturing. The flat head cutting device comprises a case, a gear motor and drive structure, a drive shaft, a face plate, a cutting machine and saw blades and a dust collecting fan component. The gear motor and drive structure is adopted to drive the drive shaft to rotate, and further drive the face plate fixed on the drive shaft to rotate. The cutting machine arranged above the face plate drives the saw blades to rotate so that dimensional precision of activated carbon sintered filter element products can be controlled accurately. The flat head cutting device is simple in structure, convenient to operate, low in manufacturing cost, safe and reliable in performance, further has small power consumption, less failure due to low rotation speed, is a novel energy-saving product, and fills the gap of the flat head cutting device for the end faces of the barrel products.

Owner:NINGBO HO WATER PURIFICATION EQUIP TECHCO LTD +1

Precision control tool for welding titanium alloy thin-wall winding drum

PendingCN113732593AEasy to installUniform and stable forceWelding/cutting auxillary devicesAuxillary welding devicesThin slabThin walled

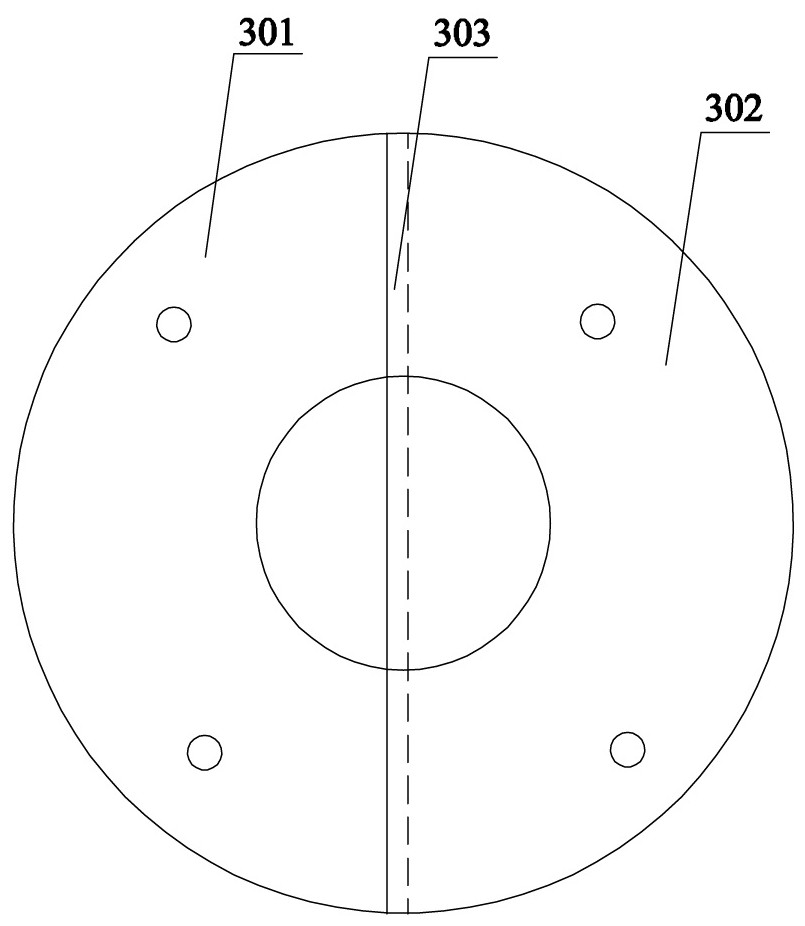

A precision control tool for welding a titanium alloy thin-wall winding drum comprises a clamping disc which is used for being arranged in the thin-wall winding drum to be welded in a sleeved mode and supporting the inner wall of the thin-wall winding drum in the radial direction of the thin-wall winding drum; the clamping disc is composed of a first disc body and a second disc body which are matched through bevels; and the precision control tool further comprises an adjusting device used for applying pressure to the first disc body and the second disc body in the axial direction of the clamping disc so as to drive the first disc body and the second disc body to move along the bevels, and then the outer diameter of the clamping disc is adjusted so that the inner wall of the thin-wall winding drum can be stably supported. Staggered mounting is achieved due to bevel butt joint of the clamping disc, the size of the clamping discs can be accurately controlled while tool installation is facilitated, it is guaranteed that the surface of a thin plate of the titanium alloy thin-wall winding drum is stressed stably and evenly, and the thin plate of the titanium alloy thin-wall winding drum is effectively prevented from deforming in the welding process.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

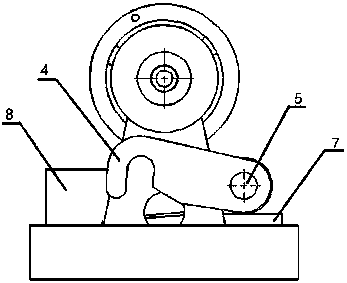

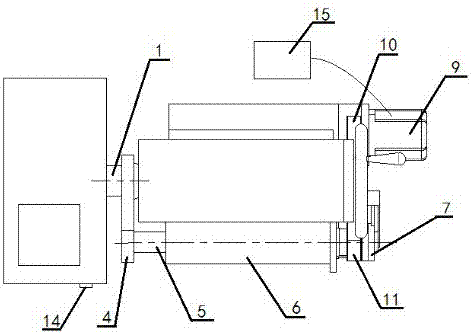

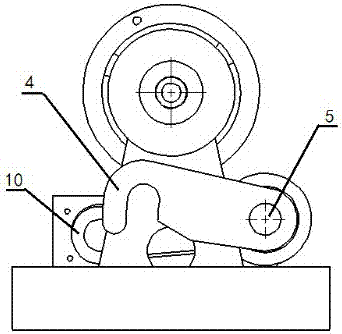

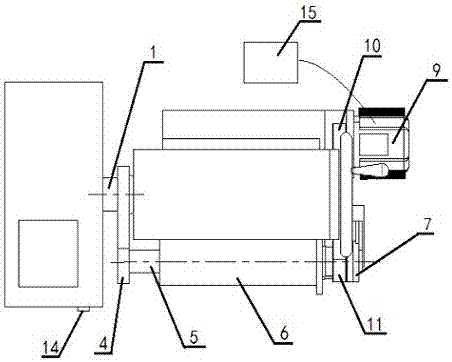

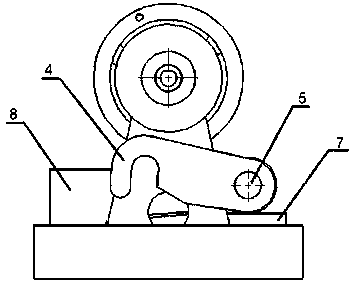

Method for achieving automatic feeding control of tailstock of numerically-controlled lathe through motor

