Patents

Literature

33results about How to "Precise control of drilling depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

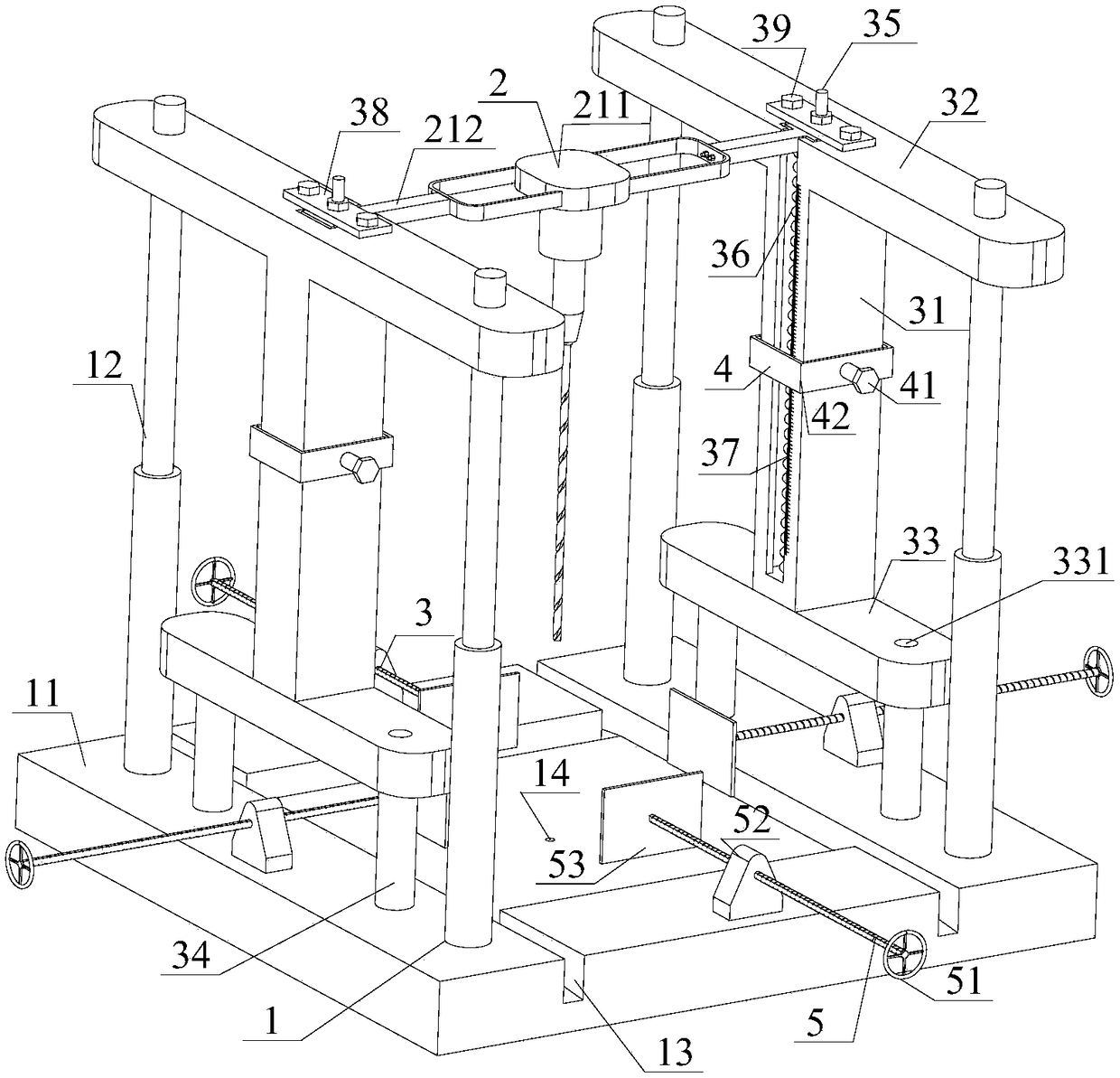

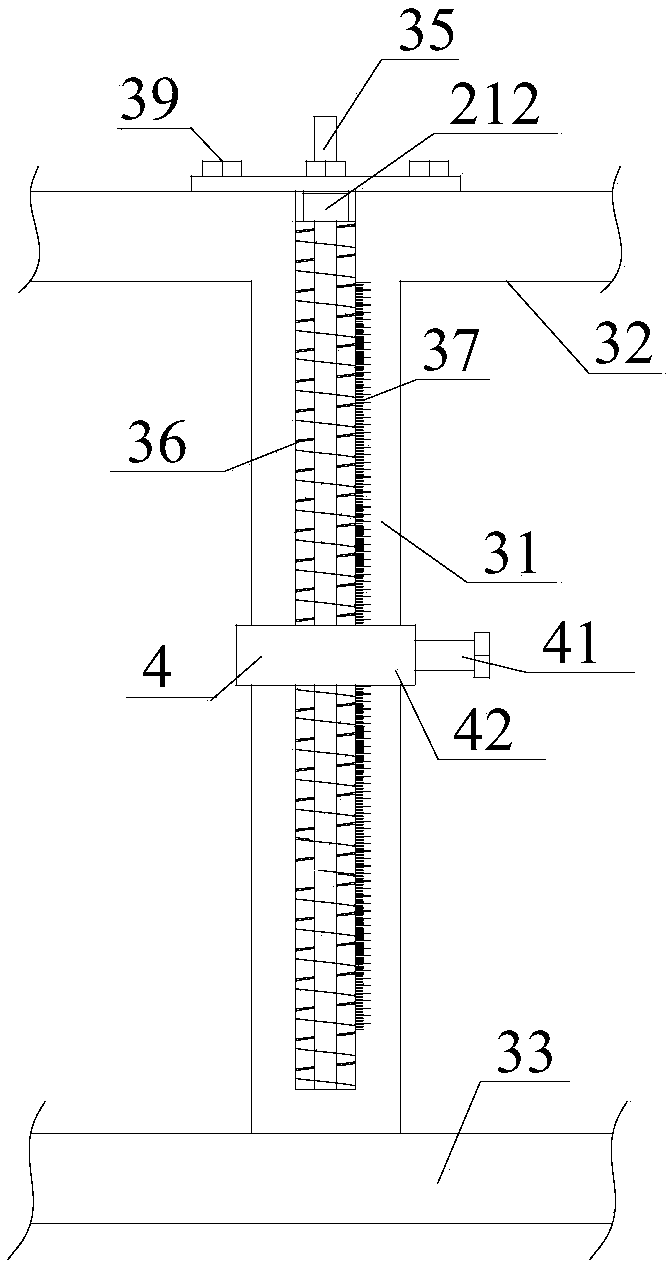

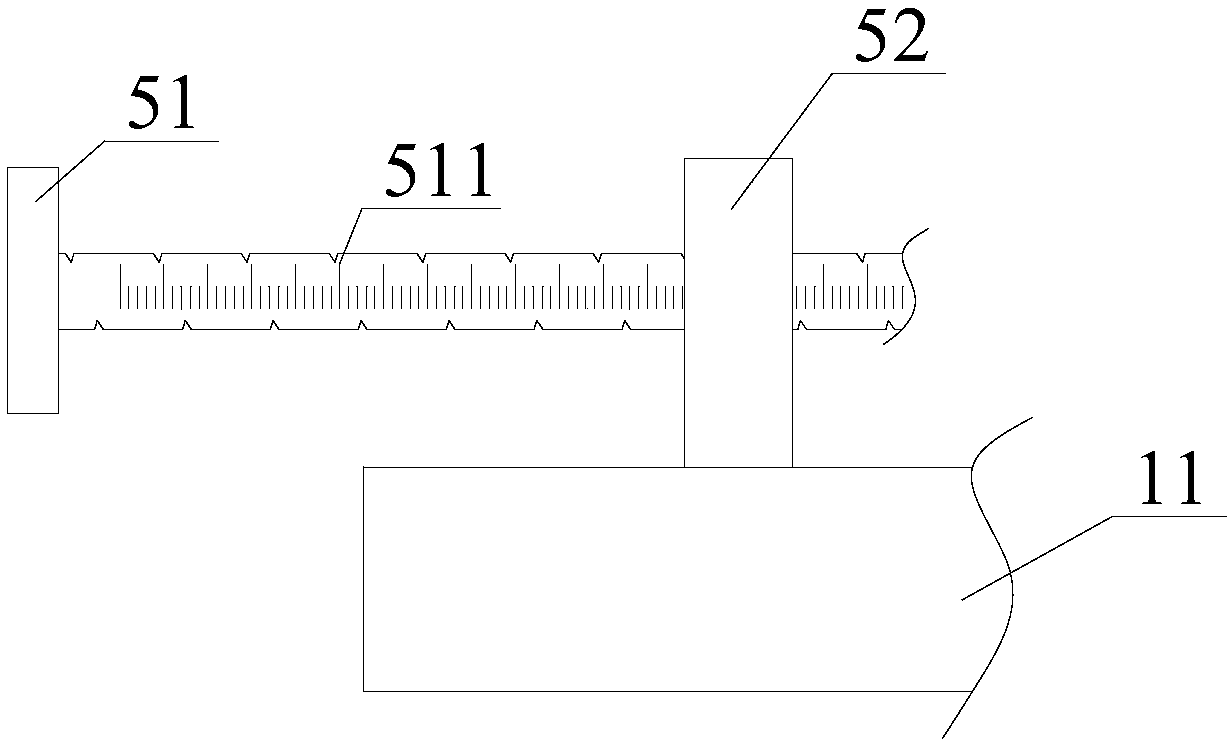

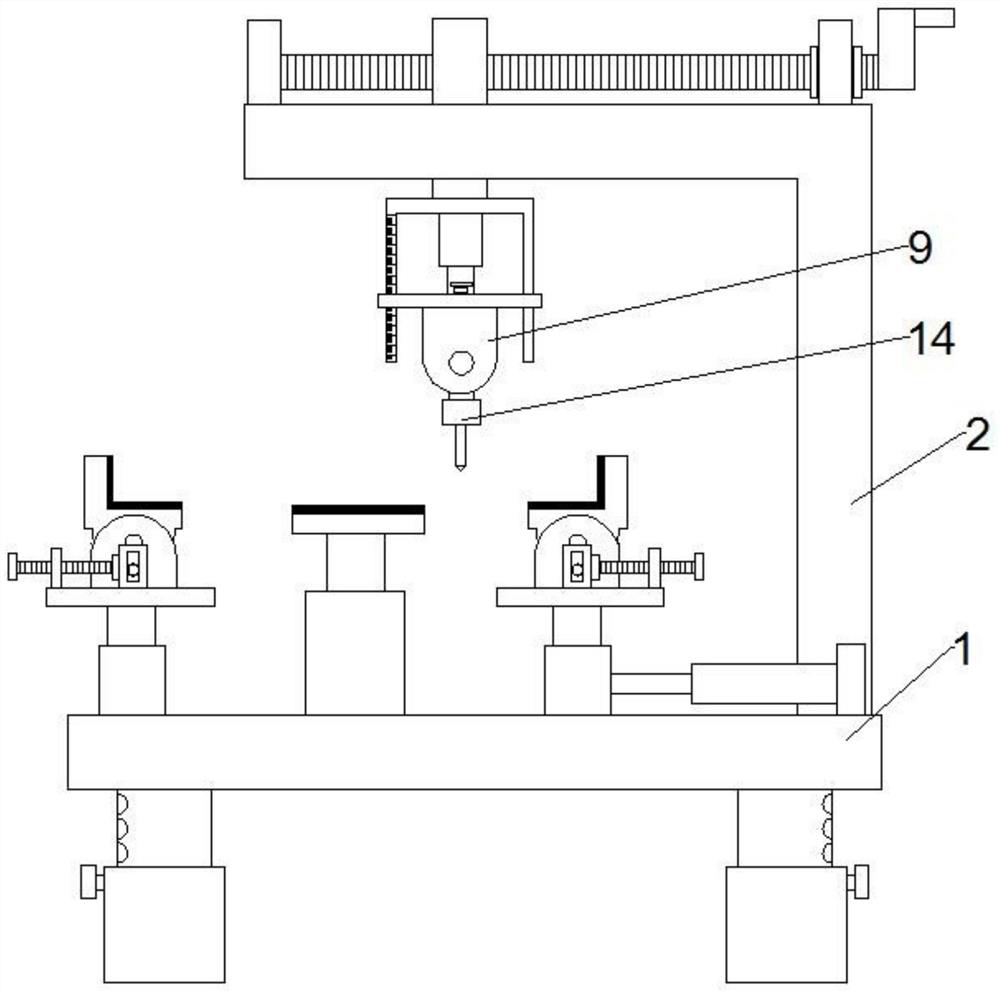

