Patents

Literature

42 results about "Thermal contact conductance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, thermal contact conductance is the study of heat conduction between solid bodies in thermal contact. The thermal contact conductance coefficient, hc, is a property indicating the thermal conductivity, or ability to conduct heat, between two bodies in contact. The inverse of this property is termed thermal contact resistance.

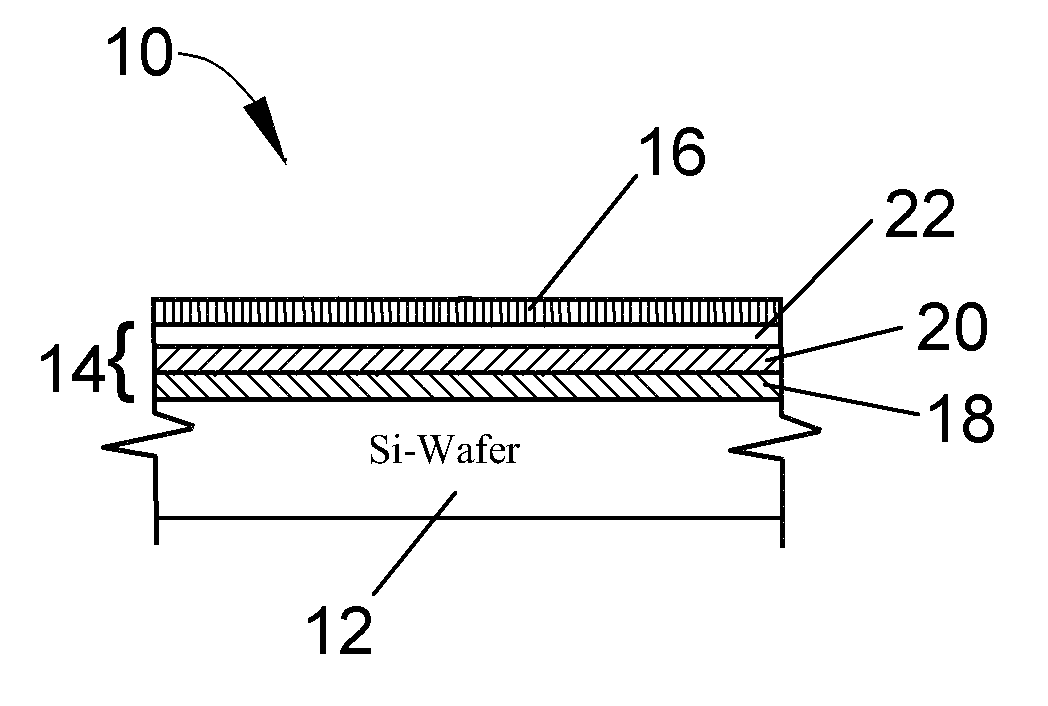

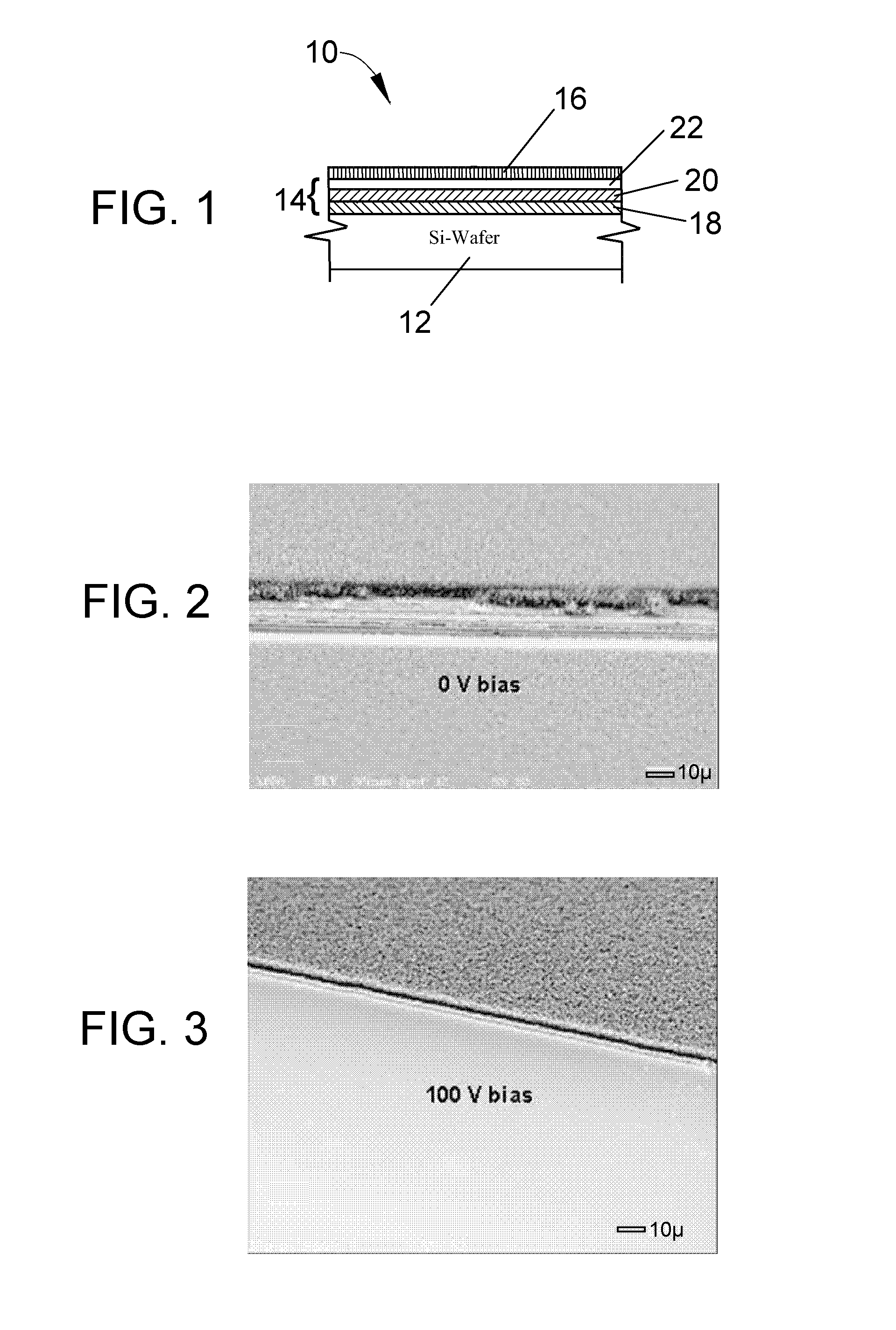

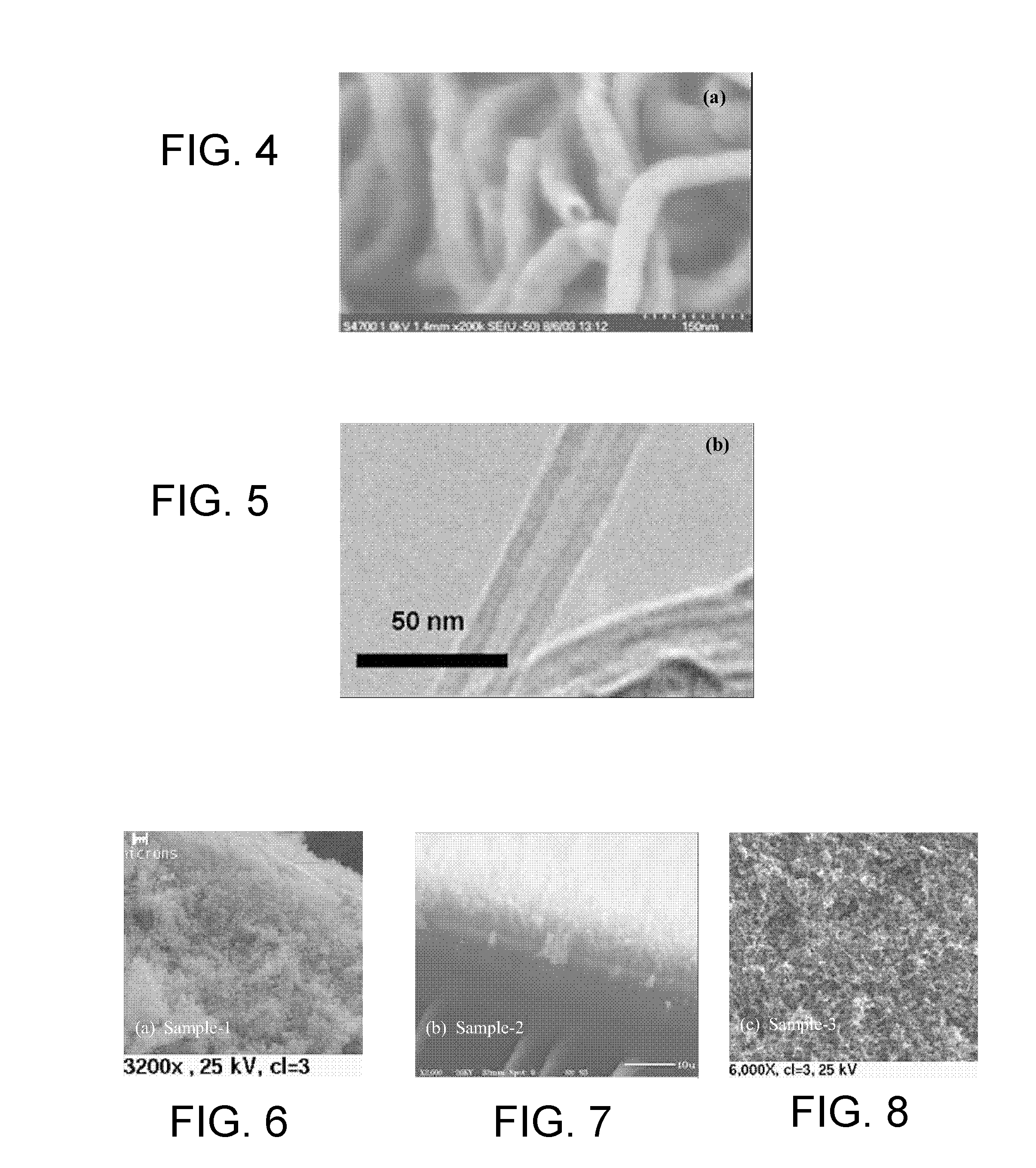

Enhancement of thermal interface conductivities with carbon nanotube arrays

ActiveUS20110007477A1High thermal contact conductanceImprove interface performanceNanotechSemiconductor/solid-state device detailsCarbon nanotubeCombined use

