Board card structure for protecting thermal contact surface based on reed

A technology of thermal contact surface and reed, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problem of corrosion resistance of damaged materials, and achieve the effect of rapid detachment and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

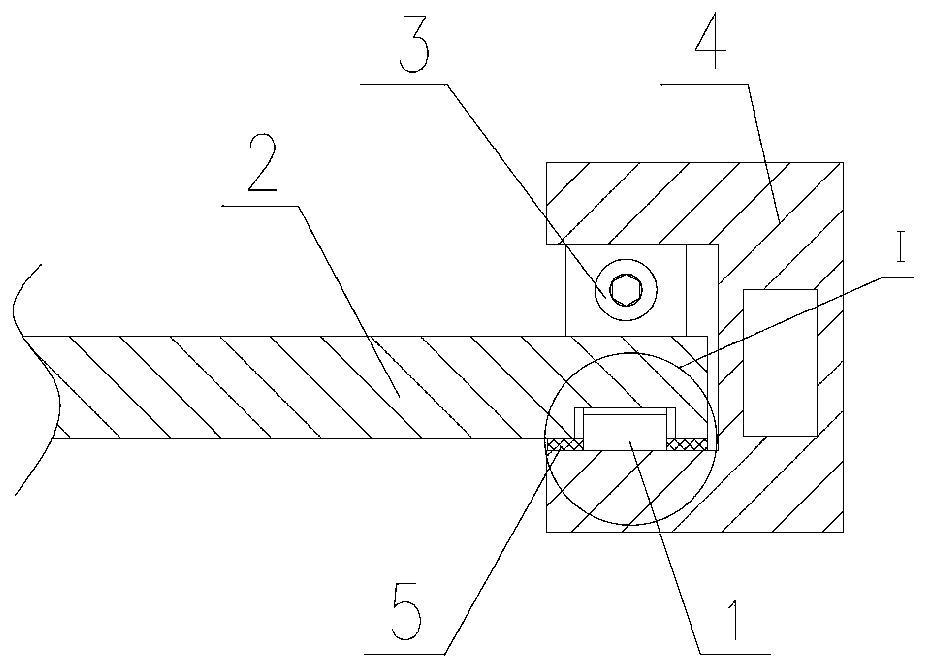

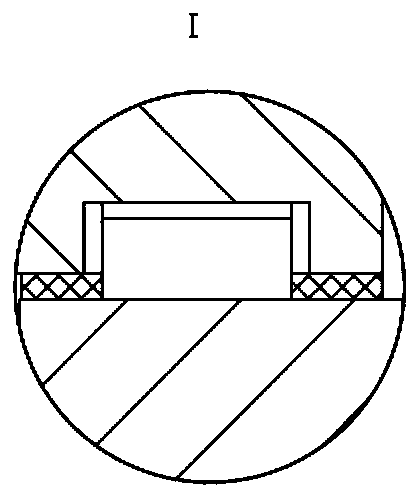

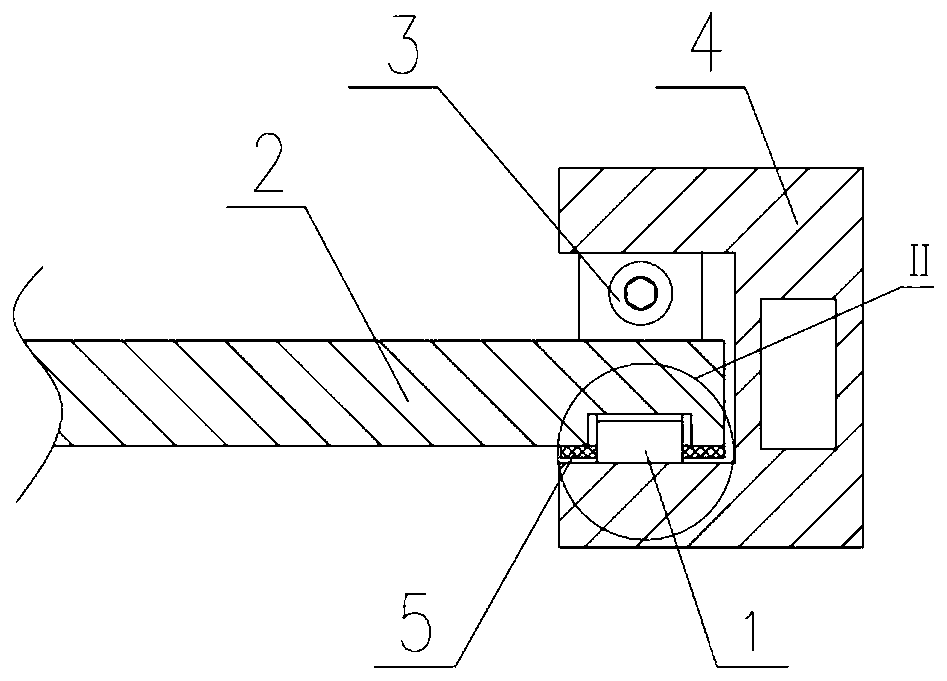

[0015] The reed-based liquid-cooled VPX chassis board thermal contact surface protection and detachment structure proposed by the present invention installs the reed 1 in the groove of the heat transfer cold plate 2, and the reed 1 is glued to the heat transfer cold plate 2 On the bottom of the groove, the highest point of the reed 1 is 0.8 mm to 1.0 mm higher than the surface of the thermal interface material 5, and the highest position of the reed 1 is connected to the slot of the heat dissipation cold plate 4 during the insertion and removal process of the heat transfer cold plate 2 and the heat dissipation cold plate 4 The contact surface contacts and produces relative motion, thereby protecting the heat transfer cold plate 2 and the thermal interface material 5 on the thermal interface. After the heat transfer cold plate 2 is inserted in place, it is locked by the locking device 3. At this time, the reed 1 is The pressure is deformed, and the heat transfer cold plate 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com