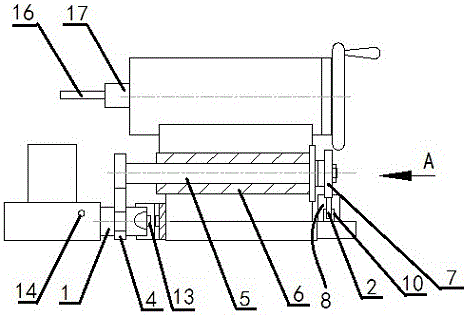

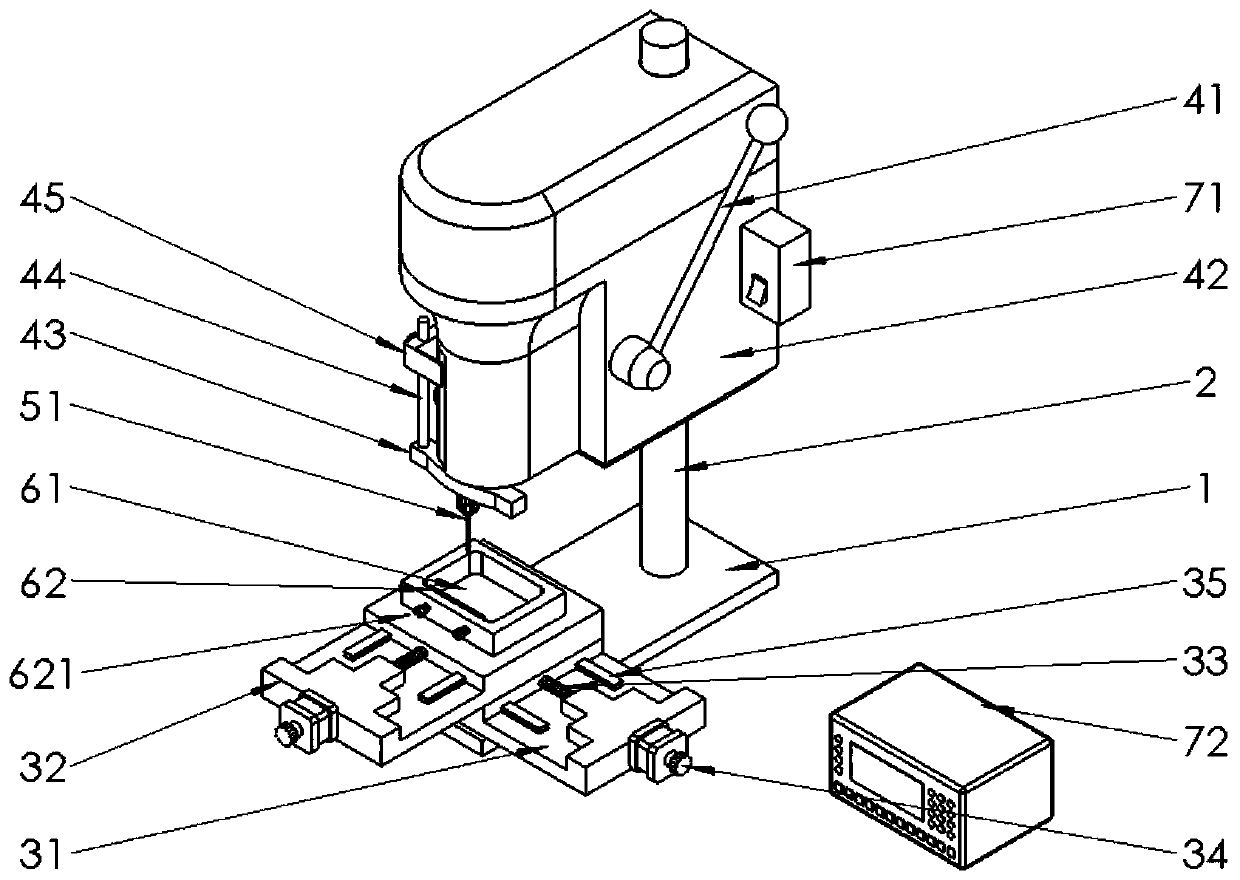

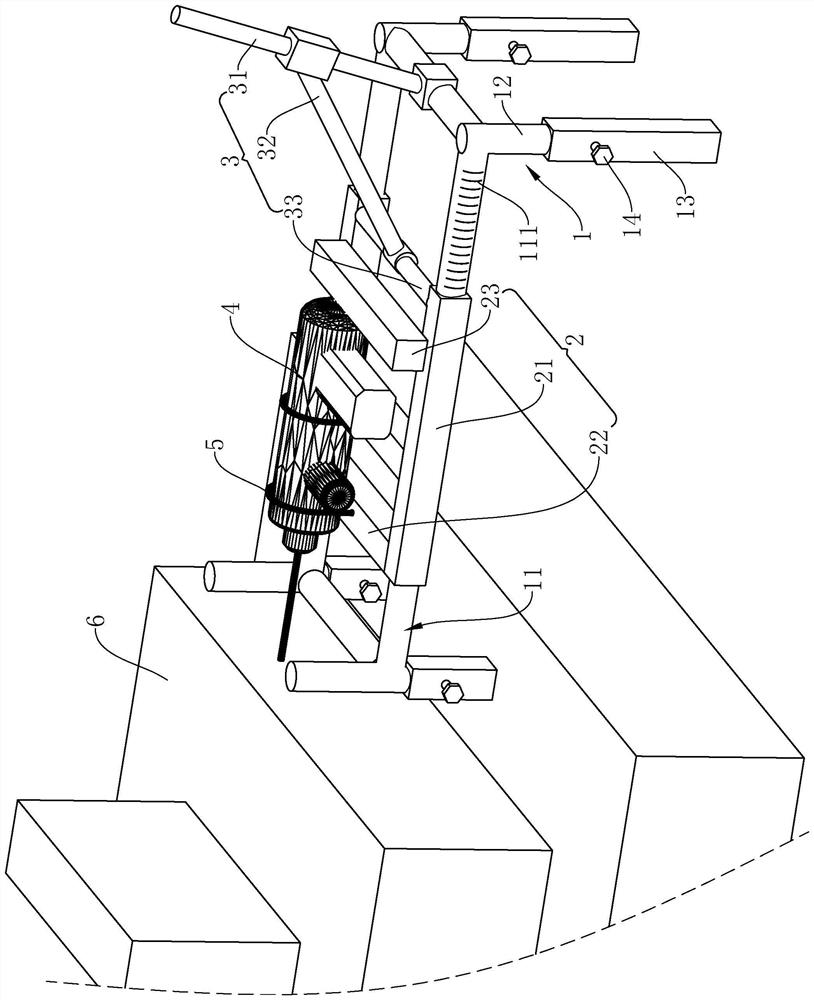

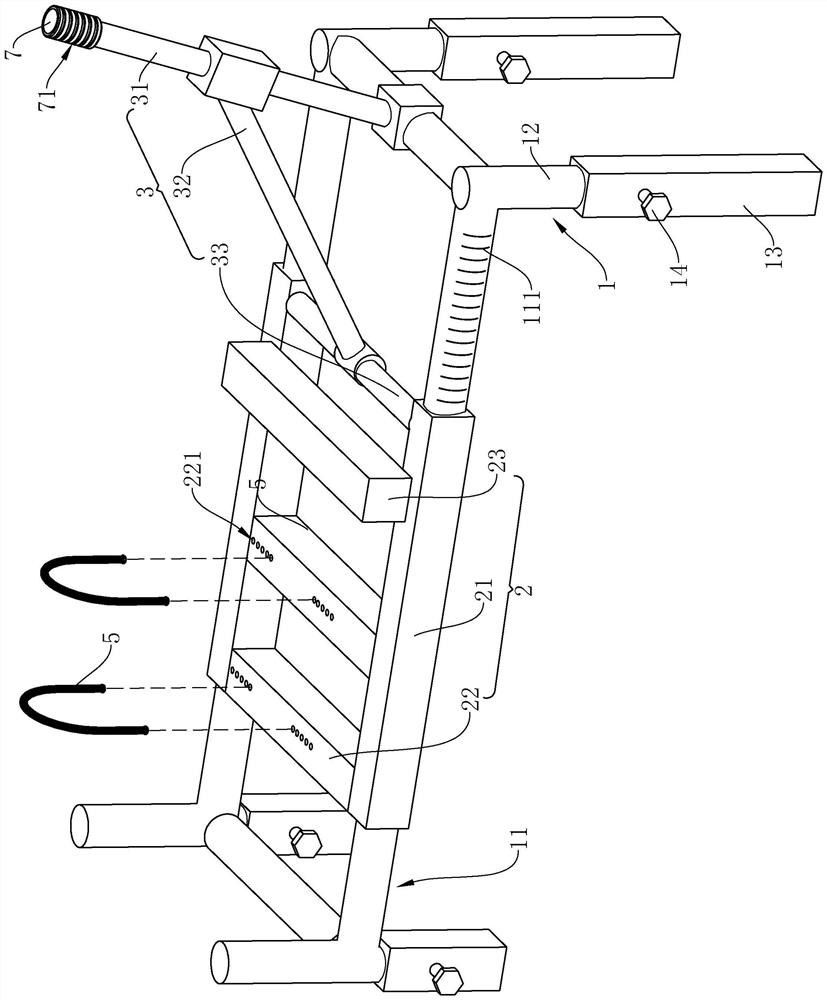

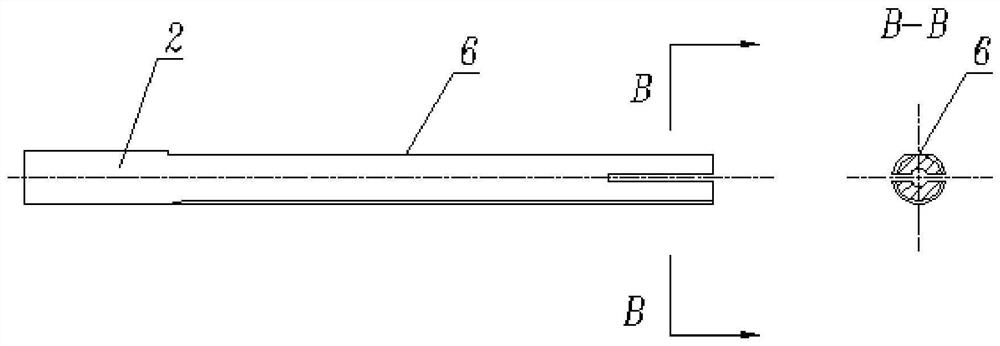

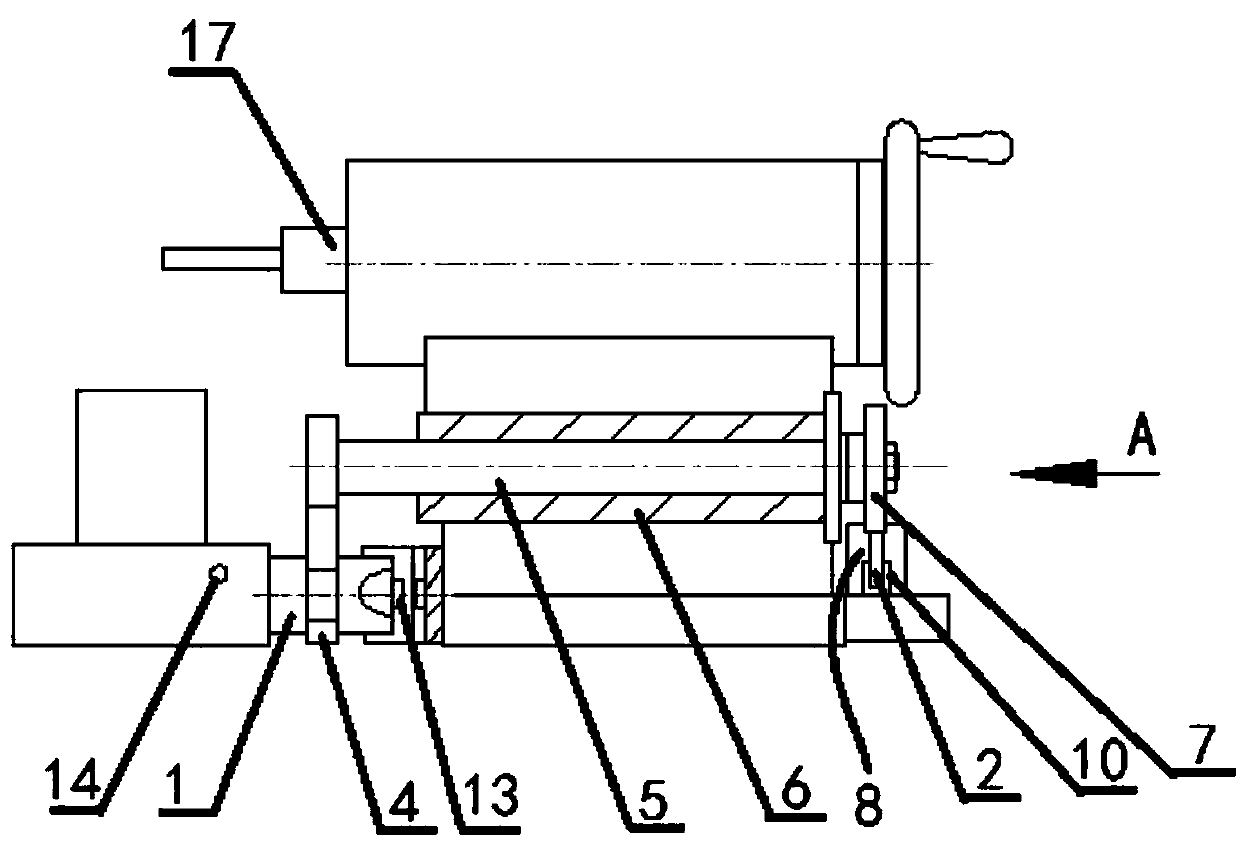

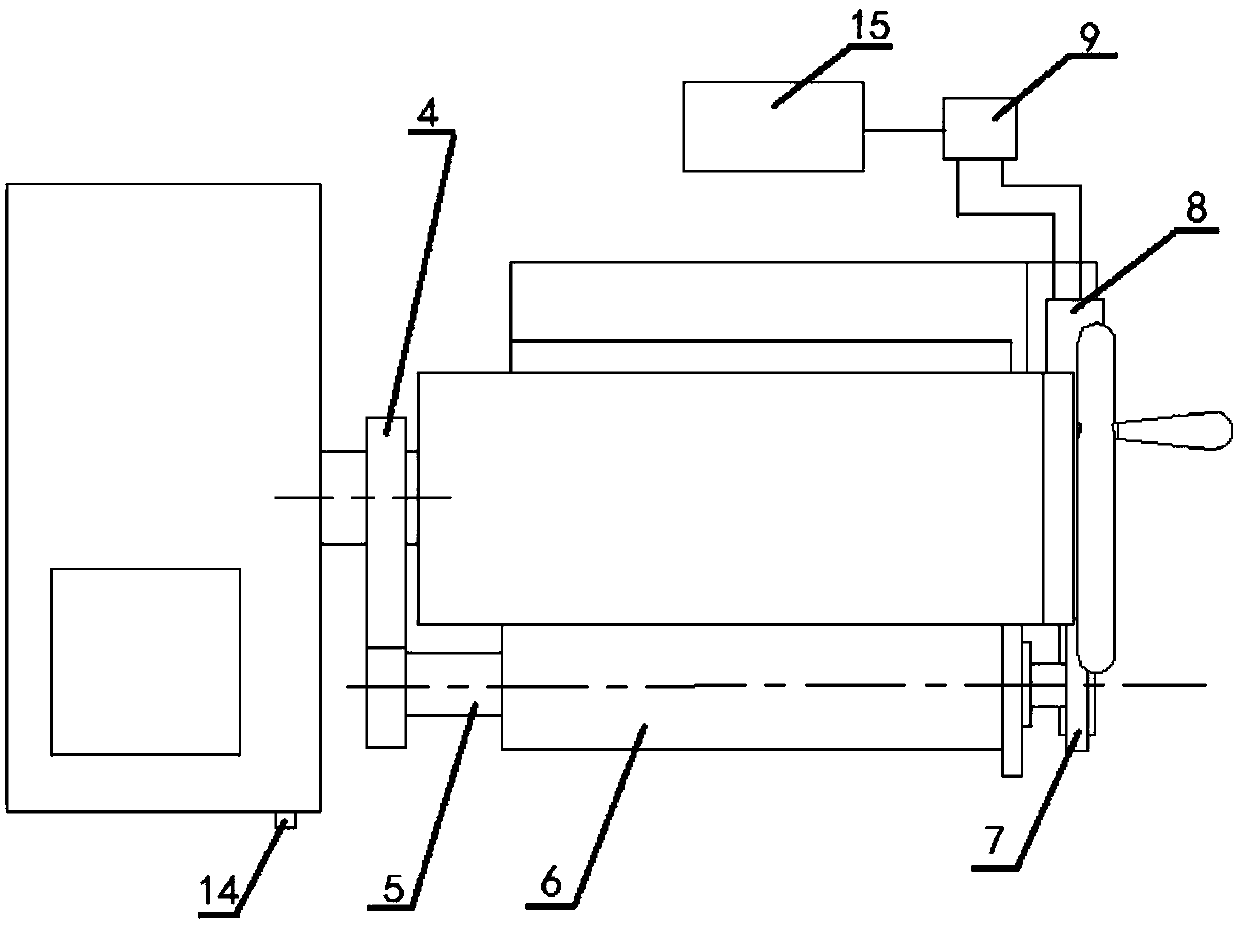