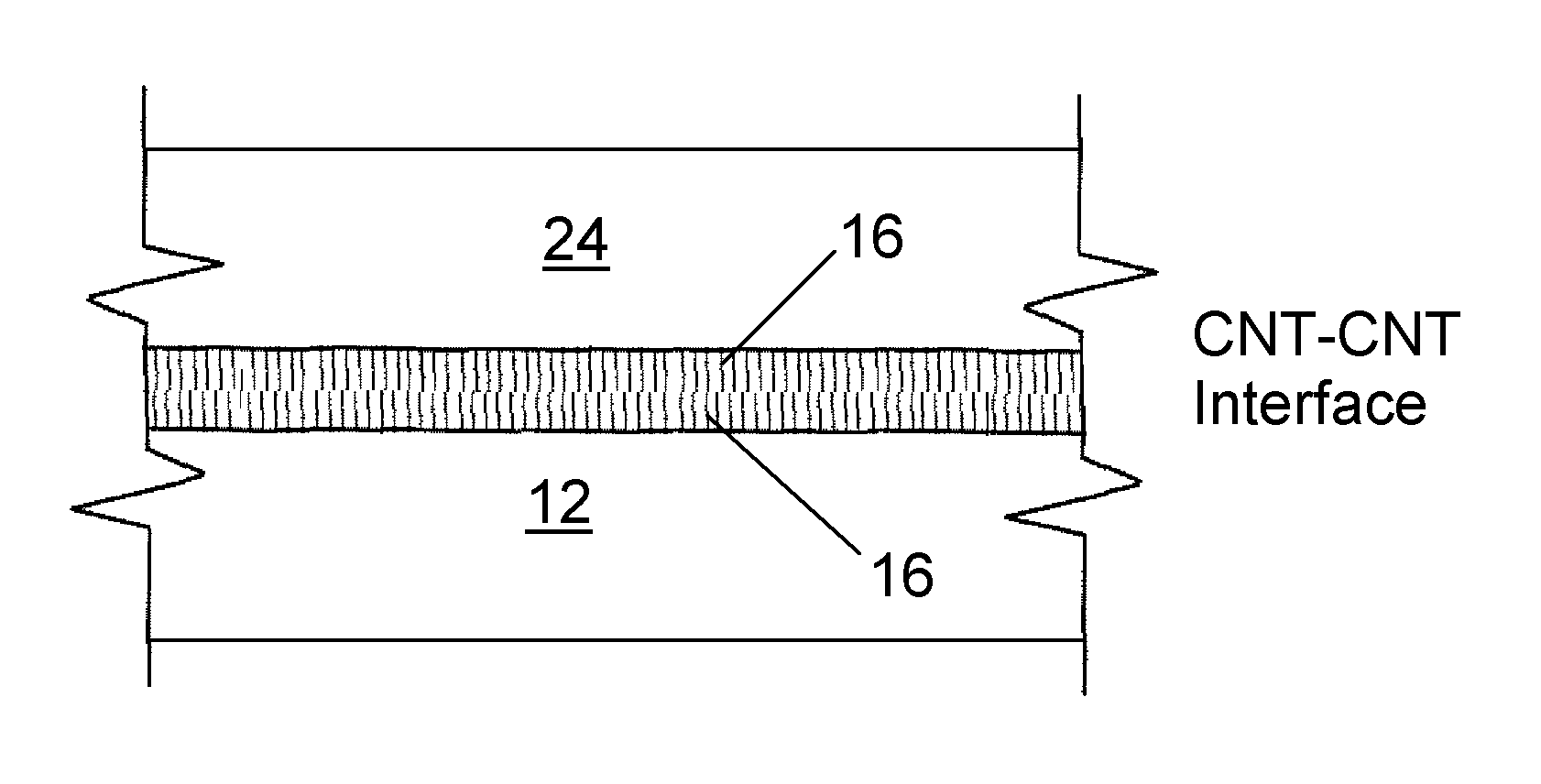

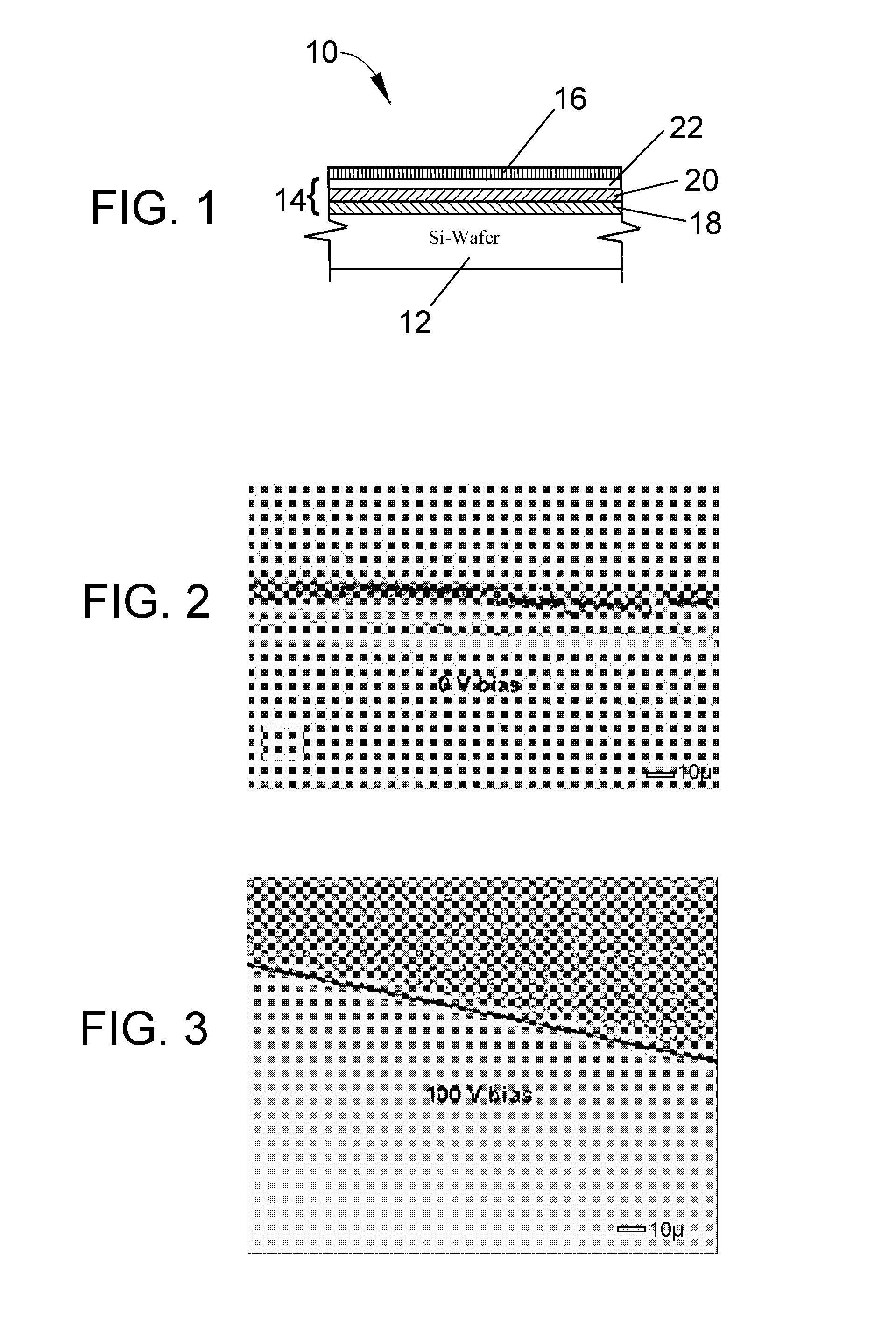

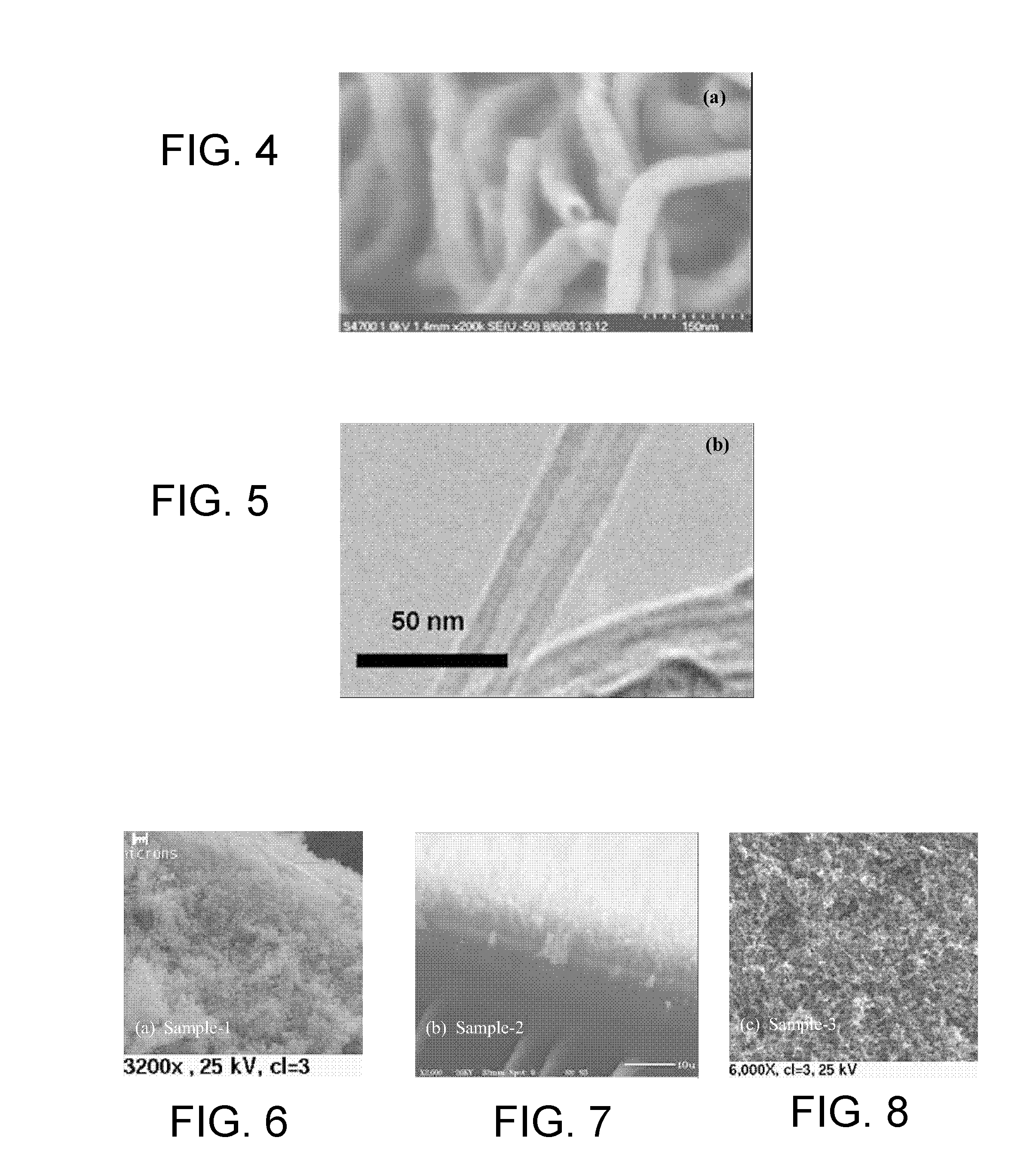

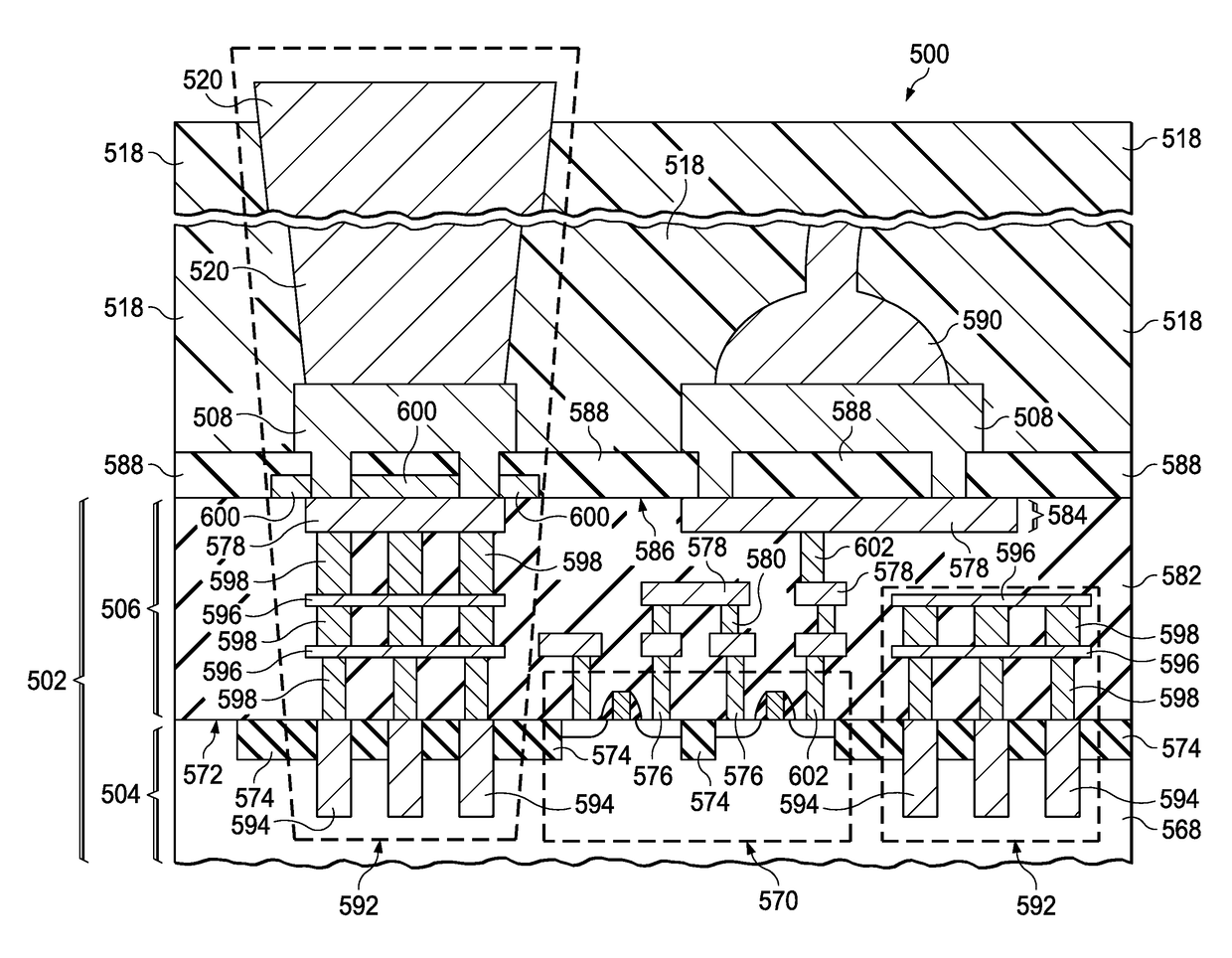

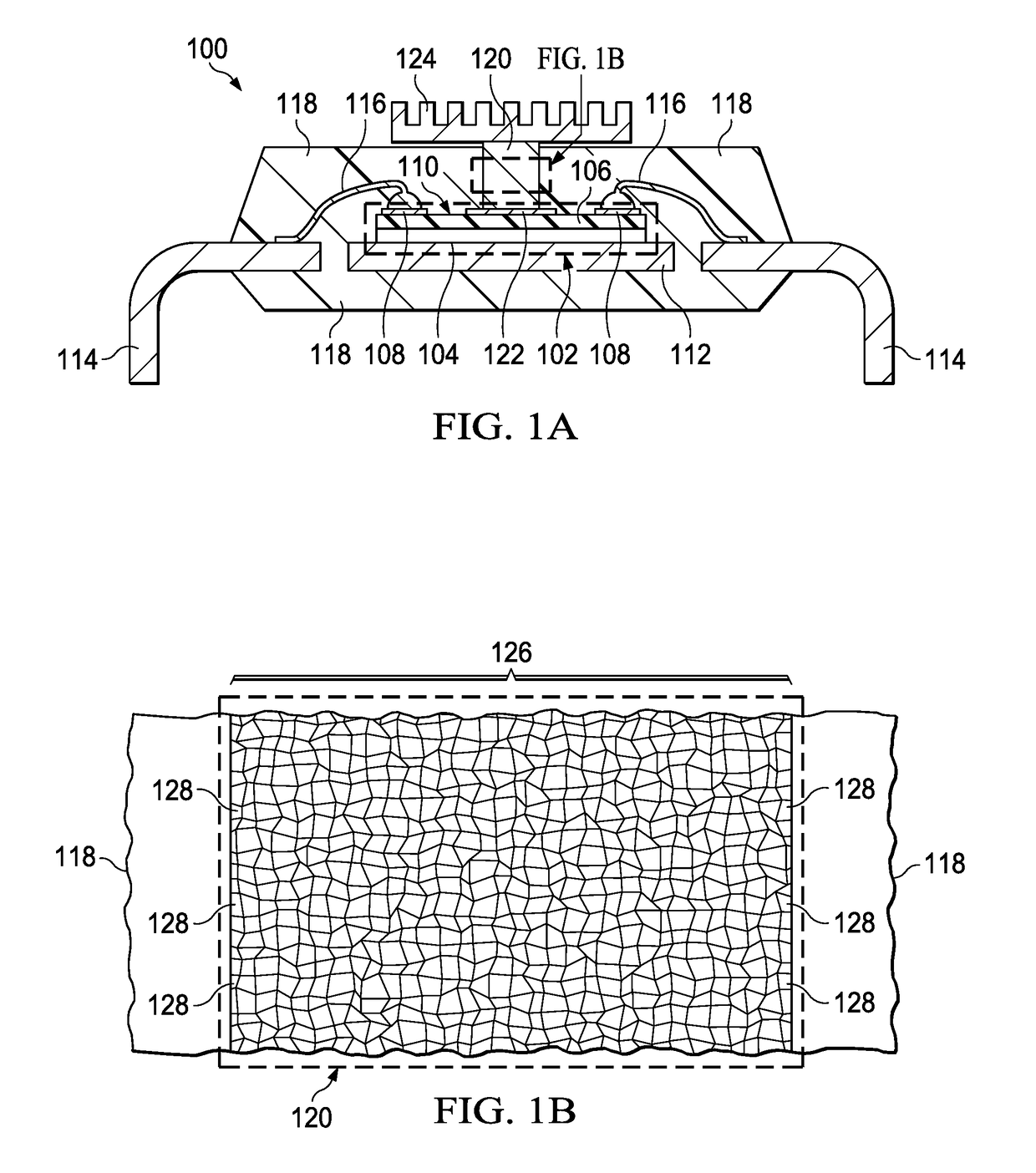

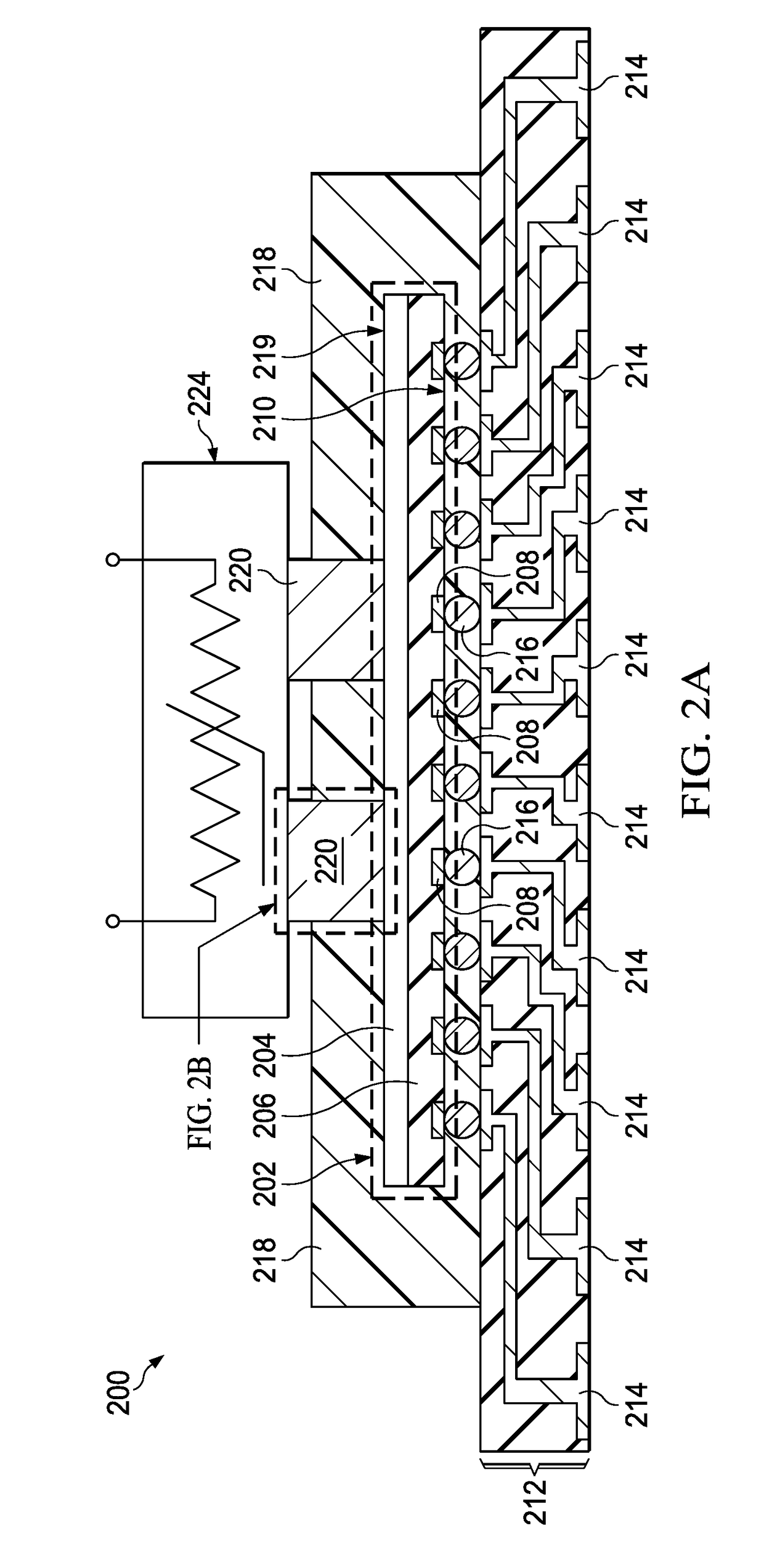

A method of forming a well-anchored carbon nanotube (CNT) array, as well as thermal interfaces that make use of CNT arrays to provide very high thermal contact conductance. A thermal interface is formed between two bodies by depositing a continuous array of carbon nanotubes on a first of the bodies so that, on mating the bodies, the continuous array is between surface portions of the first and second bodies. The thermal interface preferably includes a multilayer anchoring structure that promotes anchoring of the continuous array of carbon nanotubes to the first body. The anchoring structure includes a titanium bond layer contacting the surface portion of the first body, and an outermost layer with nickel or iron catalytic particles from which the continuous array of carbon nanotubes are nucleated and grown. Additional thermal interface materials (TIM's) can be used in combination with the continuous array of carbon nanotubes.

Owner:PURDUE RES FOUND INC

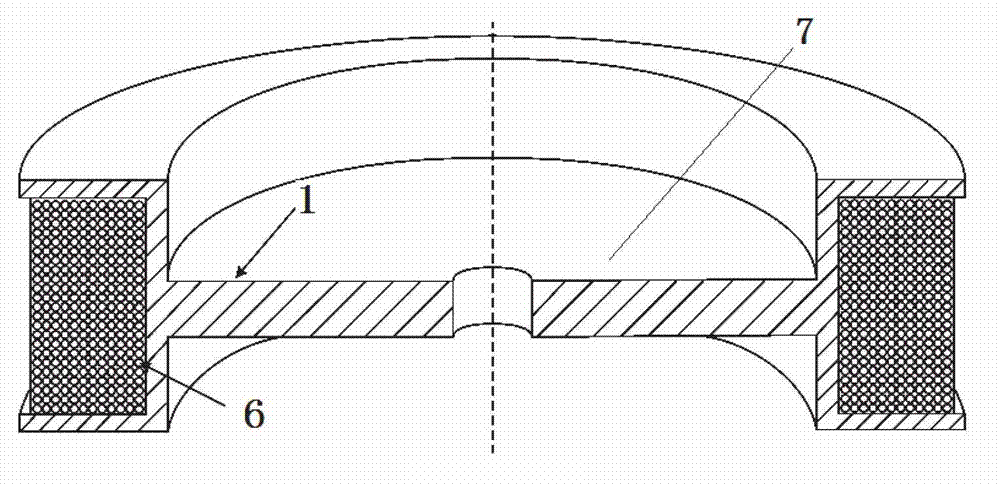

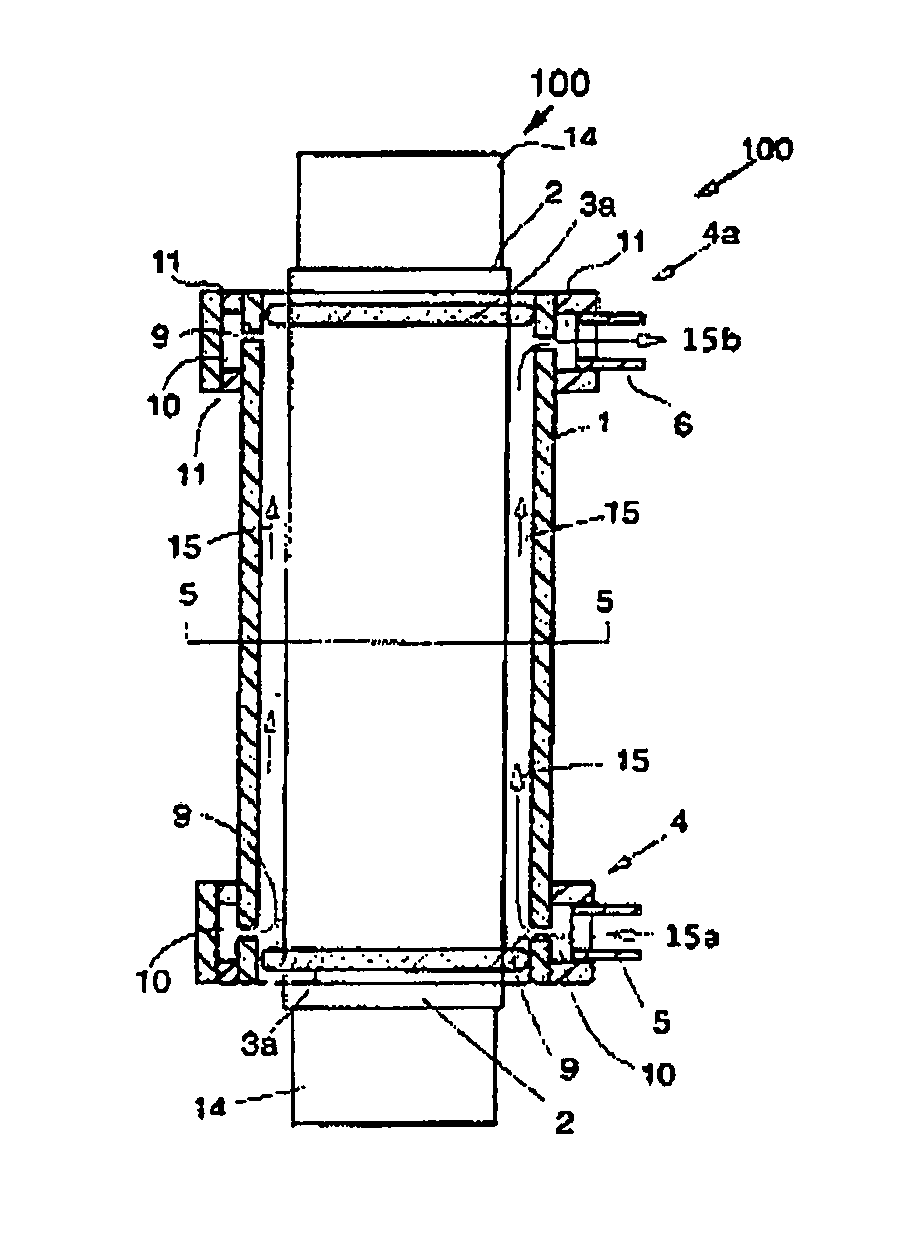

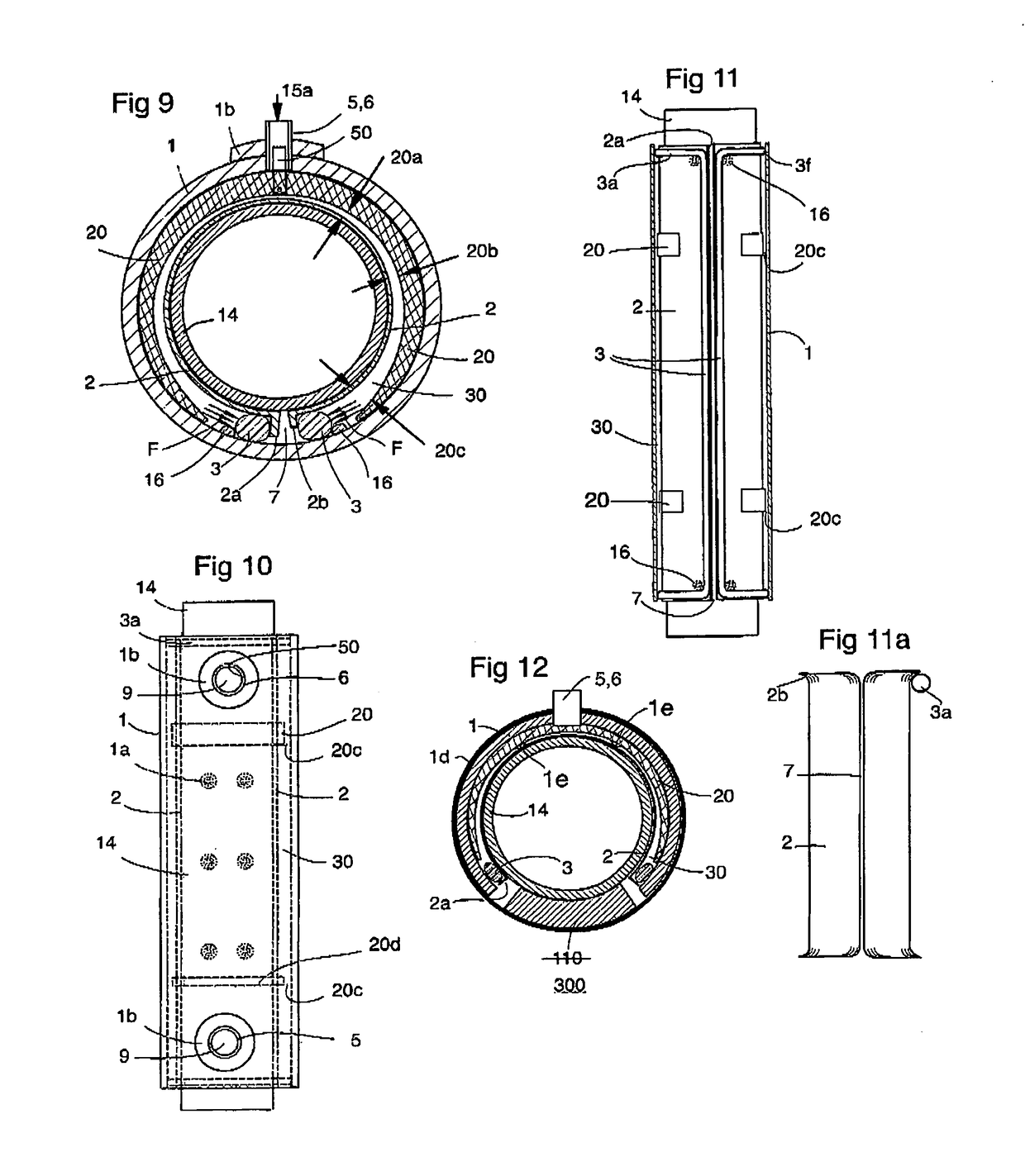

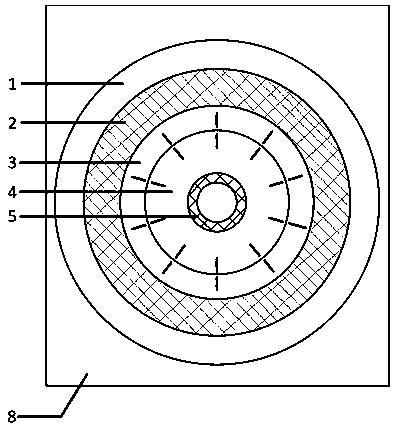

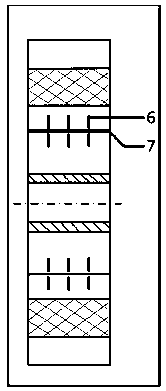

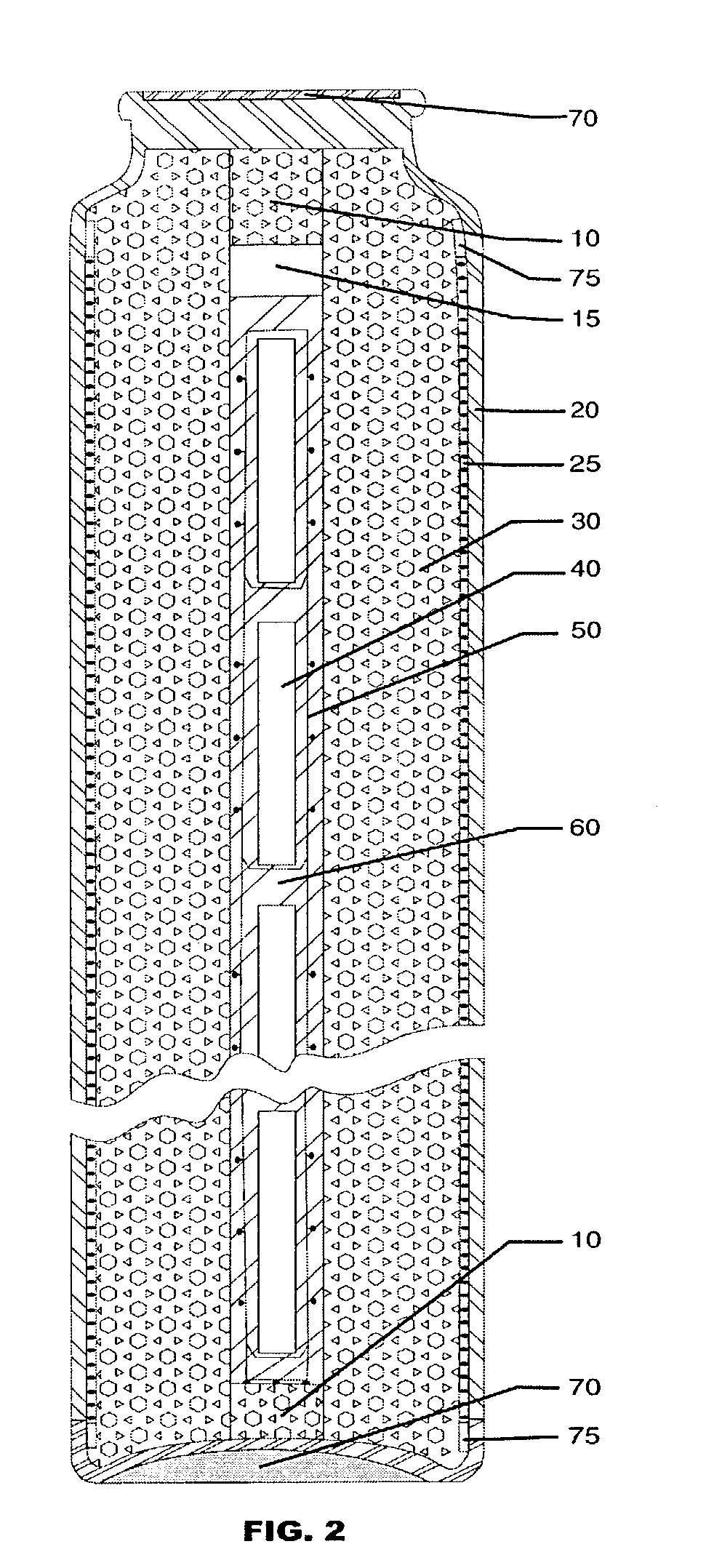

Framework for optical fiber gyroscope and manufacturing method thereof as well as method for packaging optical fiber ring

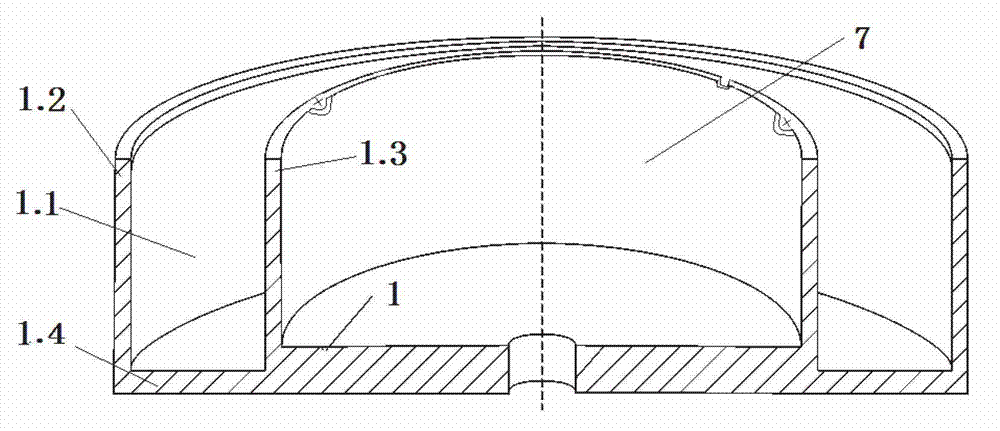

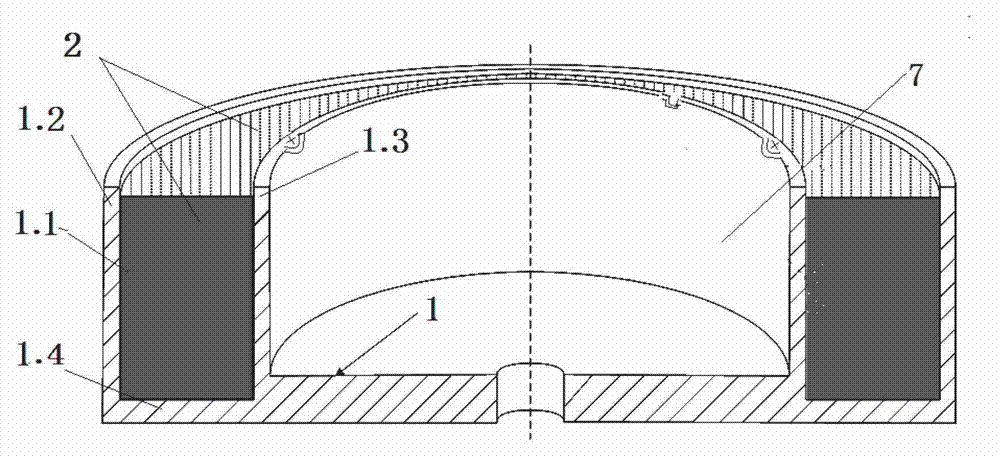

The invention relates to a heat-insulating and vibration-proof framework for an optical fiber gyroscope and a manufacturing method thereof as well as a method for packaging an optical fiber ring. The framework for the optical fiber gyroscope comprises a framework body consisting of an outer wall, an inner wall and a groove bottom; an annular groove is an opening cavity used for mounting the optical fiber ring; the inner side surface and the bottom surface of the annular groove are provided with flame-retardant and heat-insulating and vibration-proof material layers; the material layers are coated with adhesive layers; the adhesive layer at the groove bottom is provided with a lower vibration-proof gasket; an upper vibration-proof gasket is further arranged at the opening at the upper part of the annular groove; the end face of the opening of the annular groove is provided with an optical fiber gyroscope top cover. The manufacturing method comprises the steps of: manufacturing the framework body; processing the flame-retardant and heat-insulating and vibration-proof material layers; coating the adhesive layers and paving the vibration-proof gaskets. The framework for the optical fiber gyroscope has the advantages that the environment temperature and the vibration influence are avoided, framework deformation and a series of errors of the optical fiber gyroscope caused by contact thermal conduction are also avoided, the environment adaptability of the gyroscope is improved, the service life is prolonged; the framework manufacturing method and the method for packaging the optical fiber ring are easy to operate, low in cost, high in efficiency, and stable and reliable in quality.

Owner:武汉华中天勤防务技术有限公司

Enhancement of thermal interface conductivities with carbon nanotube arrays

ActiveUS8093715B2Increase effective thermal contact conductance of thermalHigh thermal contactNanotechSemiconductor/solid-state device detailsCarbon nanotubeCombined use

A method of forming a well-anchored carbon nanotube (CNT) array, as well as thermal interfaces that make use of CNT arrays to provide very high thermal contact conductance. A thermal interface is formed between two bodies by depositing a continuous array of carbon nanotubes on a first of the bodies so that, on mating the bodies, the continuous array is between surface portions of the first and second bodies. The thermal interface preferably includes a multilayer anchoring structure that promotes anchoring of the continuous array of carbon nanotubes to the first body. The anchoring structure includes a titanium bond layer contacting the surface portion of the first body, and an outermost layer with nickel or iron catalytic particles from which the continuous array of carbon nanotubes are nucleated and grown. Additional thermal interface materials (TIM's) can be used in combination with the continuous array of carbon nanotubes.

Owner:PURDUE RES FOUND INC

Semicondctor device package thermal conduit

ActiveUS20180151467A1Semiconductor/solid-state device detailsSolid-state devicesNanoparticleThermal contact conductance

A packaged electronic device includes an integrated circuit and an electrically non-conductive encapsulation material in contact with the integrated circuit. A thermal conduit extends from an exterior of the package, through the encapsulation material, to the integrated circuit. The thermal conduit has a thermal conductivity higher than the encapsulation material contacting the thermal conduit. The thermal conduit includes a cohered nanoparticle film. The cohered nanoparticle film is formed by a method which includes an additive process.

Owner:TEXAS INSTR INC

Temperature control method and temperature control device

InactiveUS20060245161A1Control is carry-outCarry-out quicklyTemperatue controlSolid-state devicesTemperature controlEngineering

In a temperature control method, a controlled part is arranged to contact a first principal surface of a heat conduction part. The heat conduction part has the first principal surface and a second principal surface opposite to the first principal surface. The first principal surface has a configuration corresponding to a configuration of the controlled part. The second principal surface has an area larger than an area of the first principal surface. At least one of a heating unit and a cooling unit is driven to set the controlled part at a predetermined temperature. The heating unit and the cooling unit are disposed on the second principal surface of the heat conduction part so that the heating unit and the cooling unit are arranged side by side.

