Cylindrical battery module cooling system and battery module

A cylindrical battery and cooling system technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of battery pack weight gain, unfavorable automated production, complex battery module structure, etc., to improve cycle life, Ensuring uniform temperature and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

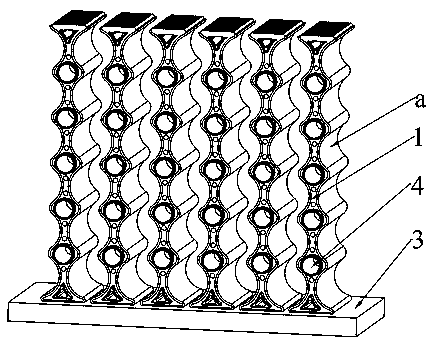

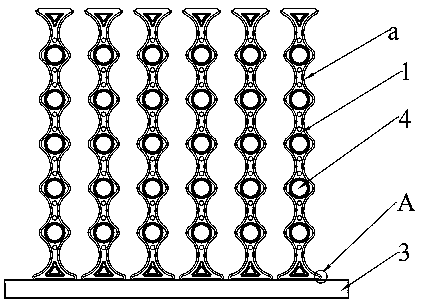

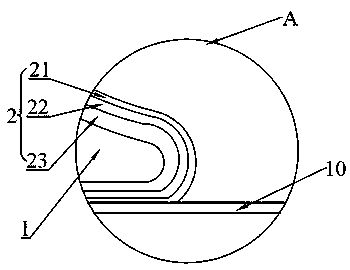

[0040] Such as Figure 1-2 As shown, the cylindrical battery module cooling system in Embodiment 1 includes a first insulating support 1, a heat conduction layer 2 and a heat exchange plate 3, and a cell matching groove a is provided on the cell contact surface of the first insulating support 1, and the first The heat exchange end surface of the insulating support 1 is in contact with the heat exchange plate 3; the heat conduction layer 2 is coated on the cell contact surface and the heat exchange end surface of the first insulating support 1; the heat conduction layer 2 includes an insulating surface layer 21, a graphite film 22 and an elastic Buffer layer 23.

[0041] The first insulating bracket 1 is provided with a weight-reducing through hole 4 that is axially aligned with the cell matching groove a.

[0042] The material of the first insulating support 1 is polycarbonate.

[0043] The material of the elastic buffer layer is foam, and the thickness of the elastic buffer...

Embodiment 2

[0047] Such as Figure 3-4As shown, embodiment 2 is based on embodiment 1, the difference is that embodiment 2 also includes a second insulating support 5 with the following structure: one side of the second insulating support 5 is provided with a cell matching groove a, and the other side is a plane . The number of cells in the assembled battery module is N, the number of insulating supports is N+1, and the arrangement is followed by the second insulating support 5, N-1 first insulating supports 1, and the second insulating supports 5. That is, the planar side of the second insulating support 5 is the surface of the battery module.

Embodiment 3

[0049] Such as Figure 5 As shown, the battery module of Example 3 includes the cylindrical battery module cooling system of Example 1, and also includes a battery cell 6, a first module bracket 7 and a second module bracket 8, and the first module bracket 7 and The second module support 8 is provided with a recessed portion 9, and the first insulating support 1 is provided with a protrusion that matches the recessed portion 9, and the protrusion on the first insulating support 1 includes a through hole 4 communicated with The protruding ring b and the V-shaped protrusion c located at both ends of the insulating support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com