Stator assembly and motor

A component and stator technology, applied in the field of stator components and motors, can solve the problems of insufficient payload of drones, low power density of motors, and elevated operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

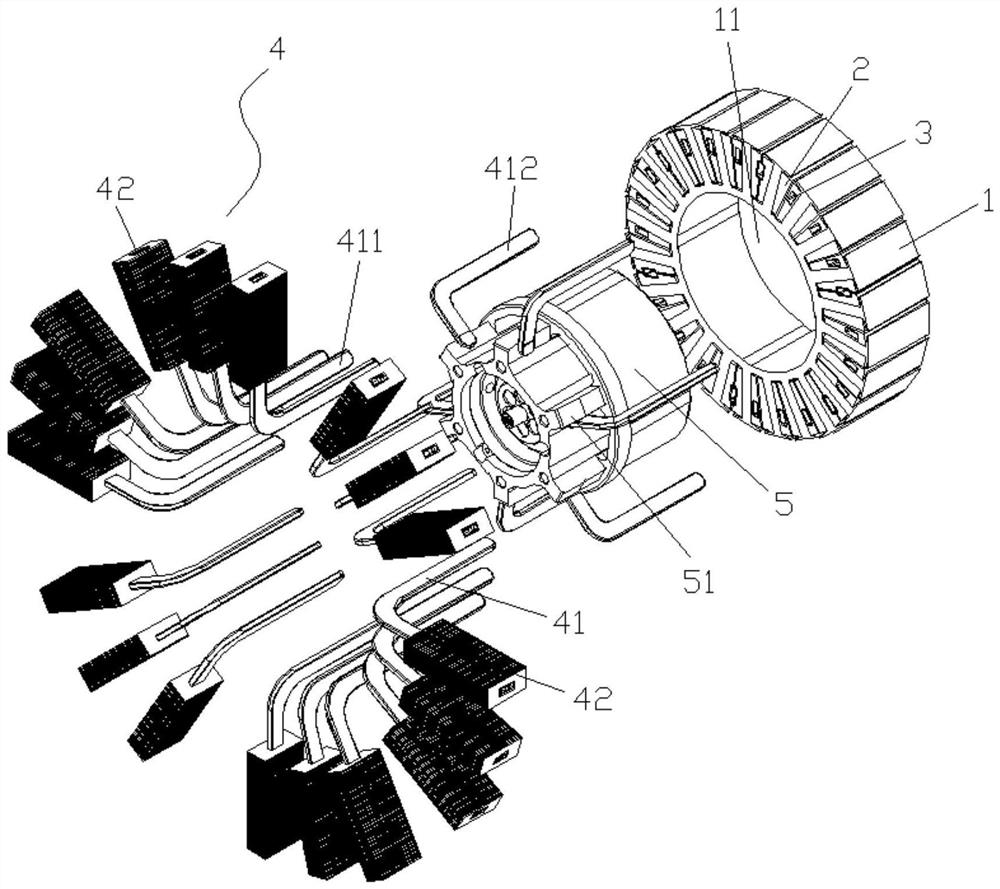

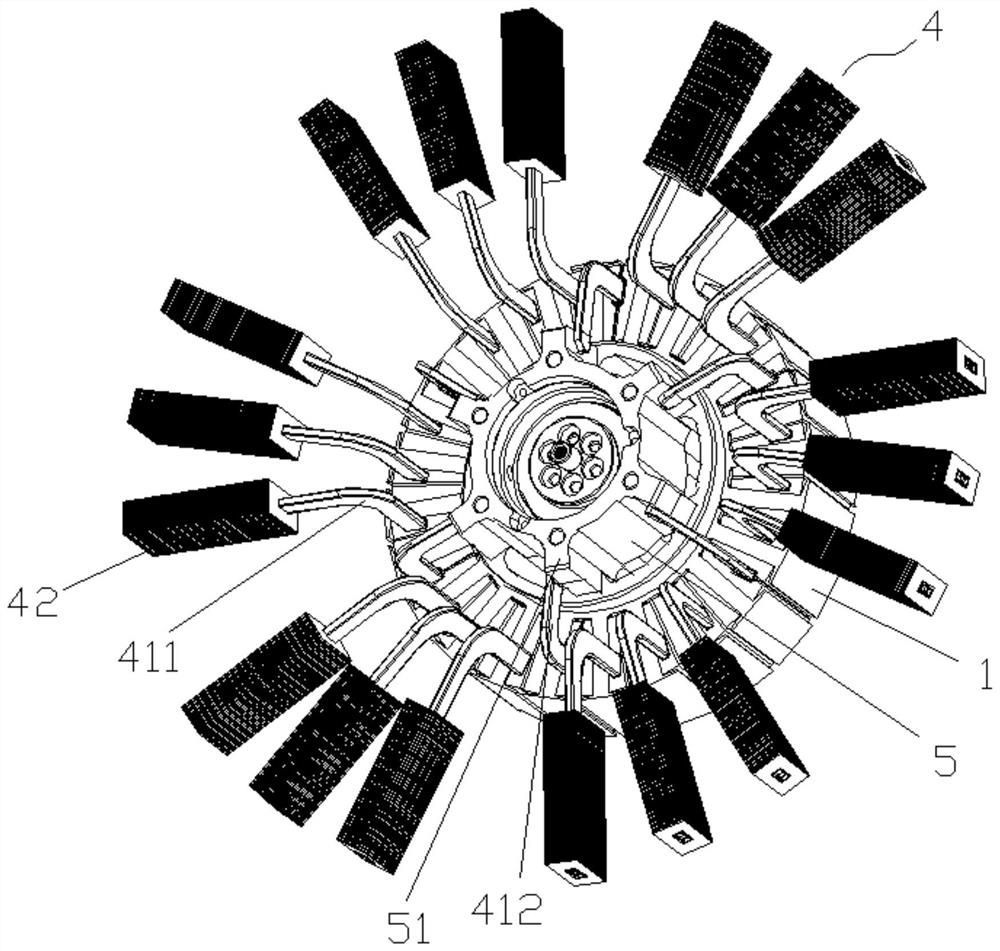

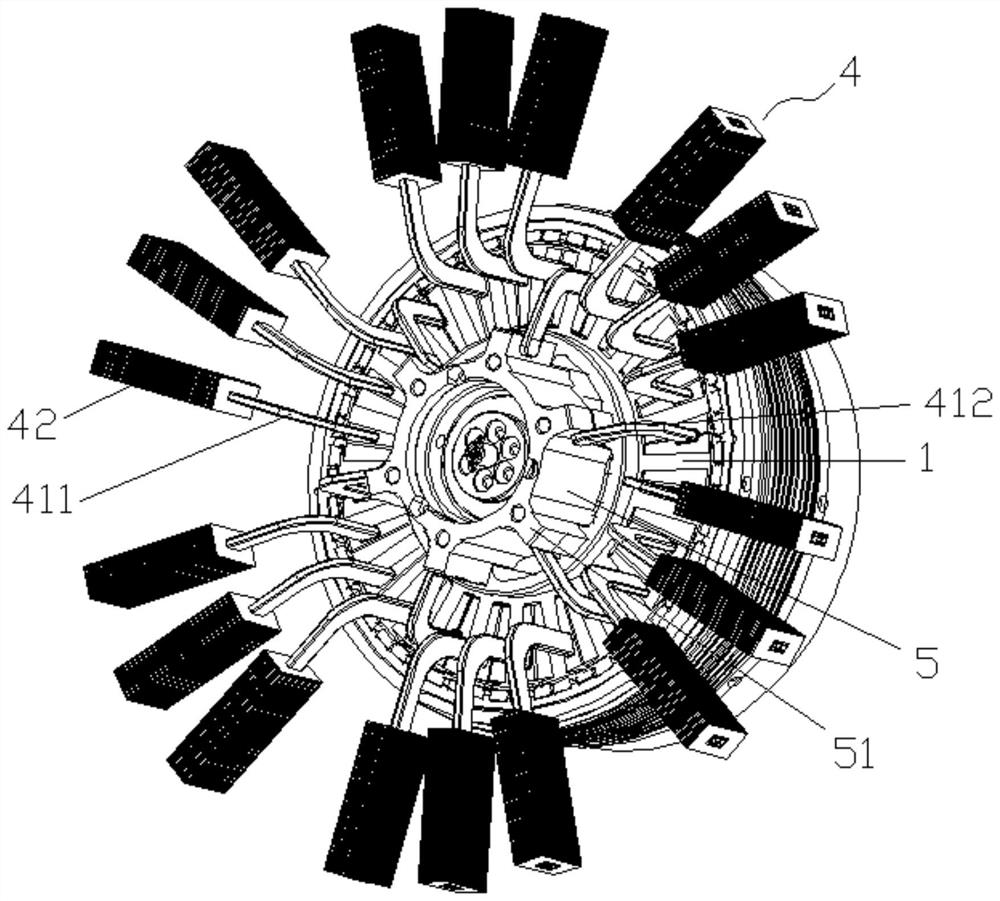

[0030] like Figure 1-5 As shown, the present invention provides a stator assembly, comprising a stator core 1 with 24 stator slots, the stator core 1 is provided with a bracket 5 for supporting the stator core 1, and the bracket 5 is an interference fit on the stator core 1. In the installation through slot 11 of the stator core 1, the bracket 5 is provided with ribs 51, each of the stator slots is provided with two layers of windings 2, and there is a gap 3 between the two layers of the windings 2. , the stator assembly also includes a heat dissipation part 4 for heat dissipation of the winding 2, the heat dissipation part 4 includes 24 heat pipes 41, and the 24 heat pipes 41 include 18 first heat pipes 411 and 6 second heat pipes 412 , one end of the 18 first heat pipes 411 is connected to a heat dissipation plate group 42 and the other end is inserted into the gap 3 of the corresponding stator slot. The heat dissipation plate group 42 is evenly distributed on the stator co...

Embodiment 2

[0037] like Image 6 As shown, the difference between this embodiment and the first embodiment is that the first connecting portion of the heat dissipation plate group 42 includes a connecting plate 423, and a plurality of the heat dissipation fins 421 are arranged on one side of the connecting plate 423, The other side of the connecting plate 423 is bonded to the first heat pipe 411 through thermal conductive silicone grease.

Embodiment 3

[0039] The difference between this embodiment and the first embodiment is that the 24 heat pipes 41 of the heat dissipation part 4 of the stator assembly are all first heat pipes 411 , and one end of the first heat pipes 411 away from the winding 2 is connected to one of the first heat pipes 411 . The heat dissipation plate group 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com