A kind of manufacturing process of easy open end and easy open end

A production process and technology of easy-open lids, applied in the field of machinery, can solve problems such as poor intermolecular tightness, low production efficiency, and item contamination, and achieve the effects of good tightness, high production efficiency and benefits, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

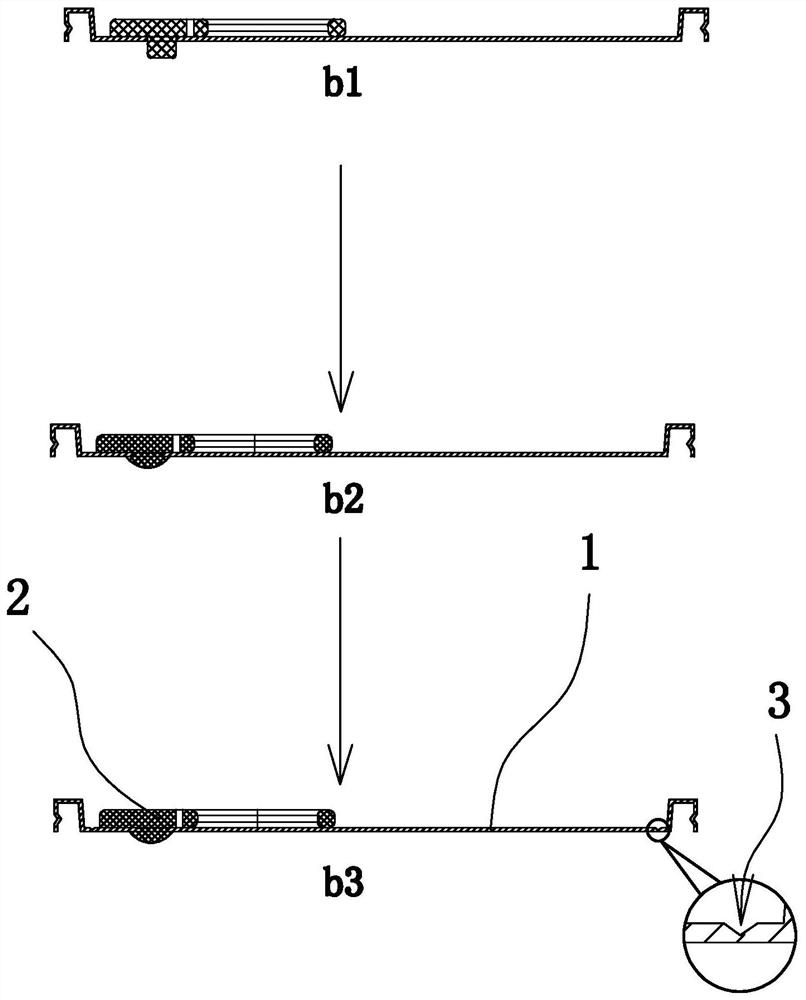

[0040] The easy-open end includes an easy-open end body 1 with pre-break marks, a pull ring 2 is fixed on the easy-open end body 1, and the easy-open end body 1 is molded by plastic material, and the thickness of the easy-open end body 1 is 0.5mm , the thickness of the easy-open lid body 1 at the pre-break mark 3 is 0.05mm.

