Hot stamping measurement tool and use method thereof

A technology for measuring tooling and hot stamping, which is applied in the direction of material thermal conductivity, etc., can solve the problems of affecting the surface morphology of the mold and shortening the life of the mold, and achieve the effect of avoiding high-temperature sheets, improving life and product performance, and rich functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

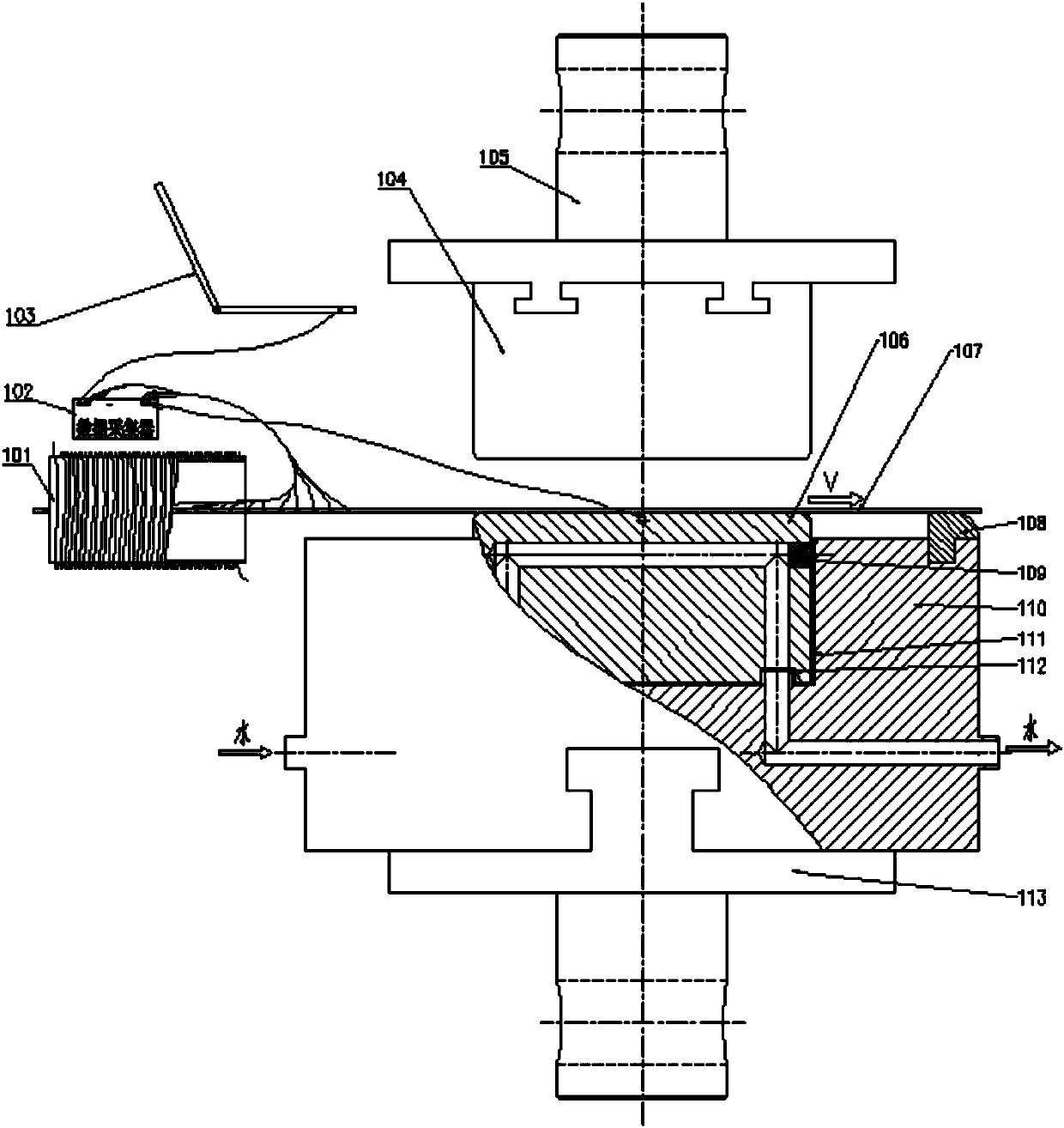

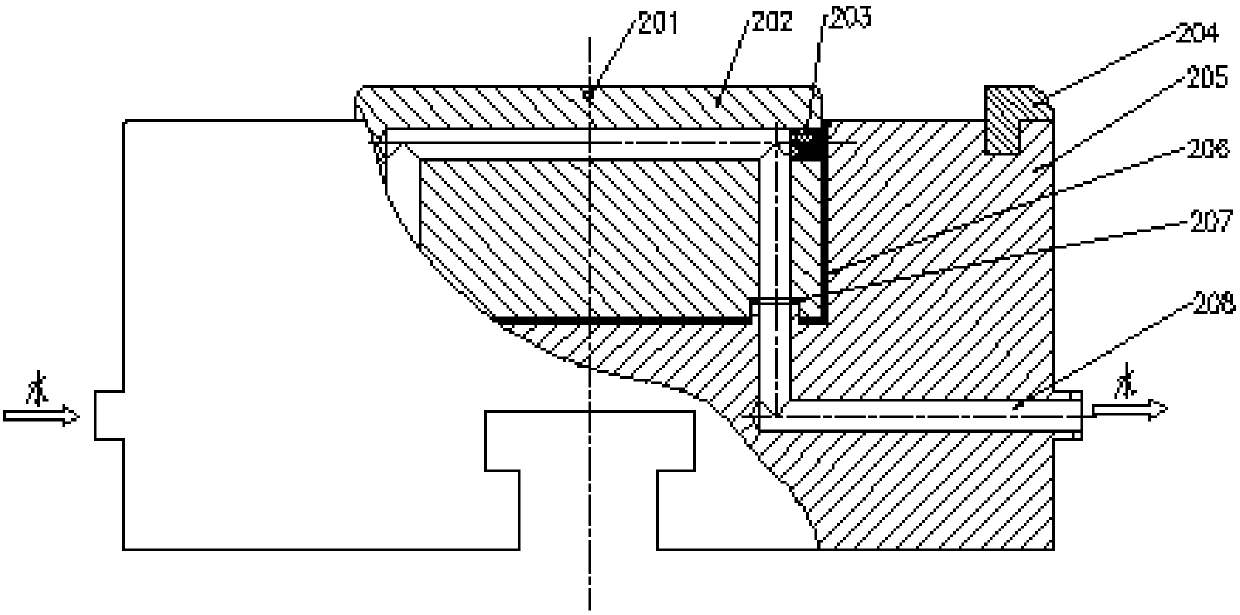