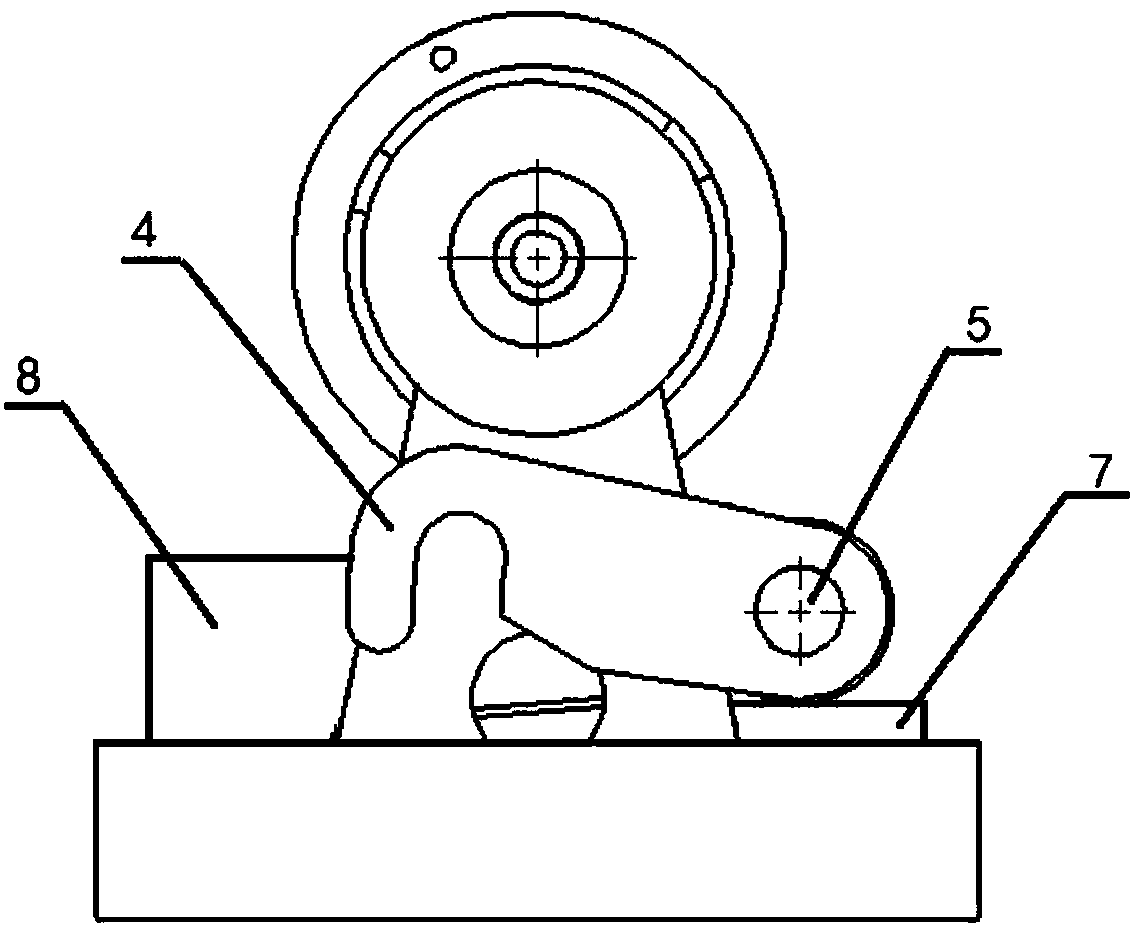

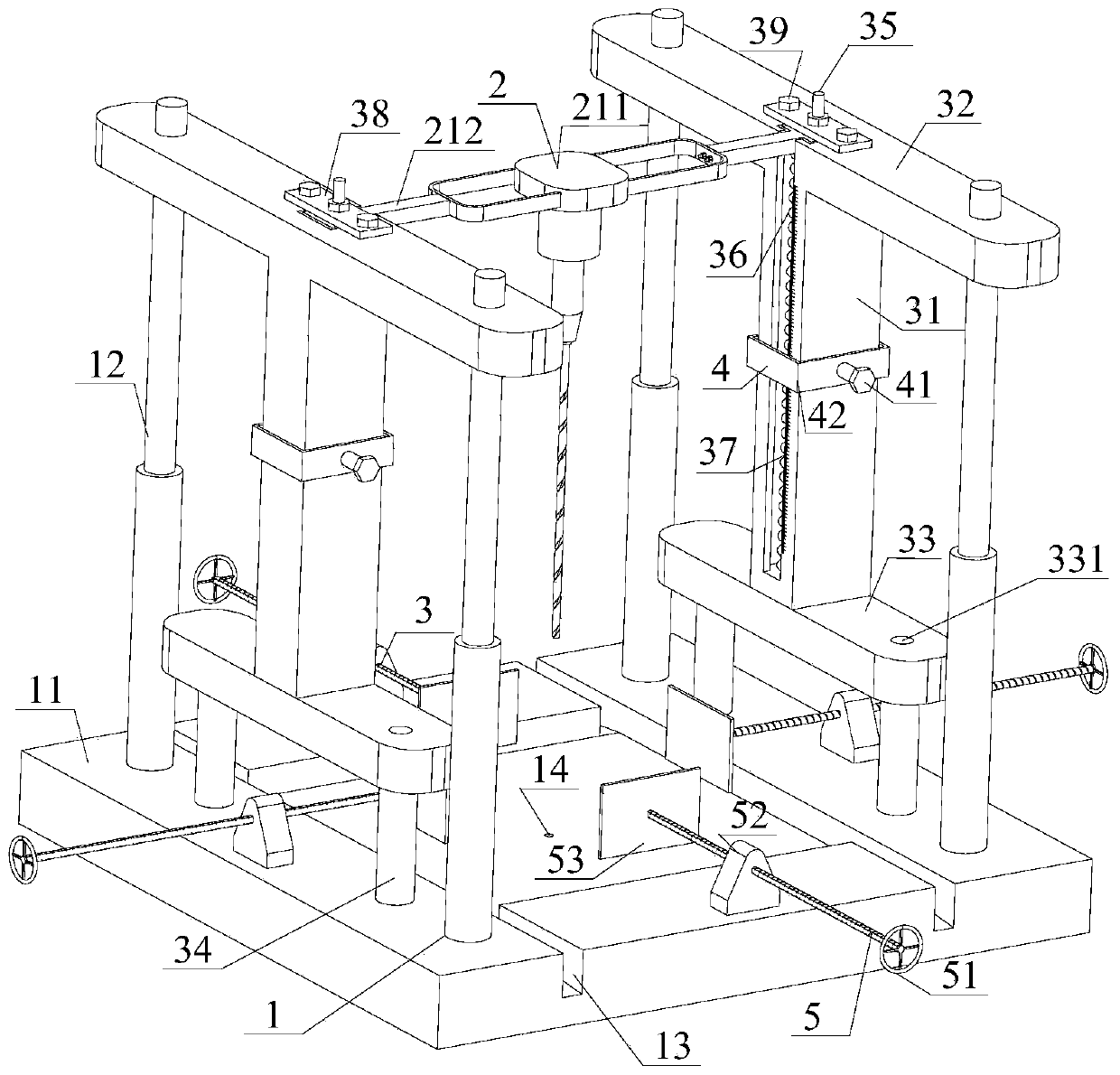

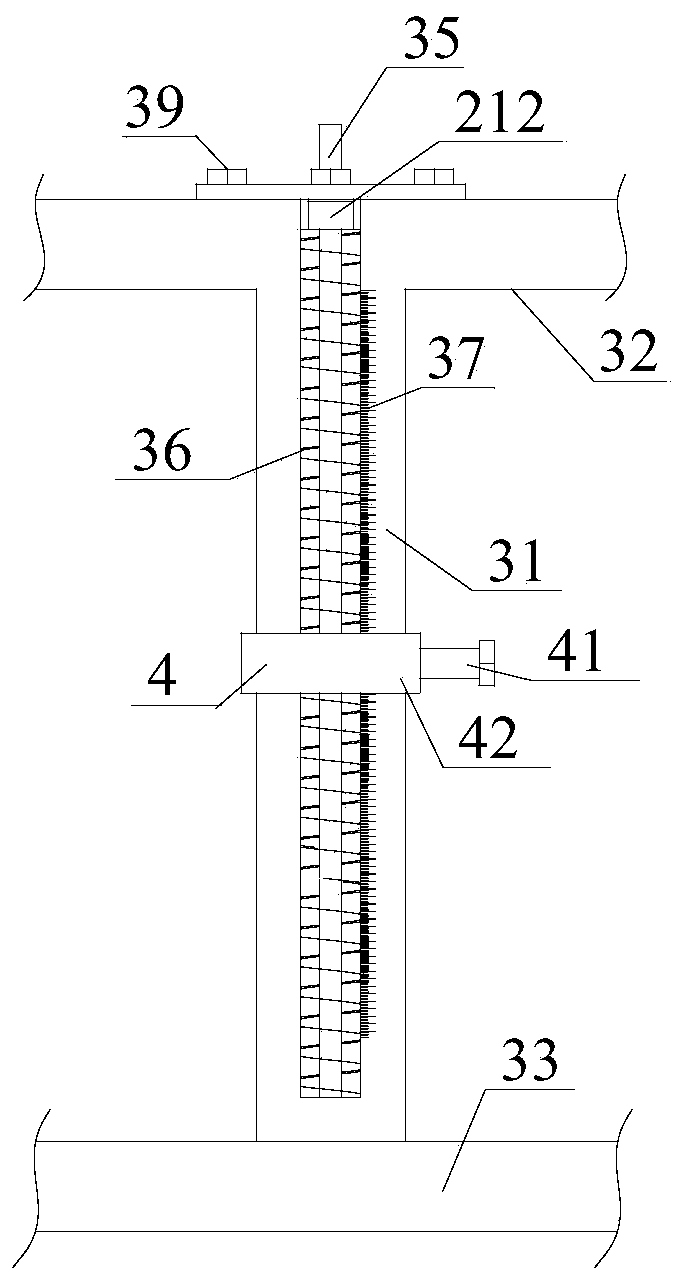

Depth-controllable rock sample drilling device and utilization method

InactiveCN108247860AAchieve fixationAchieve protectionPreparing sample for investigationWorking accessoriesRock sampleCalipers