ActiveCN106001632ARealize synchronized movementHigh degree of automationTailstocks/centresAuxillary equipmentNumerical controlDrive motor

The invention provides a method for achieving automatic feeding control of a tailstock of a numerically-controlled lathe through motor. A connecting device for connecting and separating a saddle and the tailstock of the numerically-controlled lathe is used for the method, and comprises a centering assembly, a rotating arm assembly and a driving assembly. The centering assembly comprises a centering shaft (1) and a V-shaped block (2). The rotating arm assembly comprises a rotating arm (4), a rotating shaft (5), a shaft sleeve (6) and two limiting pressing blocks (7). The driving assembly comprises a pair of band transmitting parts, a driving motor (9), a reset switch (14) and a controller (15), the controller (15) is installed in a power distribution cabinet of the lathe, the reset switch (14) is installed on the front face of the saddle of the numerically-controlled lathe and electrically connected with the controller (15), and the driving motor (9) is fixedly connected with the tailstock of the numerically-controlled lathe, and electrically connected with the controller (15).

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

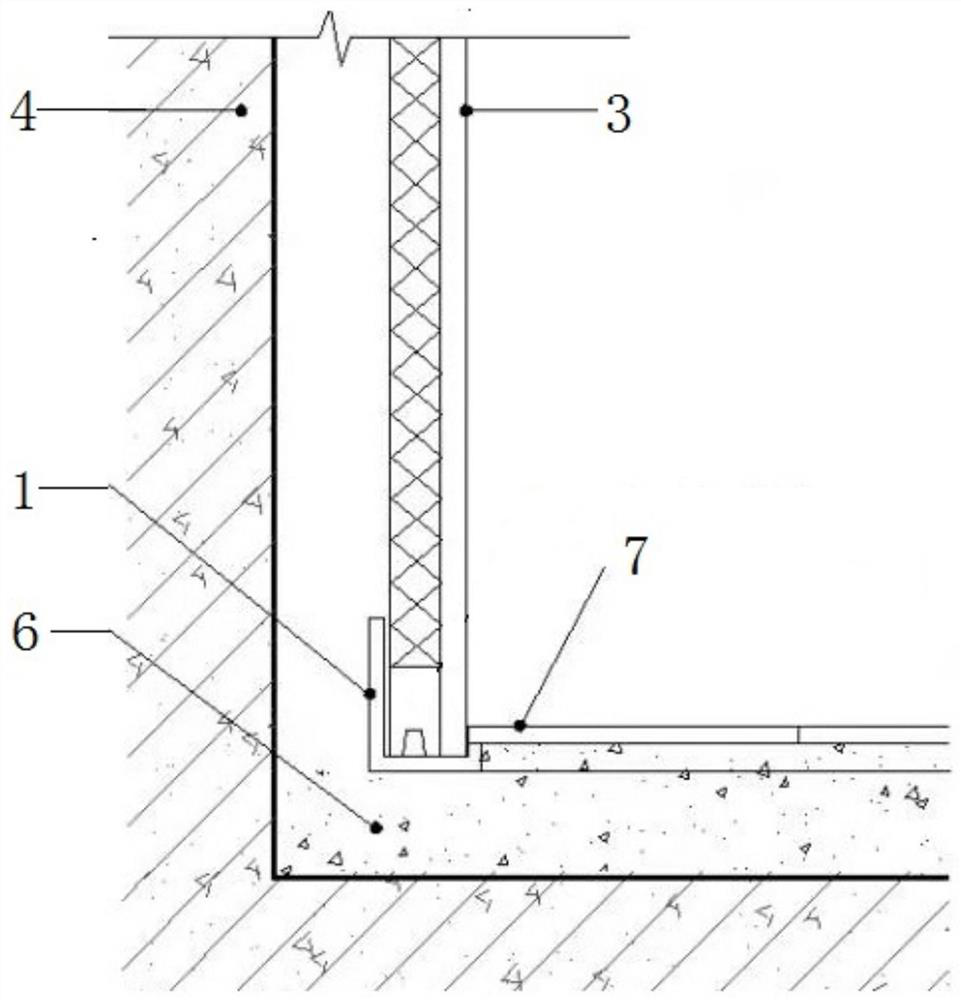

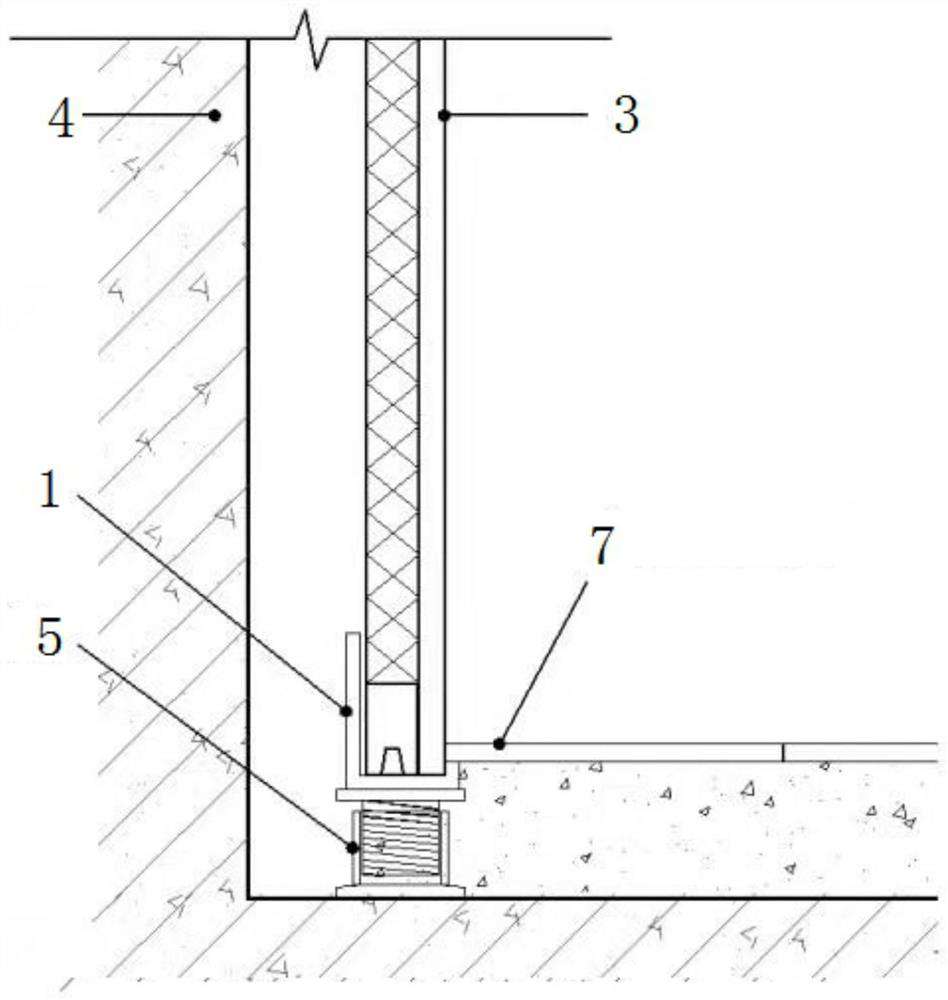

Plate mounting device and leveling mounting method thereof

PendingCN113152819AReduce spendingEasy to installCovering/liningsBuilding material handlingStructural engineeringMechanical engineering

Owner:普丽美家科技(北京)有限公司

An automatic feed control method for the tailstock of a CNC lathe that can control the finishing of the bottom of the hole

ActiveCN106112024BRealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

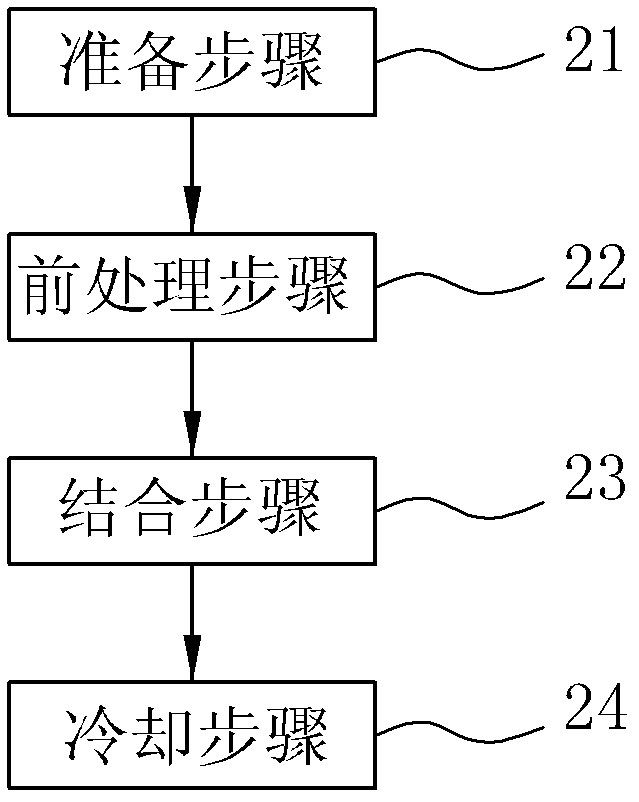

Manufacturing method for polymer composite products

The invention discloses a manufacturing method for polymer composite products. The method comprises a preparation step, a pre-treatment step, a combination step and a cooling step. The preparation step is to form a semi-finished product by using a non-polymer material and form a to-be-treated member capable of cooperating with the semi-finished product by using the polymer material; the pre-treatment step is to heat the to-be-treated member and to coat an adhesion agent on the semi-finished product; the combination