Method and device for testing thermal contact resistance of joint surfaces between cylindrical sleeve walls

A technology of contact thermal resistance and testing device, which is applied in thermomechanical coupling test and heat transfer field of solid materials, can solve the problems such as the difficulty of testing the contact thermal resistance of the interface between the walls of cylindrical sleeves, and achieve the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

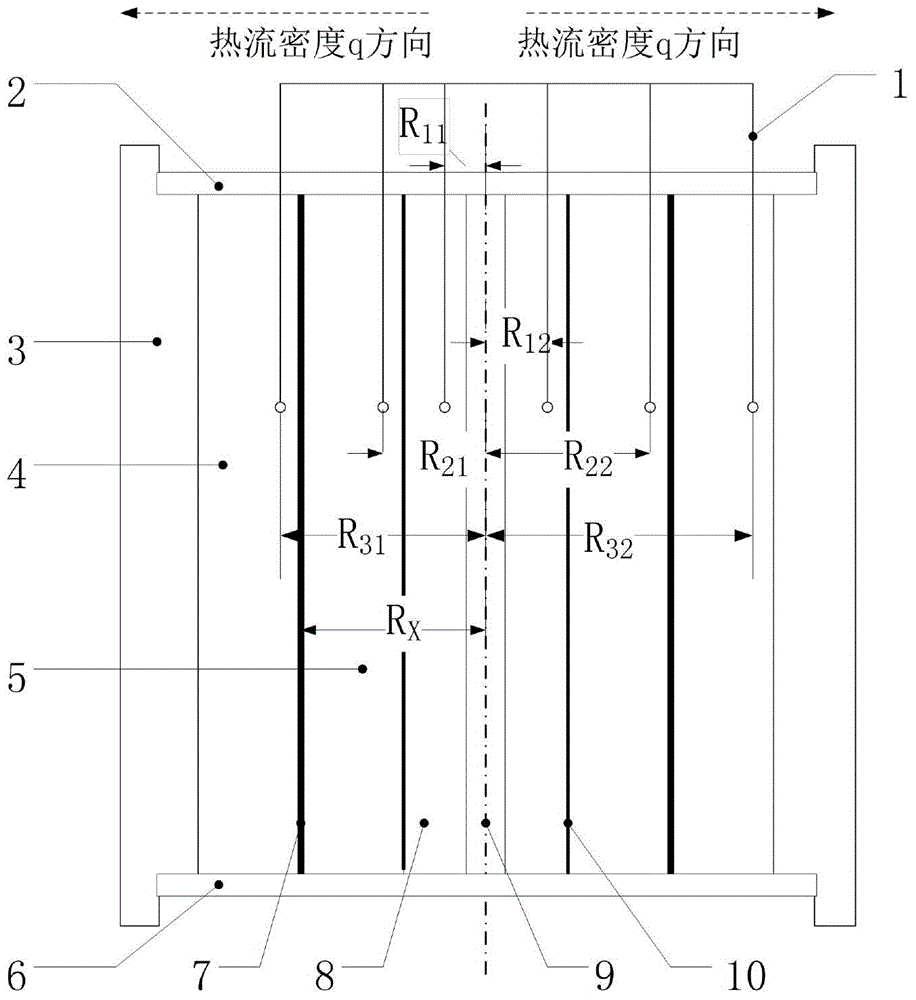

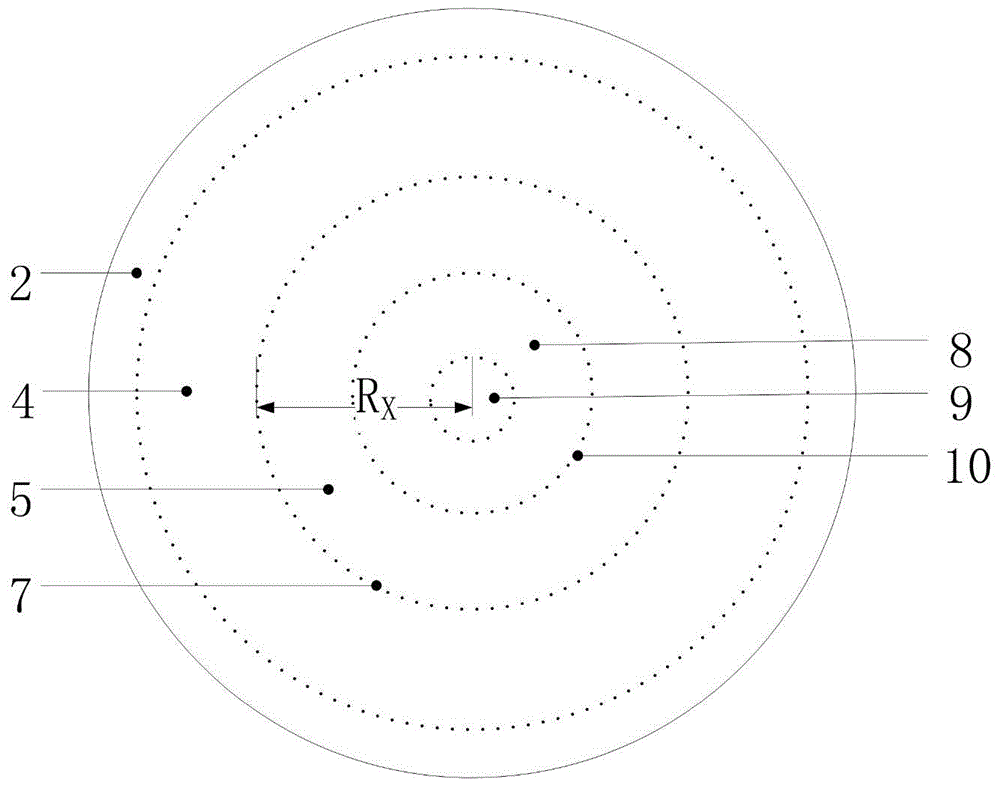

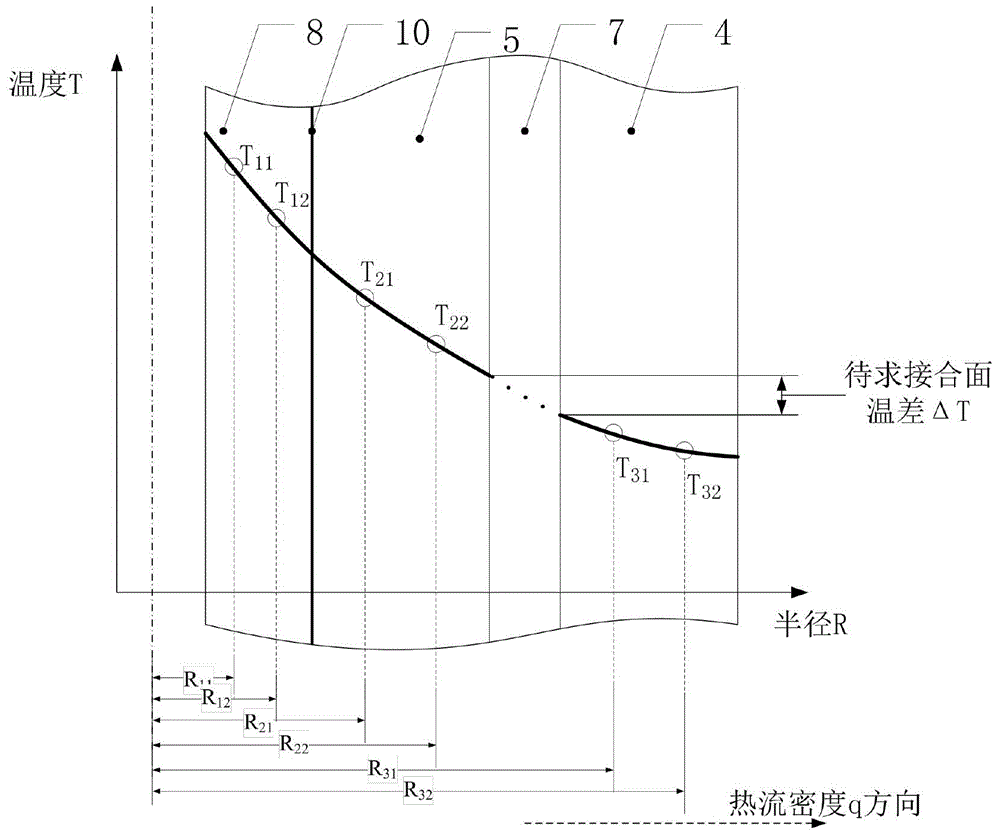

[0018] The first step, preparation of test specimens and equipment

[0019] Take two cylindrical test pieces that are in contact with each other and have a certain thickness, that is, the outer ring test piece 4 and the inner ring test piece 5; process a calibrated copper ring heat flow meter 8 and place it inside the inner ring test piece 5 to closely fit it . The upper and lower axial ends of the entire test device are respectively provided with an upper heat insulation device 2 and a lower heat insulation device 6 to ensure that the heat flow direction propagates along the radial direction. A heating device is arranged inside the calibration copper ring heat flow meter 8, and a cooling ring 3 is arranged outside the outer ring test piece 4 to form a temperature gradient. Temperature sensors 1 are installed at different radii of the calibrated copper heat flow meter 8 , at different radii of the inner ring test piece 5 , and at different radii of the outer ring test piece 4...

Embodiment 2

[0060] The difference from Example 1 is that in this example, the materials of the two test pieces, the temperature values of each measuring point, and the matching relationship are kept consistent at a certain value, and the roughness Ra of the surface of the test piece is changed, and then each roughness Ra is obtained by calculation. The contact thermal resistance R of the cylinder sleeve wall under different surface roughness Ra is obtained through numerical fitting to obtain the relationship between the contact thermal resistance R of the joint surface between the cylindrical sleeve walls under different surface roughness Ra when the test piece material, the temperature value of the measuring point, and the matching relationship are constant.

Embodiment 3

[0062] The difference from Embodiment 1 and Example 2 is that in this embodiment, the materials of the two test pieces, the temperature values of each measuring point, and the roughness Ra of the surface of the test piece are kept consistent at a certain value, and the matching relationship between the walls of the cylindrical sleeve is changed. Then, the thermal contact resistance R under different matching relationships can be obtained by calculation, and the material of the test piece, the temperature value of the measuring point, and the roughness Ra of the surface of the test piece can be obtained through numerical fitting. The relationship between the surface contact thermal resistance R.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com