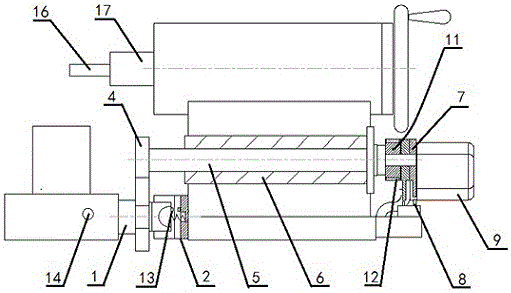

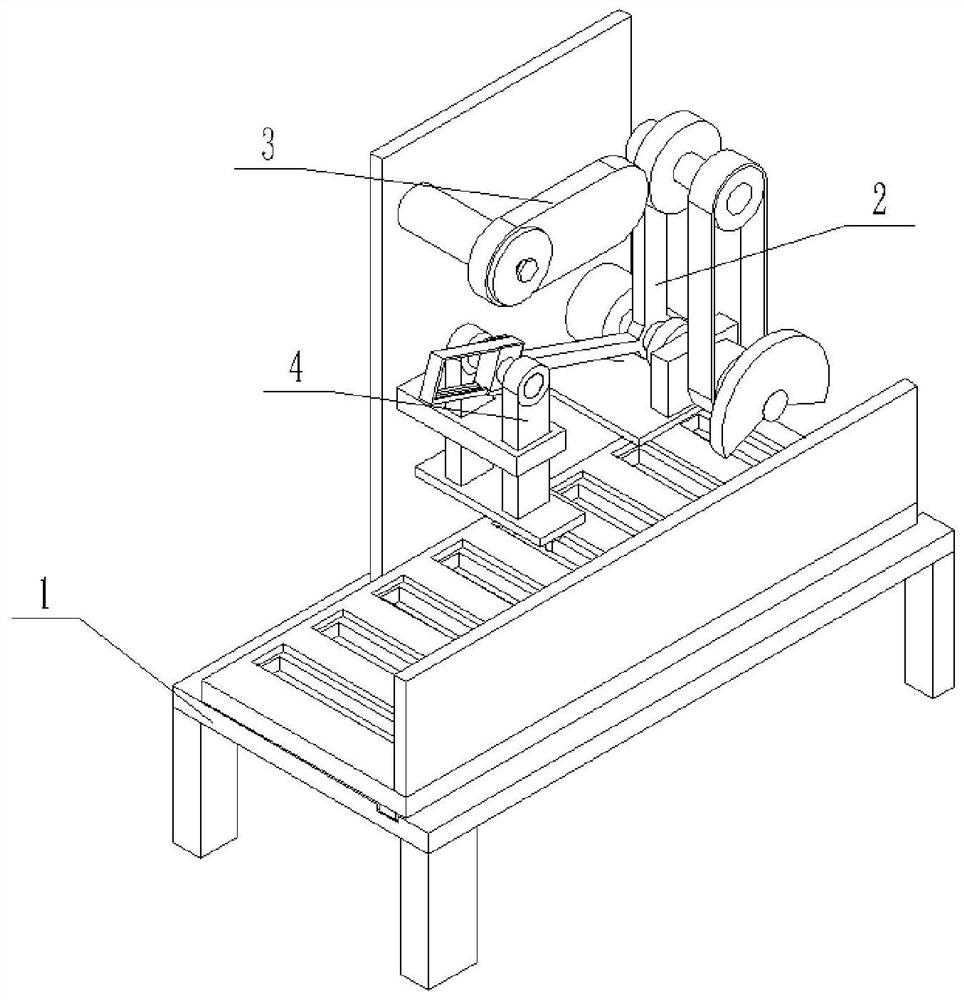

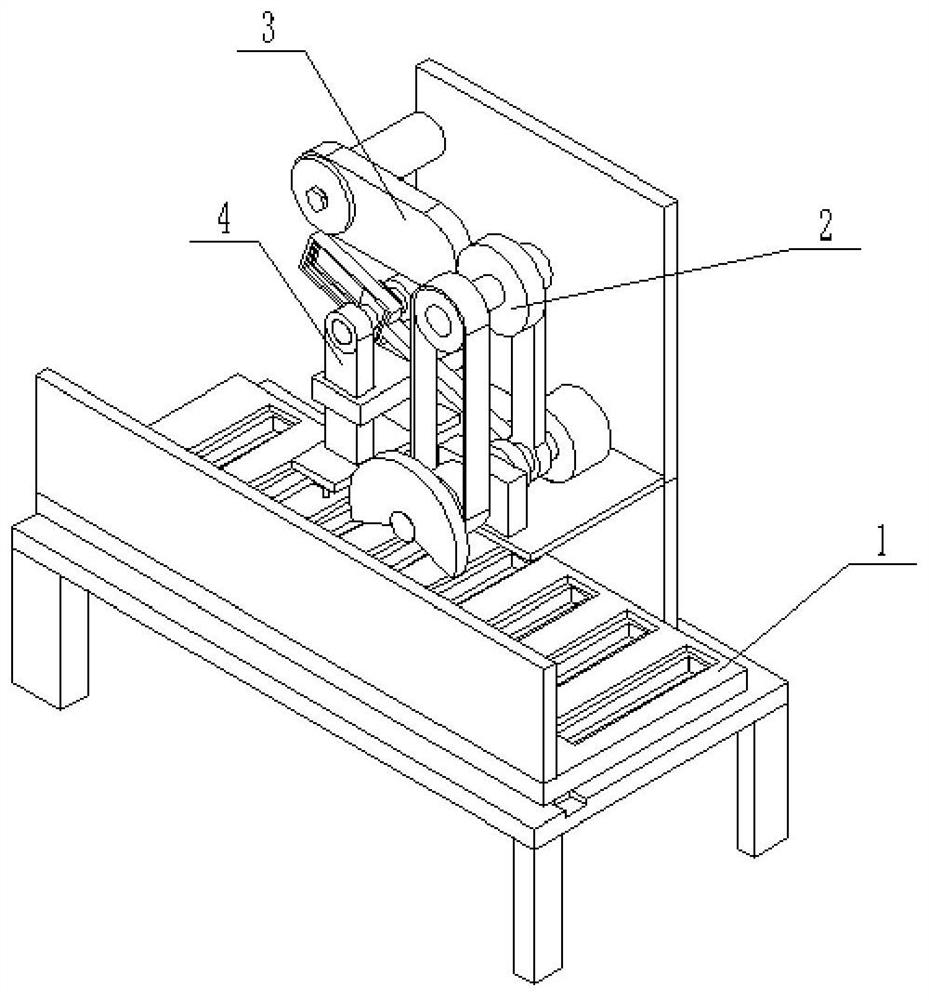

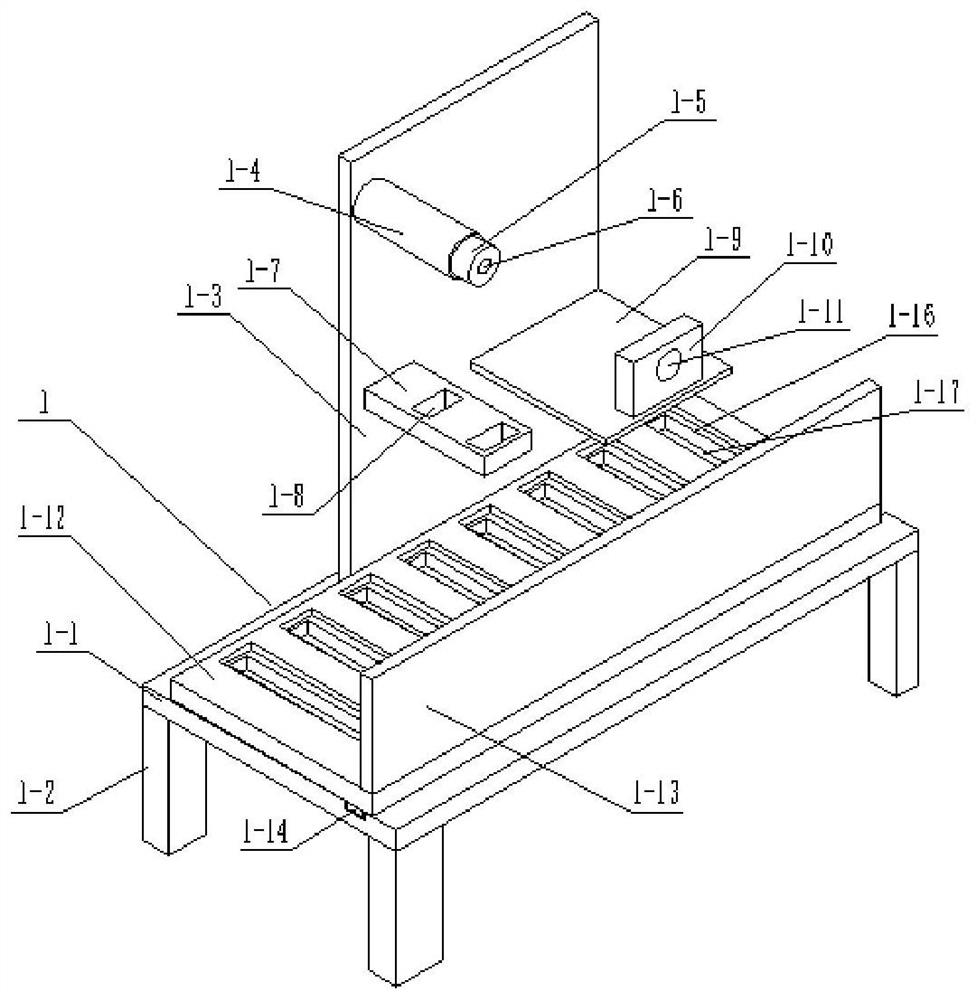

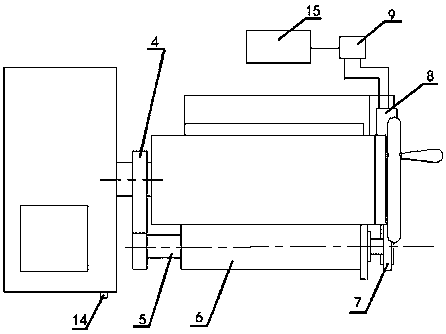

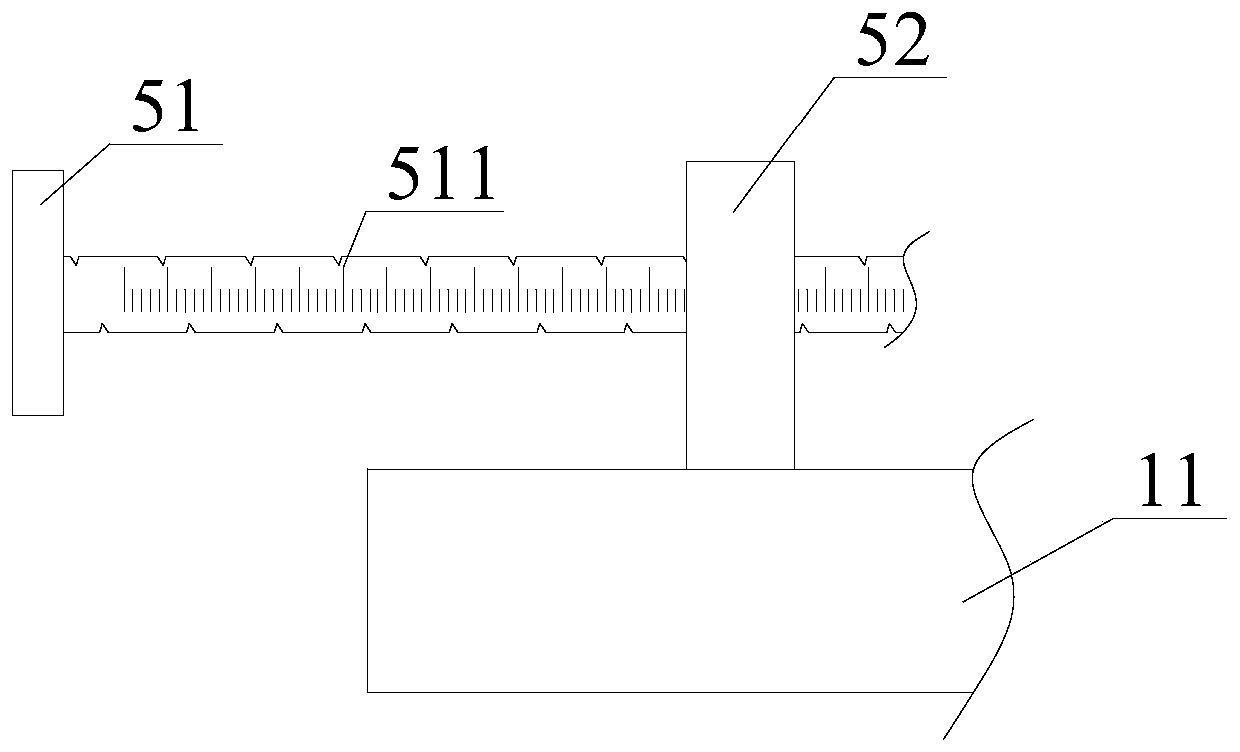

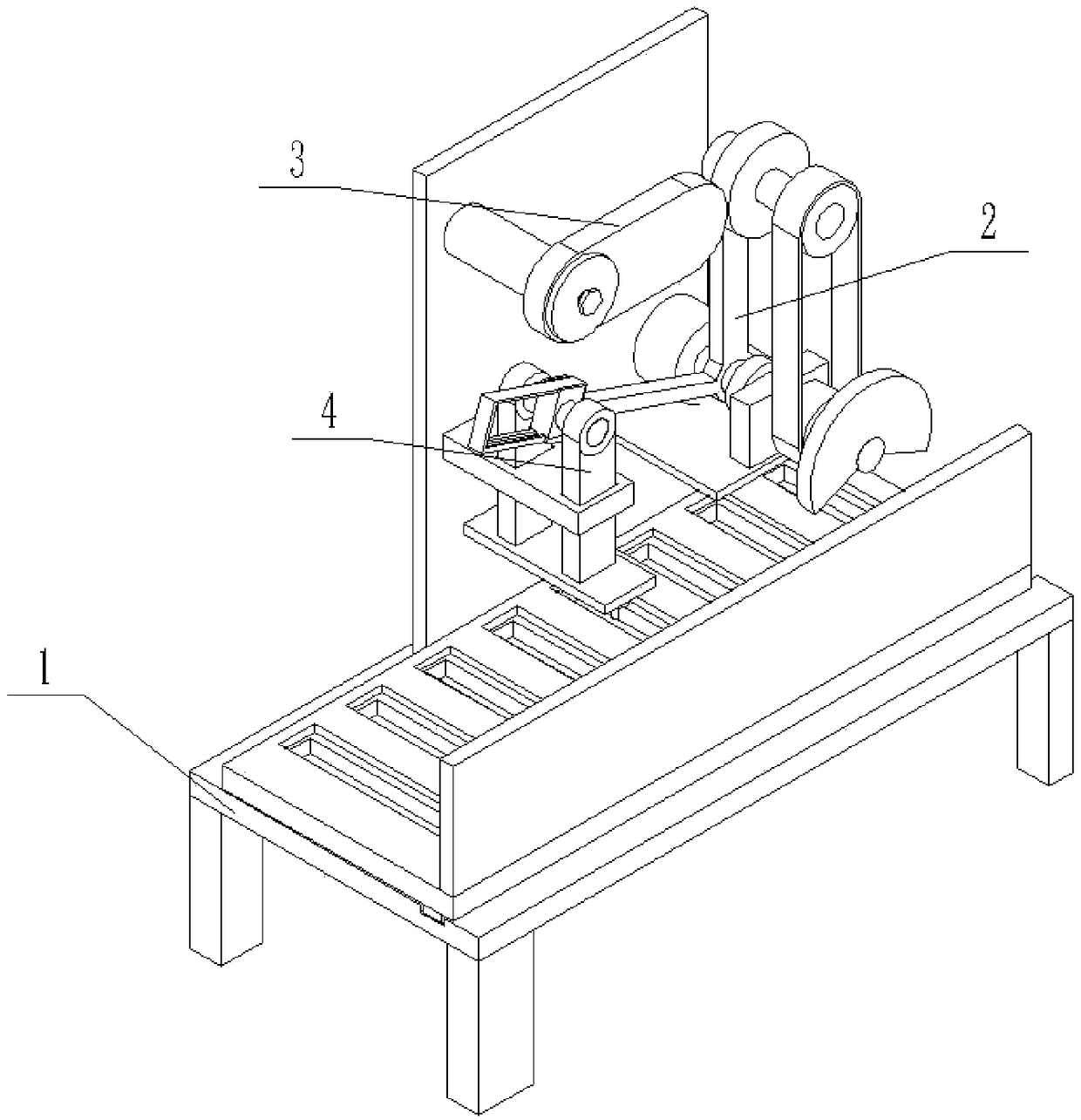

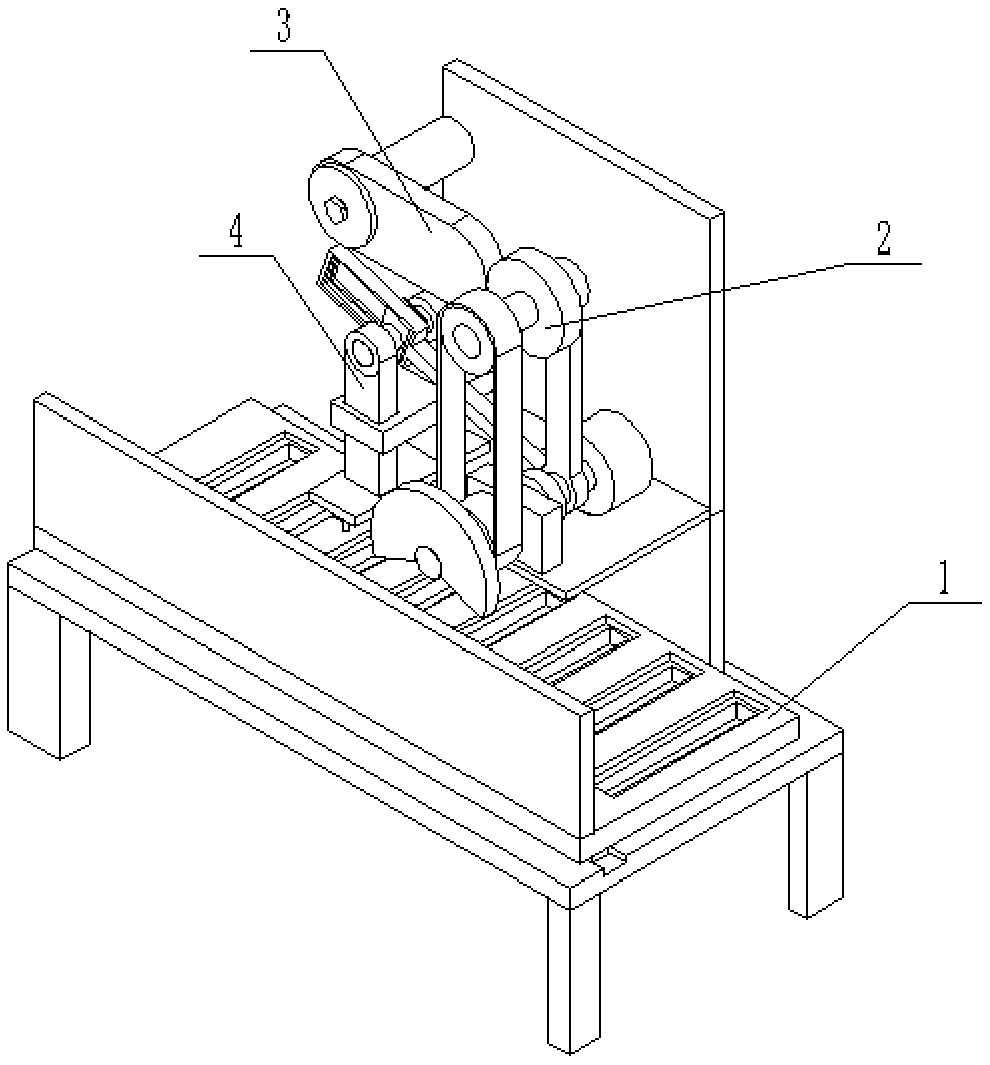

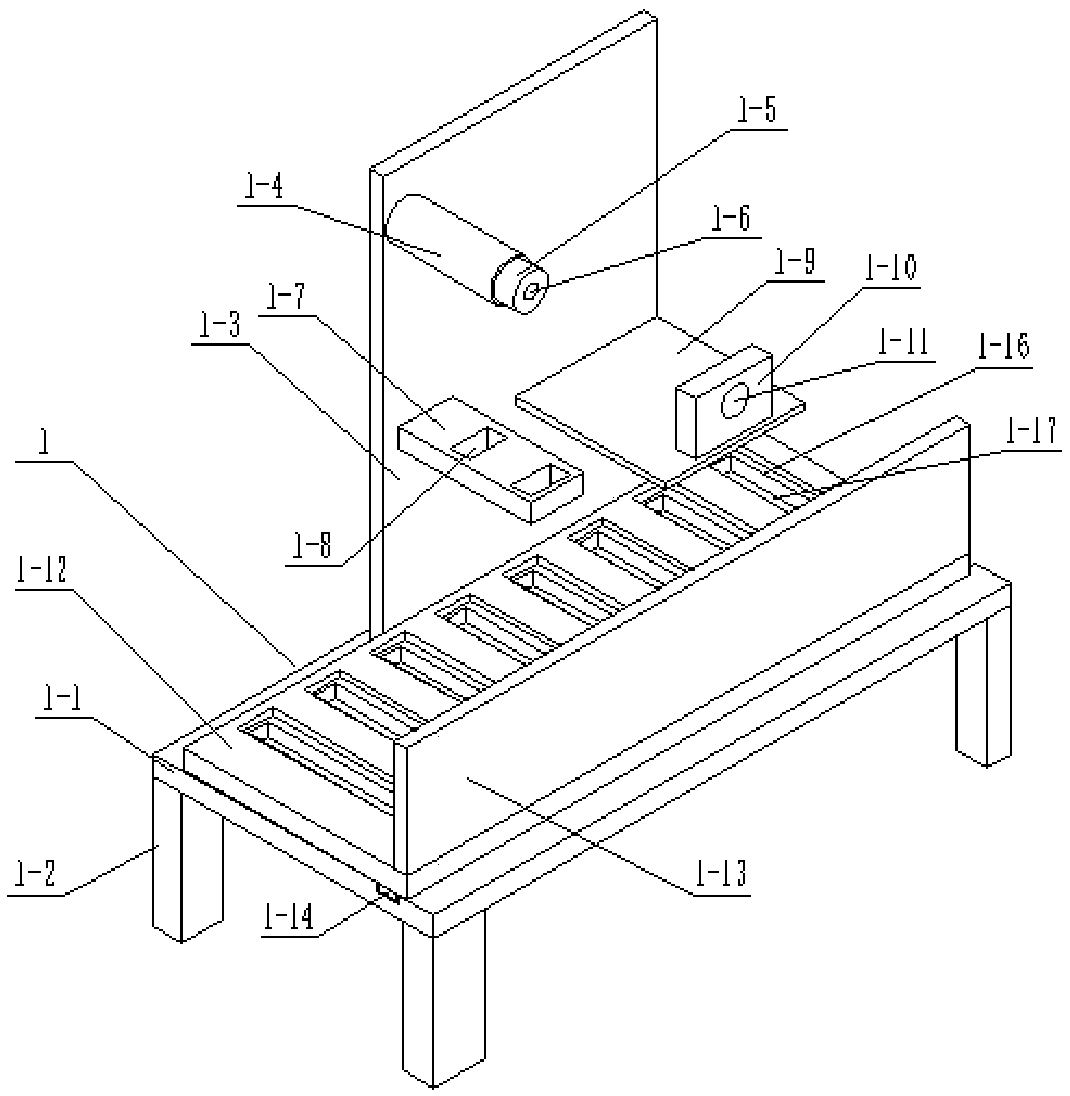

The invention discloses a depth-controllable rock sample drilling device and a utilization method. The problem about accurately drilling rock samples of different shapes is solved. The drilling devicecomprises a vertical rack, a drilling mechanism, an I-shaped slide mechanism, a caliper mechanism and a displacement mechanism, wherein