Method of connecting heat conduit and radiation fin

A technology of heat dissipation fins and heat dissipation fin groups, which is applied in semiconductor devices, indirect heat exchangers, lighting and heating equipment, etc., and can solve problems such as thermal resistance of heat pipes and heat dissipation fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

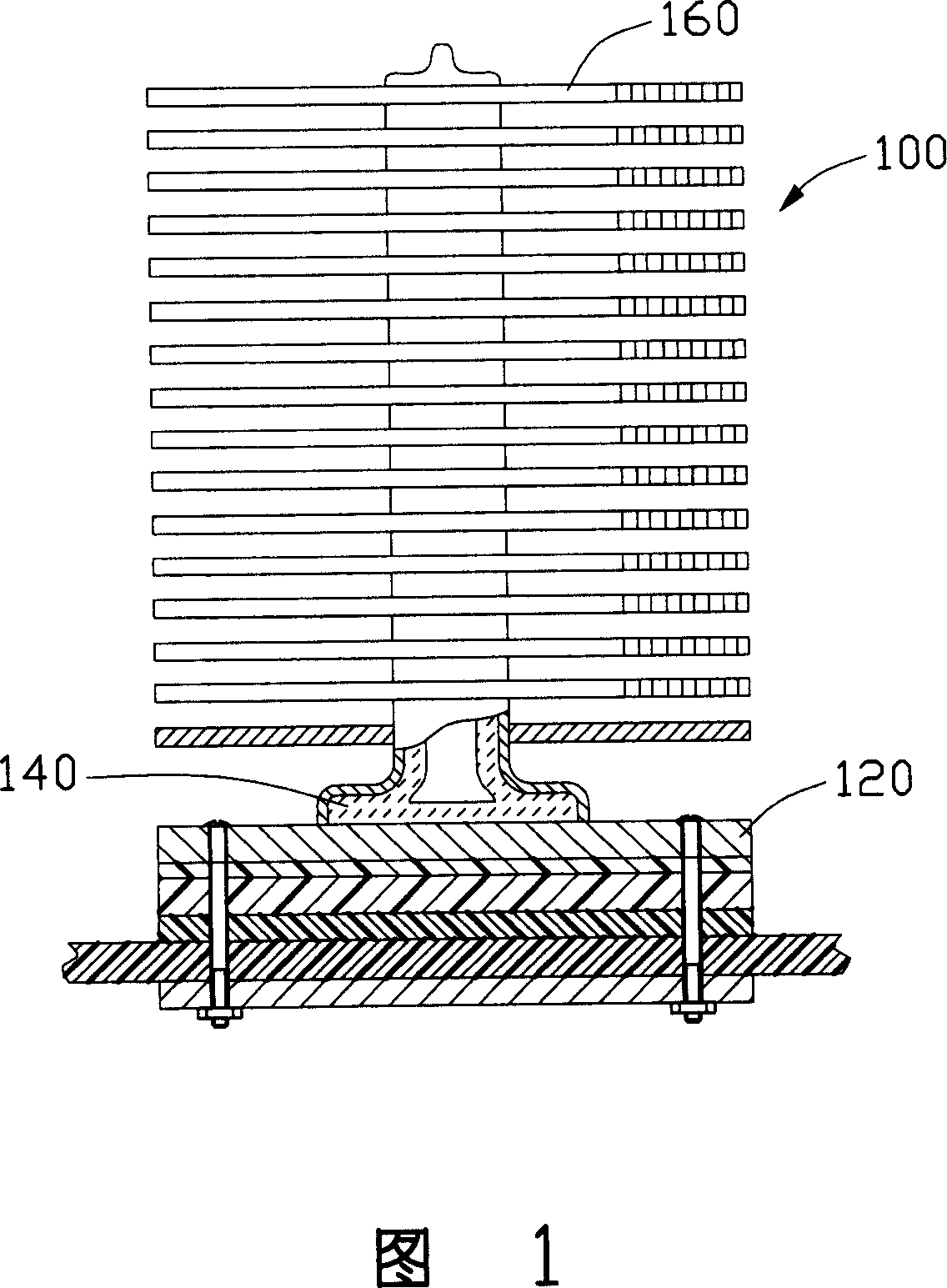

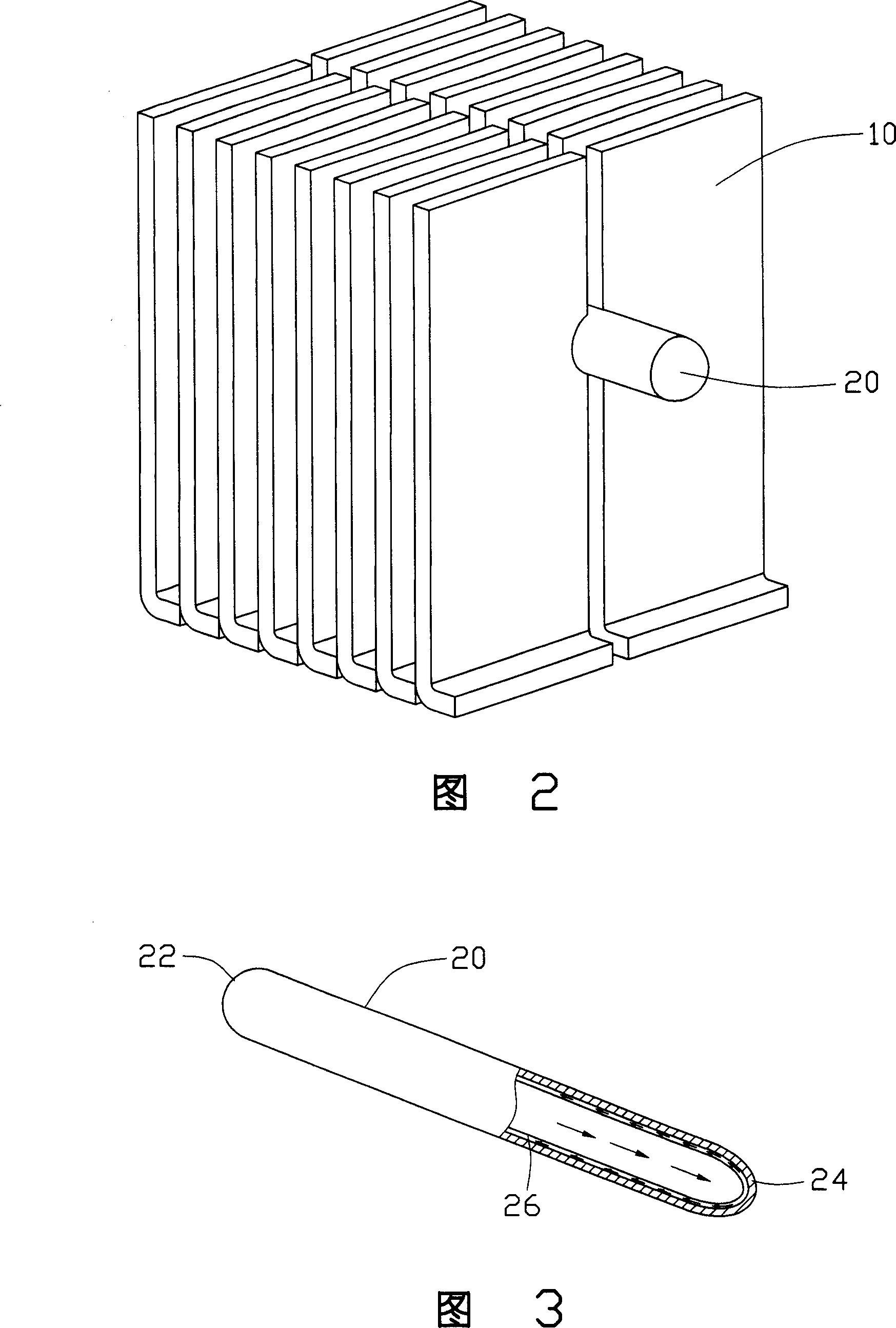

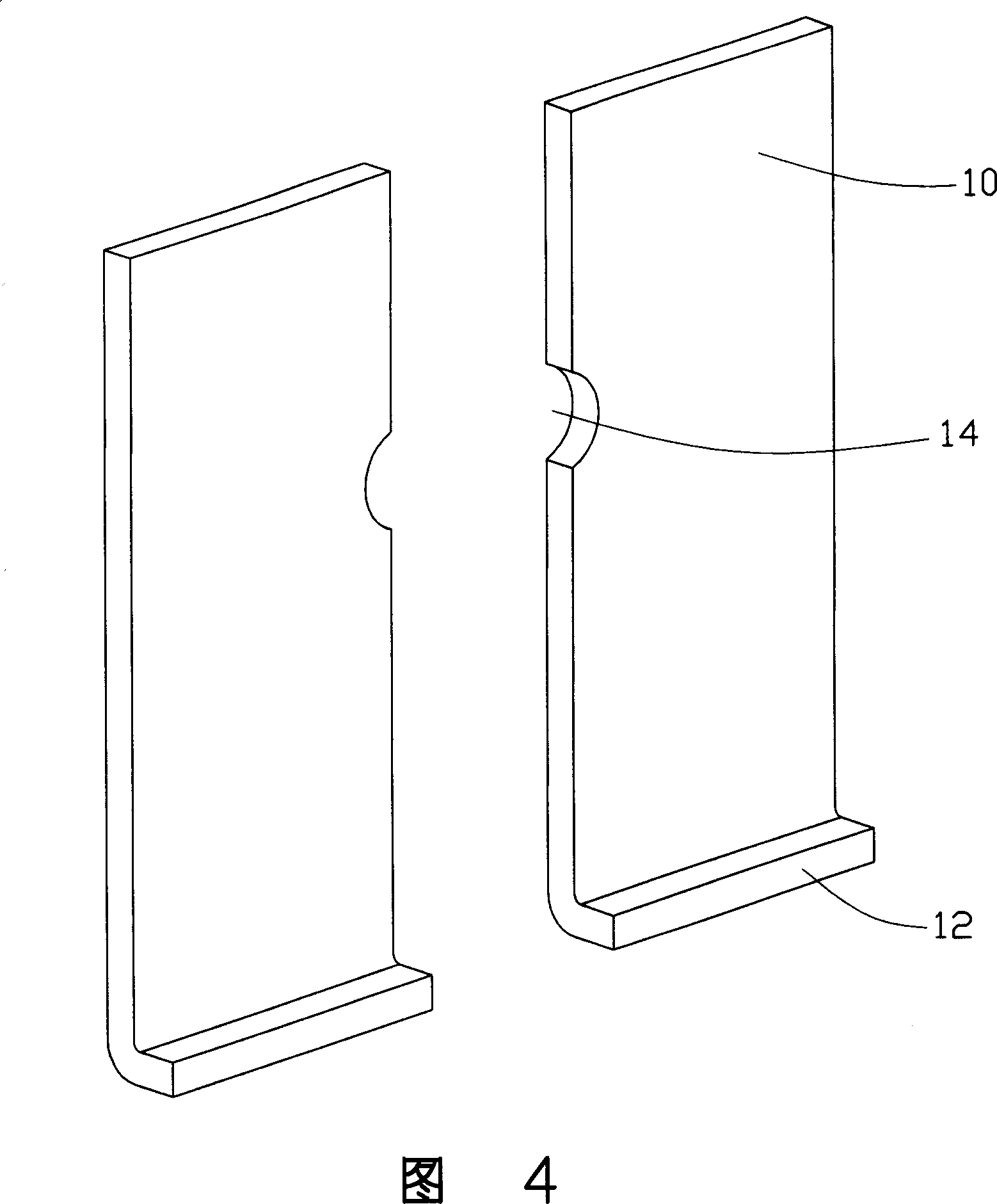

[0014] The method for combining the heat pipe and the heat dissipation fins of the present invention is applied to fast and tightly connecting the heat dissipation fins to the heat pipe. As shown in FIG. 2 , the present invention takes the connection of the heat pipe 20 and the heat dissipation fin 10 as a specific implementation mode to describe the present invention.

[0015] As shown in Figure 3, the heat pipe 20 has a pipe body, and first and second sealing ends 22, 24, wherein the inner wall of the pipe is provided with a capillary structure 26, and is filled with a working material for gas-liquid two-phase change. Fluid, the working fluid is preferably water or acetone; the capillary structure 26 can provide the power to return the working fluid that is in liquid state after releasing heat and cooling, and can also guide the fluid that is in gaseous state after absorbing heat and evaporating. , wire mesh type and sintered type are preferred; after filling the working flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com