step is to combines the semi-finished product and the to-be-treated member; and the cooling step is to cool the to-be-treated member. In the pre-treatment step, the semi-finished product and the to-be-treated member are formed in advance, so that size precision and possible deformation of the semi-finished product and the to-be-treated member can be controlled accurately so as to increase shape accuracy; and in cooperation with the adhesion agent and the characteristic of expansion caused by heat and contraction caused by cold of the material, so that the combination force between the semi-finished product and the to-be-treated member can be greatly increased.

Owner:ADVANCED INT MULTITECH CO LTD

A method for automatic control of tailstock of CNC lathe

ActiveCN106001633BRealize synchronized movementRealize finishingTailstocks/centresAuxillary equipmentMagnetic exchangeAutomatic control

Owner:三星智能科技盐城有限公司

A method for automatic feed control of tailstock of CNC lathe

ActiveCN106041135BRealize synchronized movementHigh degree of automationTailstocks/centresAuxillary equipmentNumerical controlDrive motor

The invention provides an automatic feeding control method of a tailstock of a numerical control lathe. A connection device for realizing connection and disconnection between a saddle and the tailstock of the numerical control lathe is used in the automatic feeding control method. The connection device comprises an alignment assembly, a rotating arm assembly and a driving assembly, wherein the alignment assembly comprises an alignment shaft (1) and an alignment sleeve (2) with an inner conical hole, wherein a sensor (13) is arranged at the shaft end of the alignment shaft (1) and the bottom of the conical hole of the alignment sleeve (2); the rotating arm assembly comprises a rotating arm (4), a rotating shaft (5), a shaft sleeve (6) and two limiting pressure blocks (7); the driving assembly comprises a pair of belt drivers, a driving motor (9), a resetting switch (14) and a controller (15); the controller (15) is mounted in a lathe power distribution cabinet; the resetting switch (14) is mounted on the front surface of the saddle of the numerical control lathe and is electrically connected with the controller; the driving motor (9) is fixedly connected with the tailstock of the numerical control lathe and is electrically connected with the controller (15).