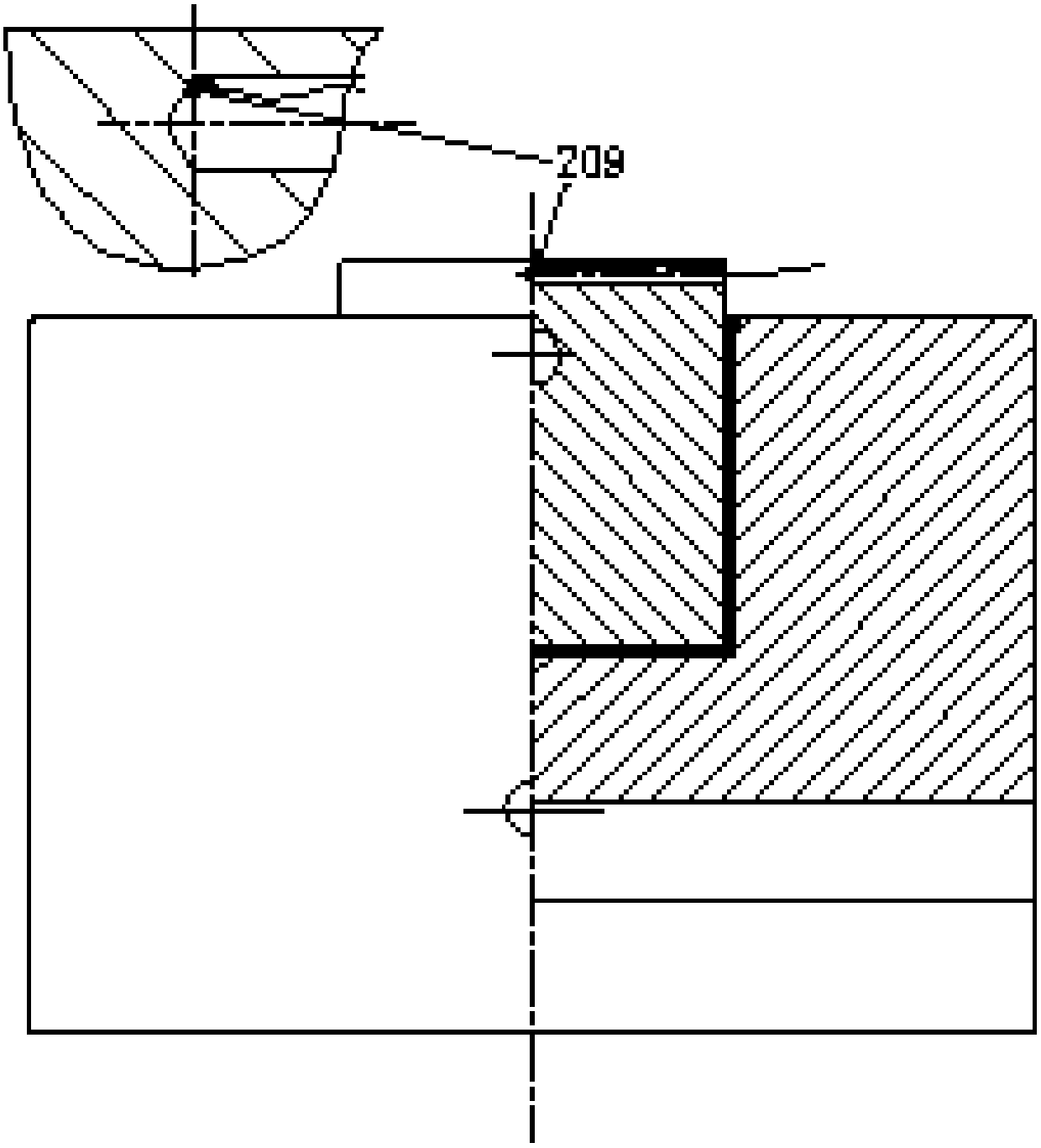

[0045] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of the hot stamping measurement tooling in a preferred embodiment of the present invention. The present invention proposes a hot stamping measuring tool, including:

[0046] Electric induction heating device 101, data collector 102, computer 103, indenter insert 104, clamp 105 connected to the tensile rod on the single-drawing machine, test insert 106, sheet material 107, tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com