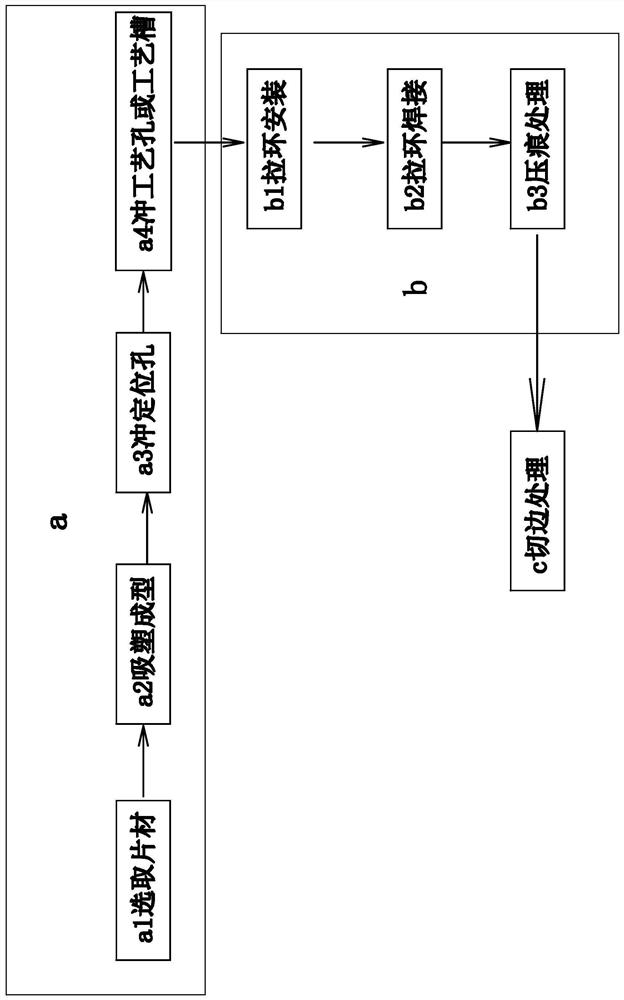

[0041] like figure 1 As shown, the manufacturing process of the easy-open lid comprises the following steps:

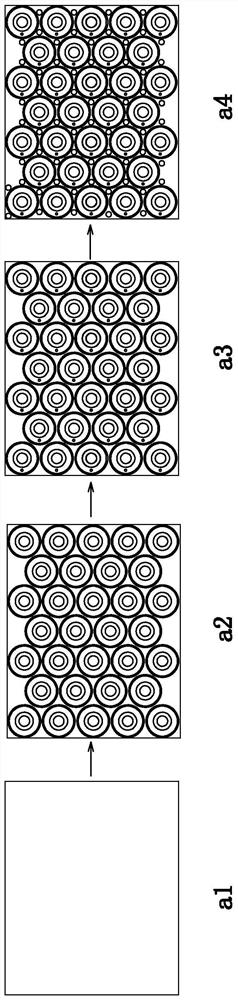

[0042] Step a: Select a sheet made of PET or PP material, and then perform blister molding treatment through a blister machine. During processing, control the temperature at 150°C and control the pressure value at -0.05MPa to form multiple sheets on the sheet. The 1 arranged in a quincunx shape has a diameter of 110 mm and a thickness of 0.5 mm after molding. Then put the sheet into the punching machine to punch holes on the sheet, and punch to form positioning holes in each corresponding 1. Then put the sheet into the stamping equipment of th...

Embodiment 2

[0047] The manufacturing process of this easy-open lid comprises the following steps:

[0048] Step a: Select a sheet made of PET or PP material, and then perform blister molding treatment through a blister machine. During processing, control the temperature at 120°C and control the pressure value at -0.01MPa to form multiple sheets on the sheet. The 1s arranged in a well-shaped shape have a diameter of 55 mm and a thickness of 1.2 mm after molding. Then put the sheet into the punching machine to punch holes on the sheet, and punch to form positioning holes in each corresponding 1. Then put the sheet into the stamping equipment of the next process to punch holes or grooves on the sheet, and form a plurality of process holes 4 or process grooves around each 1.

[0049] Step b: transfer the sheet into the tab assembly machine, the tab assembly machine has a positioning template and a positioning station, the positioning template has a groove corresponding to 1 on the sheet, the...

Embodiment 3

[0053] The manufacturing process of this easy-open lid comprises the following steps:

[0054] Step a: Select a sheet made of PET or PP material, and then perform blister molding treatment through a blister machine. During processing, control the temperature at 180°C and control the pressure value at -0.1MPa, and form multiple sheets on the sheet. The 1s arranged in a well-shaped shape have a diameter of 180 mm and a thickness of 0.3 mm after forming. Then put the sheet into the punching machine to punch holes on the sheet, and punch to form positioning holes in each corresponding 1. Then put the sheet into the stamping equipment of the next process to punch holes or grooves on the sheet, and form a plurality of process holes 4 or process grooves around each 1.

[0055] Step b: transfer the sheet into the tab assembly machine, the tab assembly machine has a positioning template and a positioning station, the positioning template has a groove corresponding to 1 on the sheet, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com