Owner:房县金正销轴有限公司

A Method of Using Motor to Realize Automatic Feed Control of CNC Lathe Tailstock

ActiveCN106001632BRealize synchronized movementHigh degree of automationTailstocks/centresAuxillary equipmentNumerical controlElectric machine

The invention provides a method for achieving automatic feeding control of a tailstock of a numerically-controlled lathe through motor. A connecting device for connecting and separating a saddle and the tailstock of the numerically-controlled lathe is used for the method, and comprises a centering assembly, a rotating arm assembly and a driving assembly. The centering assembly comprises a centering shaft (1) and a V-shaped block (2). The rotating arm assembly comprises a rotating arm (4), a rotating shaft (5), a shaft sleeve (6) and two limiting pressing blocks (7). The driving assembly comprises a pair of band transmitting parts, a driving motor (9), a reset switch (14) and a controller (15), the controller (15) is installed in a power distribution cabinet of the lathe, the reset switch (14) is installed on the front face of the saddle of the numerically-controlled lathe and electrically connected with the controller (15), and the driving motor (9) is fixedly connected with the tailstock of the numerically-controlled lathe, and electrically connected with the controller (15).

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Automatic feeding control method for tailstock of numerical control lathe

ActiveCN106041135ARealize synchronized movementHigh degree of automationTailstocks/centresAuxillary equipmentNumerical controlElectric machine

The invention provides an automatic feeding control method of a tailstock of a numerical control lathe. A connection device for realizing connection and disconnection between a saddle and the tailstock of the numerical control lathe is used in the automatic feeding control method. The connection device comprises an alignment assembly, a rotating arm assembly and a driving assembly, wherein the alignment assembly comprises an alignment shaft (1) and an alignment sleeve (2) with an inner conical hole, wherein a sensor (13) is arranged at the shaft end of the alignment shaft (1) and the bottom of the conical hole of the alignment sleeve (2); the rotating arm assembly comprises a rotating arm (4), a rotating shaft (5), a shaft sleeve (6) and two limiting pressure blocks (7); the driving assembly comprises a pair of belt drivers, a driving motor (9), a resetting switch (14) and a controller (15); the controller (15) is mounted in a lathe power distribution cabinet; the resetting switch (14) is mounted on the front surface of the saddle of the numerical control lathe and is electrically connected with the controller; the driving motor (9) is fixedly connected with the tailstock of the numerical control lathe and is electrically connected with the controller (15).

