A kind of pvc door seal with anti-migration function and preparation method thereof

A door seal, migration-resistant technology, used in special equipment for doors/windows, windows/doors, sealing devices, etc., can solve the problems of high molecular mobility, cumbersome processing technology, low production efficiency, etc. Hardness and surface smoothness, easy disassembly and installation, the effect of increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

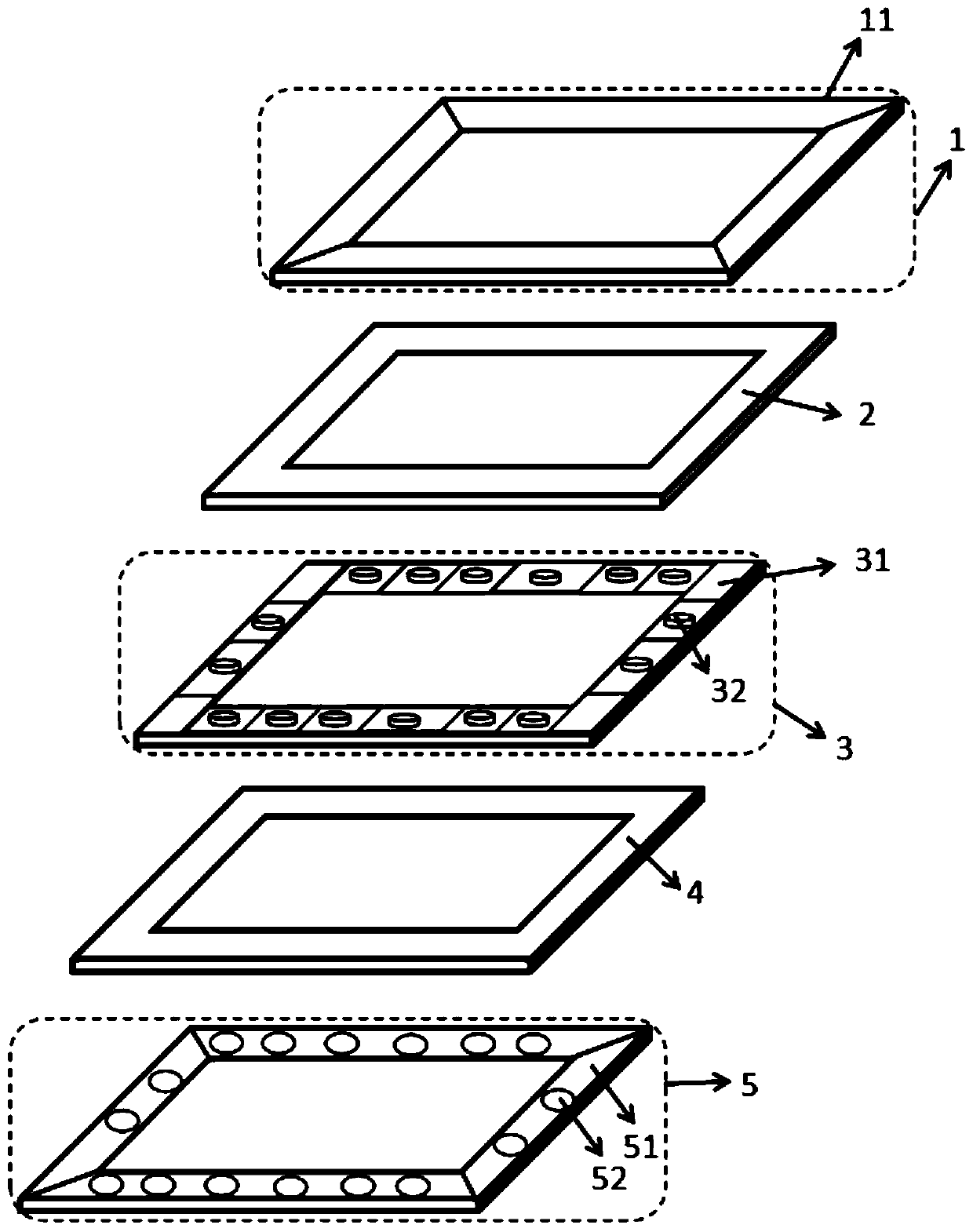

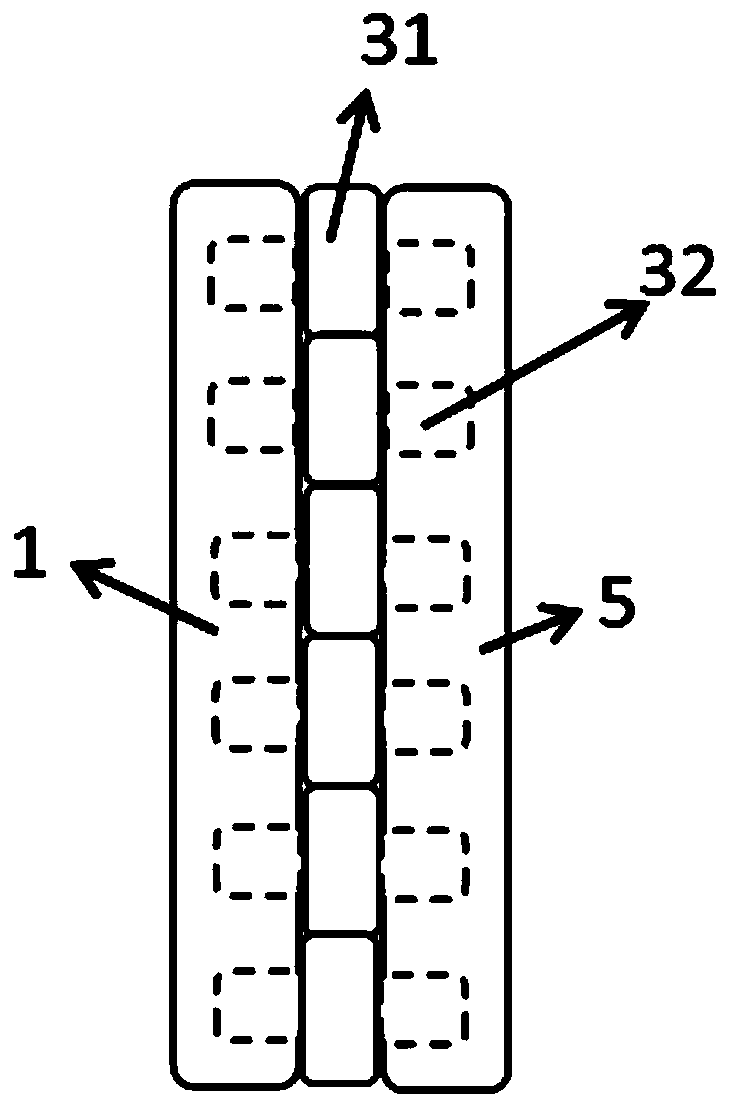

Image

Examples

Embodiment 1

[0076] First of all, before use, you need to start the machine to check the operation of the equipment. At the same time, check the raw materials and weigh each component raw material according to a certain proportion. The raw materials of each component are by weight, 95 parts of PVC resin, 55 parts of plasticizer, and 50 parts of heavy calcium carbonate. 1 part, 7 parts of calcium zinc stabilizer, 1 part of stearic acid, 0.5 part of inorganic pigment, 0.2 part of foaming regulator; the plasticizer is 15 parts of trioctyl trimellitate (TOTM) and 30 parts of epoxy resin Soybean oil (ESO) blends;

[0077] Then put the weighed PVC resin and calcium-zinc stabilizer into a high-speed mixer for stirring, and when the temperature reaches 70°C after high-speed stirring, add plasticizer, heavy calcium carbonate, stearic acid, inorganic pigment and foaming adjustment Put the agent into the high-speed mixer, and stop stirring when the temperature reaches 110°C; then put the stirred mate...

Embodiment 2