Owner:SOCIONEXT INC

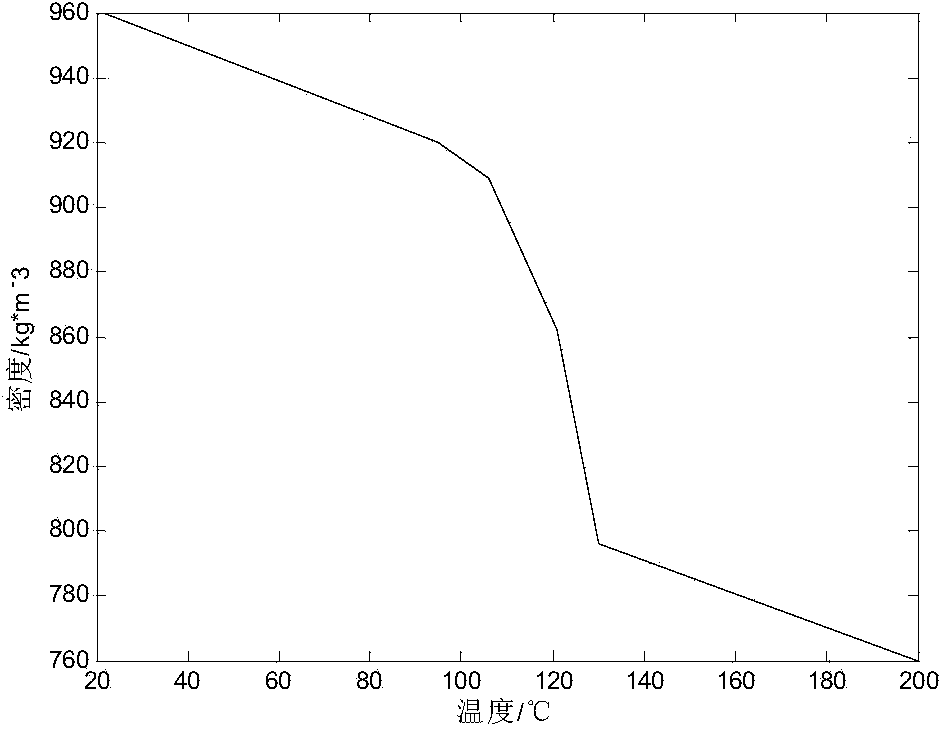

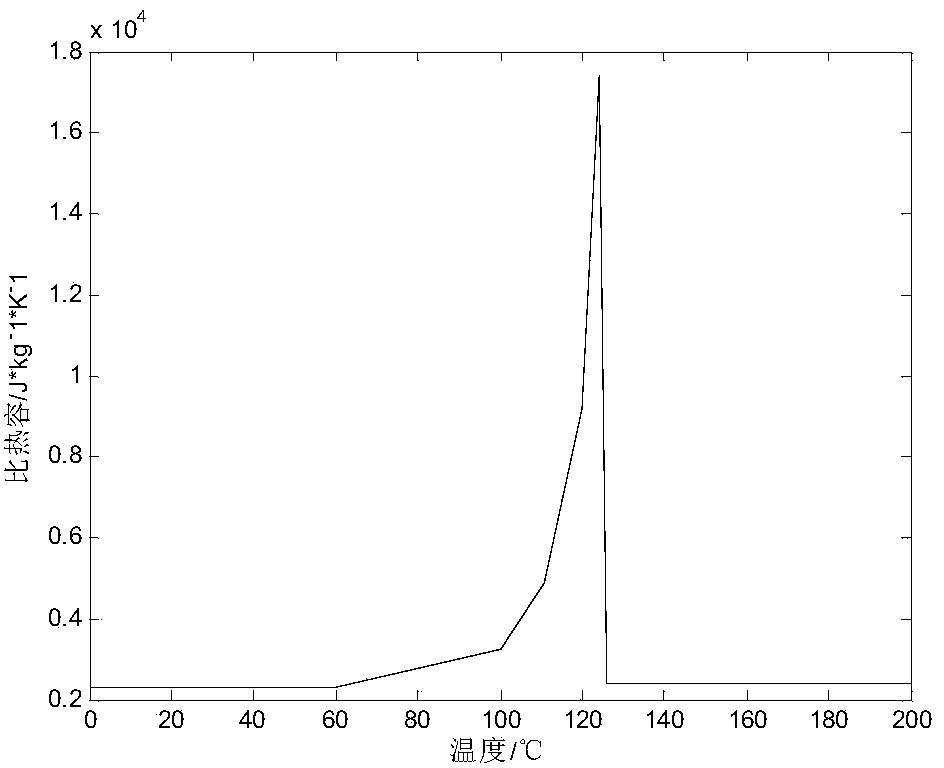

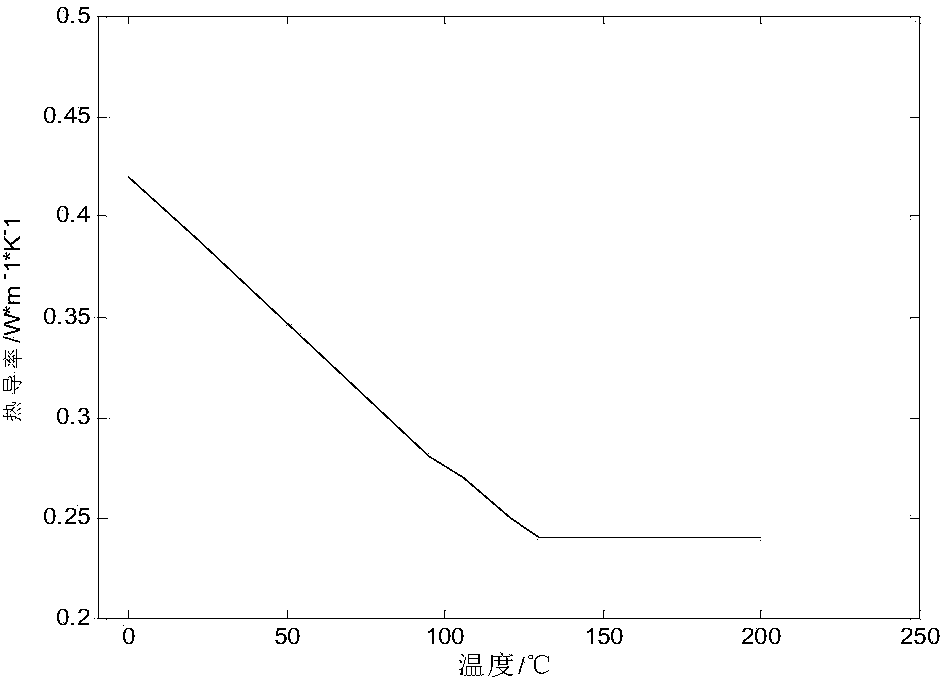

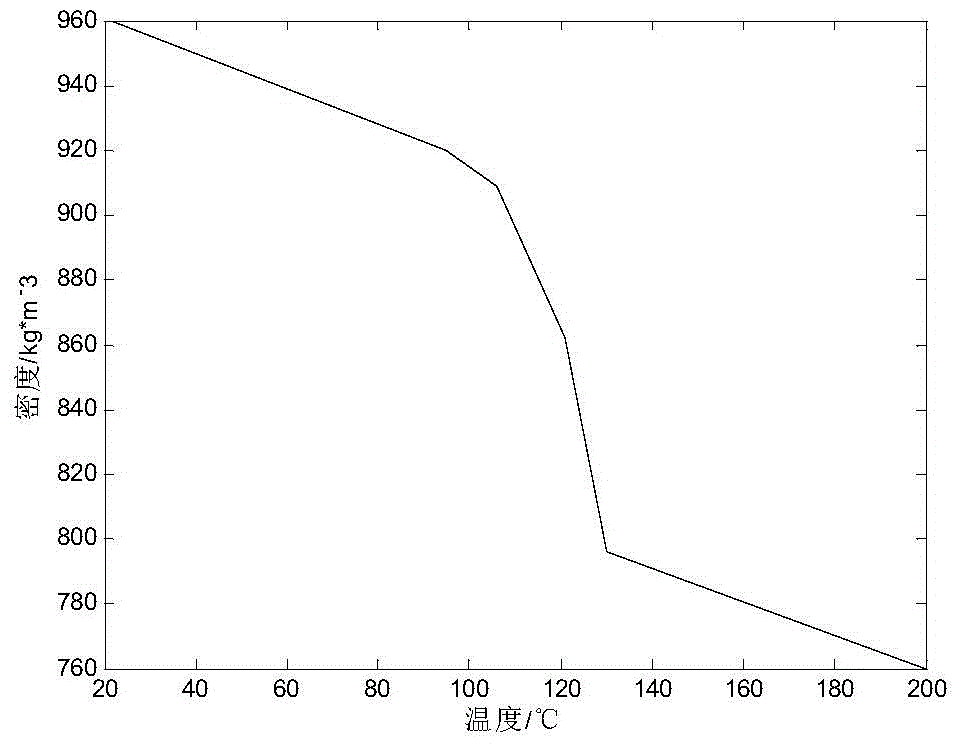

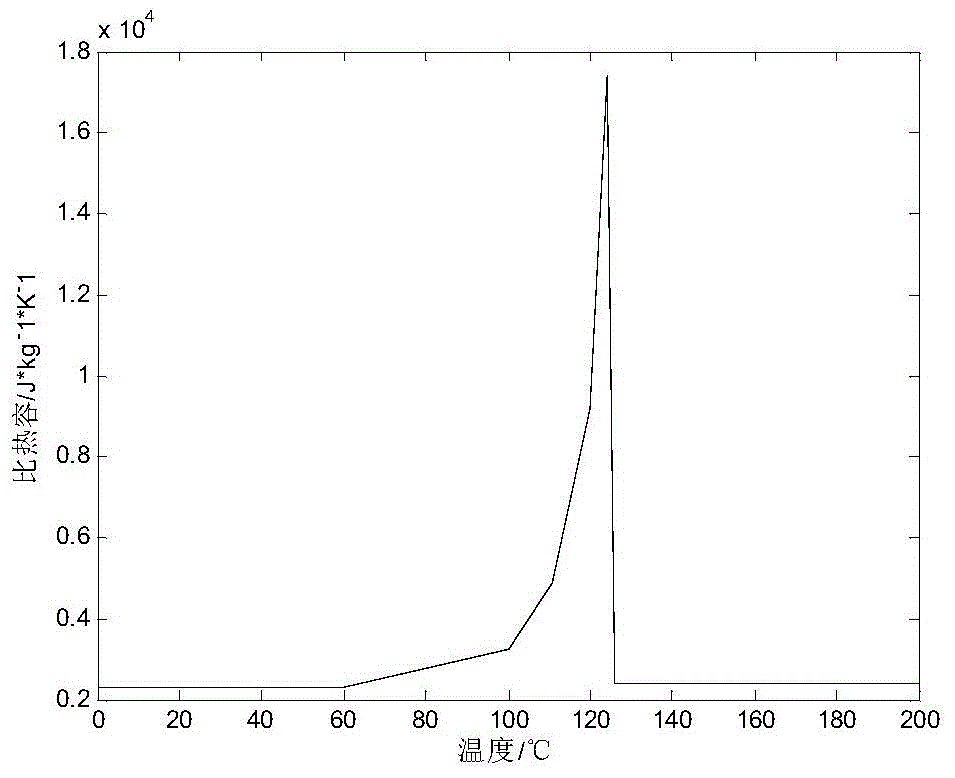

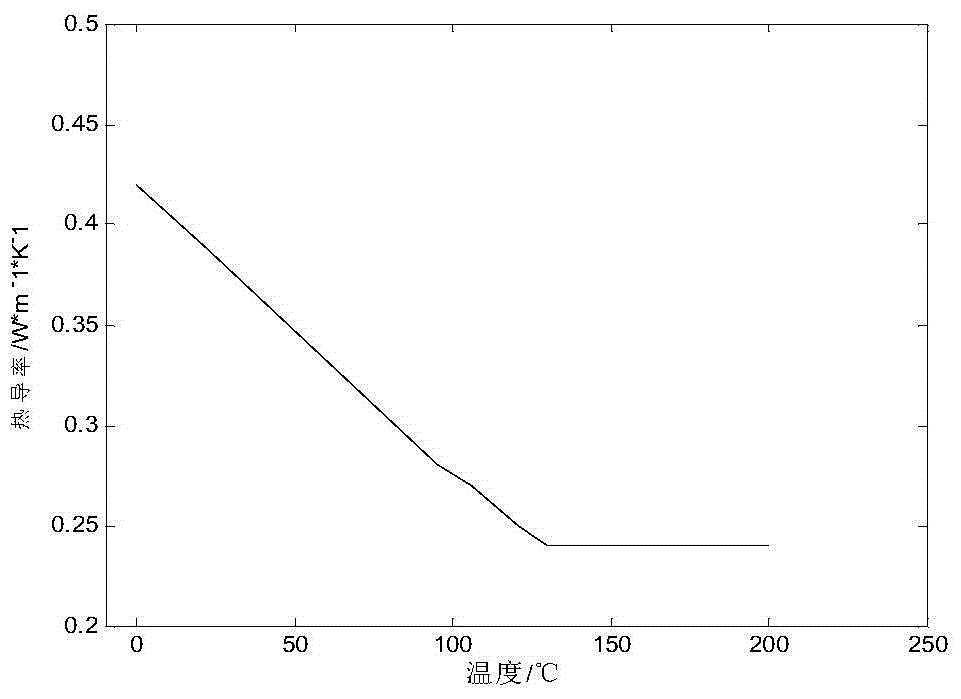

PE electric smelting pipe fitting welding parameter setting method based on finite elements

ActiveCN103745053AGuarantee welding qualityImprove formulation efficiencySpecial data processing applicationsPipe fittingFinite element method

The invention discloses a PE electric smelting pipe fitting welding parameter setting method based on finite elements. The PE electric smelting pipe fitting welding parameter setting method comprises the following steps: (1) initially determining the welding voltage of a PE electric smelting pipe fitting; (2) setting thermal analysis parameters; (3) establishing a finite element heat transfer model for connecting the electric smelting pipe fitting and a pipe in ANSYS WORKBENCH; (4) setting contact thermal conductivity coefficients between a thermal fuse and the PE material and between the electric smelting pipe fitting and the pipe in the electric smelting pipe fitting; (5) setting the division type of a model mesh and the size of the mesh, and then dividing the mesh; (6) carrying out loading heating on the model; (7) setting analysis time and step length for solution; (8) extracting the result of the solution and determining welding parameters. According to the method, the setting efficiency of the welding parameters of the electric smelting pipe fitting is improved, and the welding quality of the PE electric smelting pipe fitting is ensured.

Owner:JIANGSU SHUANGTENG PIPE IND CO LTD +1

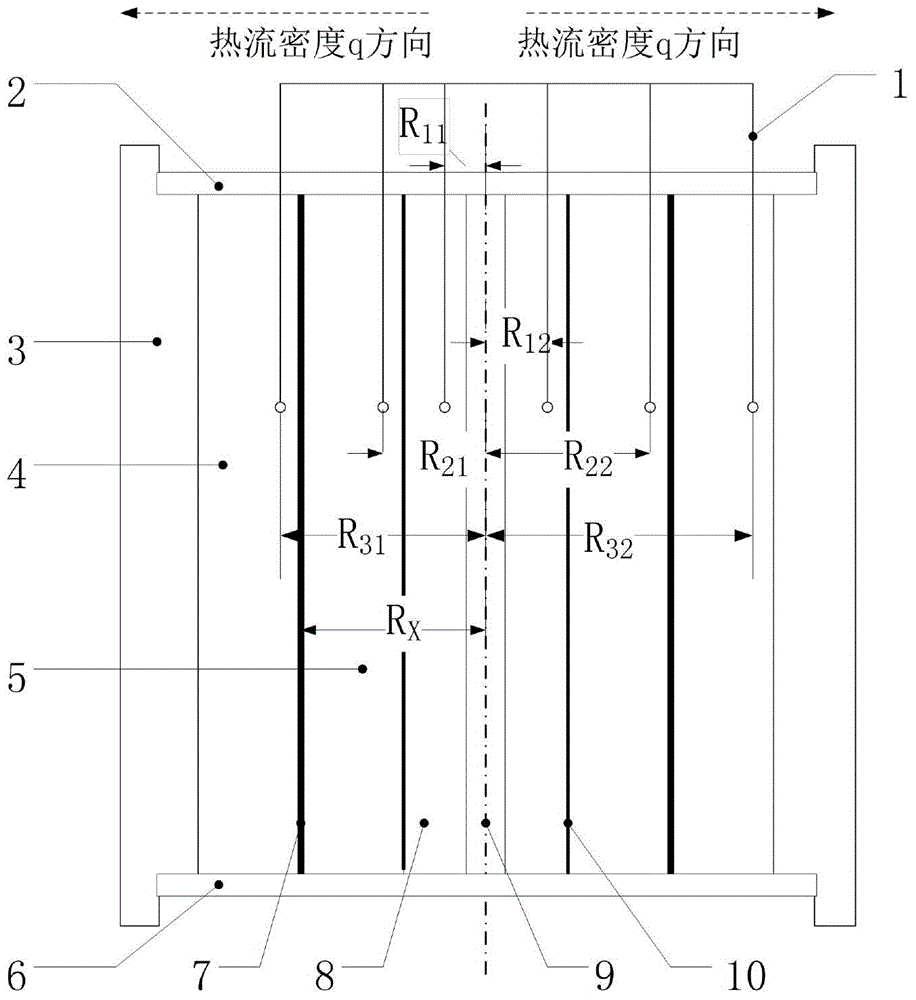

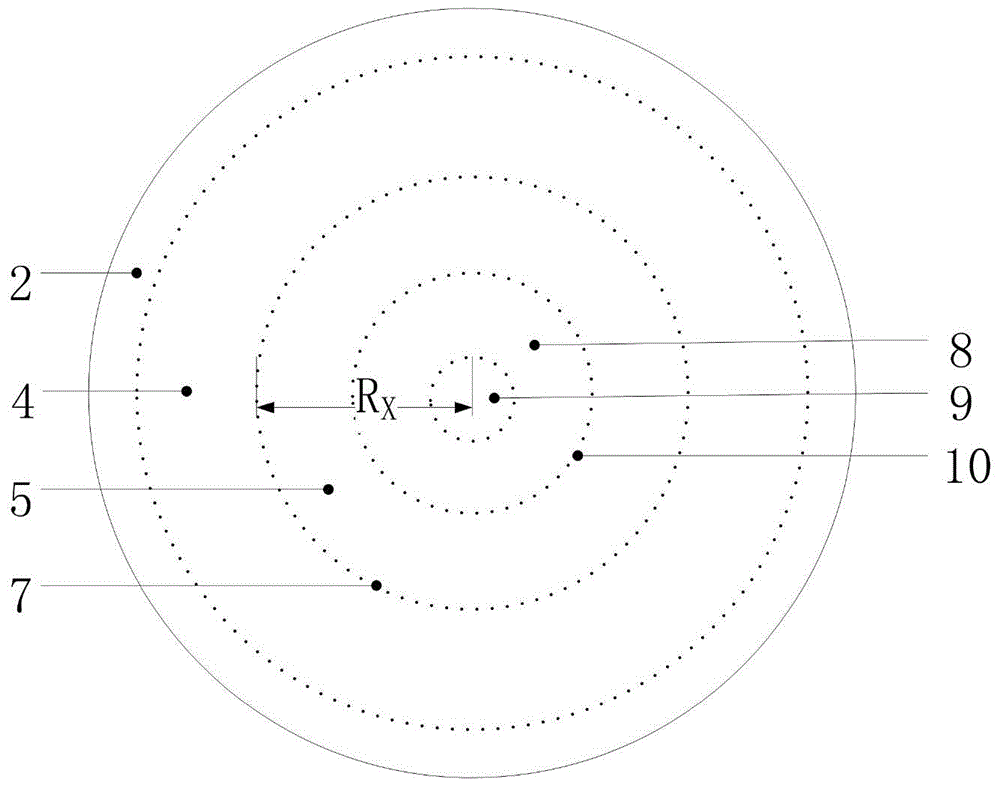

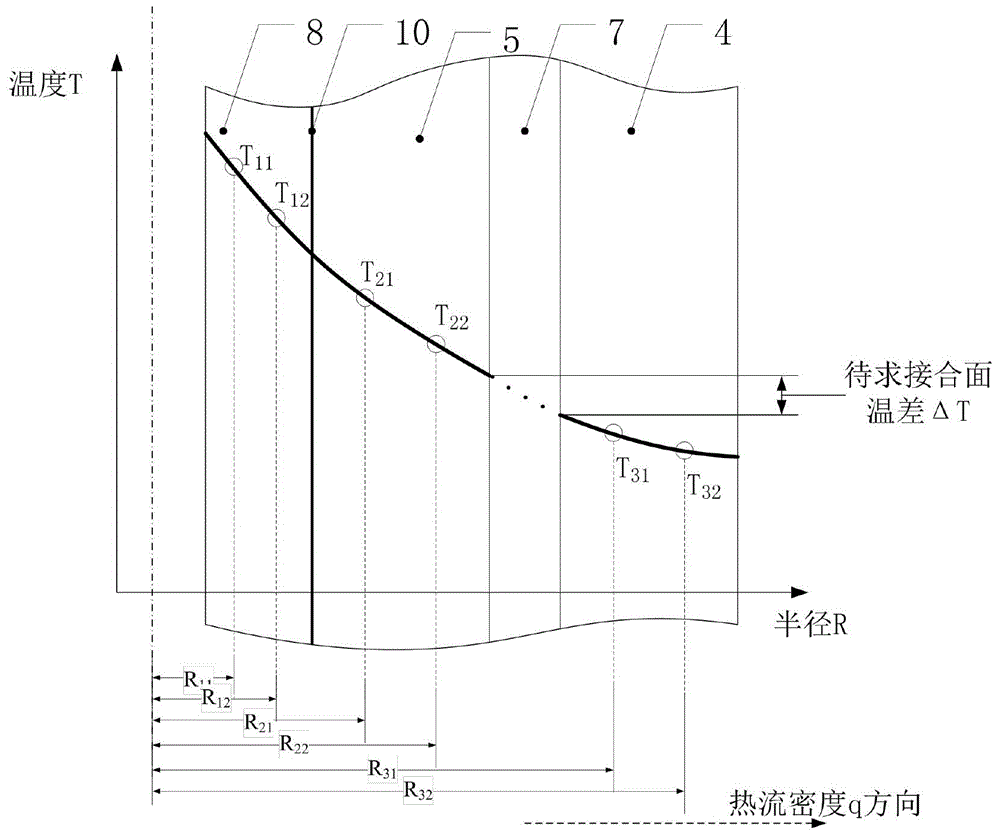

Method and device for testing thermal contact resistance of joint surfaces between cylindrical sleeve walls

ActiveCN104569045AEasy to makeMeet the experimental requirementsMaterial heat developmentHeat fluxEngineering

The invention provides a method and a device for testing the thermal contact resistance of joint surfaces between cylindrical sleeve walls. According to the method and the device, an outer-ring test piece, an inner-ring test piece and a calibrated copper ring are orderly nested and connected to each other to create a one-dimensional steady-state heat conduction environment with conduction in the radial direction of the ring-shaped test pieces. Temperature sensors arranged in different radiuses in the radial direction are used for measuring the temperatures in different radiuses of each test piece; the measured temperature values of the two test pieces are fitted by use of a numerical method and pushed out to the contact joint surfaces to obtain temperature drop at the contact joint surfaces; the heat flux density at the contact joint surfaces is obtained by use of the measured temperatures of the calibrated copper ring and according to a radial one-dimensional heat conduction line heat flux density formula per unit length; finally, the thermal contact resistance of contact joint surfaces is obtained on the basis that the thermal contact resistance is the reciprocal of the contact heat conduction; meanwhile, the heat conductivity coefficient of the inner-ring and outer-ring test pieces also can be obtained according to the law of radial one-dimensional heat conductivity coefficients.

Owner:BEIJING UNIV OF TECH

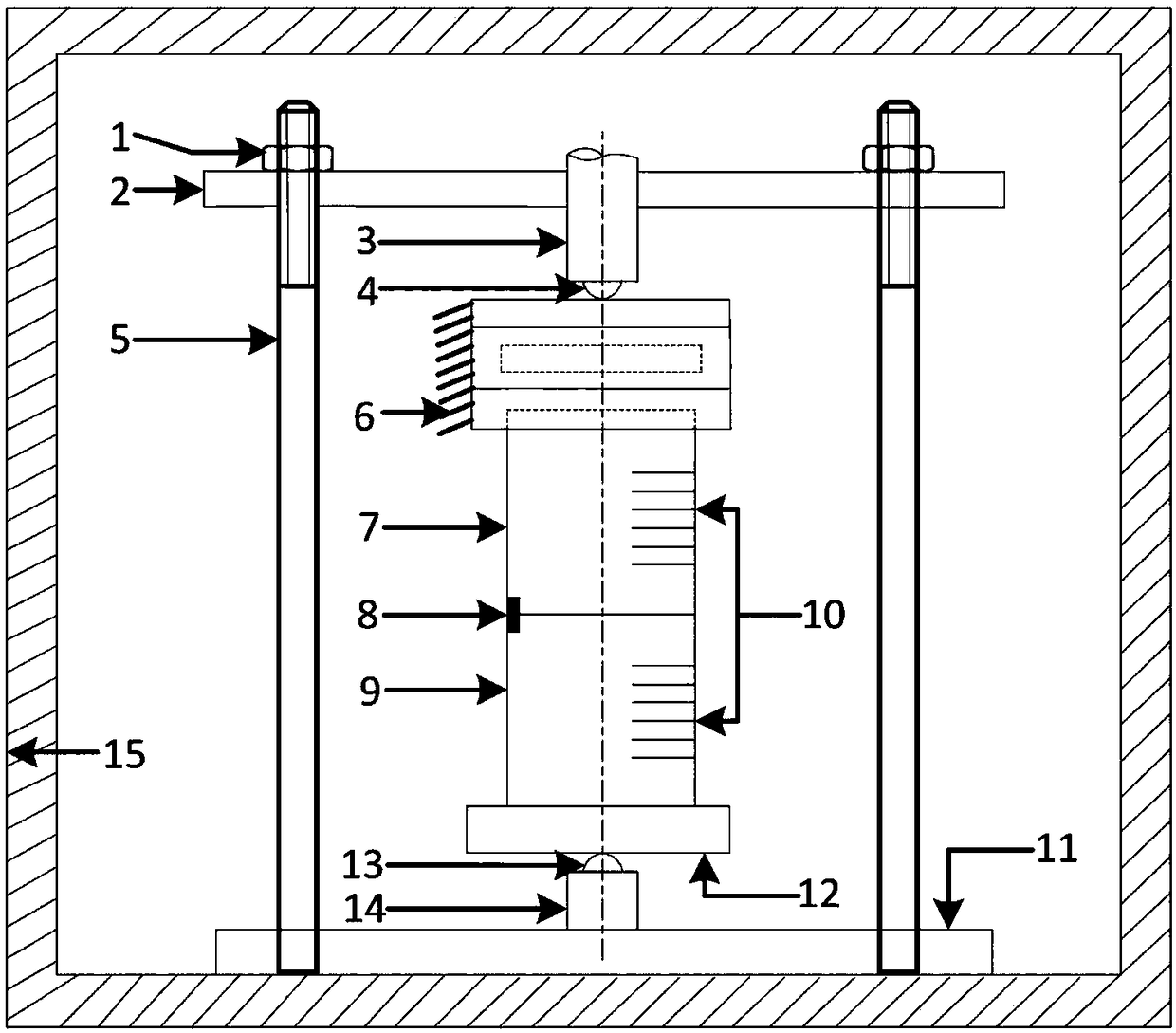

A device for measuring contact thermal conductance of a solid surface joint part

PendingCN108931551AAccurate measurementAccurate measurement and calculationMaterial thermal conductivityElectricityHeat flux

The invention relates to the technical field of contact thermal conductance measurement, and discloses a device for measuring contact thermal conductance of a solid surface joint part. The device is characterized in that the device includes: an electrical heater and a cooling plate which are opposite with each other and between which test pieces to be tested can be loaded; a loading mechanism acting on the electrical heater and / or cooling plate to tightly clamp the test pieces to be tested; a temperature sensor used for measuring the temperature of each test piece to be tested; and a heat flowmeter used for measuring the heat flux between the test pieces to be tested. A measurement result of the device is more accurate, and the device can be applied for measuring contact thermal conductance of solid surface joint parts under different environment pressures, different contact stresses and different temperature differences for components with different materials, different processing processes and different surface roughness.