Owner:房县金正销轴有限公司

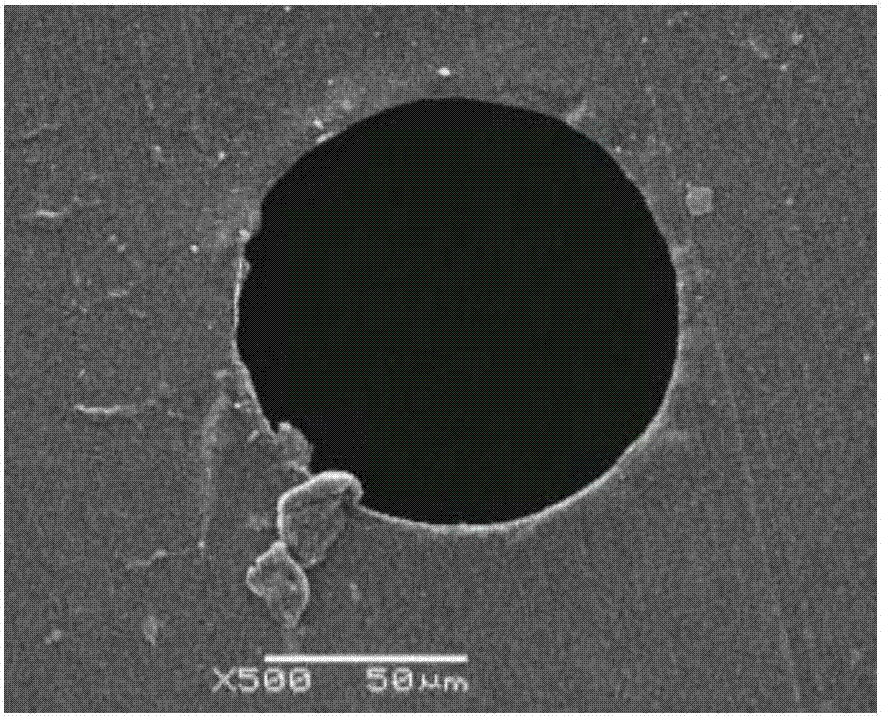

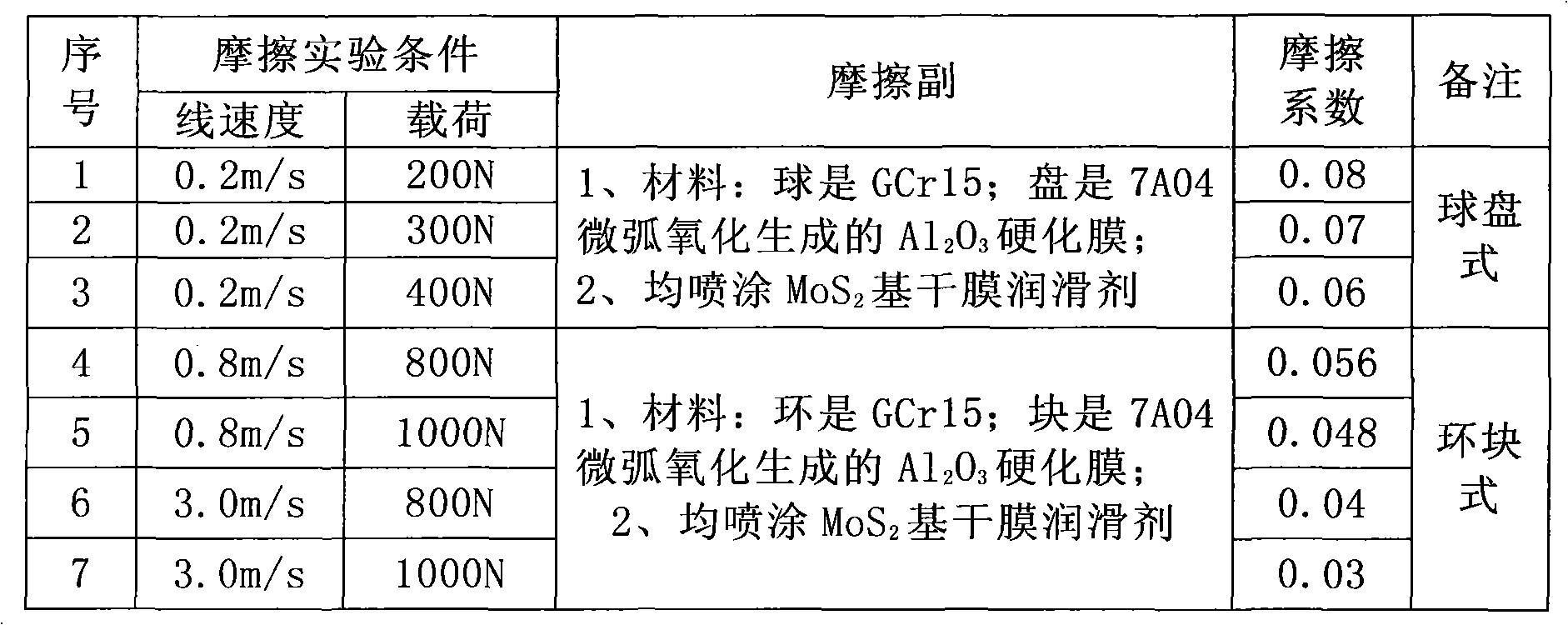

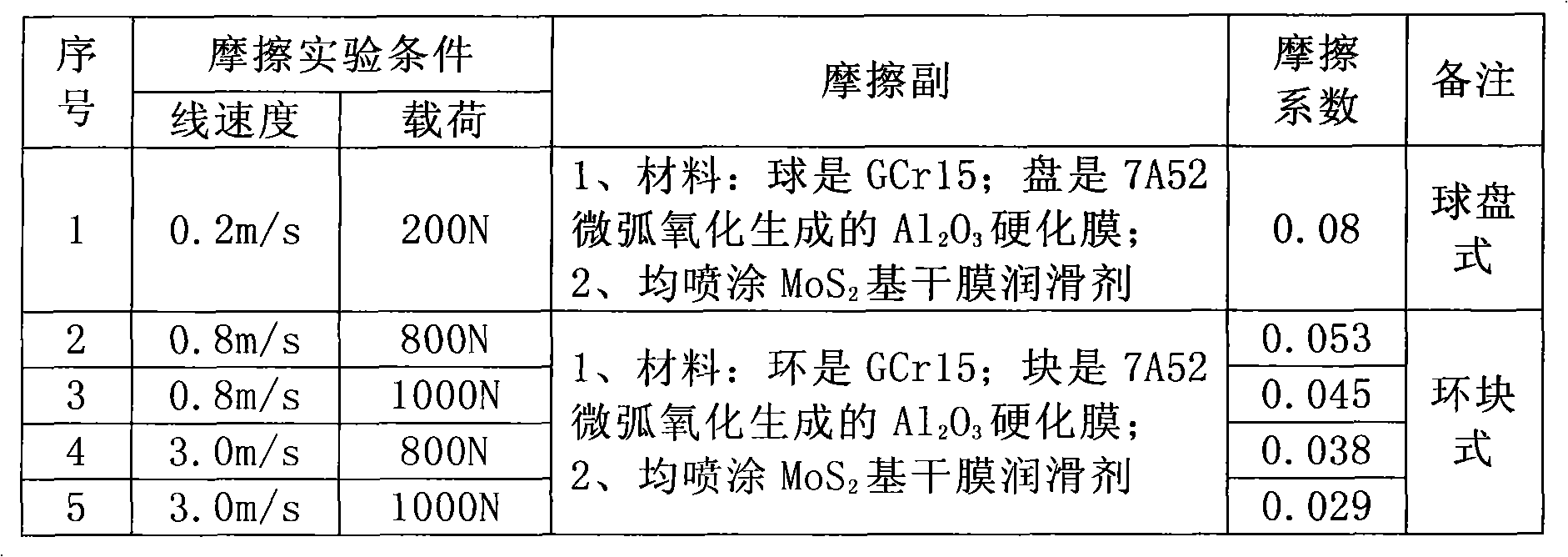

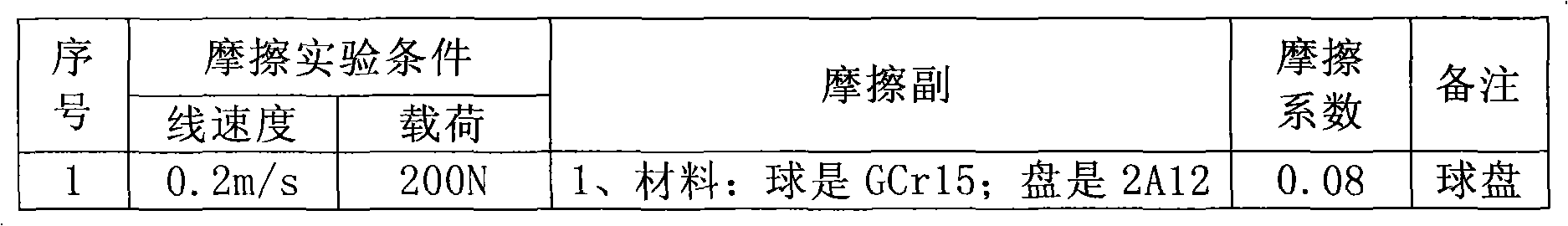

Aluminum matrix composite material with ultra-low friction coefficient and preparation method thereof

