Method and device for carrying out dry quenching and recovering heat energy in radiation and conduction heat absorption mode

A heat recovery and radiation heat transfer technology, applied in the steam generation method using heat carrier, coke cooling, coke oven, etc., can solve the problems of high equipment investment, high operating cost, complex equipment, etc., and achieve low operating cost, The equipment is simple and the effect of solving energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

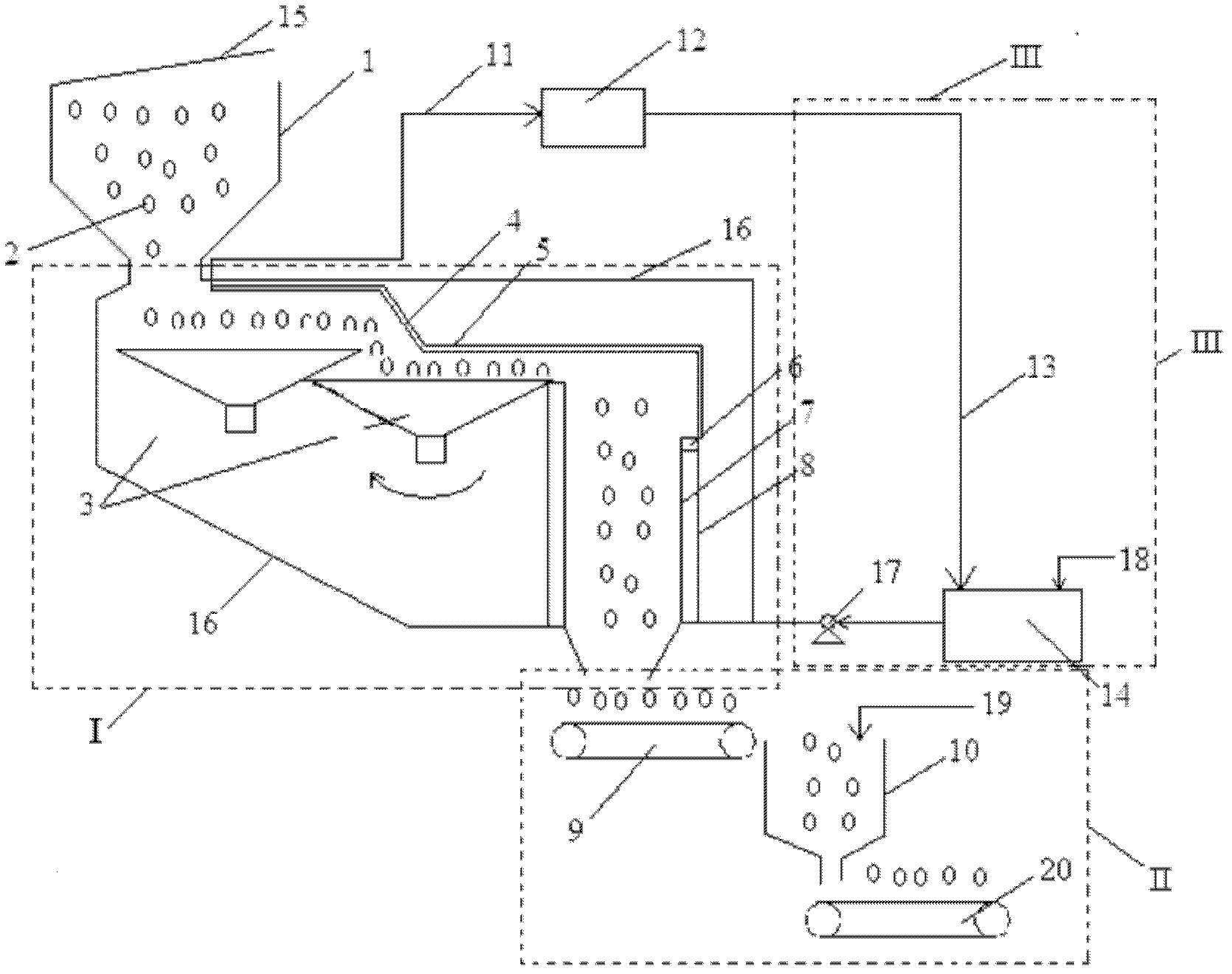

[0023] Radiation and conduction endothermic coke dry quenching process and equipment such as figure 1 and figure 2 As shown, it is composed of dotted dry quenching furnace I, low temperature coke discharge system II, water circulation system III and steam generation system IV.

[0024] The red coke 2 coming out of the coke oven is loaded into the red coke storage tank 1 in the dry quenching process by opening the top cover 15 of the red coke inlet at about 1000 ° C. After the red coke is loaded, the red coke storage tank top cover 15 closure. The coke entering the red coke storage tank moves slowly on the rotating disc red coke conveying device 3, and conducts radiation heat transfer to the radiation heat transfer tube, and a radiation heat transfer grid 4 is arranged between the red coke and the radiation heat transfer tube. The coke is conveyed through two stages and the temperature drops to 600-700°C, then enters the heat conduction heat transfer section, moves slowly by...