Owner:CHONGQING UNIV

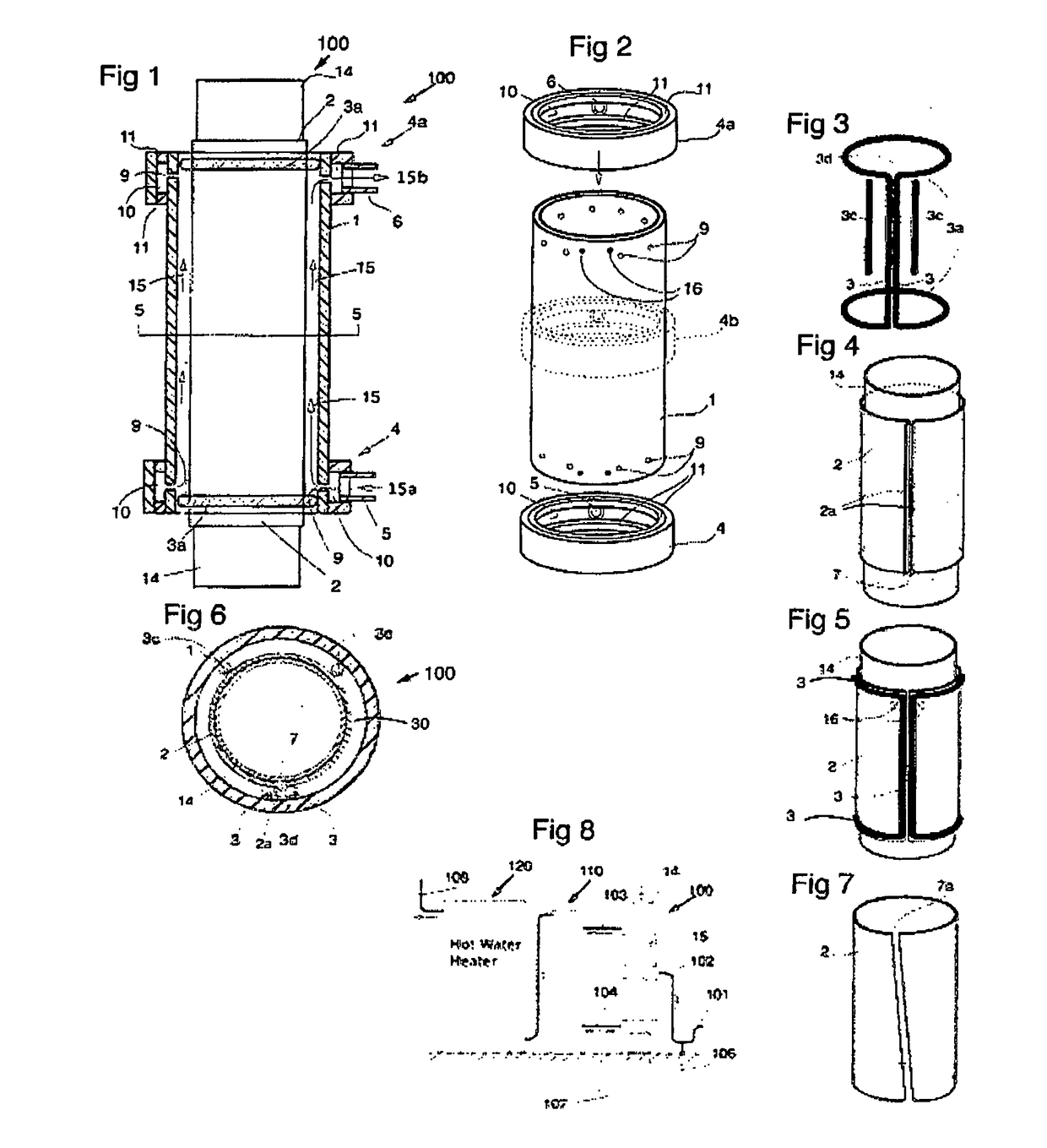

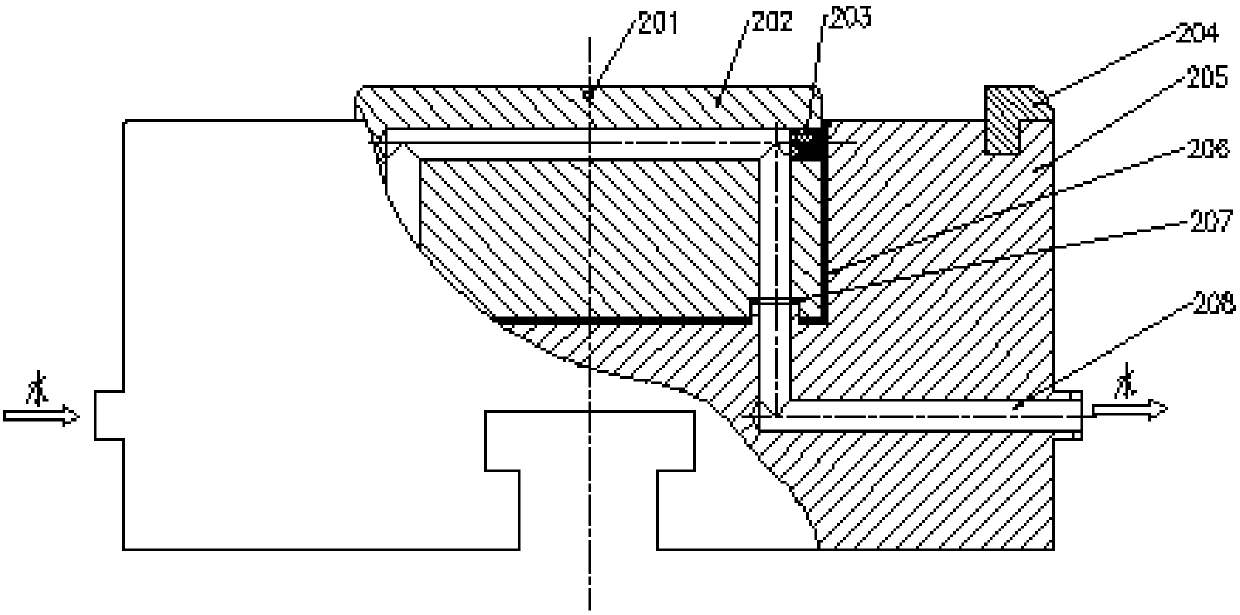

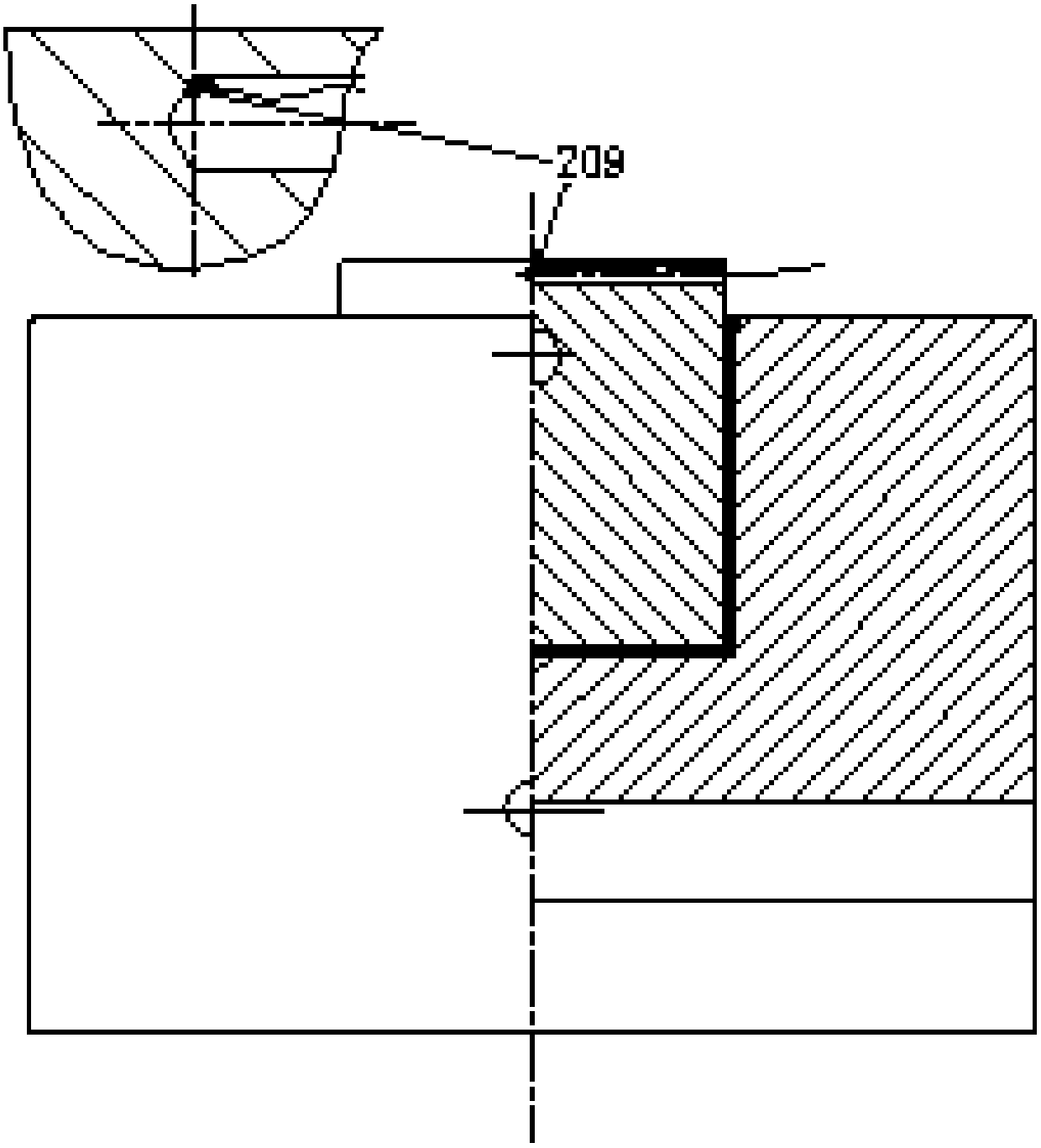

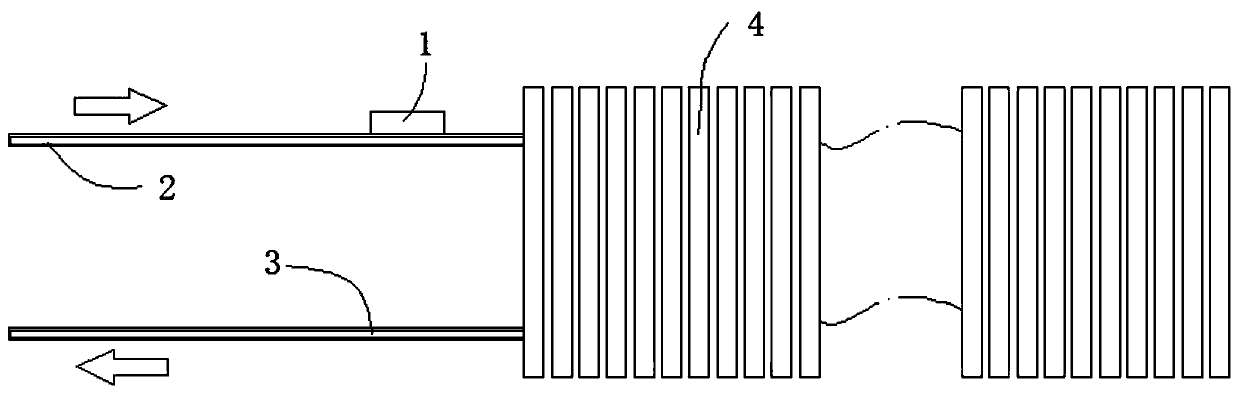

Concentric vertical pipe heat exchanger for drain water heat recovery

ActiveUS20170167804A1Increased thermal contact conductanceImprove heat transfer effectRecuperative heat exchangersHeat recovery systemsWater flowThermal contact conductance

An outer plastic tube has water connections through the wall into an annular space defined by an O-ring spacer-gasket positioned between the wall and the perimeter margin of an inner cylinder rolled from a single-layer of sheet metal. A metal drainpipe with a removable bullet-shape at one end is forced through the cylinder to expand it and to thereby compress the gasket sealing the annular space. Thermal contact conductance is increased by the compressive force of water pressure. Water flow through the heat exchanger is both annular and turbulent to optimize heat transfer.

Owner:MACKELVIE WINSTON

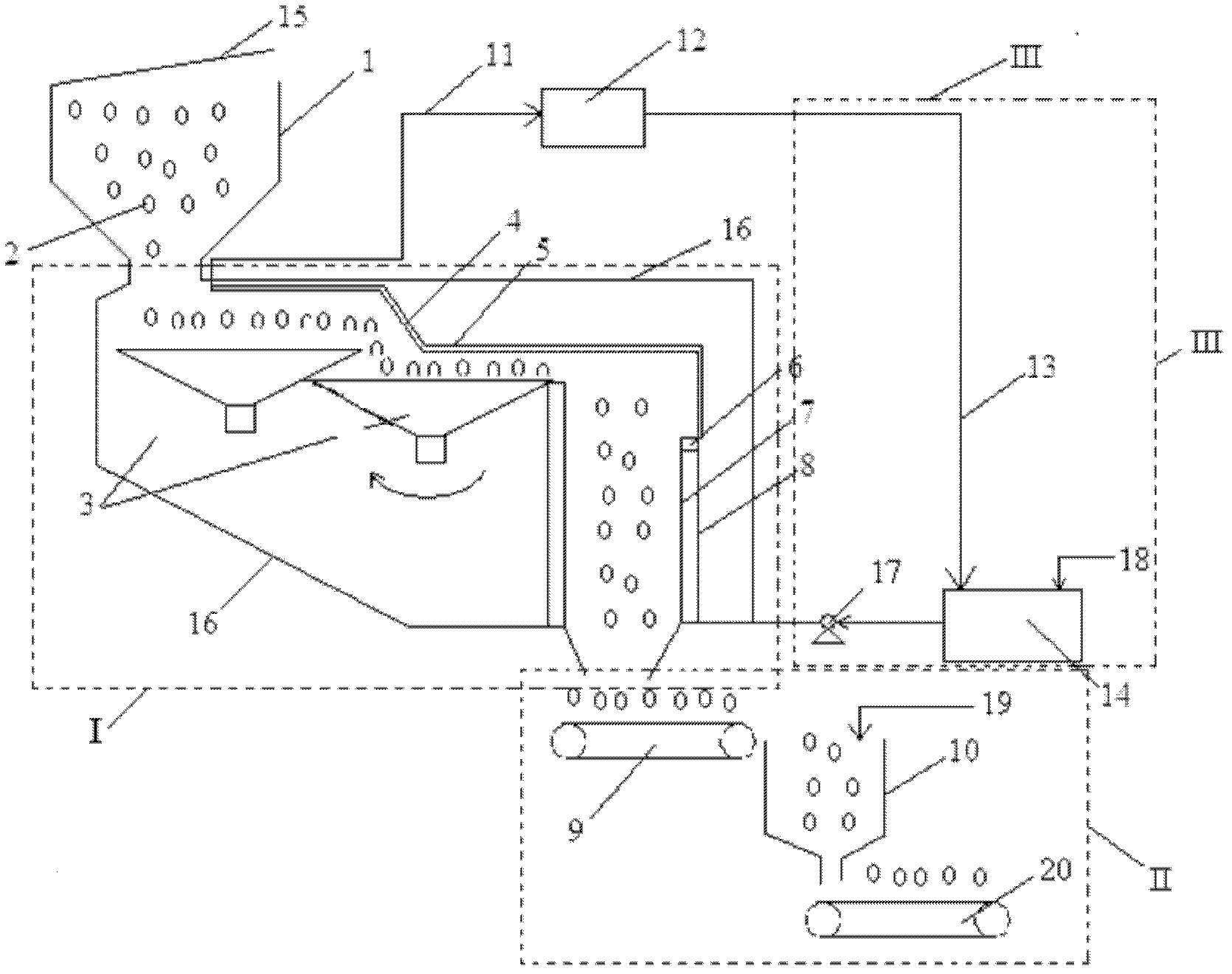

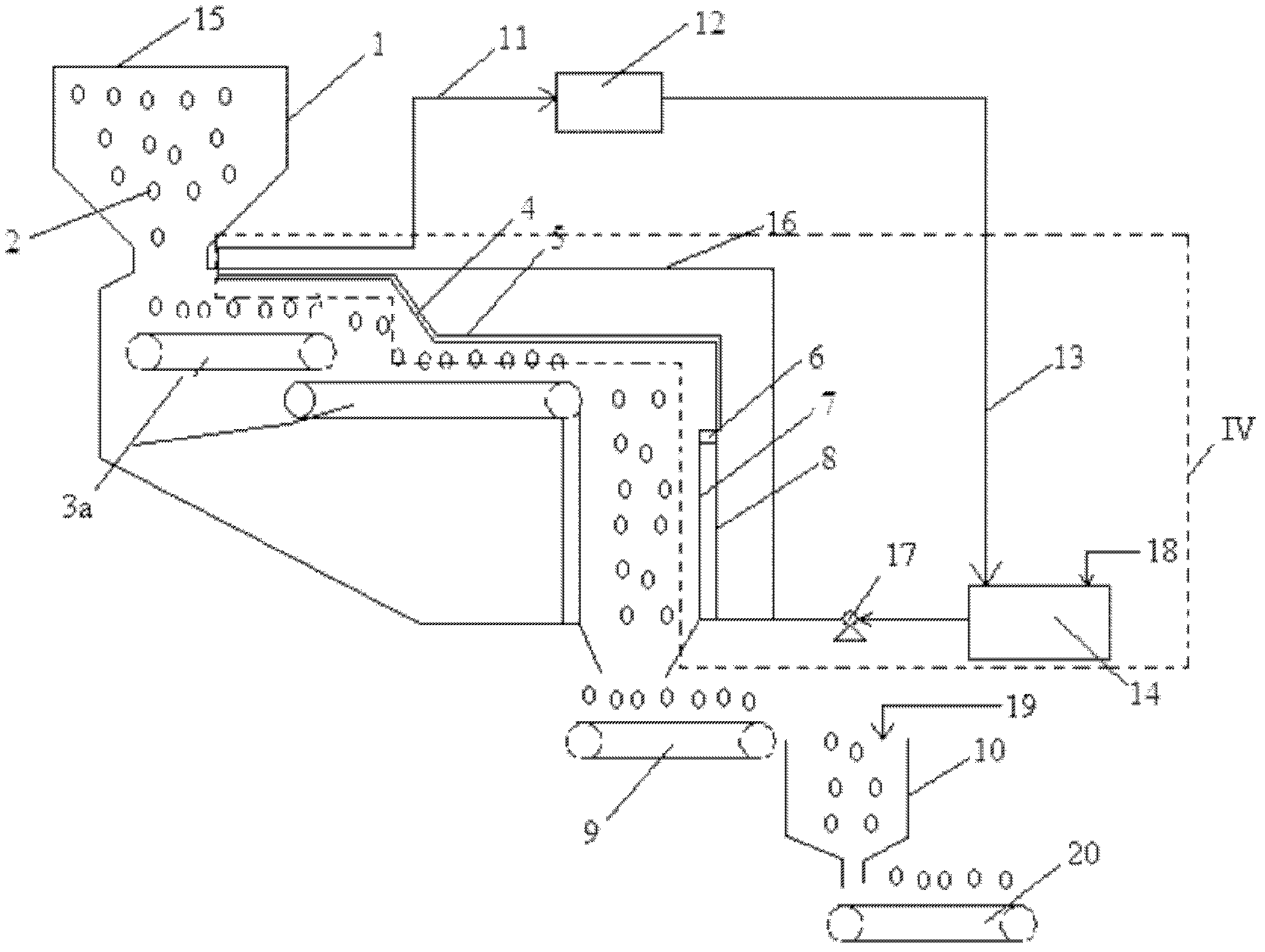

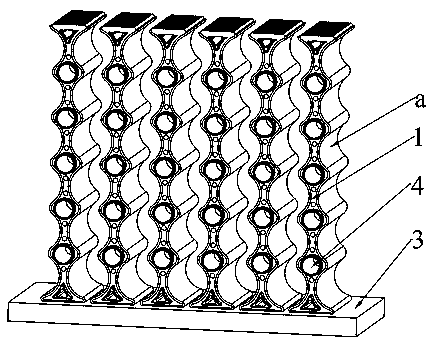

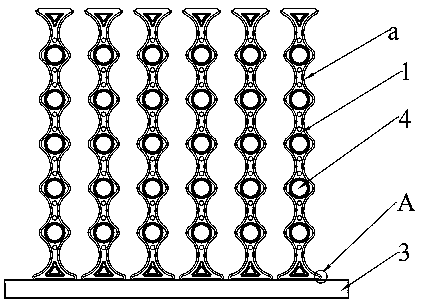

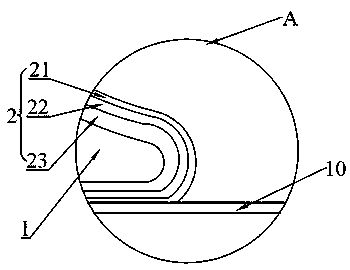

Method and device for carrying out dry quenching and recovering heat energy in radiation and conduction heat absorption mode

ActiveCN102537914ASolve pollutionLow running costCoke quenchingSteam generation using hot heat carriersThermal energyHigh energy

The invention relates to a method and a device for carrying out dry quenching and recovering heat energy in a radiation and conduction heat absorption mode. In a closed container, red cokes are subjected to heat transfer to generate steam by heat radiation, or metal heat transfer, or a combination method of firstly carrying out heat radiation and then carrying out heat transfer. By indirect heat transfer, the heat energy stored in the red cokes with the temperature of 1,000 DEG C is converted into the high temperature steam to be recovered. The device at least consists of a dry quenching furnace, a steam generating system, a water circulation system and a low temperature coke discharging system. A radiation heat transfer pipe for receiving high temperature radiant heat and a heat conduction and transfer pipe which is in direct contact with the cokes are arranged in the dry quenching furnace. Water or the steam is filled in both the radiation heat transfer pipe and the heat conduction and transfer pipe. A fluid inlet side in the radiation heat transfer pipe is connected with a fluid outlet side of the heat conduction and transfer pipe. In the practical engineering, the specific construction of the steam generating system can be designed and arranged according to a structure of a steam boiler which is widely applied. The method and the device have the characteristics of simple equipment, low operating cost, high energy recovery rate and the like.

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

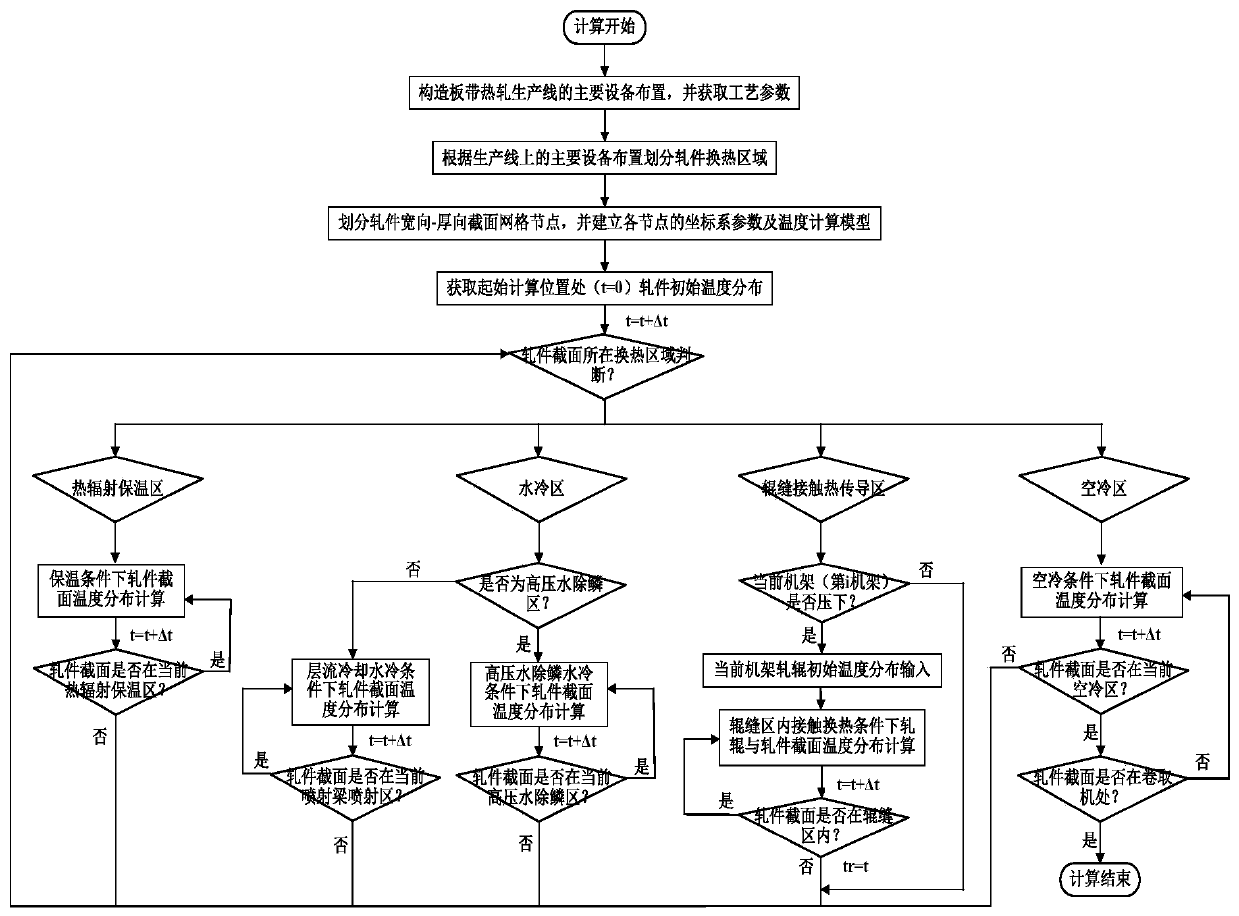

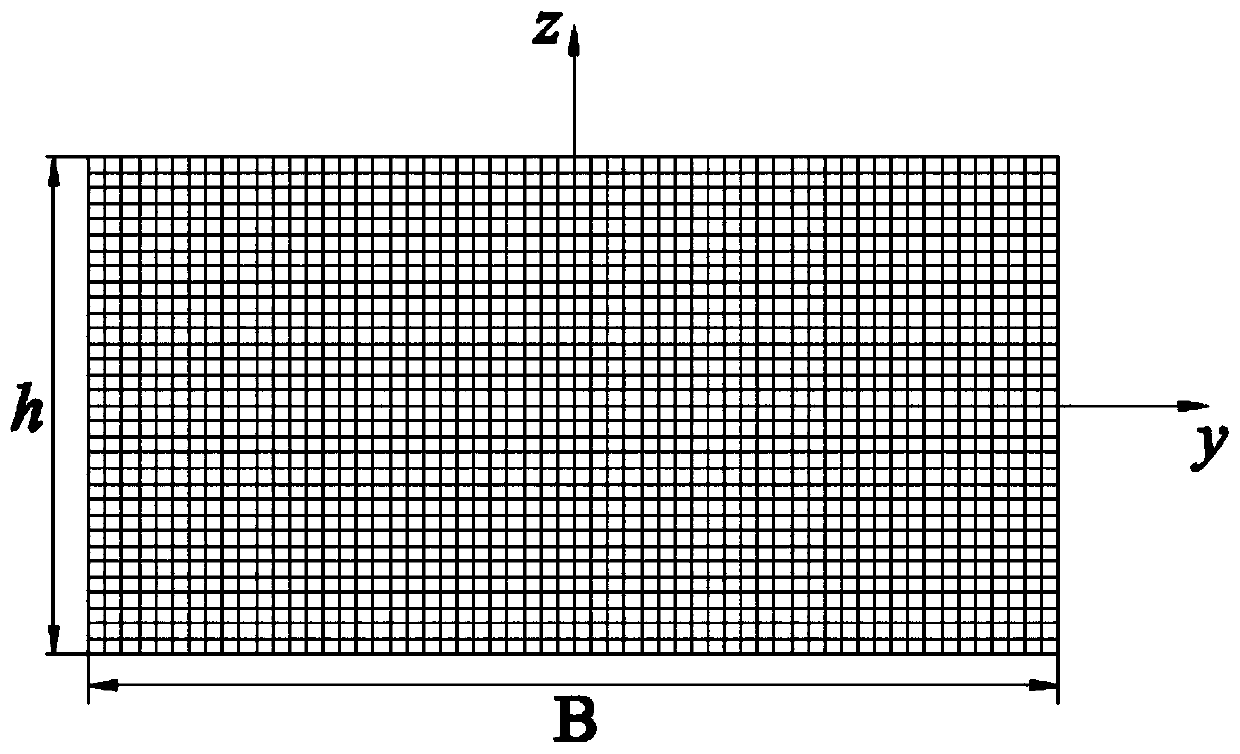

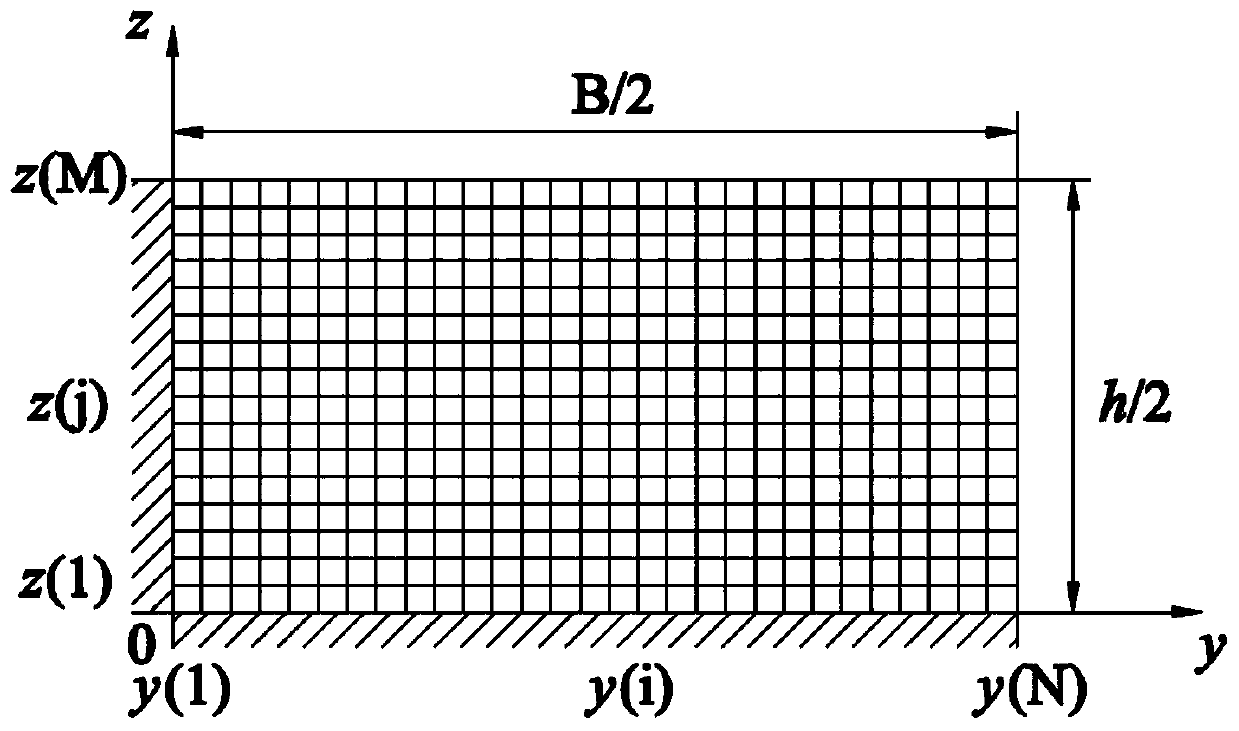

Rolled part temperature obtaining method and device for plate-strip hot-rolling production line

ActiveCN111079275APrecise control of dimensional accuracyClear principleDesign optimisation/simulationHeat conservationThermal contact conductance

The invention discloses a rolled part temperature collection method for a plate and strip hot rolling production line, which comprises the following steps of: constructing equipment arrangement of theplate and strip hot rolling production line, and obtaining related process parameters; dividing a rolled part heat exchange area according to equipment arrangement on the production line, wherein theheat exchange area comprises an air cooling area, a water cooling area, a roll gap contact heat conduction area and a heat radiation heat preservation area; dividing width-thickness section grid nodes of the rolled part, and establishing coordinate system parameters and a temperature calculation model of each node; obtaining initial temperature distribution of the rolled part at the initial calculation position; from the initial calculation position to the final calculation position, the heat exchange area where the rolled part section is located is judged firstly when calculation is conducted every time, and then the temperature distribution of the rolled part section at the position is calculated through a corresponding rolled part temperature model. The method has the beneficial effects that the principle is clear and definite, assumption and simplification conditions are few, the temperature field change of the rolled part on the given hot rolling production line can be accuratelyforecasted, and the calculation precision is higher than that of an analytical method.