InactiveCN102011166BReasonable formulaSimple processAnodisationPlasma electrolytic oxidationAluminum substrate

The invention discloses an aluminum-based composite material with an ultra-low friction coefficient and a preparation method thereof. The aluminum-based composite material with the ultra-low friction coefficient comprises an aluminum substrate, an Al2O3 hardened film layer produced by microarc oxidation on the surface of the aluminum substrate, and a MoS2-based dry film lubricating layer sprayed on the surface of the Al2O3 hardened film layer. The aluminum-based composite material has the advantages of overcoming a plurality of shortcomings of the prior art and prolonging the service life of key components and parts adopting the composite material, along with scientific formula, simple process and ultra-low friction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

A kind of manufacturing process of easy open end and easy open end

ActiveCN109130228BImprove toughnessImprove tightnessRigid containersPlastic materialsIndustrial engineering

The invention provides a manufacturing process of an easy-open lid and the easy-open lid, which belong to the technical field of machinery. It solves the problems of poor toughness and easy crushing of the existing easy-open lids. The easy-open end includes a plastic-absorbed easy-open end body, the easy-open end body is punched with pre-cut marks, and the pull ring is hot-melt connected with the easy-open end body. This production process includes the following steps: step a: select a sheet made of plastic material and perform blister molding to form an easy-open cover on the sheet; step b: press the corresponding easy-open cover on the sheet mark, and install and hot-melt connect the pull ring to form an easy-open end blank with pre-broken marks; step c, then trim the corresponding easy-open end blank on the sheet and separate it from the sheet to form an easy-open end. The easy-to-open lid is made by blister molding, and the molecules are arranged in strips and line segments. The tightness between the molecules makes the overall toughness of the lid better, not easy to be crushed, and the yield is high, and it is not easy to tear during the tearing process Crushed, easy to operate.

Owner:张仁贵

Device for cutting gel paste

InactiveCN103072149BFlat cutPrecise control of dimensional accuracyMetal working apparatusEngineeringFlywheel

The invention relates to the field of cutting devices, in particular to a device for cutting gel paste. The device is characterized by comprising a conveying device, a cutting device and a power device, wherein the conveying device comprises a first cylinder and a conveying groove; the first cylinder is arranged on the second half part of a guide rail; wheel teeth are arranged on the lower surface of the first half part of the guide rail; a cylinder rolling component is arranged at the front end of the conveying groove; a flywheel is fixed on one side of the cylinder rolling component and is in meshed connection with the first half part of the guide rail through the wheel teeth; the cutting device is arranged at the front end of the cylinder rolling component and comprises a tool and a second cylinder which is connected with the tool; the power device comprises a first power device and a second power device, which are connected with each other; and the second power device is respectively connected with the first cylinder and the second cylinder. By the adoption of the device, the accuracy of the cutting size of the gel paste is improved, labor is greatly saved, and working efficiency is improved.

Owner:THE MILITARY GENERAL HOSPITAL OF BEIJING PLA

An Automatically Controlled Tailstock Feeding Method of CNC Lathe

ActiveCN105965306BRealize synchronized movementHigh degree of automationTailstocks/centresFeeding apparatusNumerical controlAutomatic control

The invention provides an automatically-controlled numerically controlled lathe tailstock feeding method. A connecting device which combines a numerically controlled lathe saddle and a tailstock and disengages the numerically controlled lathe saddle from the tailstock is adopted. The connecting device comprises an alignment assembly, a rotating arm assembly and a driving assembly; the alignment assembly comprises an alignment shaft (1) and an alignment sleeve (2) with an inner cone hole, a sensor (13) is arranged at the shaft end of the alignment shaft (1) and at the bottom of the cone hole of the alignment sleeve (2); the rotating arm assembly comprises a rotating arm (4), a rotating shaft (5), a shaft sleeve (6) and two limiting pressing blocks (7); the driving assembly comprises a pair of belt drives, a driving motor (9), a reset switch (14) and a controller (15); the controller (15) is installed in a machine tool power distribution cabinet, the reset switch (14) is installed in front of the numerically controlled lathe saddle and electrically connected with the controller, the driving motor (9) is fixedly connected with the tailstock of the numerically controlled lathe and electrically connected with the controller (15), and a vibration reduction backing plate is arranged between the driving motor (9) and the tailstock of the numerically controlled lathe and used for reducing vibratory force generated when the driving motor (9) operates.

Owner:惠州合友五金制品有限公司

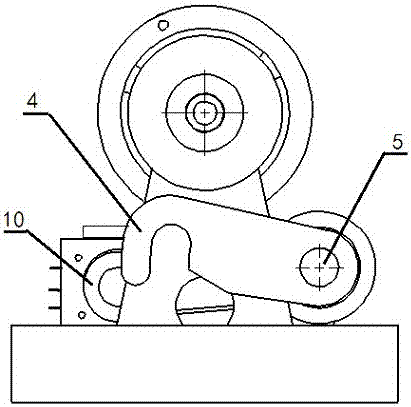

A Control Method of CNC Lathe Tail Stock Using V-block Alignment

ActiveCN106001635BRealize synchronized movementConsistent motion accuracy in the Z directionTailstocks/centresFeeding apparatusEngineeringDigital control

Owner:珠海市机械厂有限公司

Processing method of surface-mounted pads on thick copper circuit board

ActiveCN102244985BSmall sizeIncreased mounting areaConductive material chemical/electrolytical removalSolder maskSurface mounting

The invention discloses a processing method of surface-mounted pads on a thick copper circuit board. The processing method comprises the following steps: S01. patterning an external layer for the first time; 2. etching the external layer for the first time; 3. patterning the external layer for the second time; 4. etching the external layer for the second time; and 5. manufacturing a solder mask bridge among the surface-mounted pads by a fractional solder resisting method. The processing method has the beneficial effects that the surface-mounted pads are manufactured by a partitioned etching method, which strengthens size control of the surface-mounted pads and meets the design requirements; and the solder mask bridge among the surface-mounted pads are manufactured by utilizing the fractional solder resisting method so that the solder mask bridge and the circuit board are firmly connected together and are not easily separated from each other.