pushing rods are arranged on a base of the vertical rack; the samples are fixed through the pushing rods; the pushing rods are provided with scales, so that the samples are accurately moved; clamping plates are arranged in front of the pushing rods; the clampingplates are changed to adapt to the samples of different shapes; and a through hole is formed in the center of the base of the vertical rack. According to the depth-controllable rock sample drilling device, holes of the processed samples are protected; stress springs are arranged in the slide mechanism, drilling force is controlled, and the drill sticking problem is avoided; and the outer surfacesof slides and the caliper mechanism are provided with scales, so that the drilling position and drilling depth are accurately controlled. The invention further discloses an operation method for drilling the rock samples of different shapes at different depths.

Owner:SHANDONG UNIV OF SCI & TECH

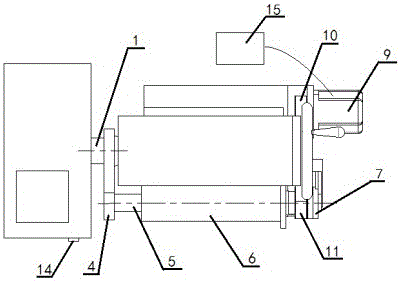

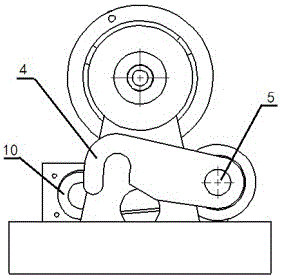

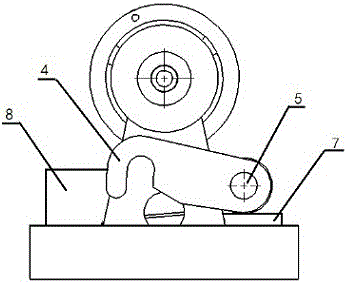

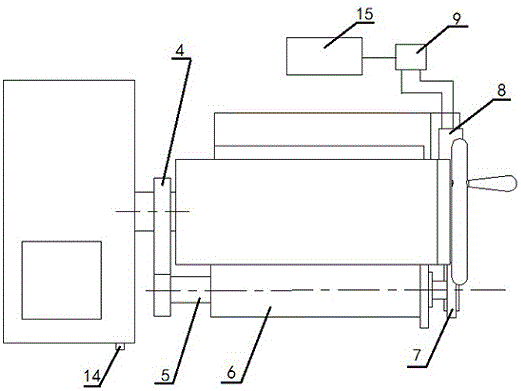

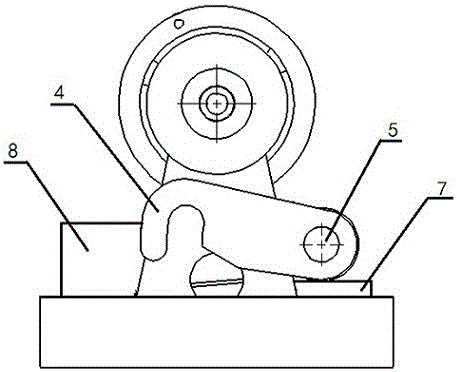

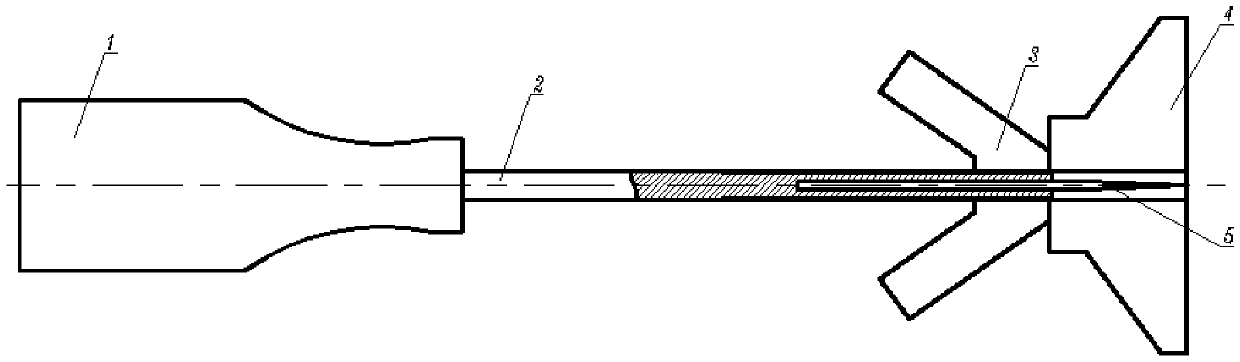

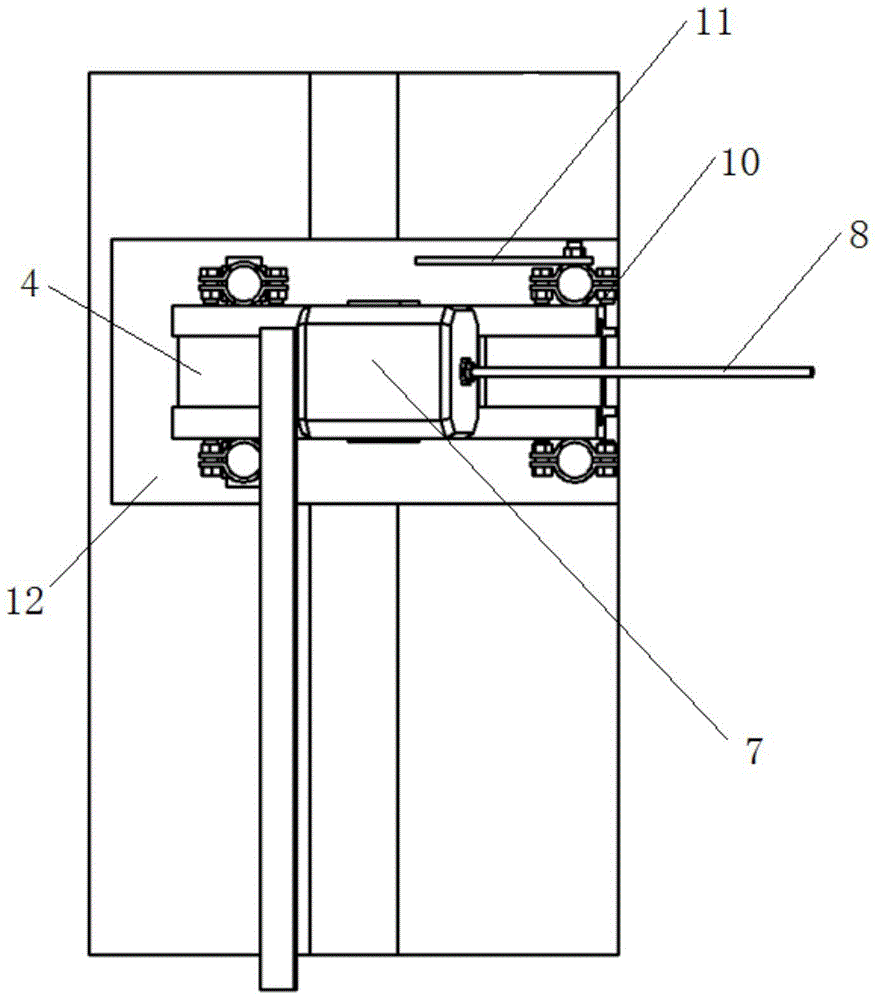

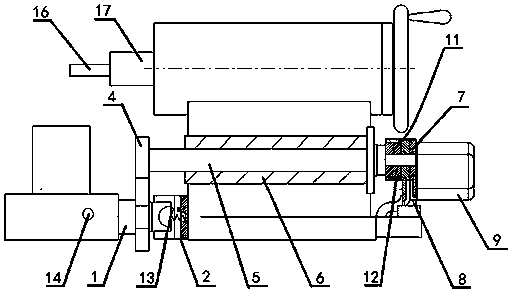

Numerical control lathe tailstock automatic control method capable of controlling drilling depth and finishing hole bottom