Owner:WISDRI ENG & RES INC LTD

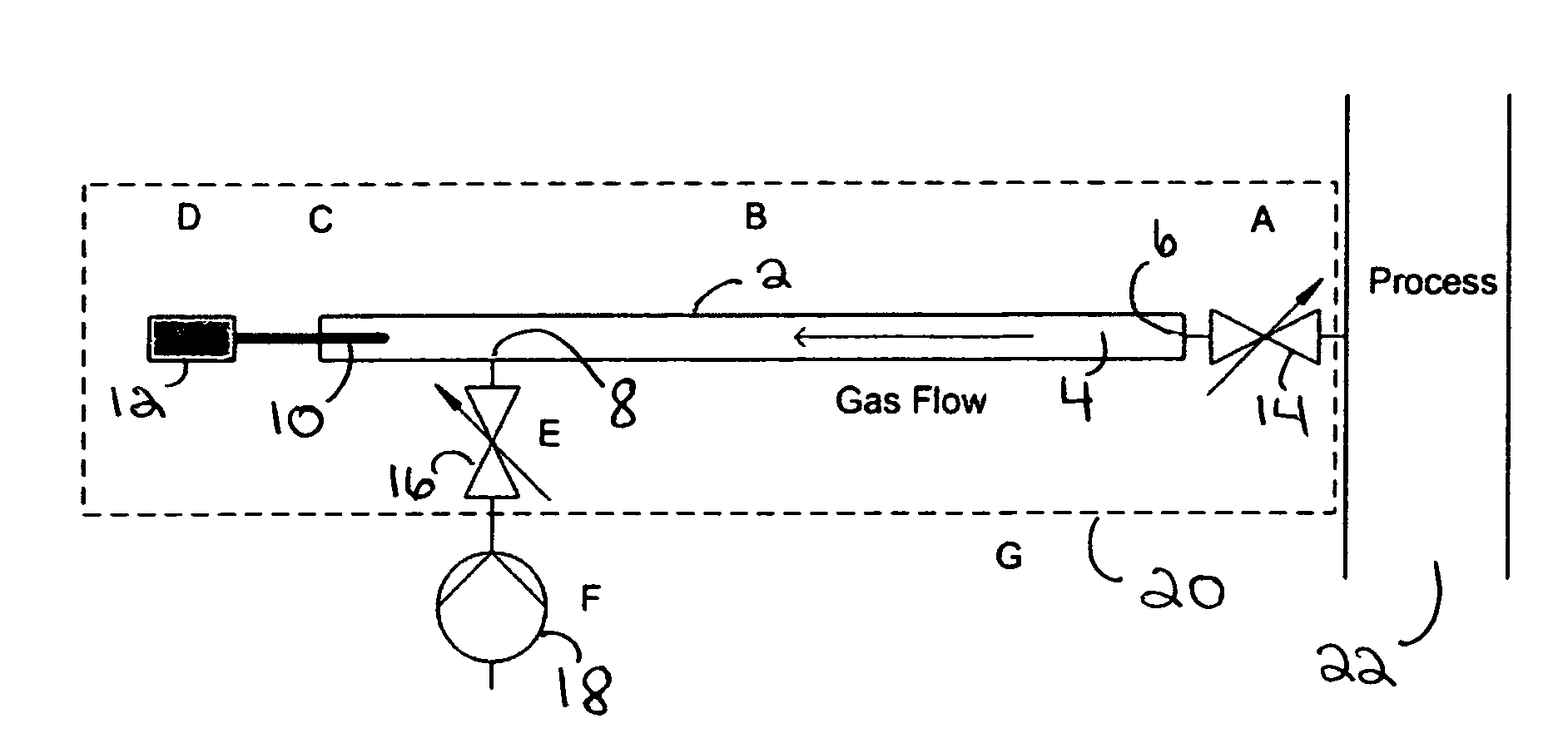

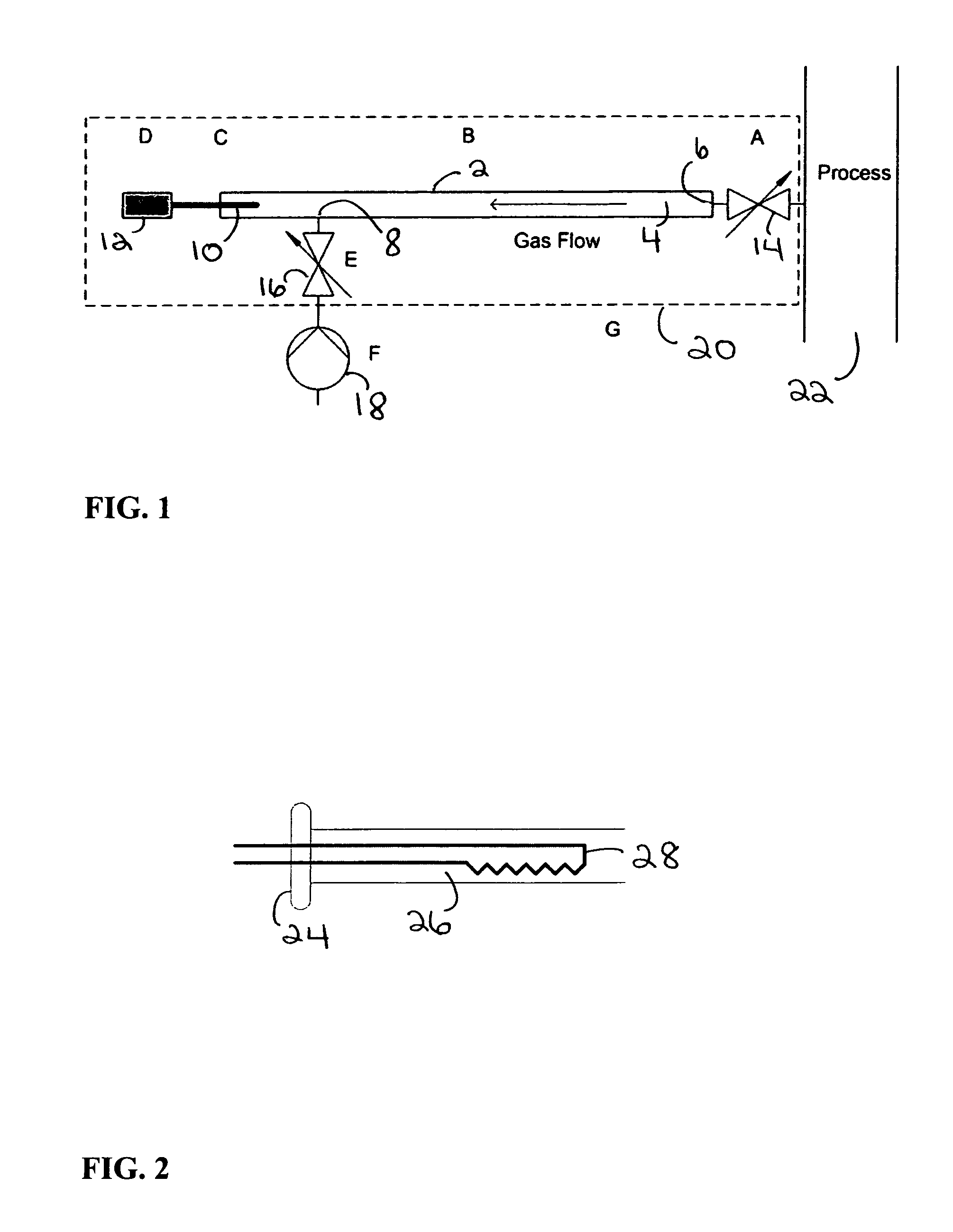

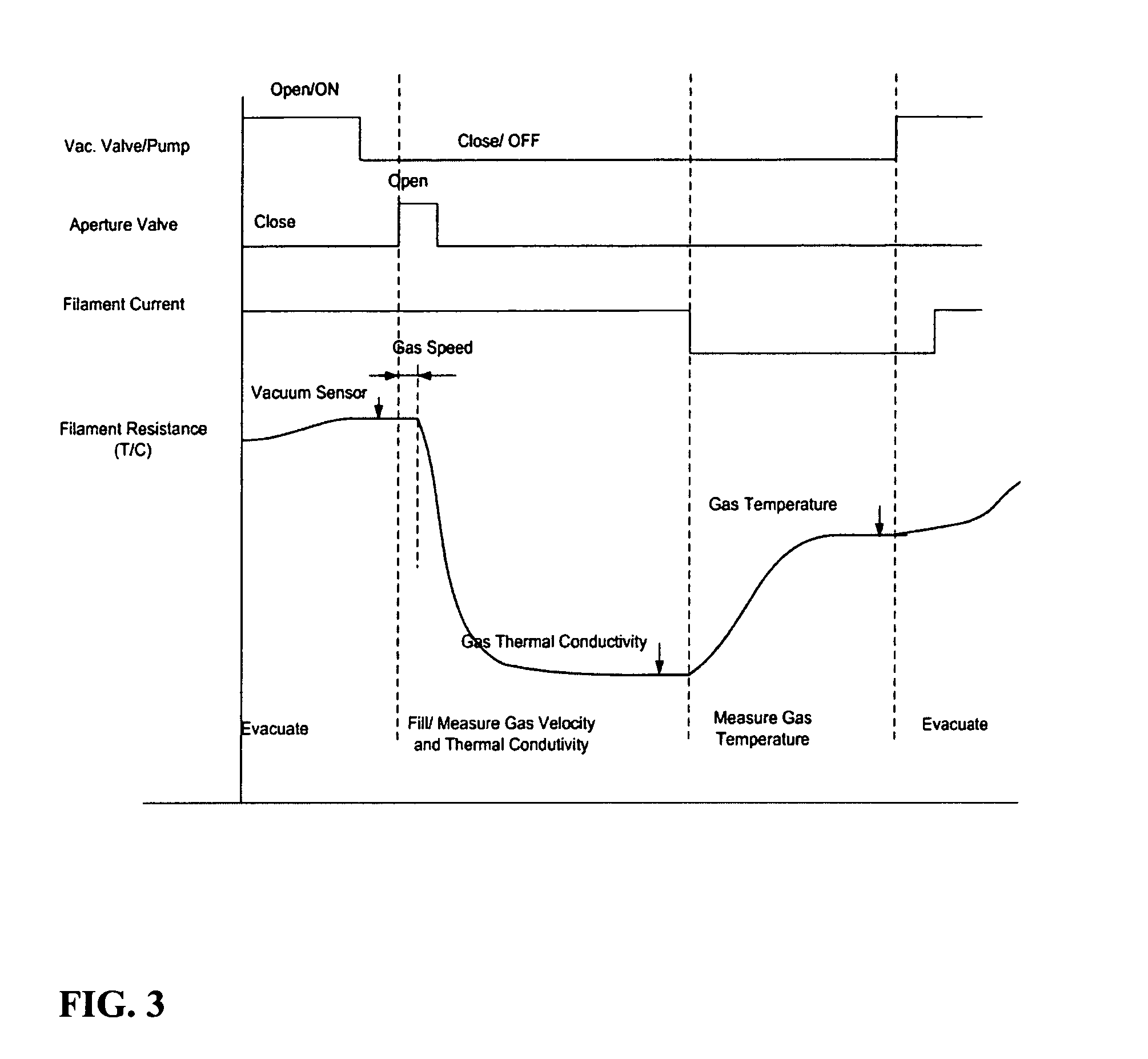

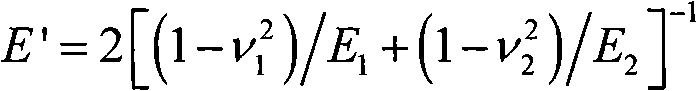

Gas sensor based on dynamic thermal conductivity and molecular velocity

InactiveUS7398681B2Less interferenceMaterial thermal conductivityVolume/mass flow by thermal effectsSingle sampleProduct gas

An apparatus and method for gas detection. The apparatus comprises a) a sample chamber for holding a gas sample, b) a sealable vacuum port in fluid communication with the sample chamber, for evacuating the sample chamber, c) a sealable inlet port in fluid communication with the sample chamber, for introducing the gas sample into the evacuated sample chamber, and d) a thermal conductivity sensing element at least partly disposed within the sample chamber, for measuring the thermal conductivity of the gas sample. A gas sample released into the evacuated sample chamber requires a time interval to contact the thermal conductivity sensing element. The time interval is a measure of gas speed. Thermal conductivity and temperature of the gas sample are measured following determination of gas speed. By determining three parameters in a single sample of gas, different gas mixtures having similar thermal conductivities can be distinguished.

Owner:RGT UNIV OF CALIFORNIA

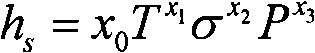

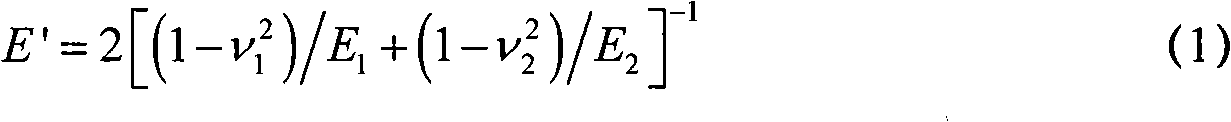

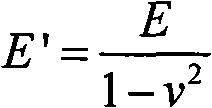

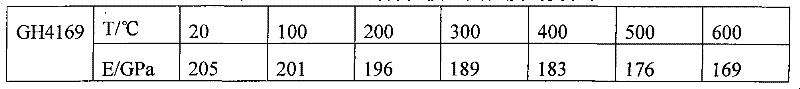

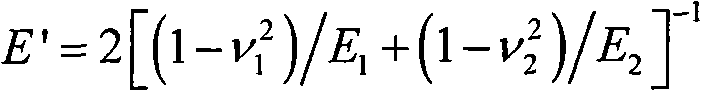

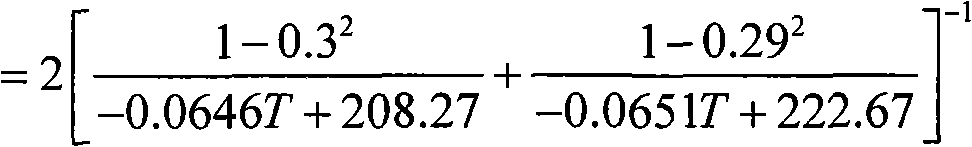

Method for testing contact thermal resistance of GH4169/K417 alloy

InactiveCN102033077AEasy to testThe testing process is simpleMaterial heat developmentRegression analysisMetallic materials

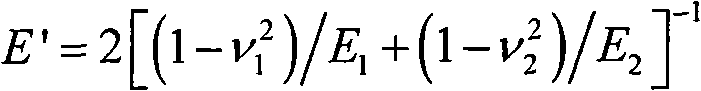

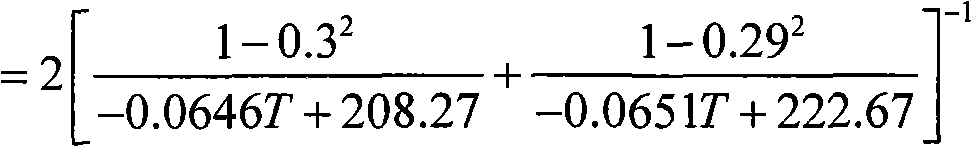

The invention discloses a method for testing the contact thermal resistance of a GH4169 / K417 alloy. The method comprises the following steps: first, confirming the reduced elastic moduli of two contact materials, and then modeling according to the plastic deformation theory of metal materials; simplifying models; confirming unknown parameters bo, b1, b2 and b3 through stepwise regression experiments, and obtaining an optimal regression equation; obtaining the contact thermal conduction of the GH4169 / K417 alloy through regression analysis results, calculating the reciprocal of the contact thermal conduction, and obtaining the contact thermal resistance. When temperature is within the interval of 100-600 DEG C and independent variables choose the temperature and pressure value, hs=26.534T0.107P1.297, and when the independent variables only choose the pressure value, hs=41.43P1.291. By using the invention, the contact thermal conduction can be obtained according to a simple formula under the condition of randomly changing testing temperature and pressure only after the needed parameters b0, b1 and b3 are obtained through experiment data, and the testing process of the contact thermal resistance is simple and can be repeatedly used. Under the premise of ensuring engineering practicability and the accuracy of testing results, the testing process of the contact thermal conduction is greatly simplified.

Owner:BEIHANG UNIV

Cylindrical battery module cooling system and battery module

PendingCN110718726AExcellent plane thermal conductivityGuaranteed temperature uniformitySecondary cellsCell component detailsThermodynamicsEngineering

The invention discloses a cylindrical battery module cooling system, and the system comprises an insulating bracket, a heat conduction layer and a heat exchange plate; a battery cell matching groove is formed in a battery cell contact surface of the insulating bracket, and a heat exchange end surface of the insulating bracket is in contact with the heat exchange plate; the heat conduction layer coats the battery cell contact surface and the heat exchange end surface of the insulating bracket; the heat conduction layer comprises an insulation surface layer, a graphite film and an elastic bufferlayer. The cylindrical battery module cooling system takes an insulating bracket as a support, a battery cell contact surface and a heat exchange end surface of the insulating bracket are provided with a heat conduction layer comprising an insulating layer, a graphite film and an elastic buffer layer, and a battery cell, the heat conduction layer and a heat exchange plate are combined to form aneffective solid-solid contact heat conduction structure. The invention also discloses a battery module.