Owner:WUXI SHENNAN CIRCUITS CO LTD

Numerical control lathe tailstock control method using V-shaped block for centering

InactiveCN108526498ARealize synchronized movementConsistent motion accuracy in the Z directionTailstocks/centresFeeding apparatusGear wheelTailstock

The invention provides a numerical control lathe tailstock control method using a V-shaped block for centering. According to the numerical control lathe tailstock control method, a connecting device which is used for connecting and disconnecting a saddle and a tailstock of a numerical control lathe is adopted; the connecting device comprises a centering component, a rotating arm component and a driving component; the centering component comprises a centering shaft and the V-shaped block; the rotating arm component comprises a rotating arm, a rotating shaft, a shaft sleeve and a main gear; theshaft sleeve is fixed to the front side surface of the tailstock of the numerical control lathe; the rotating shaft penetrates through the shaft sleeve; the front end of the rotating shaft is fixedlyconnected with the rotating arm; the other end of the rotating shaft is fixedly connected with the main gear; the front end of the rotating arm is provided with a hook part which can be clamped into aring slot; the driving component comprises a gear rack, a cylinder, an electromagnetic reversing valve, a gear rack guide groove, a reset switch and a controller; the controller is installed inside apower distribution cabinet of the lathe and is electrically connected with a numerical control system and the electromagnetic reversing valve; and the reset switch is installed in front of the saddleof the numerical control lathe and is electrically connected with the controller.

