Self-resistance electric heating intelligent incremental forming method

A technology of incremental forming and electric heating, applied in forming tools, metal processing equipment, electrical digital data processing, etc., can solve the problems of reducing the efficiency and intelligence of process manufacturing, and unable to achieve accurate analysis of such processes, to improve usability, Accurate results and extended application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

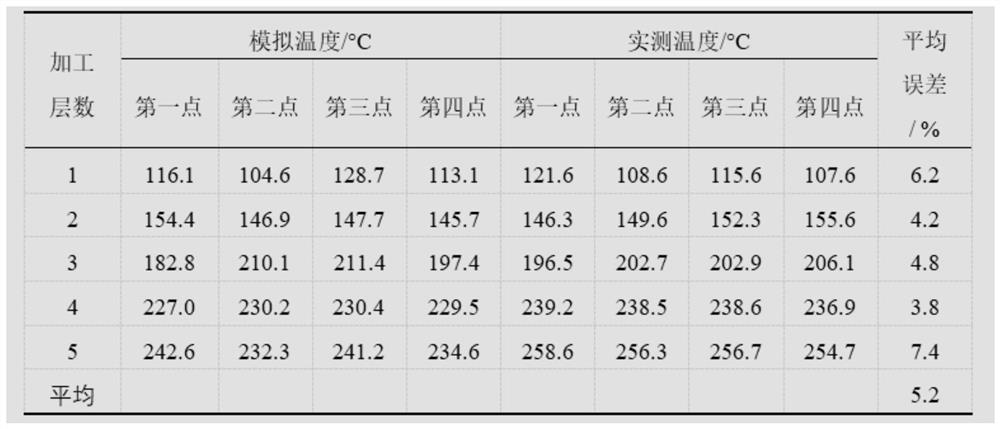

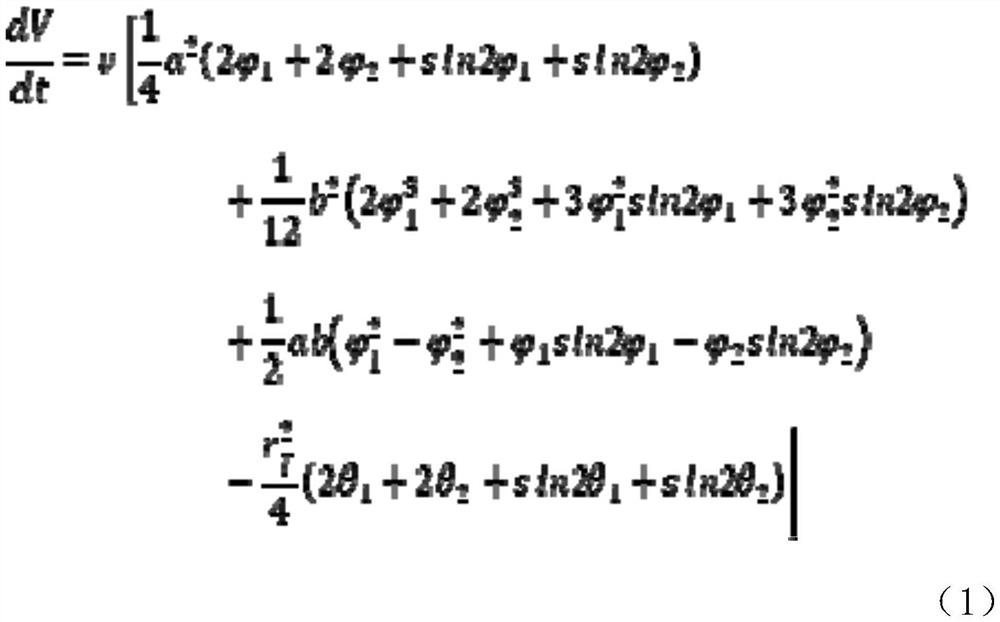

[0029] Existing studies have shown that the Joule heating effect in self-resistance electric heating progressive forming is based on the phenomenon of self-resistance electric heating in the deformation area, and the temperature rise effect of the deformation area changes with the change of the equivalent resistance, current intensity and the spatial size of the deformation area. However, the existing research usually uses trial and error methods to set the heat flow to describe the temperature change in the deformation region.

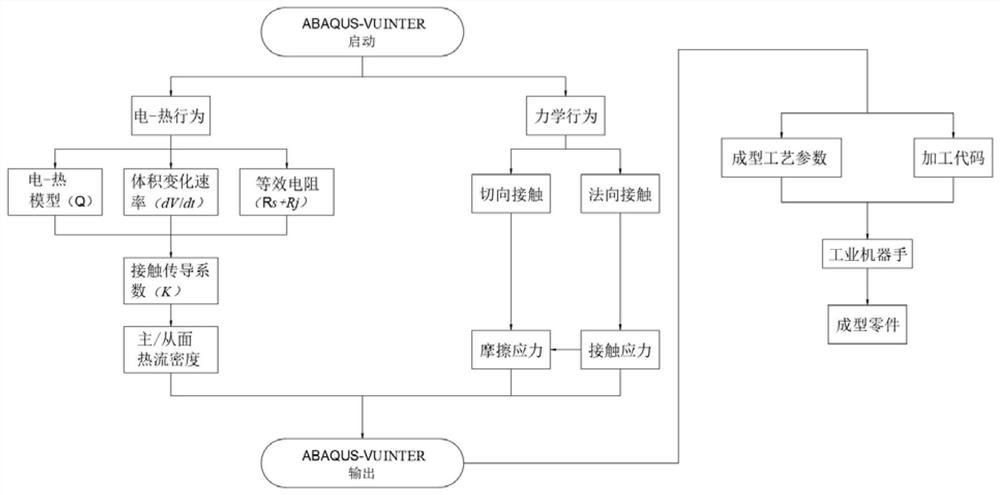

[0030] A numerical simulation method of the Joule effect in self-resistance electric heating progressive forming of the present invention is characterized in that it considers the connection between the electric field parameter, the volume change of the deformation region and the forming process parameters, and uses the ABAQUS-VUINTER user subroutine of the display algorithm Secondary development of software.

[0031] see Figure 1-2 , the invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com