InactiveCN106001631ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlAutomatic control

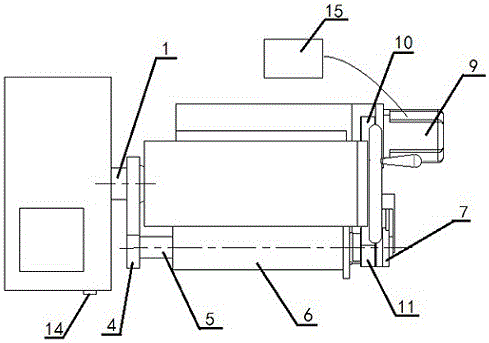

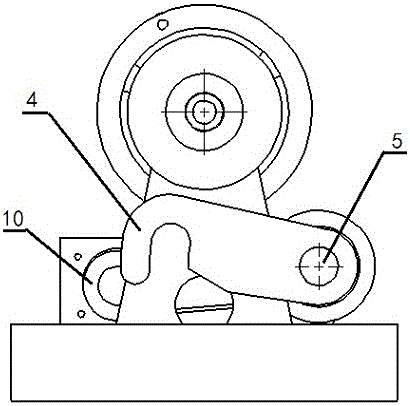

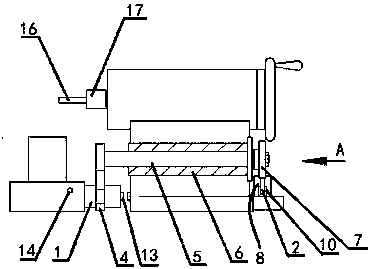

The invention provides a numerical control lathe tailstock automatic control method capable of controlling the drilling depth and finishing a hole bottom. A connection device achieving connection and disconnection of a saddle and the tailstock of a numerical control lathe is adopted and comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is installed in a tube sleeve of the tailstock of the numerical control lathe. The centering assembly comprises a centering shaft and a centering sleeve with an inner cone hole. The shaft end of the centering shaft and the bottom of the cone hole of the centering sleeve are provided with a sensor. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting pressure blocks, the driving assembly comprises a pair of belt drivers, a driving motor, a reset switch and a controller, the controller is installed in a distribution cabinet of the lathe, the reset switch is installed on the front face of the saddle of the numerical control lathe, and the driving motor is fixedly connected with the tailstock of the numerical control lathe and electrically connected with the controller.