Owner:赵红艳

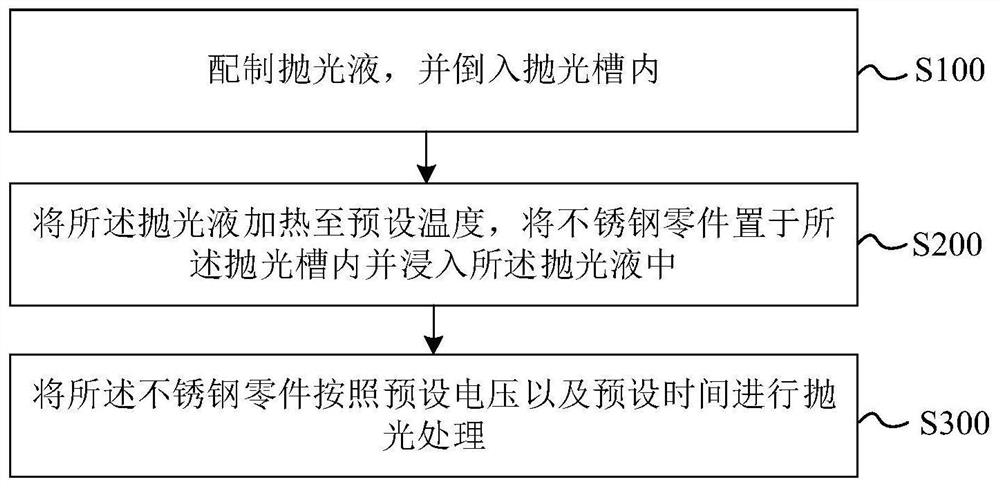

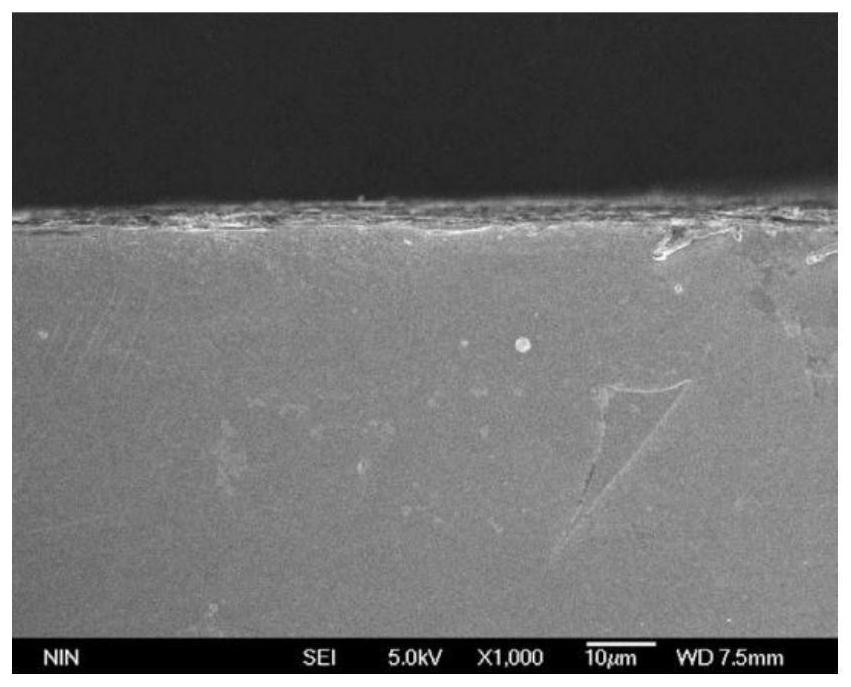

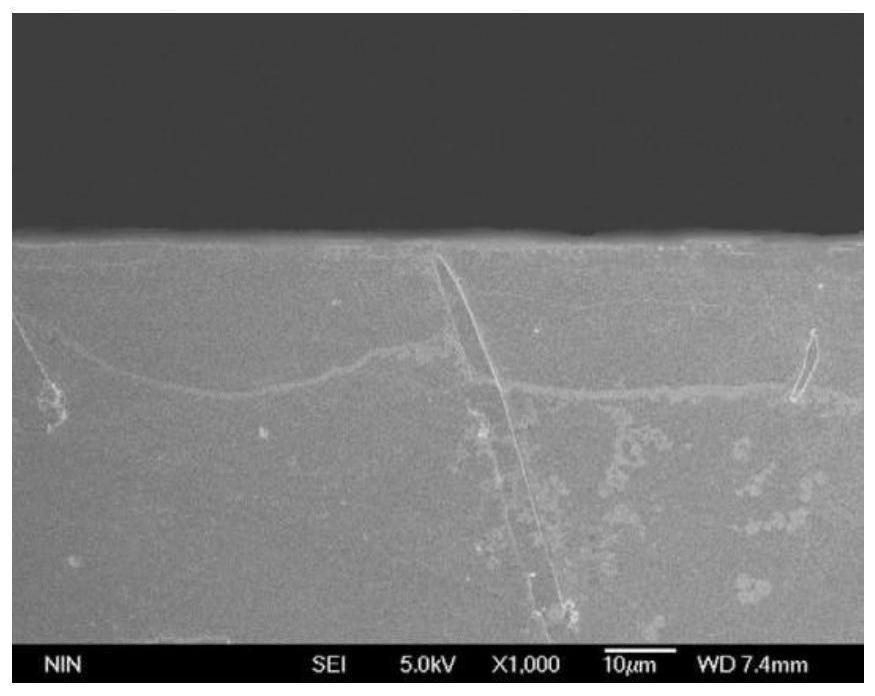

Method for removing deteriorated layer on stainless steel surface

ActiveCN114232065AEfficient removalPrecise control of dimensional accuracyO-Phosphoric AcidSodium phosphates

The invention relates to a method for removing a deteriorated layer on the surface of stainless steel, and relates to the technical field of polishing. The method is used for stainless steel subjected to hot isostatic pressing treatment and comprises the steps that a polishing solution is prepared and poured into a polishing tank; the polishing solution is heated to a preset temperature, and the stainless steel part is placed in the polishing groove and immersed in the polishing solution; the stainless steel part is subjected to polishing treatment according to preset voltage and preset time; wherein the polishing solution comprises a salt solution, an additive and water, the salt solution is at least two of potassium chloride, barium chloride and ammonium sulfate, and the additive is at least one of phosphoric acid, acetic acid, ethylene diamine tetra (methylene sodium phosphate) and sodium gluconate. The polishing solution prepared from the salt solution, the additive and the water can effectively remove a metamorphic layer on the surface of the stainless steel part, so that the size precision of the part subjected to hot isostatic pressing treatment can be accurately controlled, and the product is good in surface smoothness, flat, smooth and bright in color.

Owner:西安赛隆增材技术股份有限公司

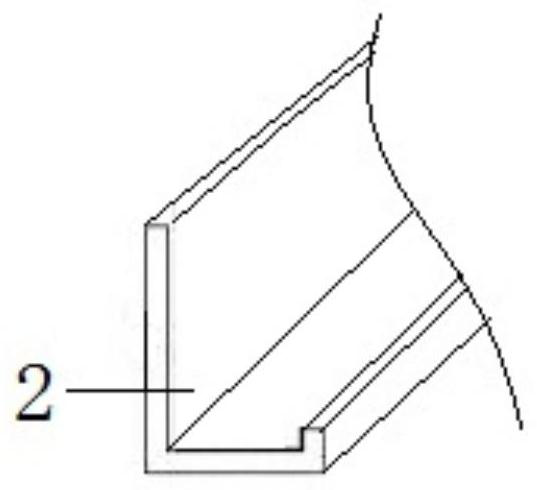

A kind of pvc door seal with anti-migration function and preparation method thereof

ActiveCN109281596BHigh hardnessImprove surface smoothnessSealing arrangementsDioctyl terephthalateEngineering

The invention discloses a PVC door gasket with a migration-resisting function and a preparation method thereof. The PVC door gasket is prepared from the raw materials in parts by weight: 90-110 partsof PVC resin, 50-70 parts of a main plasticizer, 50-60 parts of a filling agent, 6-10 parts of a stabilizer, 1-2 parts of a lubricating agent, 0.5-1.5 parts of pigment, 0-0.6 part of a flame retardant, and 0.2-0.4 part of an assistant, wherein a plasticizer is a mixture of the main plasticizer and auxiliary plasticizers, and the main plasticizer is one or more of trioctyl trimellitate (TOTM), dioctyl sebacate (DOS) and dioctyl terephthalate (DOTP). Production efficiency of a first door gasket and a second door gasket is greatly improved, the processing cost is lowered, and meanwhile the molecular migration rate of the first door gasket and the second door gasket is greatly reduced; the PVC door gasket obtained by installing the first door gasket and the second door gasket is reasonable instructure, impact force received during door closing and opening is effectively relieved, airtightness is good, and wide application prospects are achieved.

Owner:GUANGDONG SHUNDE JIANGSUN MAGNETIC CO LTD

Device for cutting gel paste

InactiveCN103072149AFlat cutPrecise control of dimensional accuracyMetal working apparatusEngineeringFlywheel

The invention relates to the field of cutting devices, in particular to a device for cutting gel paste. The device is characterized by comprising a conveying device, a cutting device and a power device, wherein the conveying device comprises a first cylinder and a conveying groove; the first cylinder is arranged on the second half part of a guide rail; wheel teeth are arranged on the lower surface of the first half part of the guide rail; a cylinder rolling component is arranged at the front end of the conveying groove; a flywheel is fixed on one side of the cylinder rolling component and is in meshed connection with the first half part of the guide rail through the wheel teeth; the cutting device is arranged at the front end of the cylinder rolling component and comprises a tool and a second cylinder which is connected with the tool; the power device comprises a first power device and a second power device, which are connected with each other; and the second power device is respectively connected with the first cylinder and the second cylinder. By the adoption of the device, the accuracy of the cutting size of the gel paste is improved, labor is greatly saved, and working efficiency is improved.

Owner:THE MILITARY GENERAL HOSPITAL OF BEIJING PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com