Embodiment 2

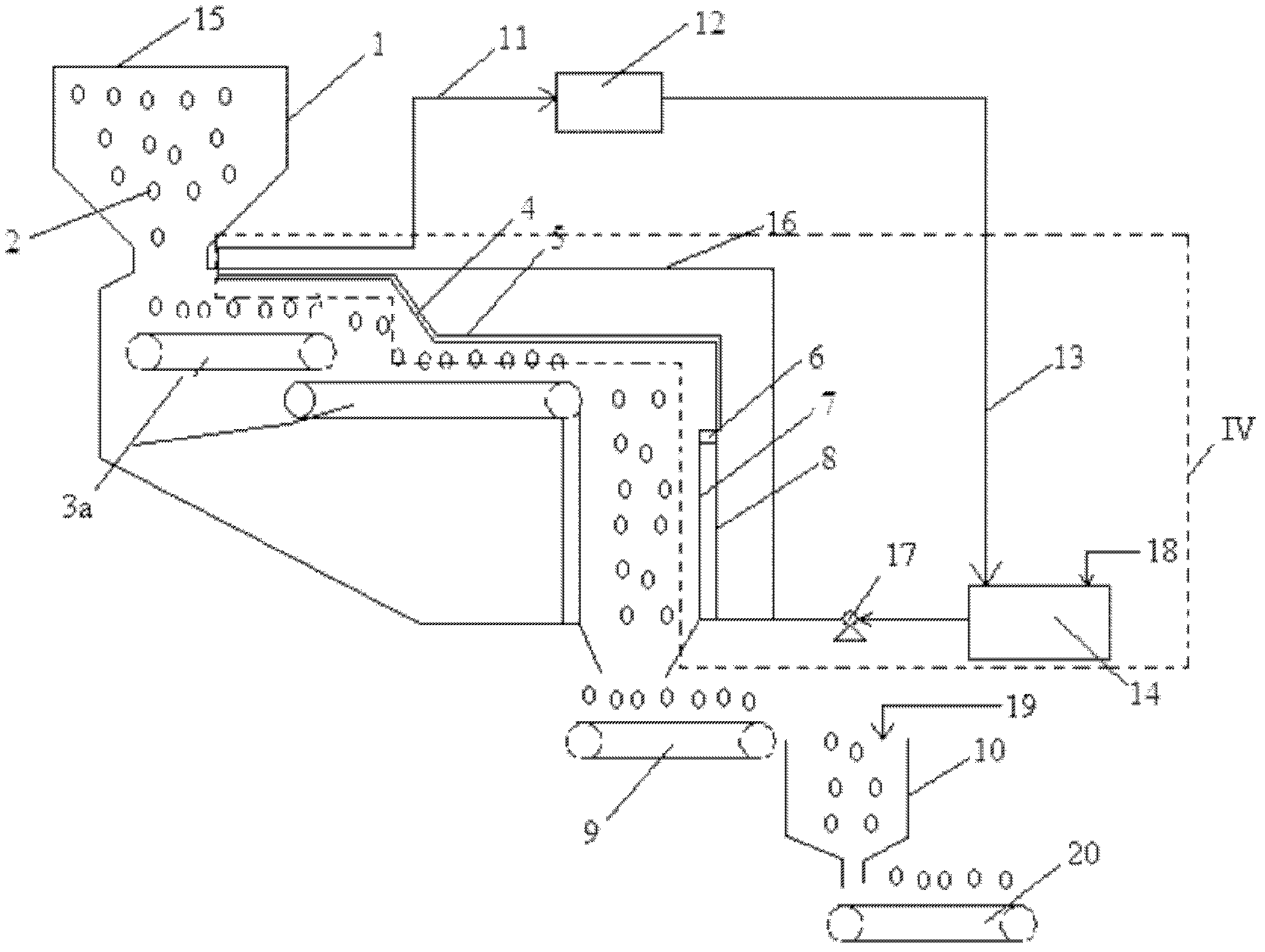

[0026] This embodiment adopts the radiation and conduction heat-absorbing CDQ process in which the storage tank is a vertical cylinder. The CDQ process and equipment are as follows figure 2 As shown, the red coke coming out of the coke oven is sent to the red coke storage tank in the dry quenching process, and the red coke at about 1000 °C is transported by the belt conveyor 3a in the radiation heat transfer stage and slowly moves to the conduction heat transfer stage, red coke moves slowly from top to bottom under the action of gravity in the conduction heat transfer stage. The high-pressure cooling water enters the heat conduction heat pipe from bottom to top through the high-pressure water pump, conducts heat exchange with the coke, enters the saturated water vapor tank and then enters the radiation heat transfer pipe, and generates 450 ° C, 4.6 MPa after heat transfer with the upper red coke. The superheated steam enters the power generation unit. In the radiation heat t...

Embodiment 3

[0028] This embodiment adopts as Figure 4 The storage tank shown in 1a is a radiation and conduction endothermic coke CDQ process with a combination of inclined cylinder and vertical cylinder. The red coke from the coke oven is sent to the red coke storage in the CDQ process. The angle between the upper part of the inclined cylinder body and the horizontal plane of the red coke storage tank is 50°, which is conducive to the slow movement of coke under the action of gravity. After heat exchange of 1100℃ red coke, in the radiation heat exchange stage, the coke is dropped from 1100℃ to 600℃, and in the conduction heat transfer stage, the coke is no longer sprayed with water but discharged directly after being dropped from 600℃ to 150-120℃ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com