An injection molding device and injection molding method

A technology of injection molding and mould, which is applied in the direction of coating, etc., can solve problems such as flashing, poor dimensional accuracy, and easy defects in the orifice, and achieve the effects of prolonging service life, small diameter, and precise size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

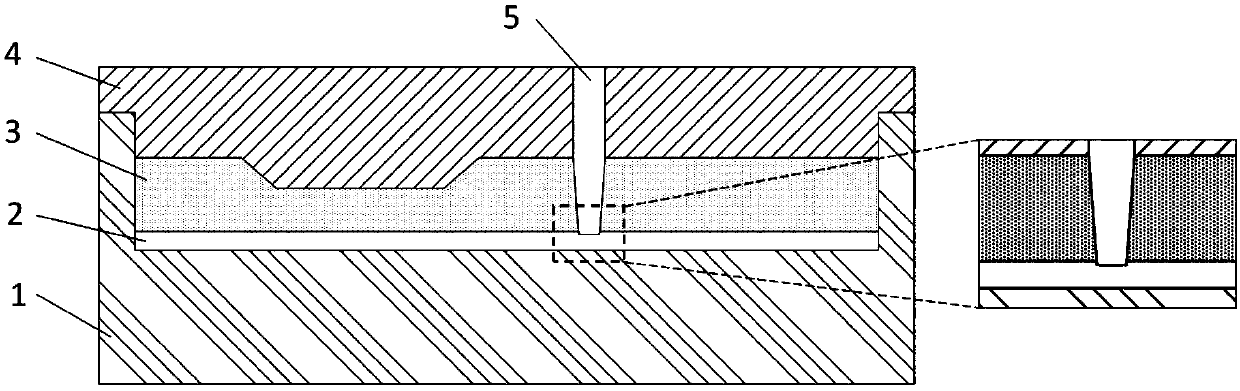

[0031] refer to figure 1 , in one embodiment, an injection molding device, comprising an upper mold and a lower mold, the upper mold or the lower mold is provided with a steel needle insert with a steel needle, the lower mold or the upper A layer of elastic film is arranged on the mold surface of the mold opposite to the steel needle, the shape and size of the steel needle are the shape and size required for injection molding micropores, and the steel needle is drawn from the upper mold or the lower mold The top protrudes toward the elastic film, and is arranged such that the end surface of the steel needle is pressed into the interior of the elastic film after the mold is closed. By controlling the pressing depth of the steel needle, the deformation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com