Flat head cutting device for end faces of barrel products

A cutting device and product technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of difficult size control, troublesome production, large consumption, etc., and achieve precise control of dimensional accuracy, easy operation, and low rotation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

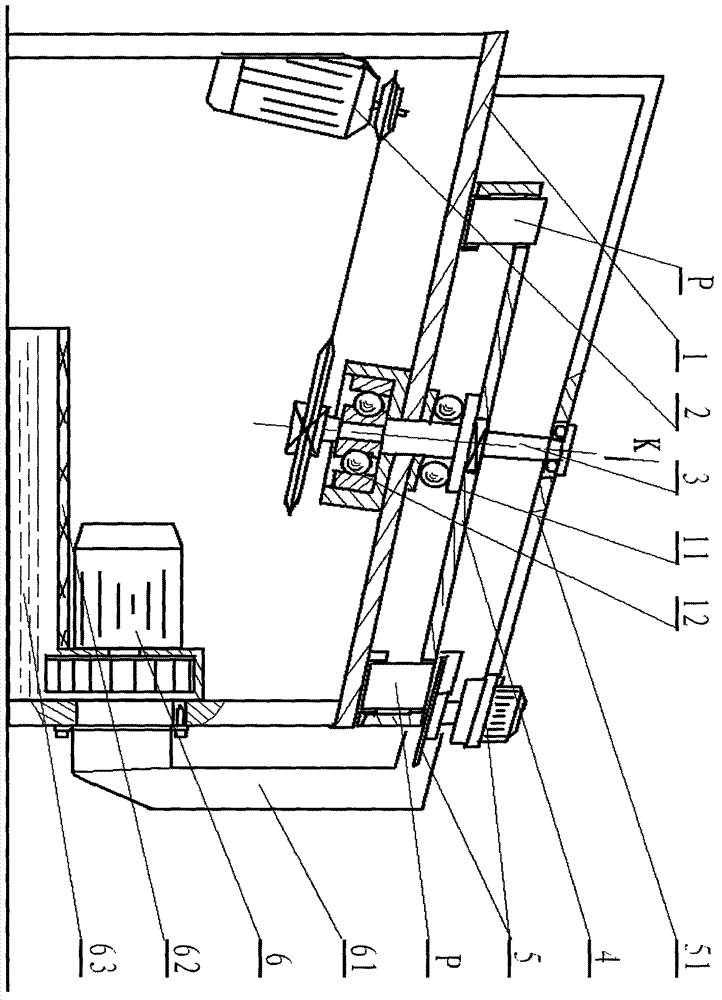

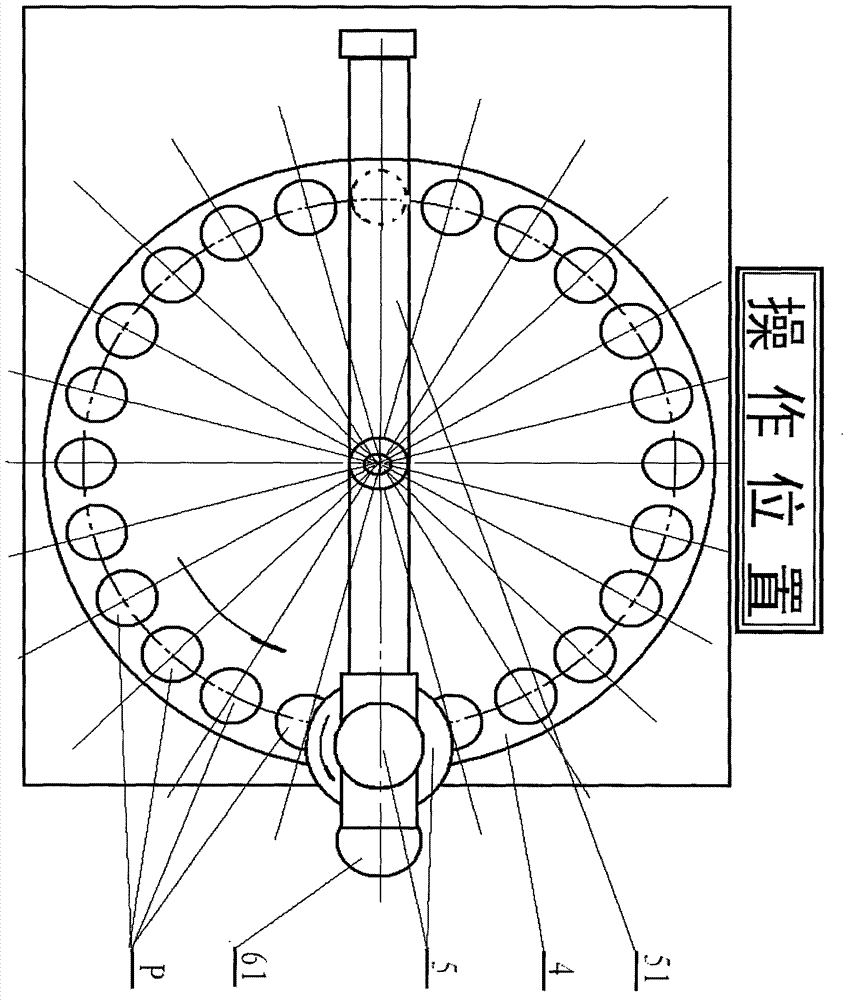

[0010] refer to figure 1 , figure 2 It is an embodiment of the end face flat head cutting device of a drum product of the present invention: it is a special machine for processing a drum filter element with a diameter of 60 mm and a height of 80 mm. It consists of a chassis 1, a geared motor and a transmission structure 2, a transmission shaft 3, a face plate 4, a cutting machine and a saw blade 5, and a vacuum fan assembly 6, and consists of 6 parts. Geared motor and transmission structure 2. The vacuum fan assembly 6 is installed and fixed in the case 1. The case 1 is welded with 4 mm thick A3 iron plate to form a sealed box with a length of 1.2 meters and a width of 1 meter. The height of the upper slope is 0.8 The geared motor and the geared motor of the transmission structure 2 adopt the national standard geared motor of 0.4 kilowatts and 4 revolutions per minute, and the geared motor and the transmission structure of the geared structure 2 adopt the national standard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com