Owner:LINKDATA NEW ENERGY CO LTD

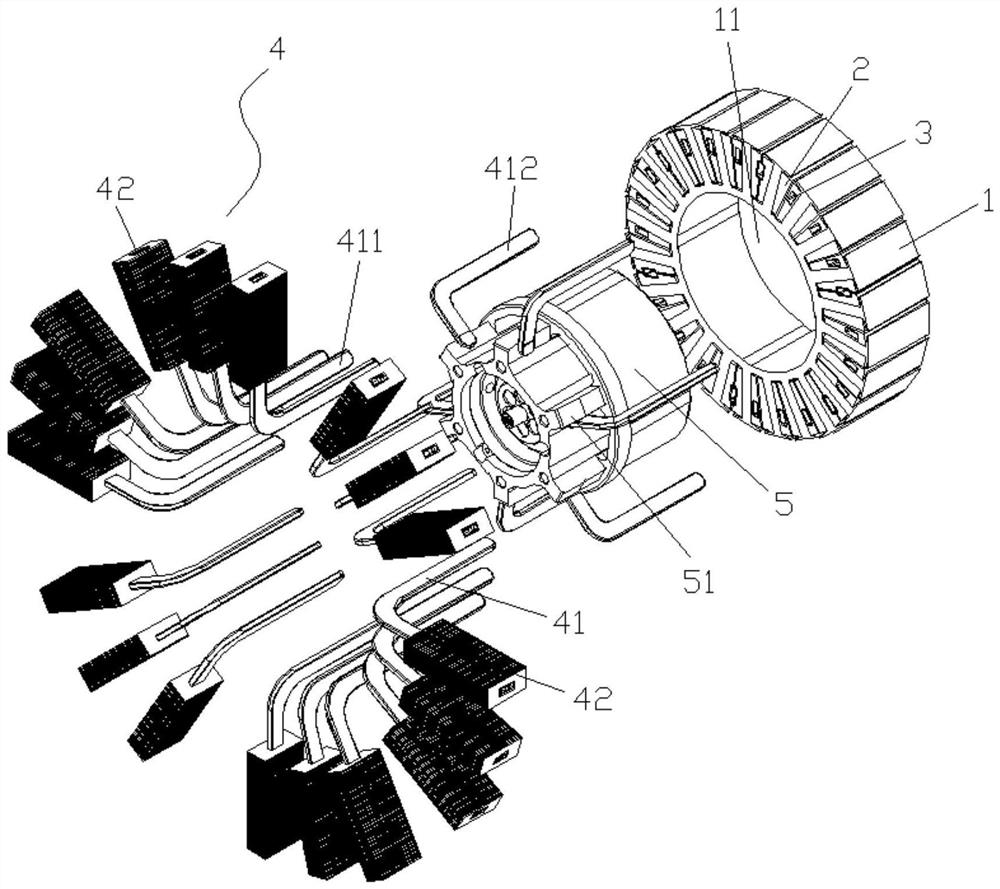

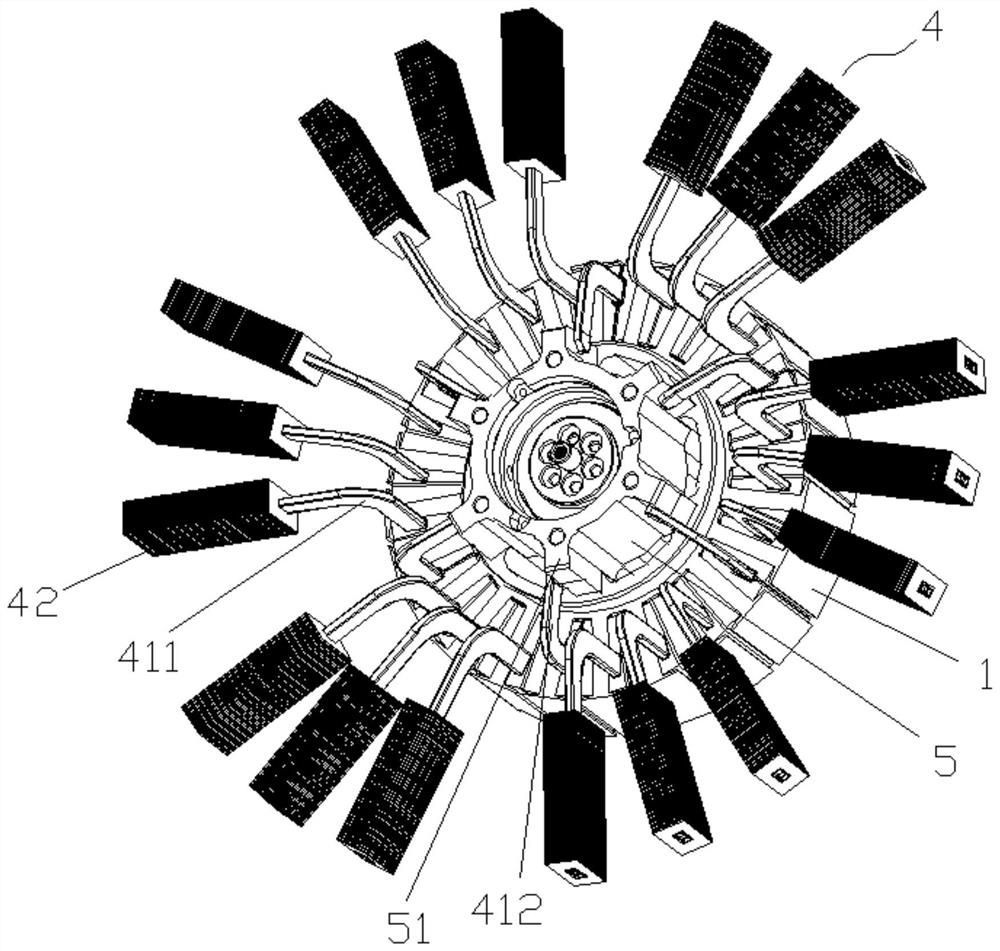

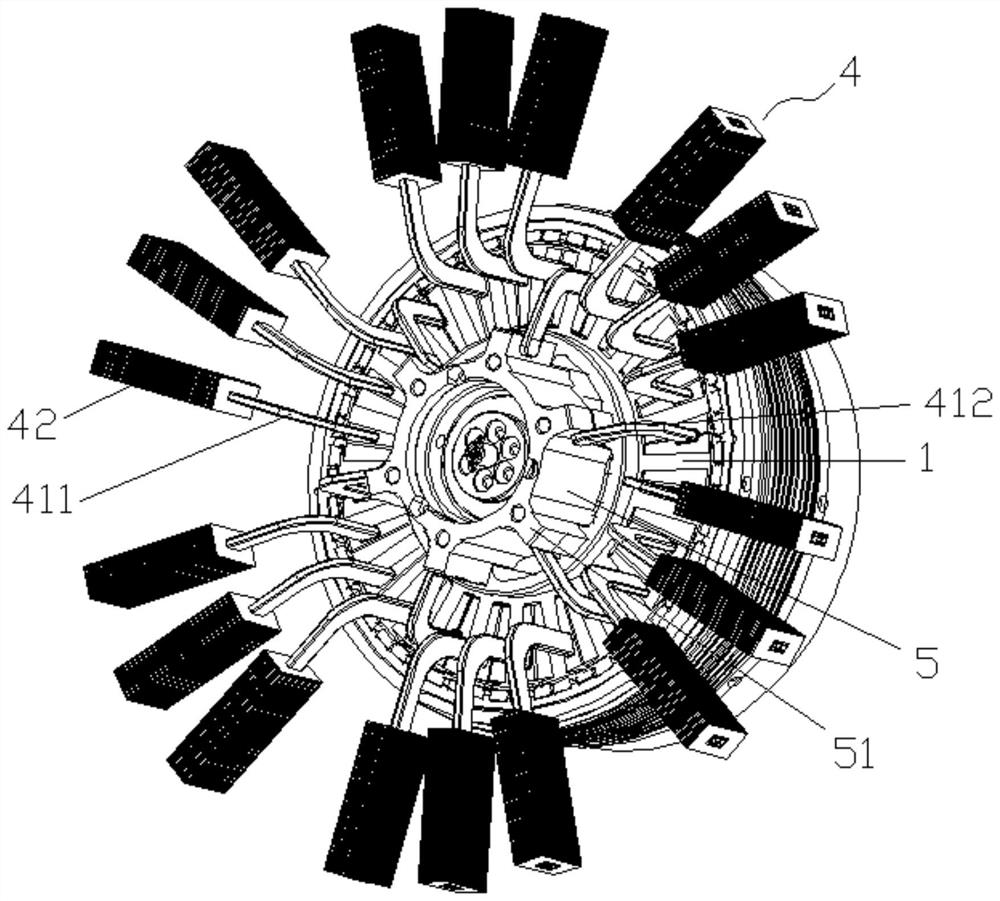

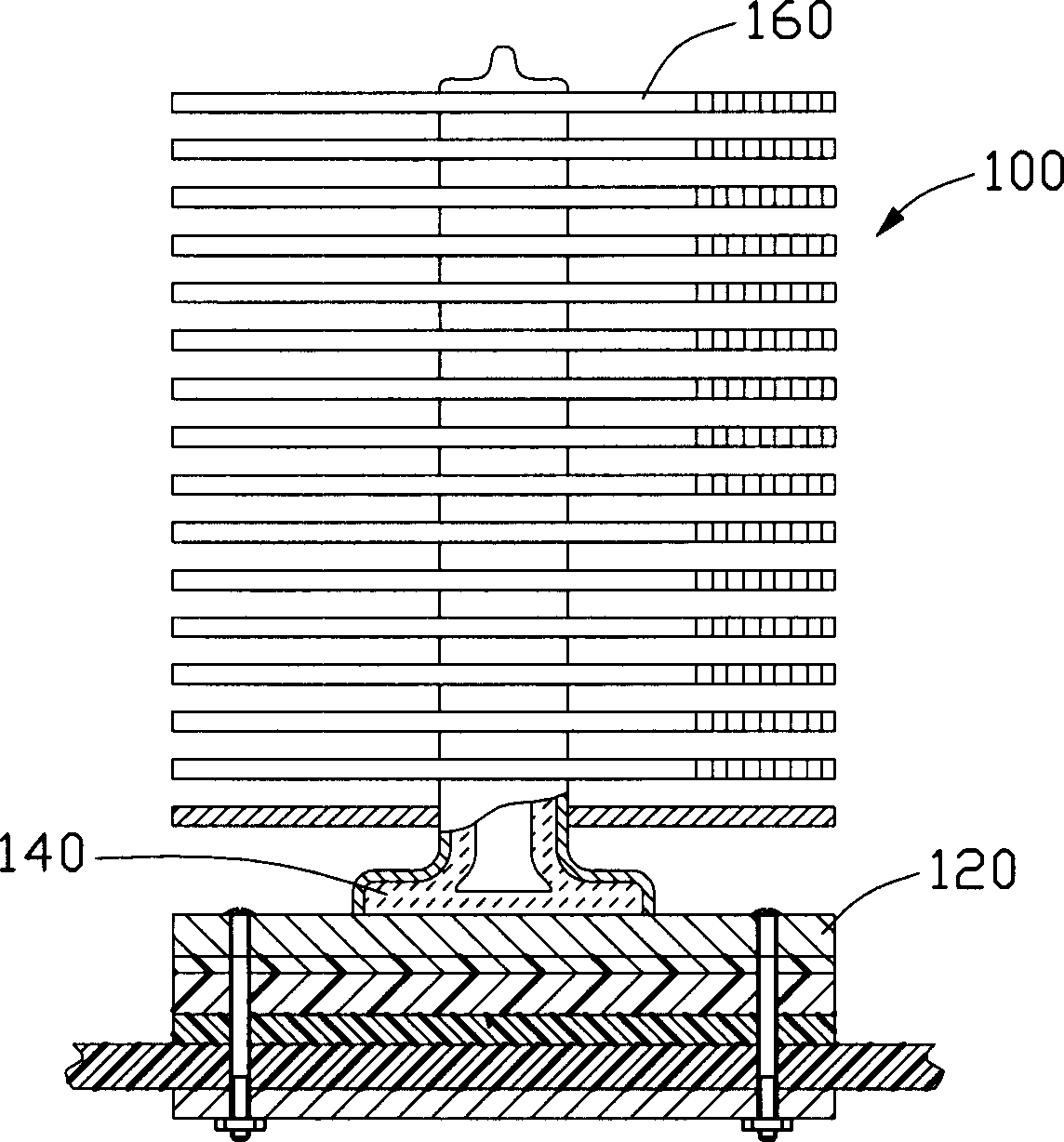

Stator assembly and motor

PendingCN114844270AStable temperature rise reductionImprove power densityEfficient propulsion technologiesMagnetic circuit stationary partsElectric machineUncrewed vehicle

The invention provides a stator assembly and a motor, the stator assembly comprises a stator core with a plurality of stator slots, each stator slot is internally provided with two layers of windings, a gap is arranged between the two layers of windings, the stator assembly further comprises a heat dissipation part used for heat dissipation of the windings, the heat dissipation part comprises a heat conduction pipe and a heat dissipation element, and the heat conduction pipe is arranged in the heat dissipation element. One end of the heat conduction pipe is connected with the heat dissipation element, the other end of the heat conduction pipe is inserted into the gap and conducts heat with the winding through contact, the gap is filled with heat conduction silicone grease with electrical insulation, and the heat conduction silicone grease is used for transferring heat generated by the winding to the heat conduction pipe. According to the stator assembly and the motor in the technical scheme, the stable temperature rise of the motor applying the technical scheme is greatly reduced during operation, and the power density and the reliability are greatly improved, so that the problem of insufficient effective load of an unmanned aerial vehicle caused by overhigh operation temperature rise and low motor power density of the motor in the prior art is solved; therefore, the effective load, the endurance time and the reliability of the unmanned aerial vehicle are improved.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

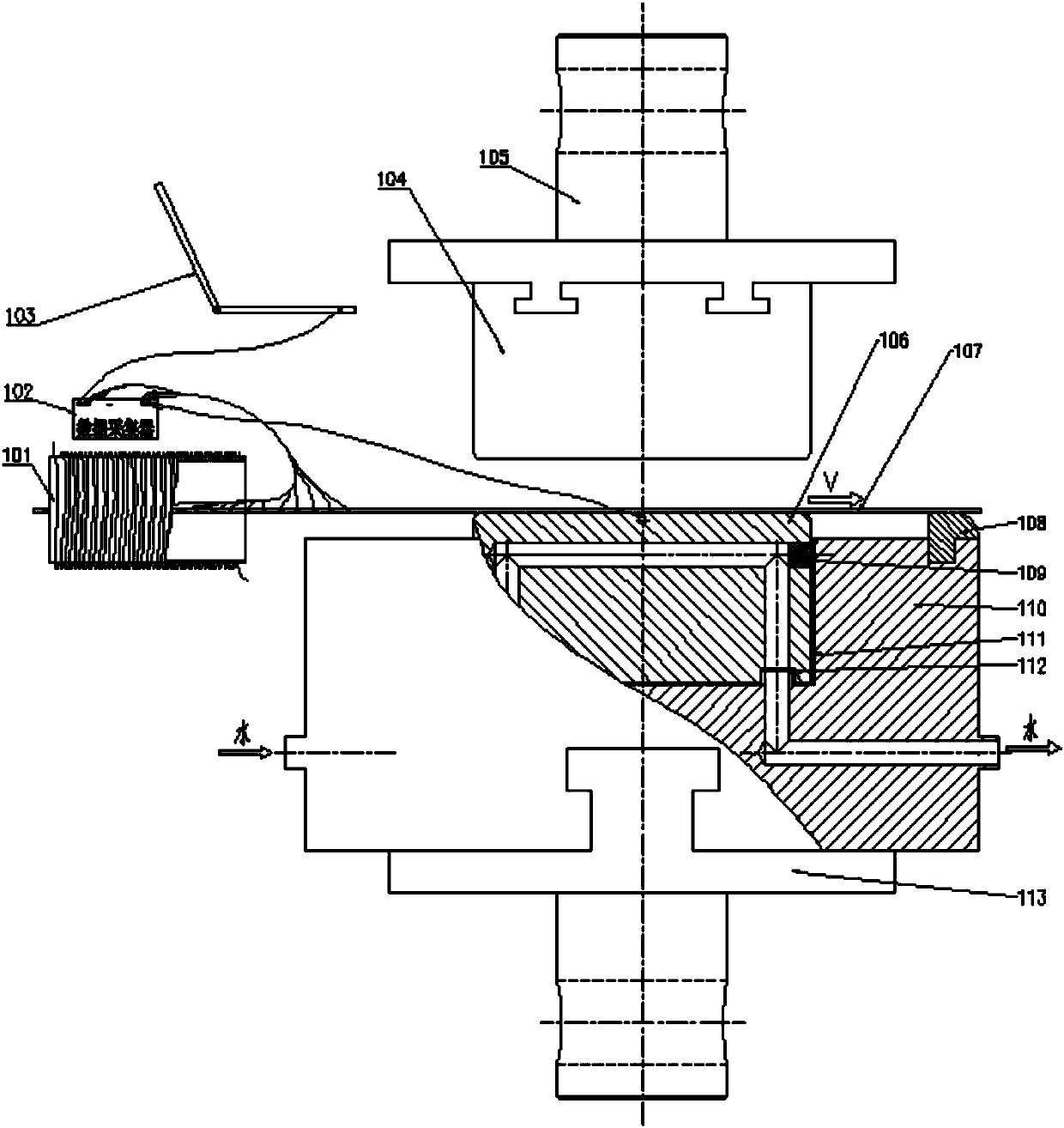

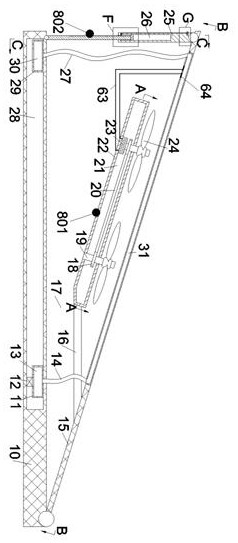

Hot stamping measurement tool and use method thereof

PendingCN107907563AReduce the temperatureExtend your lifeMaterial thermal conductivityIncreasing energy efficiencyHot stampingThermal coefficient

The embodiment of the invention provides a hot stamping measurement tool and a use method thereof. The hot stamping measurement tool is refitted based on an ordinary single pull machine and mainly comprises devices of a water cooling substrate, an insert made of a mould material, a clamp for clamping the insert, a batten for testing, a plate material movement driving device, a device for heating aplate material, a thermoelectric couple for monitoring a temperature, a data collector, a computer for data observation and the like. According to the hot stamping measurement tool disclosed by the embodiment of the invention, the heating device, the testing device and the driving device are arranged on the same platform; varieties of parameters of a contact heat transfer coefficient between a hot stamping plate material and a mould, convective heat transfer coefficient of a runner, friction abrasion of the module and the like can be measured; the hot stamping measurement tool has the advantages of high automation degree, strong operability and rich functions; the parameters obtained from the testes can provide accurate input for hot press simulation analysis and has important significance in prolonging service life of the hot stamping mould and improving product performance.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Measuring apparatus for contact thermal conductivity of surface joint part of annular-surface contact

InactiveCN108828007AAccurate measurementAccurate measurement and calculationMaterial heat developmentHeat flowThermal contact conductance

The invention discloses a measuring apparatus for contact thermal conductivity of a surface joint part of annular-surface contact. The measuring apparatus includes, in an inner-outer relative arrangement, an annular cooling plate, an annular electric heater, a temperature sensor, and a heat-flow meter. Two to-be-tested pieces are loaded between a cooling tube and the electric heater. The temperature sensor is used for measuring the temperature of the joint surface between the contacted to-be-tested pieces. The heat-flow meter is used for measuring the heat flow density between the two to-be-tested pieces. The measuring apparatus can accurately measure the contact thermal conductivity of the annular surface joint parts.

Owner:CHONGQING UNIV

Contact thermal resistance test method of GH4169/K417 alloy with additional heating

InactiveCN102033078AThe testing process is simpleEasy to testMaterial heat developmentRegression analysisMetallic materials

The invention discloses a contact thermal resistance test method of a GH4169 / K417 alloy with additional heating. The method comprises the following steps of: firstly, confirming the reduced elasticity modulus of two contact materials and then modeling according to a plastic deformation principle of a metal material; simplifying the model; finally, confirming unknown parameters through a stepwise regression test to acquire an optimal regression equation; and acquiring the contact thermal conduction of the GH4169 / K417 alloy according to a regression analysis result and taking the reciprocal of the contact thermal conduction to acquire contact thermal resistance. When the temperature is in an interval of 100-600 DEG C, and temperature and pressure values are selected as independent variables, hs=160.4528T0.012P1.005; and when only the pressure value is selected as the independent variable, hs=168.85P1.007. If the needed parameters are acquired only through test data, the contact thermal conduction can be acquired according to a simple formula under the conditions of randomly changing test temperature and pressure so as to simplify and repeatedly use the test process of the contact thermal resistance. The method provided by the invention greatly simplifies the test process of the contact thermal conduction on the premise of ensuring the engineering practicability and the test result accuracy.

Owner:BEIHANG UNIV

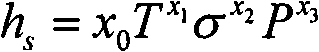

Cesium and strontium capsule disposal package

A package and process of using the package for disposal of radioactive cesium and strontium waste capsules. The package comprises a standard Hanford vitrified high-level waste canister as an outer container, which is approximately filled with three components: the first is a monolithic material with a defined cavity having a composite density less than about 3.5 grams per cubic centimeter and a melting temperature above that expected within the disposal package; the second is a frame for limiting relative movement of the capsules; and, the third are components forming an uninterrupted physical contact, thermal conduction pathway from the waste container to the outside of the package. The package includes lids for closing the disposal package. In the method of the invention, the capsules are loaded into position within the monolithic material, encased in thermally conducting material, and then lids are added to close the package.

Owner:KURION

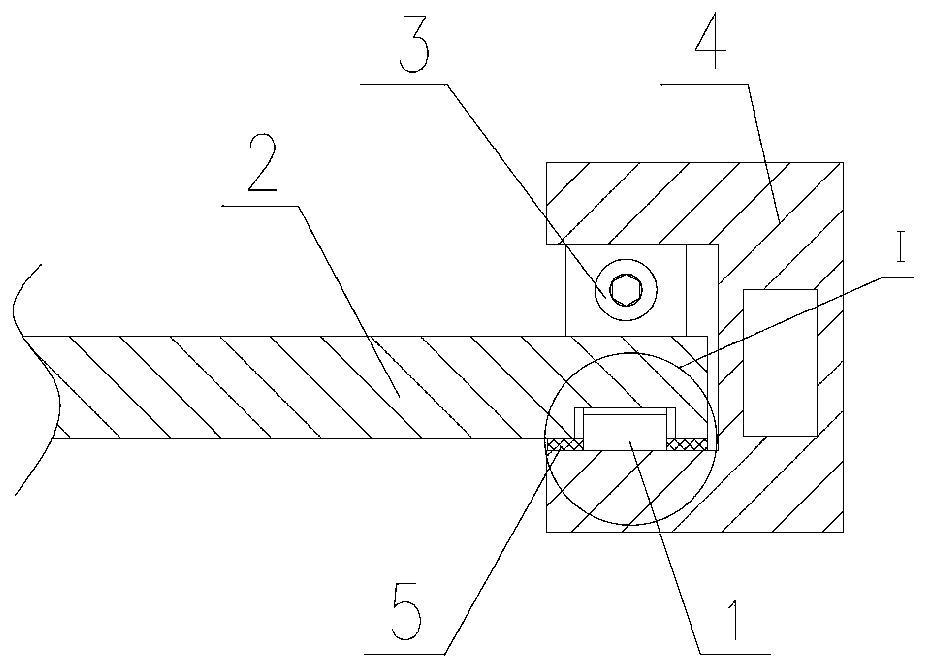

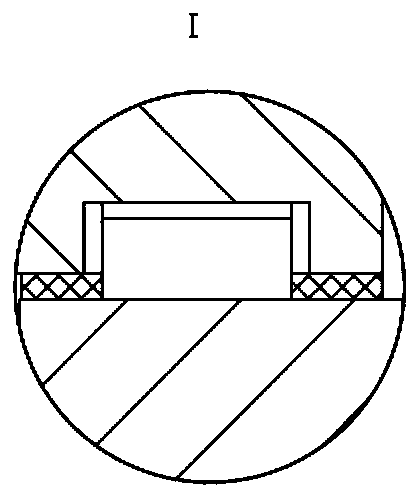

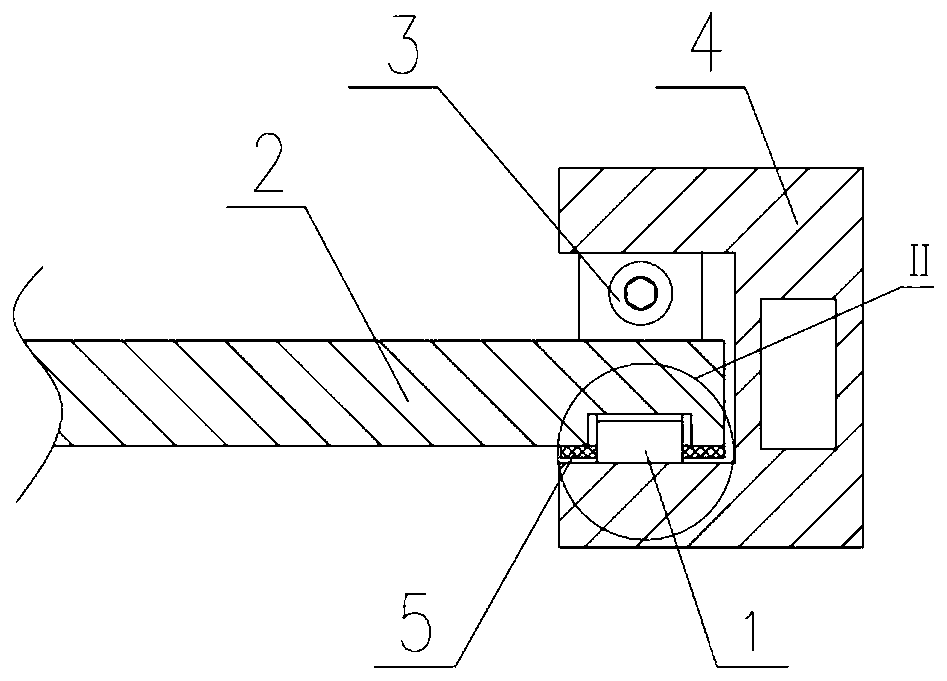

Board card structure for protecting thermal contact surface based on reed

InactiveCN110456892AAvoid damageQuick breakDigital processing power distributionEngineeringThermal contact conductance

The invention discloses a board card structure for protecting a thermal contact surface based on a reed. The board card structure structurally comprises a reed (1), a heat transfer cold plate (2), a locking device (3), a heat dissipation cold plate (4) and a heat conduction interface material (5). According to the structure, a groove is designed on a heat transfer contact surface of a heat transfer cold plate (2) of a case board card and is used for installing the reed (1); and in the board card plugging process, through the elastic force of the reed (1), the contact surfaces of the heat conduction interface material (5) on the heat transfer cold plate (2) and the heat dissipation cold plate (4) are rapidly separated and keep a relative distance, so that the heat conduction interface material (5) is prevented from being damaged in the plugging process.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