[0083] First of all, before use, you need to start the machine to check the operation of the equipment. At the same time, check the raw materials and weigh each component raw material according to a certain proportion. The raw materials of each component are by weight, 100 parts of PVC resin, 60 parts of plasticizer, and 53 parts of light calcium carbonate. 1 part, 8 parts of barium zinc stabilizer, 1.3 parts of stearic acid, 1 part of inorganic pigment, 0.3 part of flame retardant, 0.3 part of foam regulator; the plasticizer is 20 parts of dioctyl sebacate (DOS) and A blend of 40 parts epoxidized soybean oil (ESO);

[0084] Then put the weighed PVC resin and barium-zinc stabilizer into a high-speed mixer for stirring, and when the temperature reaches 75°C, add plasticizer, light calcium carbonate, stearic acid, inorganic pigment, flame retardant Put the foam regulator into the high-speed mixer, stir until the temperature reaches 115°C, stop stirring; then put the stirred mate...

Embodiment 3

[0090]First of all, before use, you need to start the machine to check the operation of the equipment. At the same time, check the raw materials and weigh each component raw material according to a certain proportion. The raw materials of each component are by weight, 105 parts of PVC resin, 65 parts of plasticizer, and 55 parts of active light calcium. 9 parts, 9 parts of lead salt stabilizer, 1.5 parts of stearic acid, 1.5 parts of inorganic pigment, 0.6 parts of flame retardant, 0.4 parts of foam regulator; of which 25 parts of plasticizer are dioctyl terephthalate (DOTP) and 40 parts of epoxidized soybean oil (ESO);

[0091] Then put the weighed PVC resin and lead salt stabilizer into a high-speed mixer for stirring, and when the temperature reaches 80°C, add plasticizer, active light calcium, stearic acid, inorganic pigment, flame retardant Put the foam regulator into the high-speed mixer, and stop stirring when the temperature reaches 120°C; then put the stirred material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com