Multi-color multi-material photo-thermal sensor based on thin film thermoelectric device and test equipment

A thermoelectric device, multi-color technology, applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problems of low measurement accuracy and difficulty in effective and accurate measurement of small temperature difference changes, so as to increase signal sensitivity and solve interface problems. Thermal resistance and electrical resistance issues, the effect of increasing integration density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

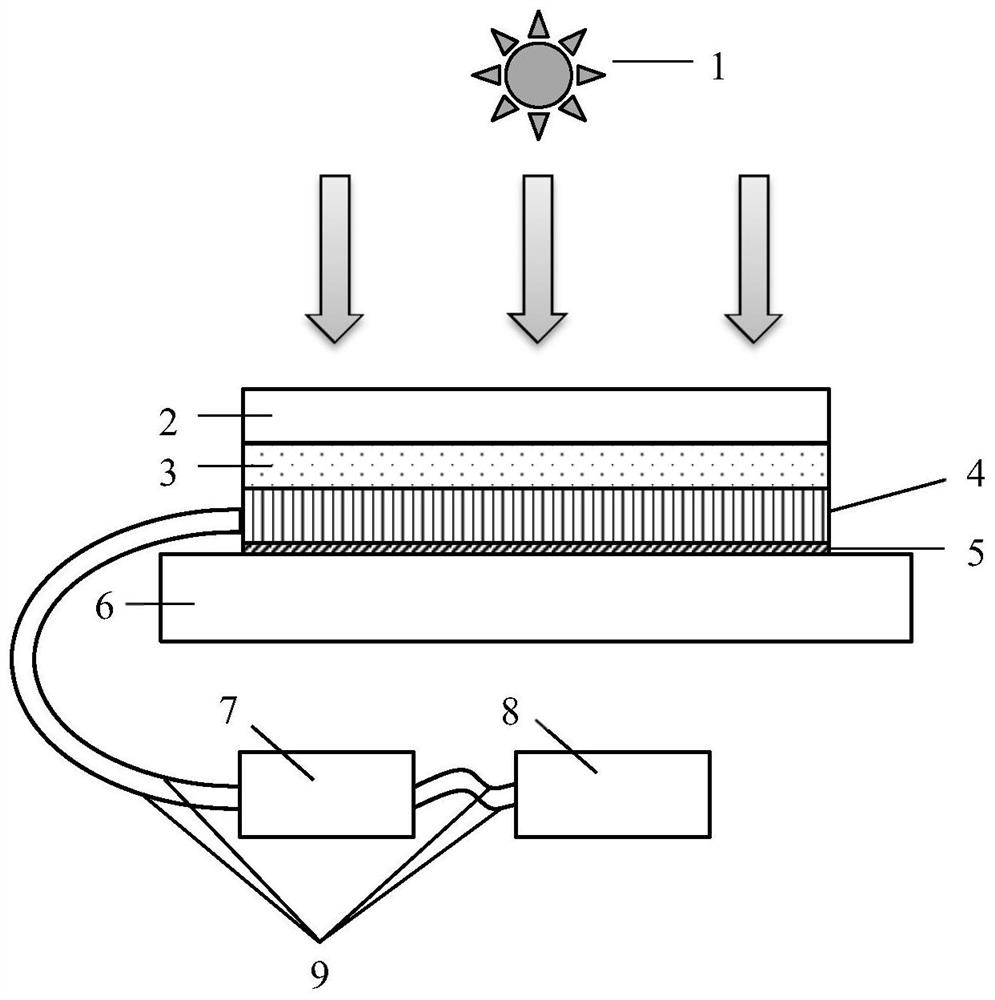

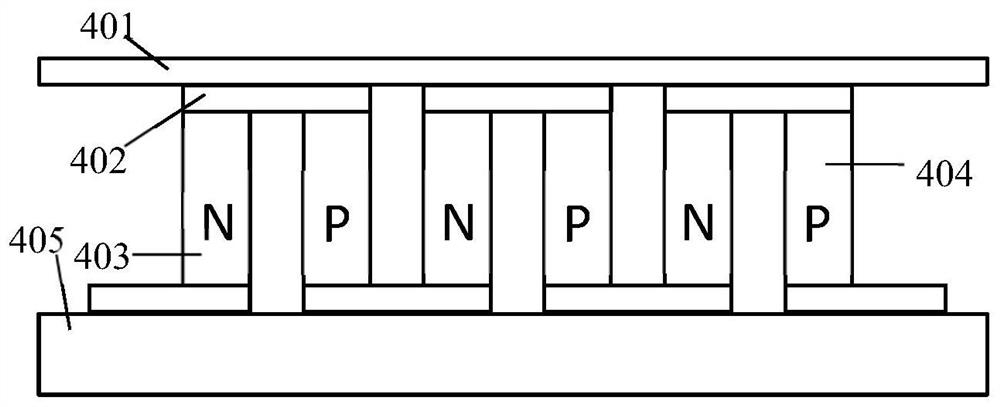

[0029] Such as figure 1 As shown, this embodiment provides a multi-color and multi-material photothermal sensor based on thin-film thermoelectric devices, including a light source 1, a quartz plate 2, a thin-film thermoelectric device 4, a temperature control module 6, a voltage boosting and noise reduction module 7, and a data acquisition module 8. One end of the thin-film thermoelectric device 4 is the hot end in contact with the sample 3 to be tested, and the other end is in contact with the temperature control module 6. The voltage boosting and noise reduction module 7 is respectively connected to the thin-film thermoelectric device 4 and the data acquisition module 8 through wires 9. The thin-film thermoelectric Device 4 adopts a π-type structure in which the heat flow is perpendicular to the interface. When the photothermal sensor is used, the sample 3 to be tested is placed on the hot end, and receives the light source 1 through the quartz plate 2. The temperature contr...

Embodiment 2

[0036] In the multi-color and multi-material photothermal sensor based on the thin-film thermoelectric device provided in this embodiment, the thin-film thermoelectric device 4 is in contact with the temperature control module 6 through the thermally conductive interface material 5, so that the cold end of the thin-film thermoelectric device is in close contact with the temperature control module, reducing the contact thermal resistance. The thermally conductive interface material can be thermally conductive silicone grease, thermally conductive silicone sheet, thermally conductive phase change material, or thermally conductive tape. All the other are with embodiment 1.

Embodiment 3

[0038] In the multi-color and multi-material photothermal sensor based on thin-film thermoelectric devices provided in this embodiment, the quartz plate is a high-transmittance quartz plate, which has high transmittance to ultraviolet light, visible light, and infrared light. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com