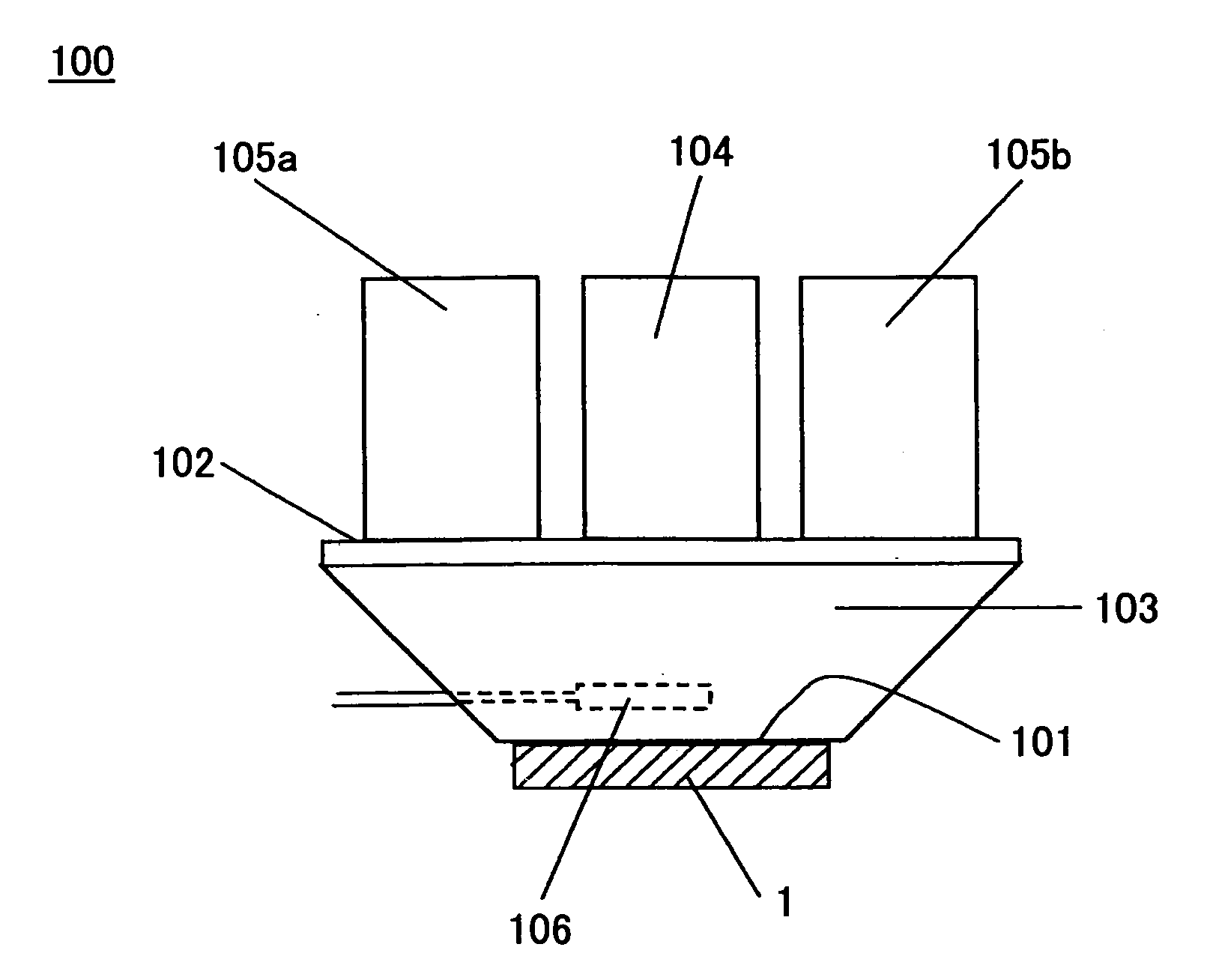

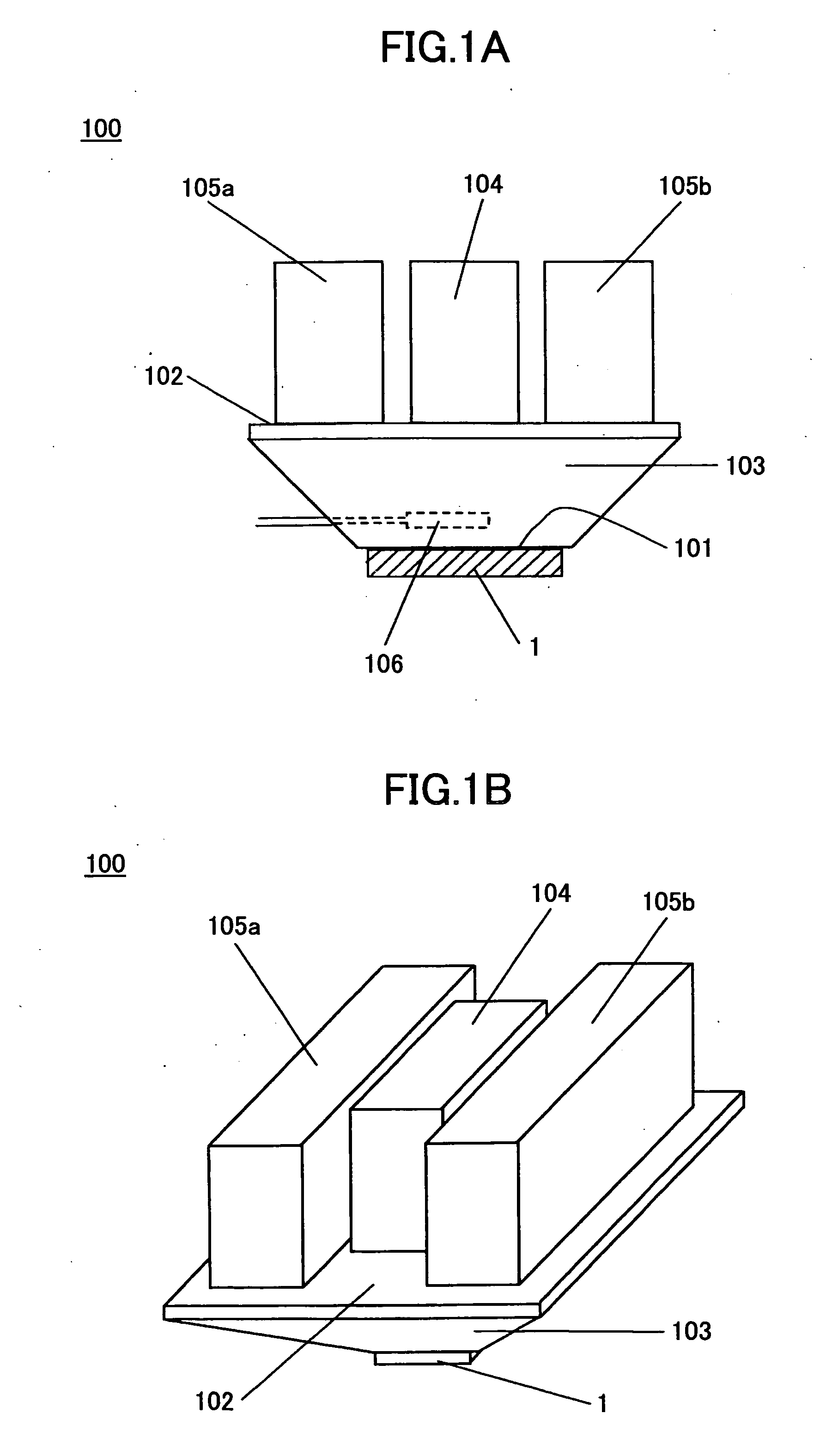

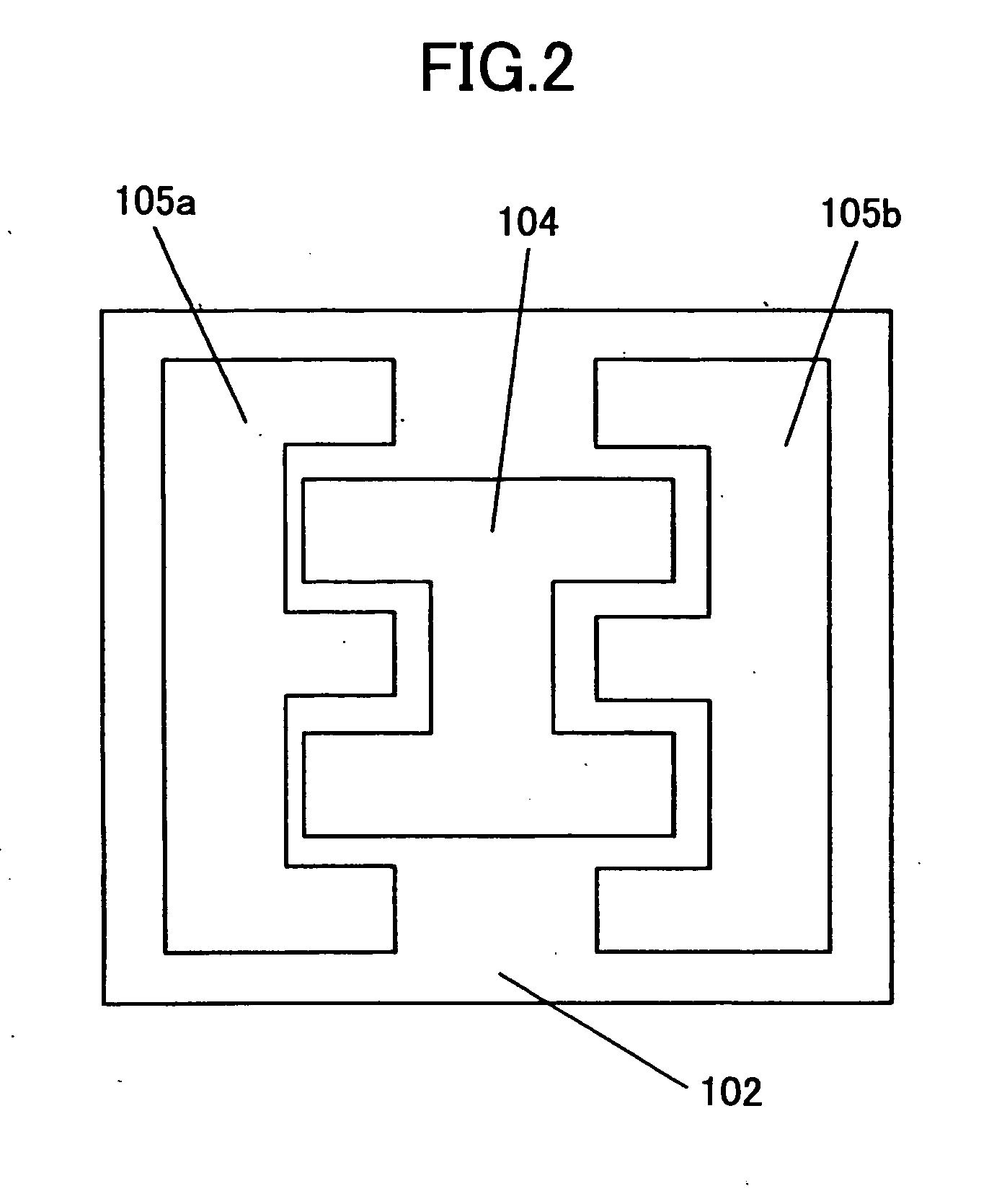

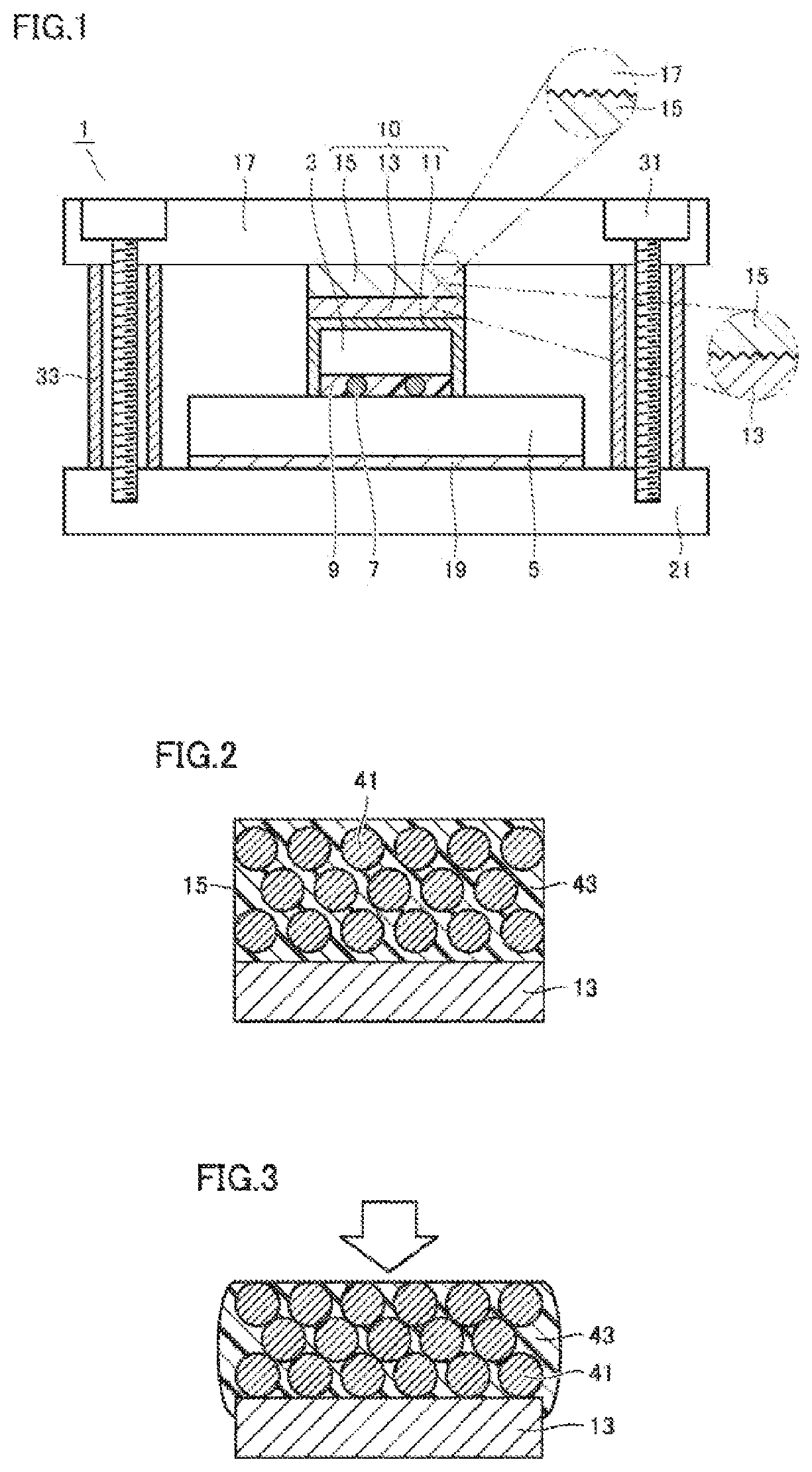

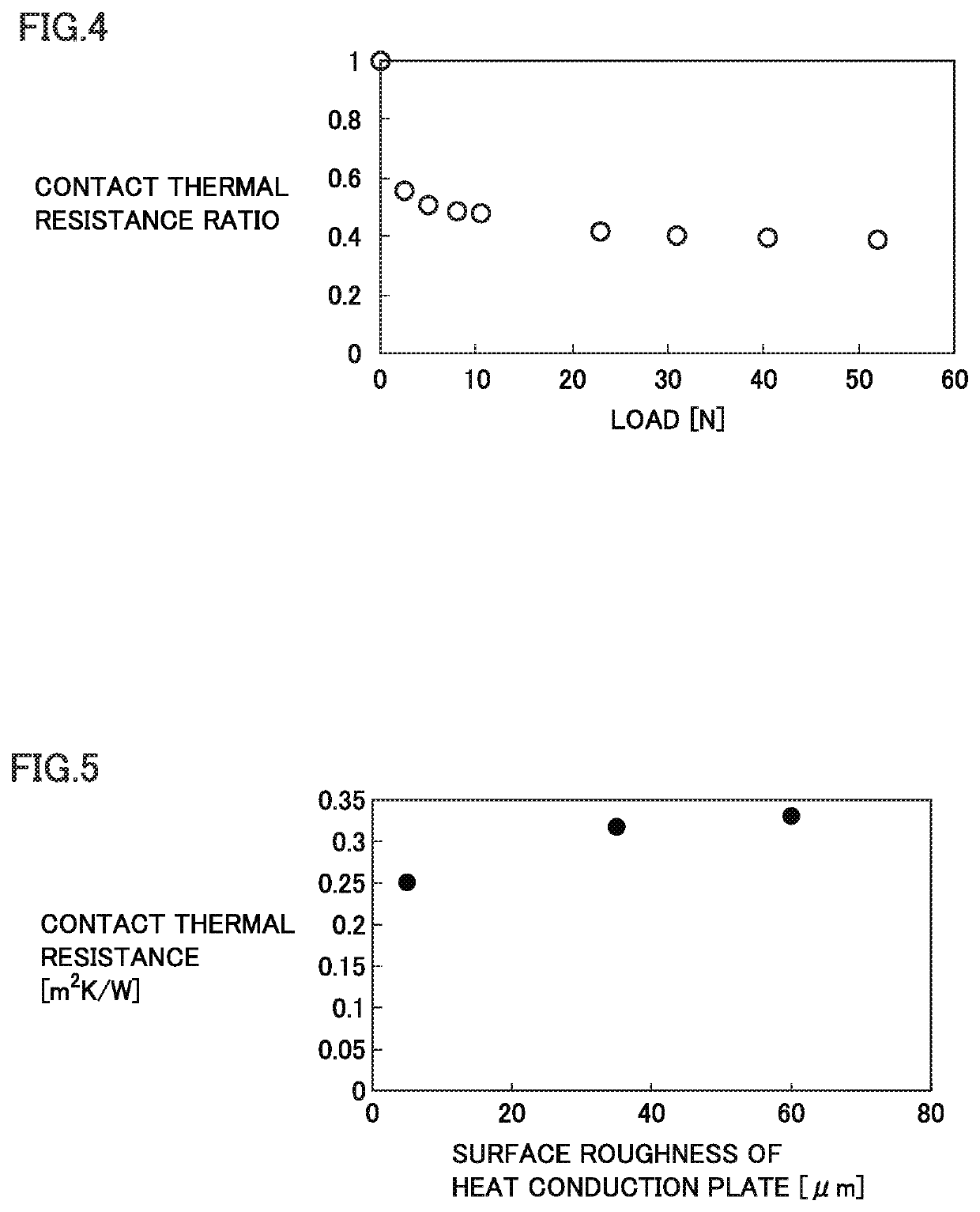

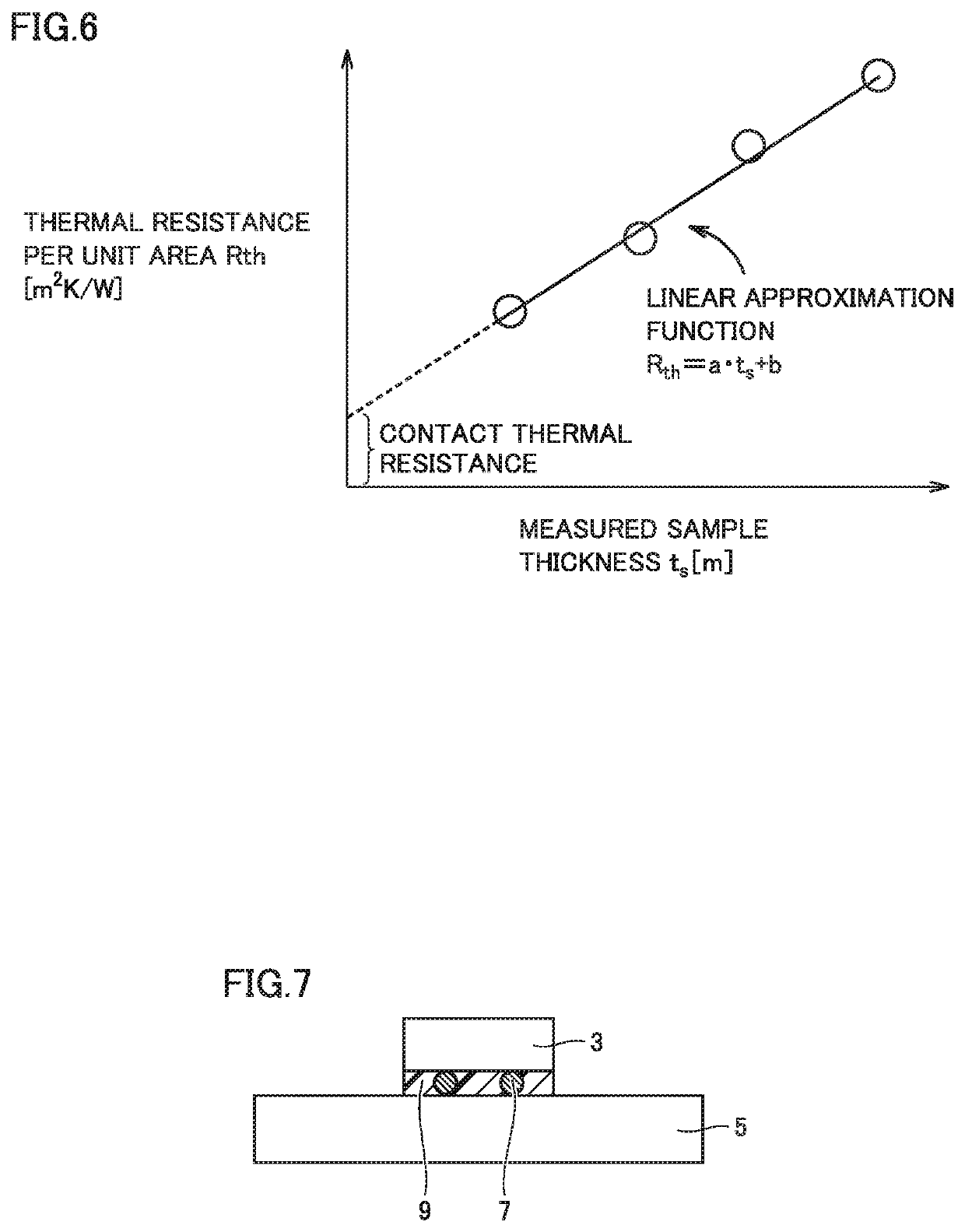

Semiconductor device and method for manufacturing the same and wireless communication apparatus

ActiveUS11081449B2Efficiently dissipatedLikely to heatMagnetic/electric field screeningSemiconductor/solid-state device detailsDevice materialEngineering

An electromagnetic wave absorption sheet is arranged to contact an upper surface and side surfaces of an electronic component mounted on a wiring board, a heat conduction plate is arranged to contact the electromagnetic wave absorption sheet, a heat transfer sheet is arranged to contact the heat conduction plate, and a heat dissipation member is arranged to contact the heat transfer sheet. Heat conductive particles contained in the heat transfer sheet contact a flat surface portion of the heat conduction plate. The electromagnetic wave absorption sheet, the heat conduction plate, and the heat transfer sheet are interposed between the heat dissipation member and the electronic component, as a heat conduction member for conducting heat generated in the electronic component and the like to the heat dissipation member.

Owner:MITSUBISHI ELECTRIC CORP

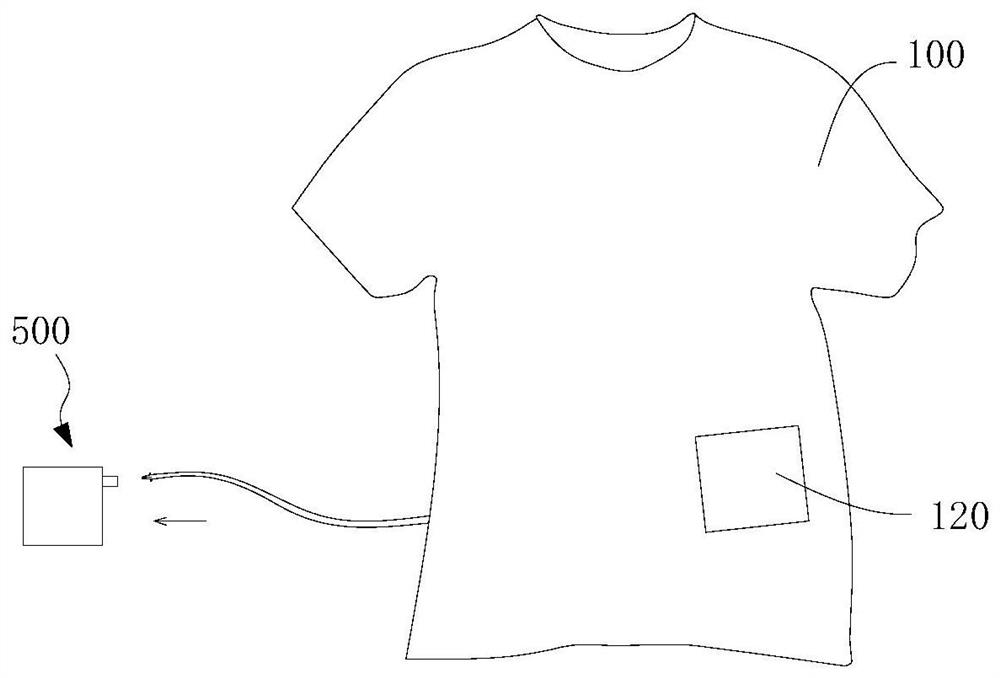

Wearable device for heat preservation

PendingCN111838836AIncrease the heating areaIncrease contact areaTherapeutic coolingTherapeutic heatingPhysical medicine and rehabilitationSkin contact

The invention provides a wearable device for heat preservation. The device is used for preventing and treating the hypothermia phenomenon of a patient in the perioperative period in the operation process and comprises a heating body which is in a clothes shape and can convert electric energy into heat energy, and the heating body is provided with a heat conduction face used for making contact withthe skin of the patient. The heating body is directly made into the clothes shape; when the patient wears the device, the heat conduction surface on the heating body is contacted with the patient; the contact area between the heat conduction surface and the patient is large, and the contact position between the heat conduction surface and the patient can provide heat for the patient, so that theheating area of the patient is increased, the heating efficiency is greatly improved, the body temperature of the patient is maintained at a set temperature, the phenomenon of hypothermia in the perioperative period is prevented, and the operation is safer and more reliable.

Owner:SICHUAN PROVINCIAL PEOPLES HOSPITAL

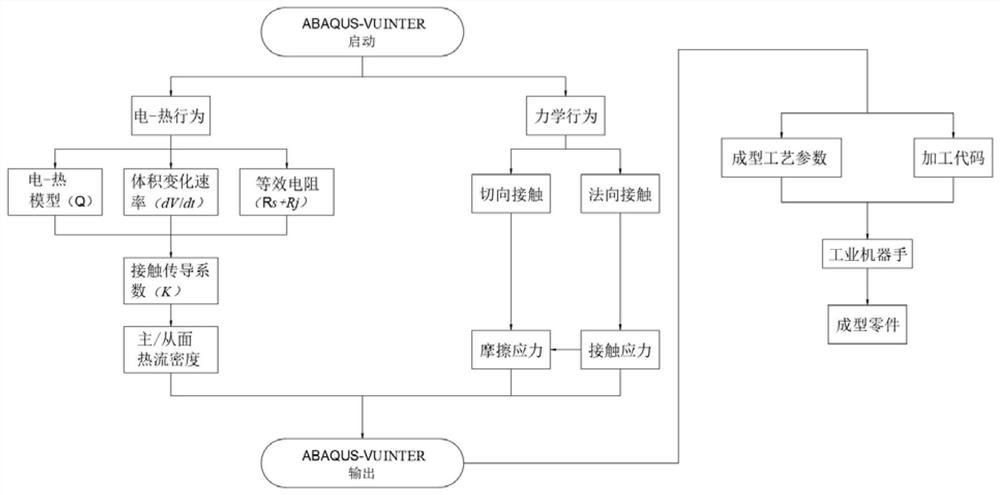

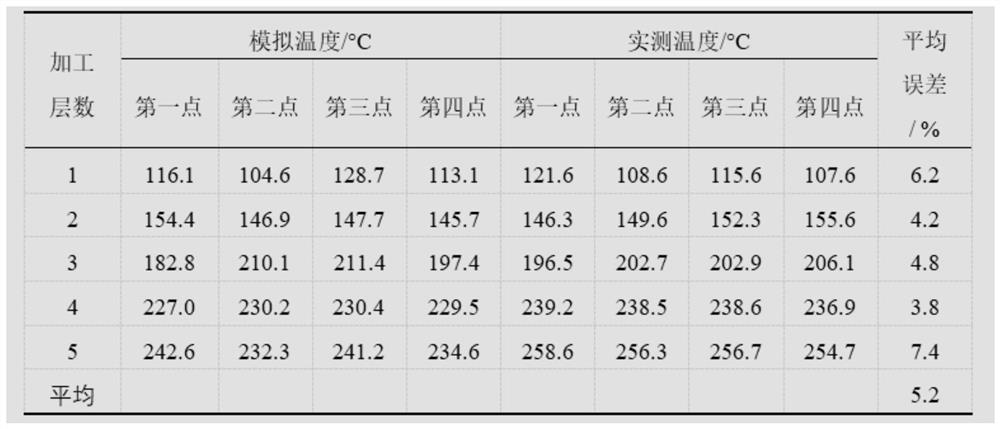

Self-resistance electric heating intelligent incremental forming method

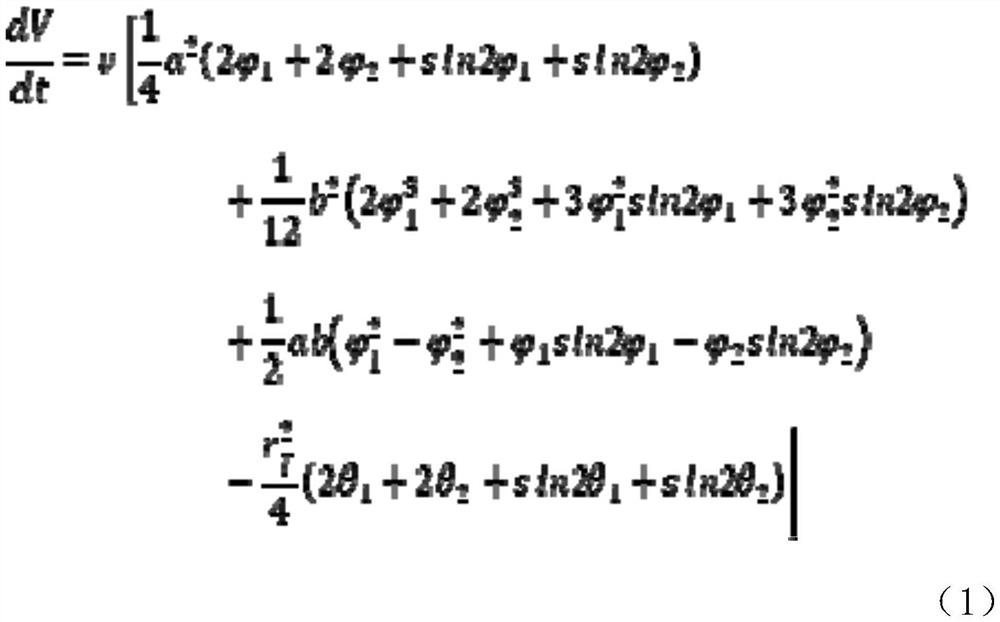

ActiveCN112439834AAchieve forecastImprove usabilityGeometric CADShaping toolsElectrical resistance and conductanceComputational model

The invention discloses a self-resistance electric heating intelligent incremental forming method. The method comprises the following steps that step A, a calculation model of a volume change rate (dV / dt) of a deformation area is established according to spatial geometric change characteristics of a contact area of a forming tool and a plate in incremental forming; step B, a calculation model of the resistance (Rs) and the contact resistance (Rj) of a material in the area is established according to the circuit characteristics of the contact area in the self-resistance electric heating incremental forming; step C, an instantaneous joule heat model (Q) and an equivalent contact heat conduction coefficient calculation model (K) between the forming tool and the plate contact area are established; and step D, the related parameters are substituted into a user subprogram ABAQUS-VUINTER to obtain a local deformation temperature value. According to the method, the difficulty of electricity, heat and force three-field coupling numerical simulation can be effectively solved, a simulation result is combined with forming equipment, the simulation and manufacturing integrated process is realized, and the processing efficiency and intelligence of the forming process are improved.

