An Automatically Controlled Tailstock Feeding Method of CNC Lathe

A CNC lathe tailstock and CNC lathe technology, applied in the field of CNC lathes, can solve the problems of low processing efficiency, time-consuming and laborious, and the tailstock cannot be automatically fed, and achieve the effect of expanding functions and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

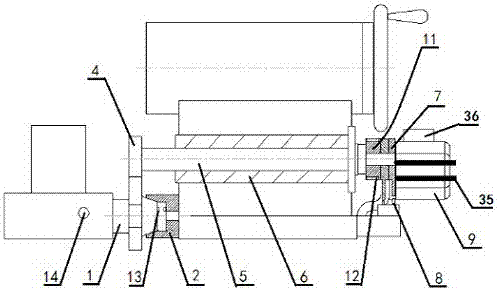

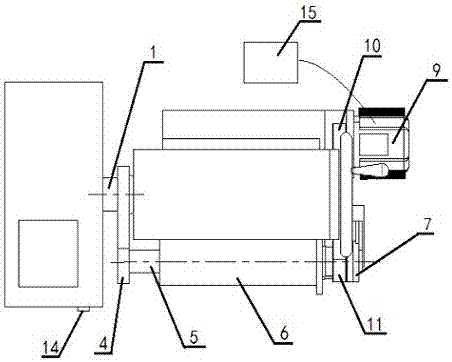

[0015] An automatically controlled CNC lathe tailstock feeding method, which uses a CNC lathe saddle and a tailstock coupling and disengagement connection device, including a centering assembly, a rotating arm assembly and a drive assembly. The centering The assembly includes a pair of center shafts 1 and a centering sleeve 2 with an inner tapered hole. A ring groove 3 is provided in the middle of the centering shaft 1. The centering shaft 1 is fixedly connected with the saddle of the CNC lathe, and the centering sleeve 2 is connected to the end of the CNC lathe. The base is fixedly connected, the front end of the centering shaft 1 and the inner taper hole of the centering sleeve 2 form a conical surface fit. The shaft end of the centering shaft 1 and the bottom of the taper hole of the centering sleeve 2 are provided with a sensor 13 which can be Magnetic effect sensor or Hall effect sensor, or photoelectric sensor;

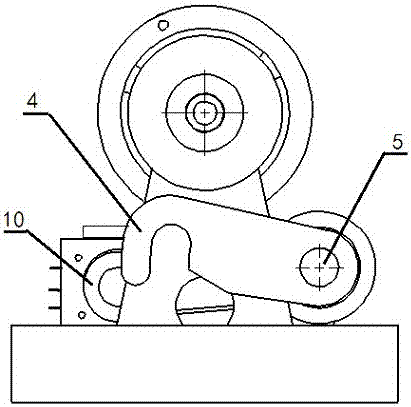

[0016] The rotating arm assembly includes a rotating arm 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com