Owner:SUZHOU RES INST OF NUAA +1

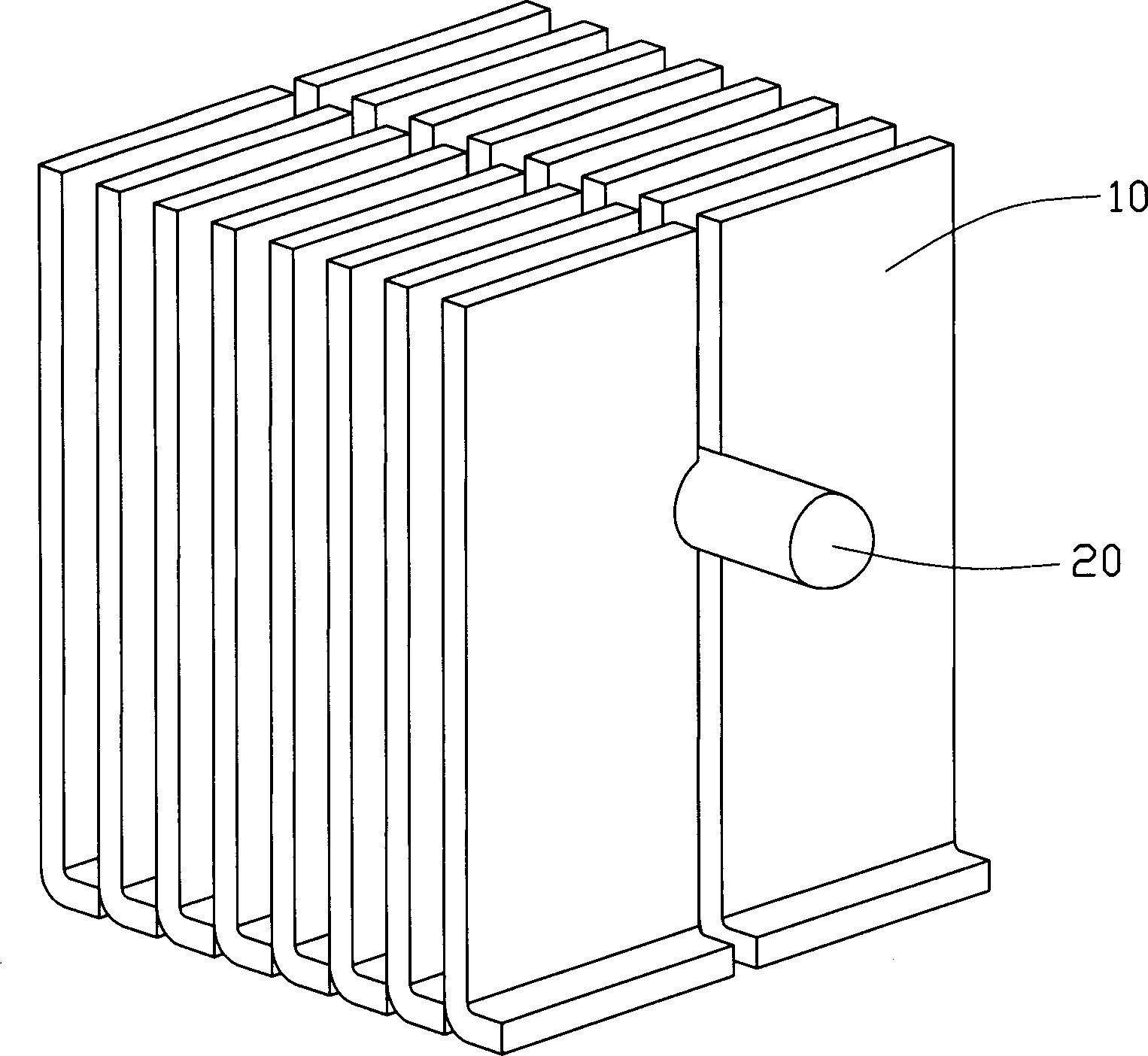

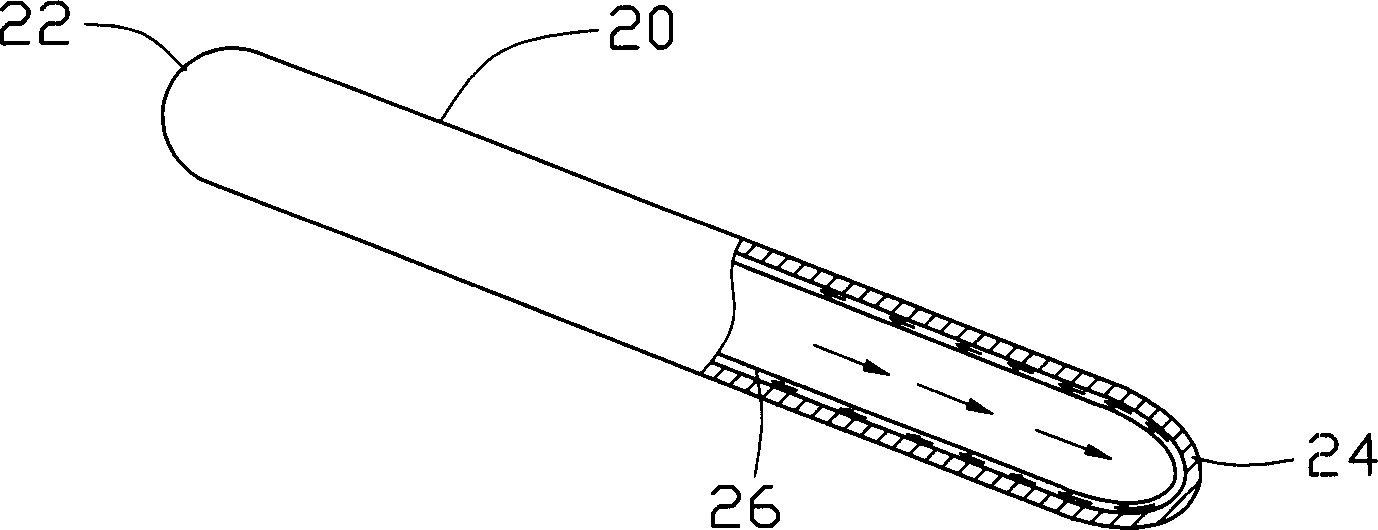

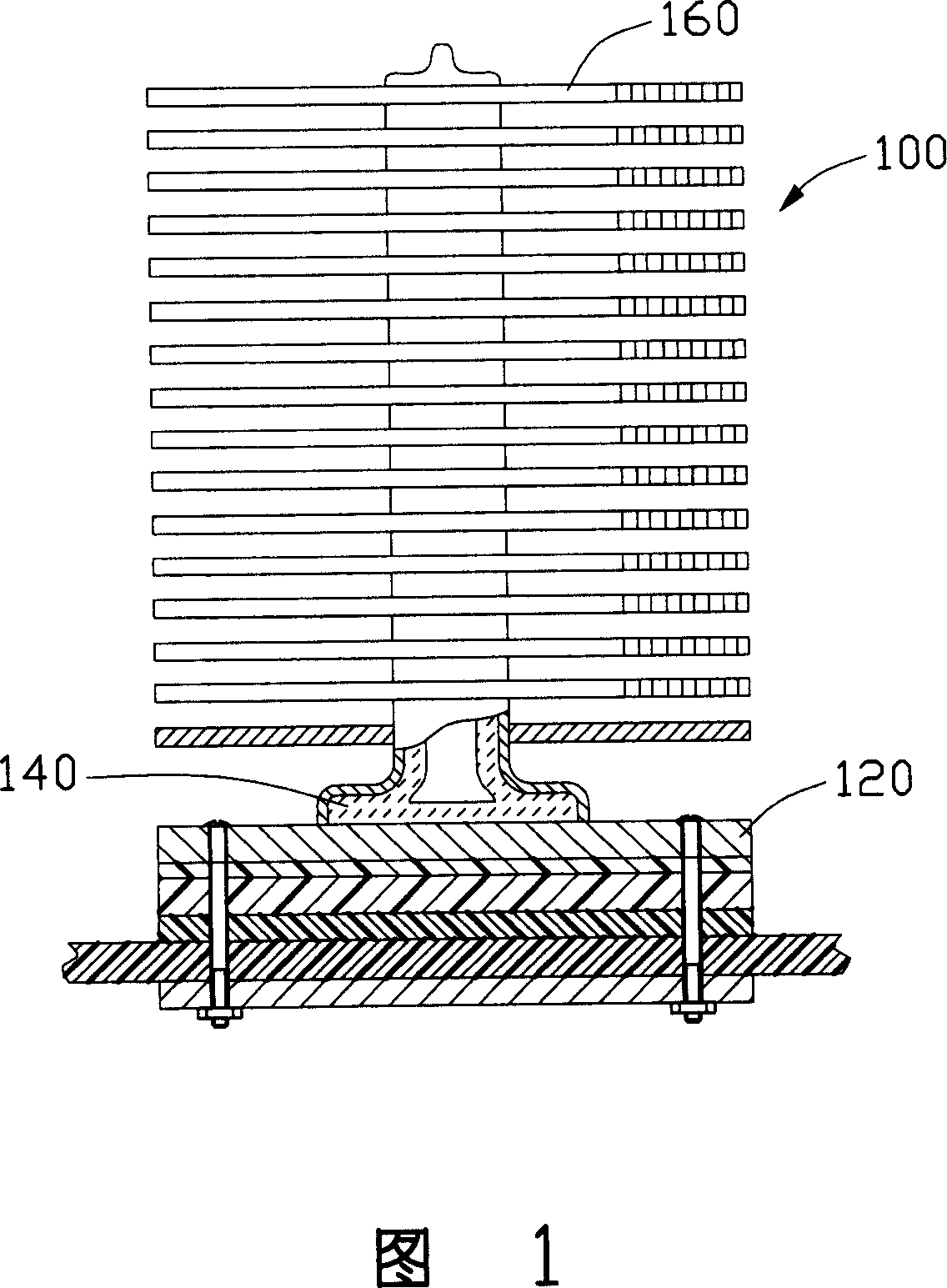

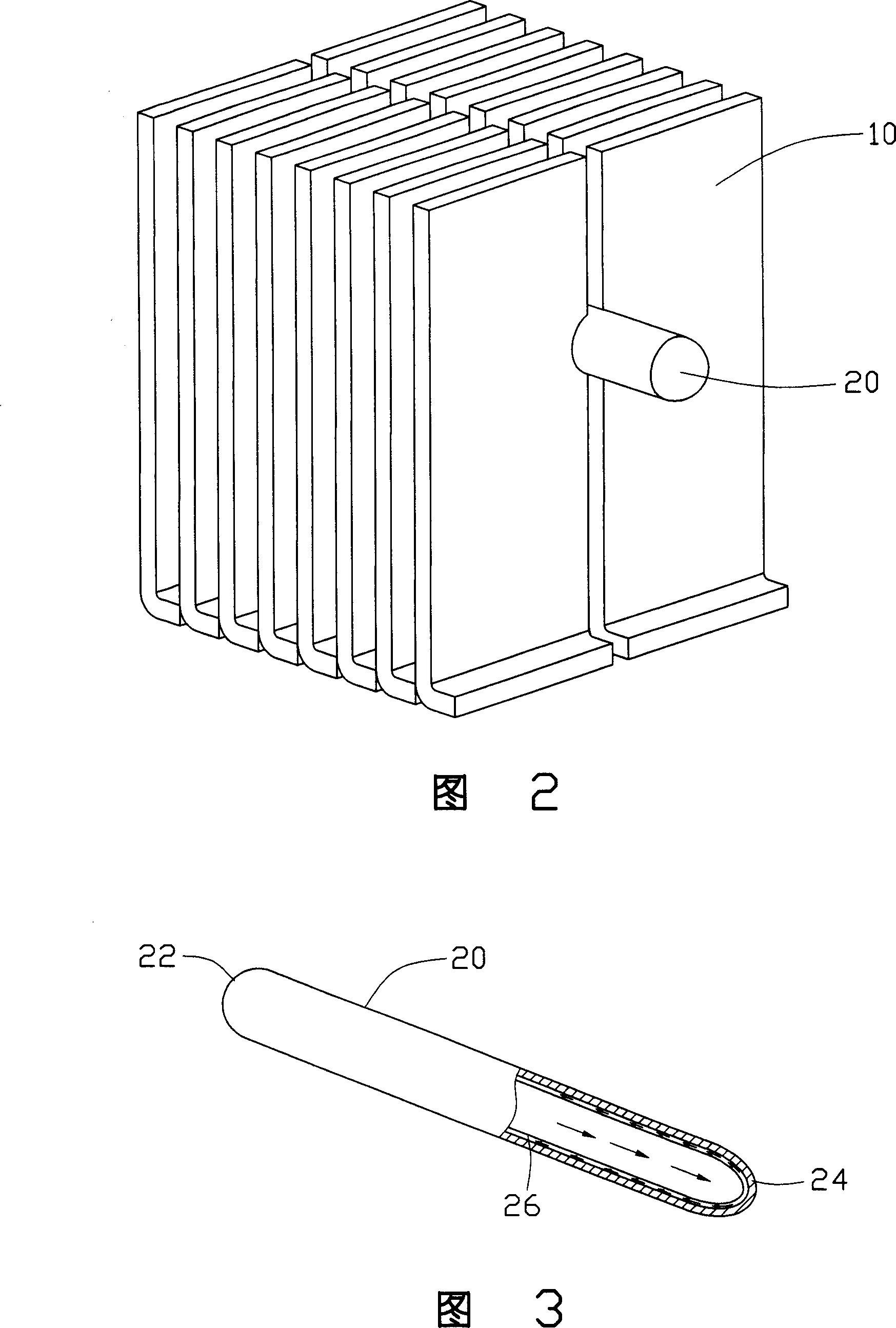

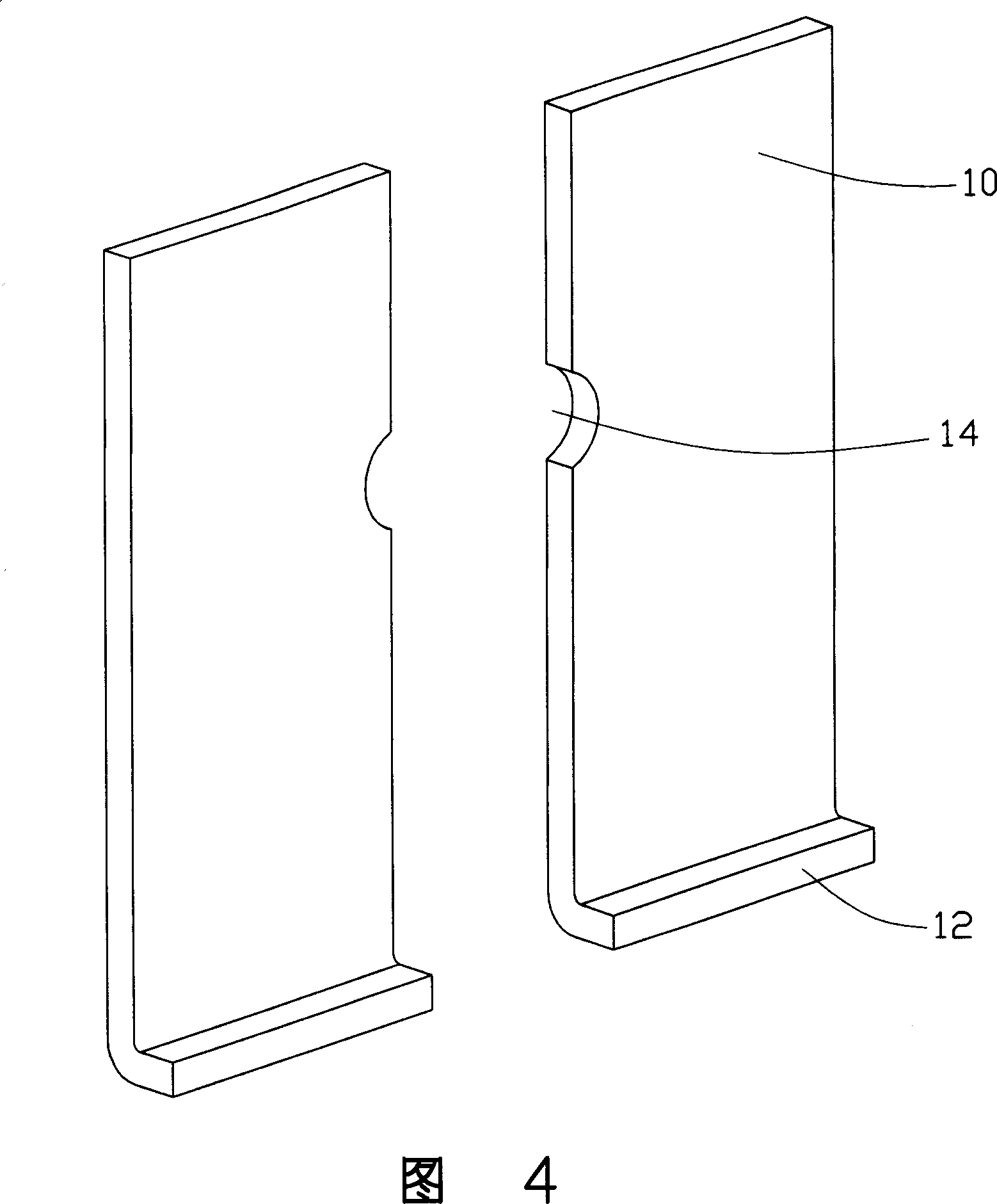

Method of connecting heat conduit and radiation fin

InactiveCN1624907ASolve the problem of thermal resistance caused by the gapSolve the problem of thermal resistanceDigital data processing detailsSemiconductor/solid-state device detailsThermal contact conductanceEngineering

A jointing method of heat conduct pipe and radiating fin. A open is on the radiating fin then rotating the heat conduct pipe, and the radiating fin paralleled move to the conduct pipe; when the open contacts the heat conduct pipe, holding the heat conduct pipe rotating, and generating friction between the heat conduct pipe and the radiating fin the heat created by friction make the frictional surface as plastic melting state; and the heat conduct pipe and the open of the joined by pressure.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

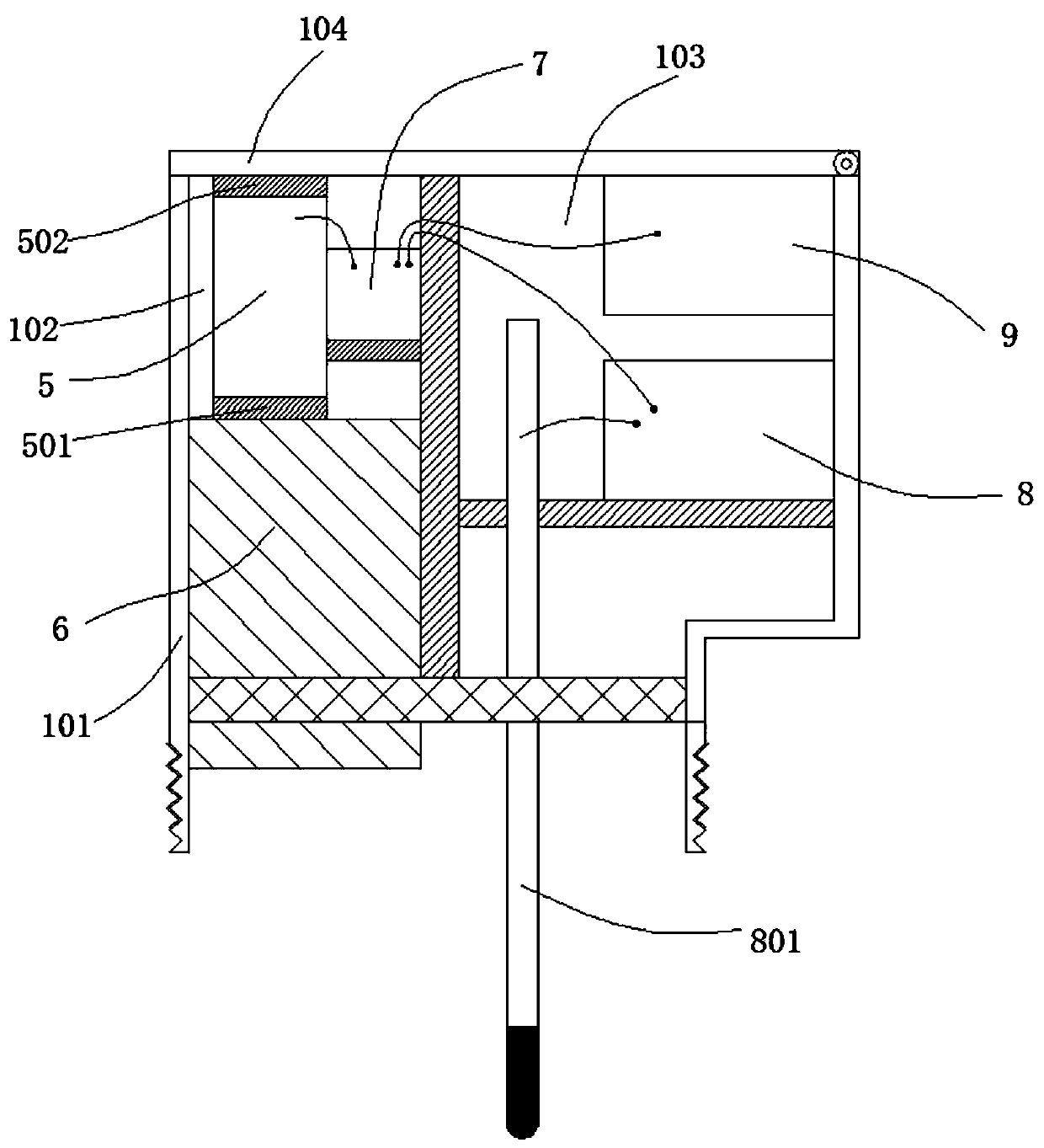

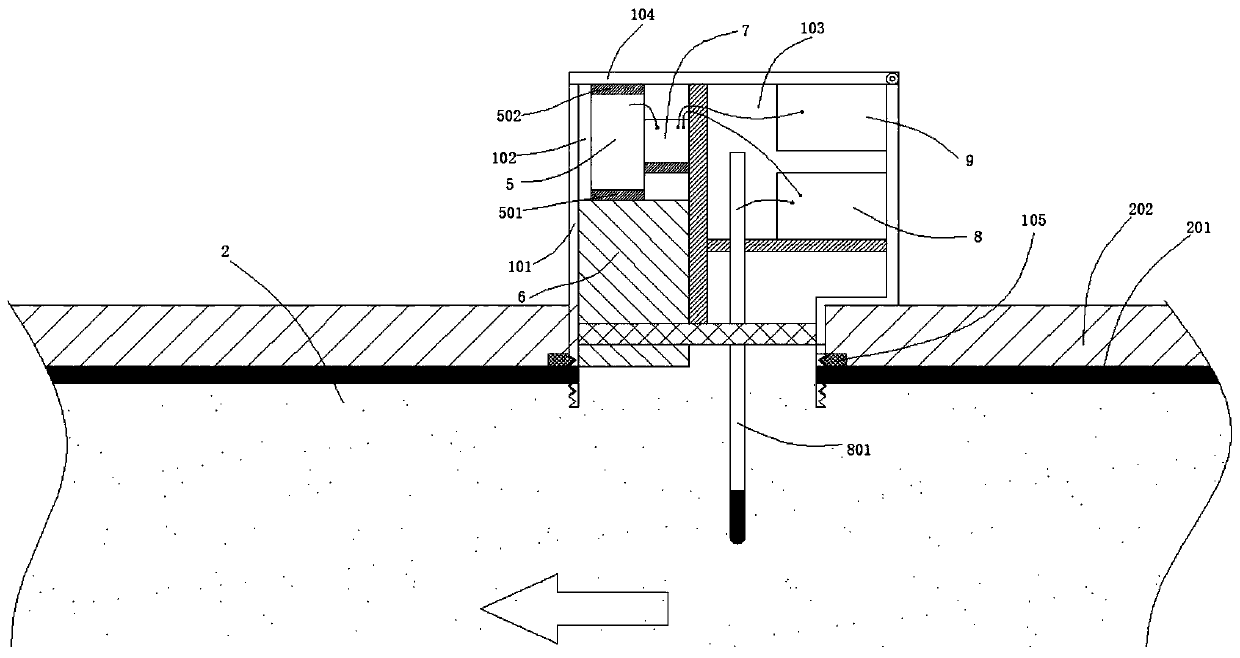

Heat distribution pipeline state parameter acquisition device based on semiconductor thermoelectric power generation

ActiveCN111525840ASave energyNot affected by power supplyMeasurement devicesGenerators/motorsThermodynamicsProcess engineering

The invention discloses a heat distribution pipeline state parameter acquisition device based on semiconductor thermoelectric power generation. The device comprises: a thermal energy semiconductor thermoelectric power generation module, a heat conduction end, a constant voltage module, a parameter acquisition module and a communication module, wherein the thermal energy semiconductor thermoelectric power generation module comprises a cold contact surface and a hot contact surface, the cold contact surface is in contact with the environment, the hot contact surface is contacted with the heat conduction end, the heat conduction end is attached to the surface of a heat distribution pipeline or extends into the heat distribution pipeline, the parameter acquisition module is provided with a parameter acquisition detection end extending into the heat distribution pipeline, and the parameter acquisition module acquires each parameter in the heat distribution pipeline through the parameter acquisition detection end; and a communication module for sending the parameters acquired by the parameter acquisition module to an external receiving end, and the thermal energy semiconductor thermoelectric power generation module converts high-temperature heat energy in the heat distribution pipeline into electric energy and supplies power to the parameter acquisition module and the communication module. According to the invention, heat energy in a heat distribution pipeline is used for power generation, and the device is suitable for scenes where power cannot be taken and is not affected by environmental conditions.

Owner:浙江英集动力科技有限公司

A method for formulating welding process parameters of pe electrofusion pipe fittings based on finite element

ActiveCN103745053BGuarantee welding qualityImprove formulation efficiencySpecial data processing applicationsPipe fittingFinite element method

The invention discloses a PE electric smelting pipe fitting welding parameter setting method based on finite elements. The PE electric smelting pipe fitting welding parameter setting method comprises the following steps: (1) initially determining the welding voltage of a PE electric smelting pipe fitting; (2) setting thermal analysis parameters; (3) establishing a finite element heat transfer model for connecting the electric smelting pipe fitting and a pipe in ANSYS WORKBENCH; (4) setting contact thermal conductivity coefficients between a thermal fuse and the PE material and between the electric smelting pipe fitting and the pipe in the electric smelting pipe fitting; (5) setting the division type of a model mesh and the size of the mesh, and then dividing the mesh; (6) carrying out loading heating on the model; (7) setting analysis time and step length for solution; (8) extracting the result of the solution and determining welding parameters. According to the method, the setting efficiency of the welding parameters of the electric smelting pipe fitting is improved, and the welding quality of the PE electric smelting pipe fitting is ensured.

Owner:JIANGSU SHUANGTENG PIPE IND CO LTD +1

Method for testing contact thermal resistance of GH4169/GH4169 by additional heating

InactiveCN101980008BEasy to testThe testing process is simpleMaterial heat developmentRegression analysisStepwise regression

The invention discloses a method for testing the contact thermal resistance of GH4169 / GH4169 by additional heating, which comprises the following steps of: firstly, determining a reduced elastic modulus between two materials; secondly, modeling according to a plastic deformation theory; thirdly, simplifying a model; and finally, determining unknown parameters through a stepwise regression test toobtain an optimal regression equation; obtaining contact thermal conductance hs according to a regression analysis result, wherein hs is 145583796.6T0.159P-1.932 when temperature and pressure values are independent variables and the temperature is between 100 and 600 DEG C, and hs is 165751460.8P-1.863 when only the pressure value is an independent variable; and obtaining the contact thermal resistance R according to a formula R=1 / hs, wherein test data required by the regression test is obtained by a contact thermal resistance test, and temperature compensation is performed on a contact interface of two samples in the testing process. By the method, the required parameters can be obtained only according to the test data, and the contact thermal resistance can be obtained according to a simple formula under the condition of arbitrarily changing test temperature and test pressure, so that the contact thermal resistance testing process is simple and can be reused.

Owner:BEIHANG UNIV

Contact thermal resistance test method of GH4169/K417 alloy with additional heating

InactiveCN102033078BThe testing process is simpleEasy to testMaterial heat developmentRegression analysisMetallic materials

Owner:BEIHANG UNIV

Method of connecting heat conduit and radiation fin

InactiveCN1319160CSolve the problem of thermal resistance caused by the gapSolve the problem of thermal resistanceDigital data processing detailsSemiconductor/solid-state device detailsThermal contact conductanceEngineering

A jointing method of heat conduct pipe and radiating fin. A open is on the radiating fin then rotating the heat conduct pipe, and the radiating fin paralleled move to the conduct pipe; when the open contacts the heat conduct pipe, holding the heat conduct pipe rotating, and generating friction between the heat conduct pipe and the radiating fin the heat created by friction make the frictional surface as plastic melting state; and the heat conduct pipe and the open of the joined by pressure.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

External water-cooling radiator for notebook computer

InactiveCN111708420AReduce the temperatureAutomatic adjustment of placement inclinationDigital data processing detailsCold airThermal contact conductance

The invention discloses an external water-cooling radiator for a notebook computer. The external water-cooling radiator includes a bottom plate; a rotating plate is hinged to the right end of the upper surface of the bottom plate; a first cavity which is through up and down is formed in the rotating plate; metal pipes which are uniformly distributed at equal intervals and have better heat-conducting property are fixedly arranged between the left wall and the right wall of the first cavity; fixing rods which are symmetrical in the front-back direction are fixedly arranged on the lower surface of the rotating plate. A fan mechanism used for cooling a notebook computer is fixed to the left end of the fixing rod. An angle mechanism used for controlling the inclination angle of the rotating plate is arranged between the left end of the lower surface of the rotating plate and the left end of the upper surface of the bottom plate. Through contact heat conduction water-cooling heat dissipationof the metal pipe and the metal shell of the notebook computer and cold air heat convection heat dissipation of the fan, the temperature of the notebook computer can be more effectively reduced, theheat dissipation effect can be enhanced by adding ice blocks to reduce the water temperature, and the placement inclination angle of the notebook computer can be automatically adjusted.

Owner:BINZHOU FANGXIN COMP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com