Owner:惠州市天力和丰精密五金有限公司

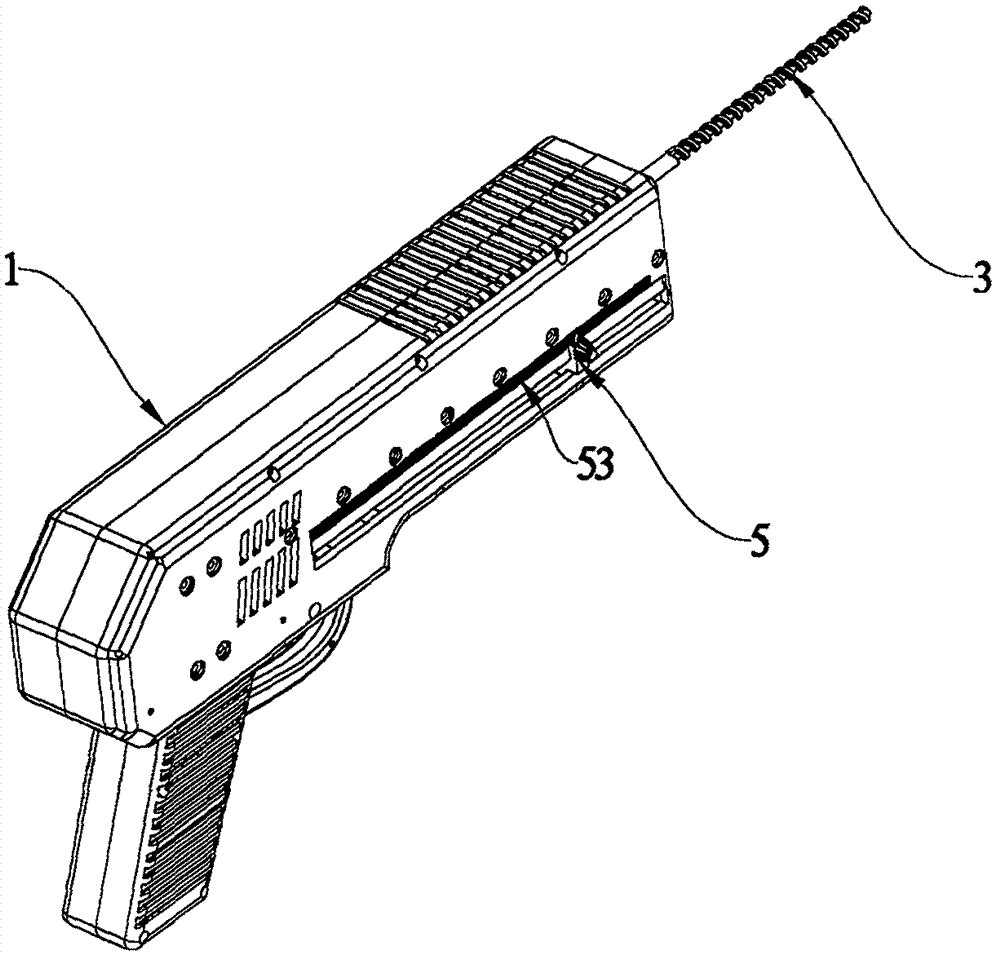

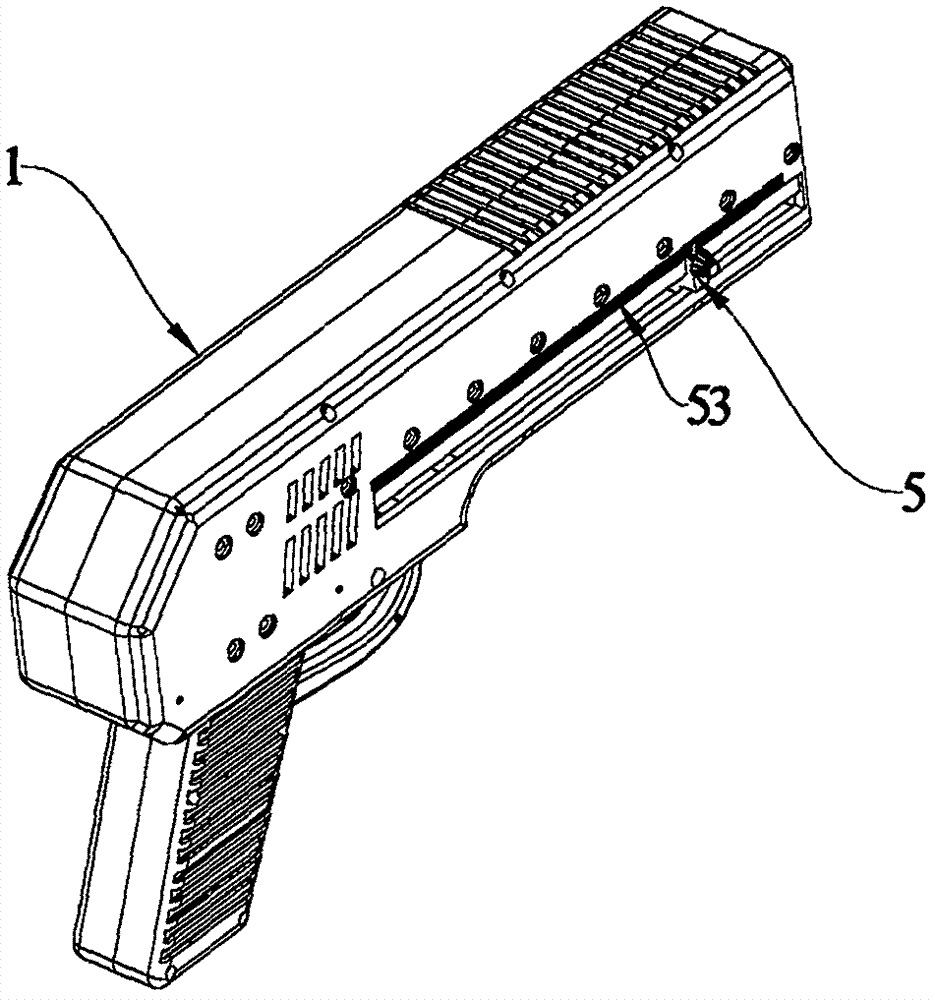

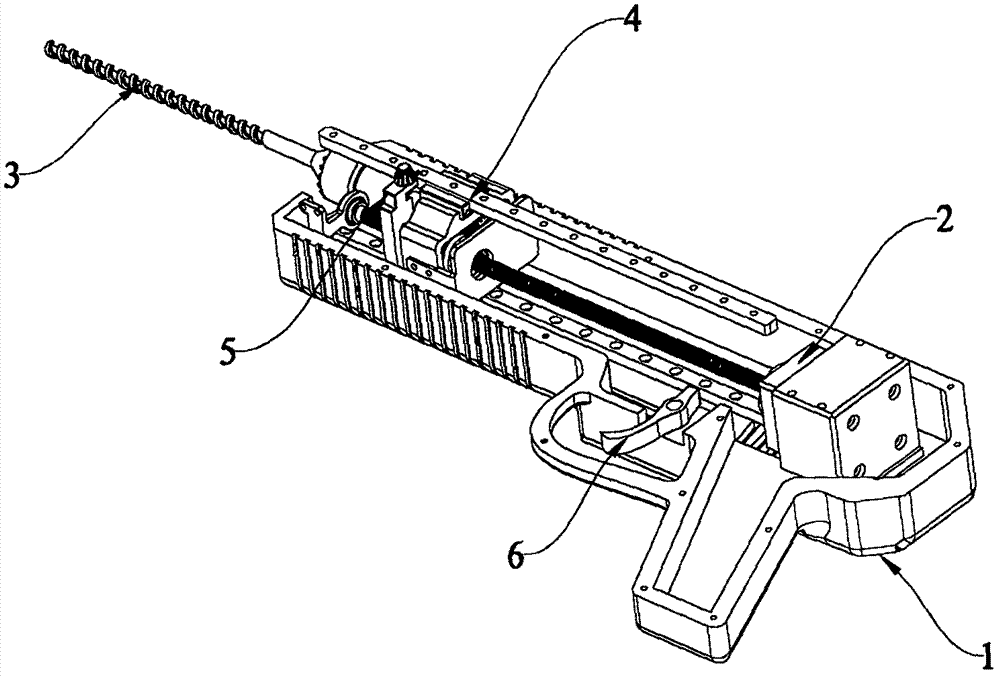

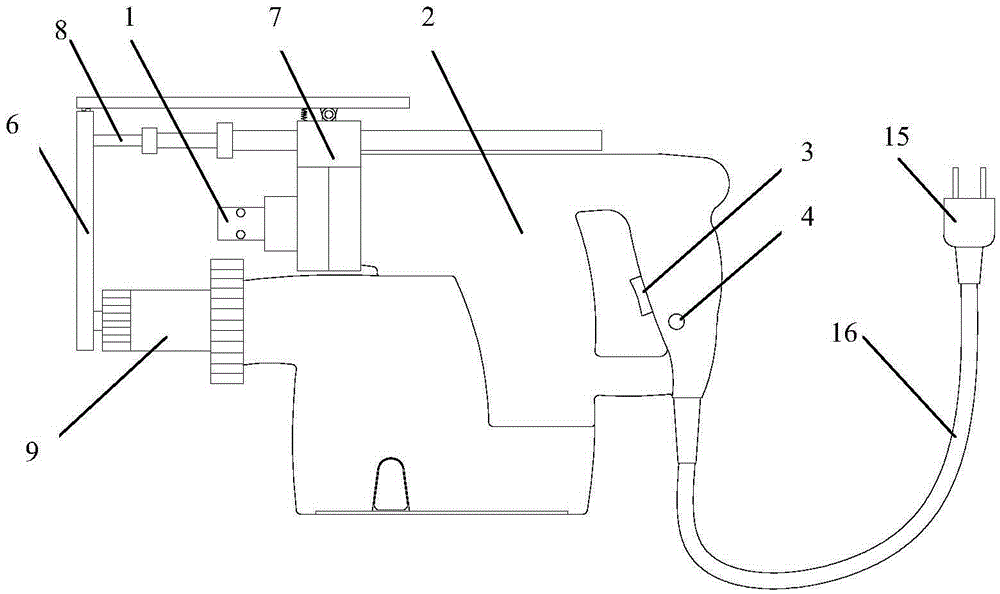

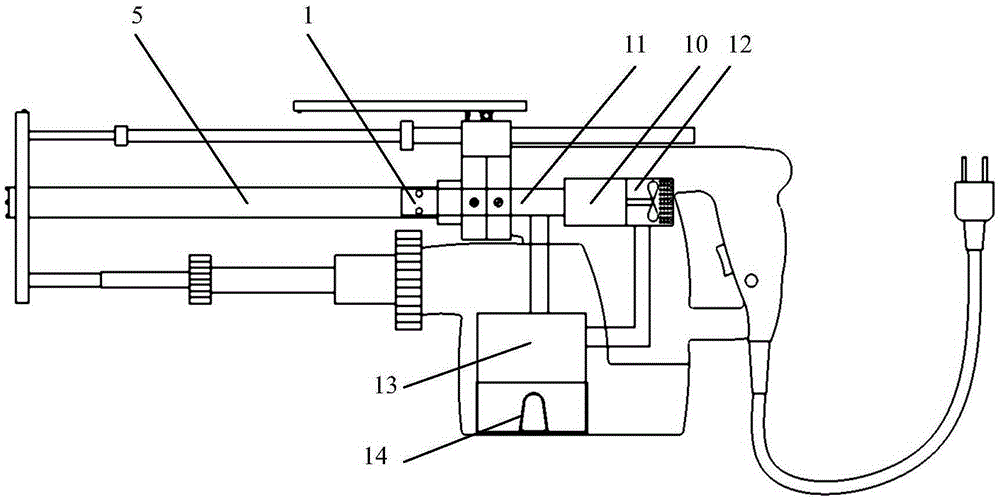

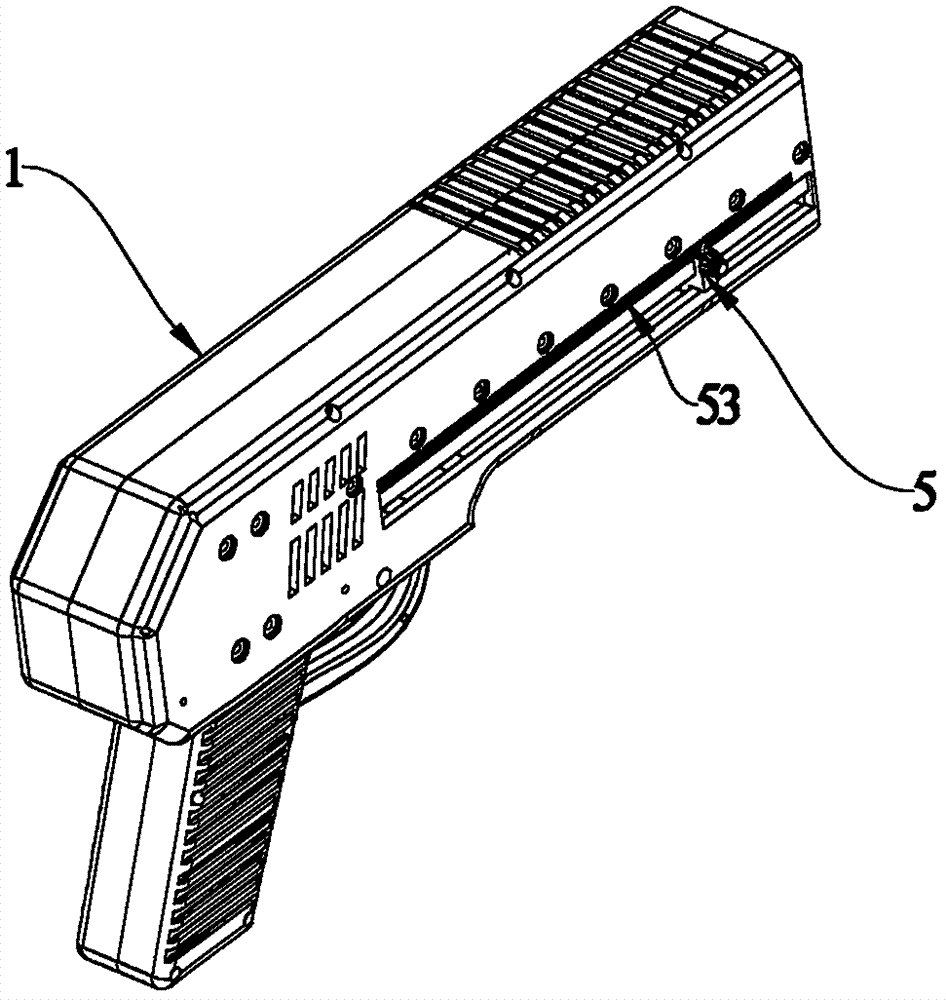

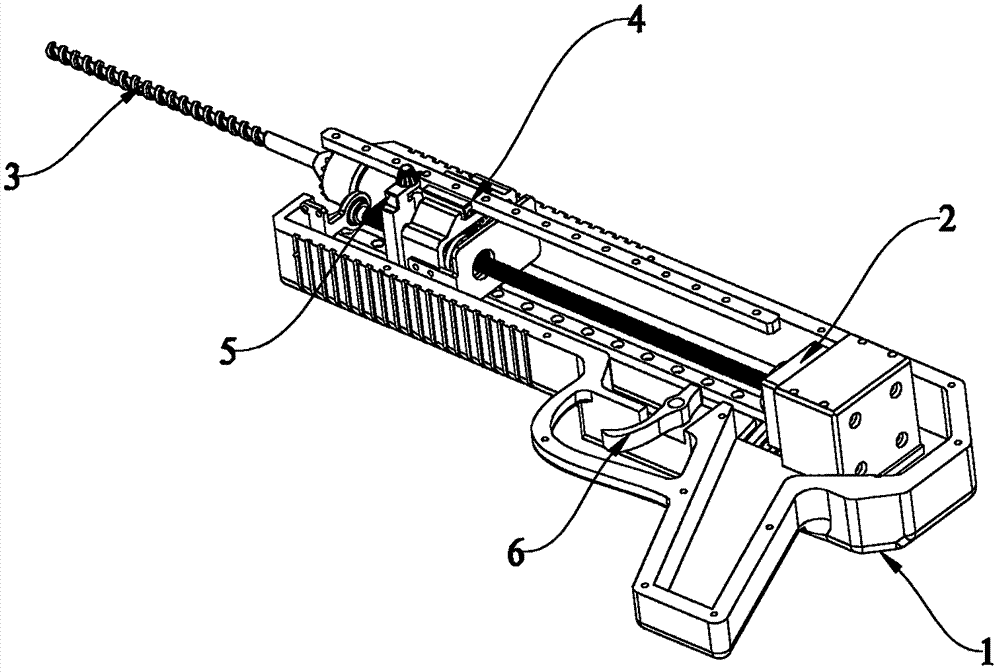

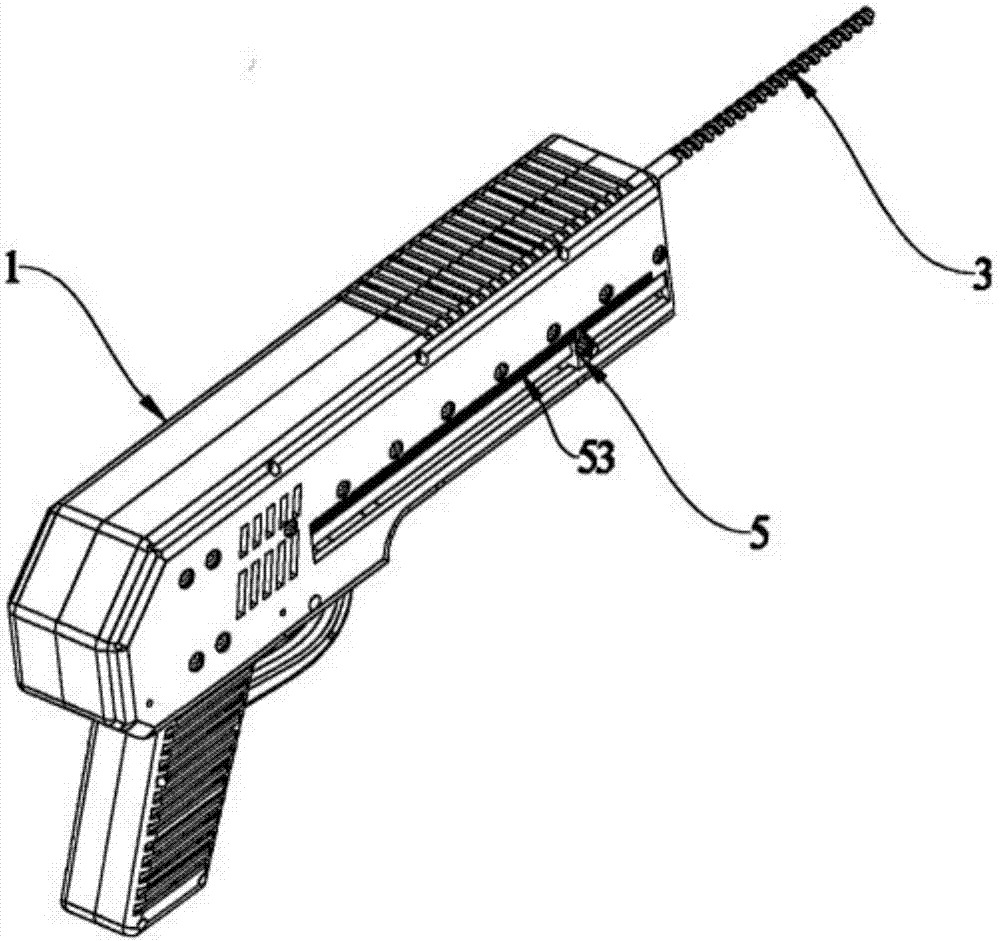

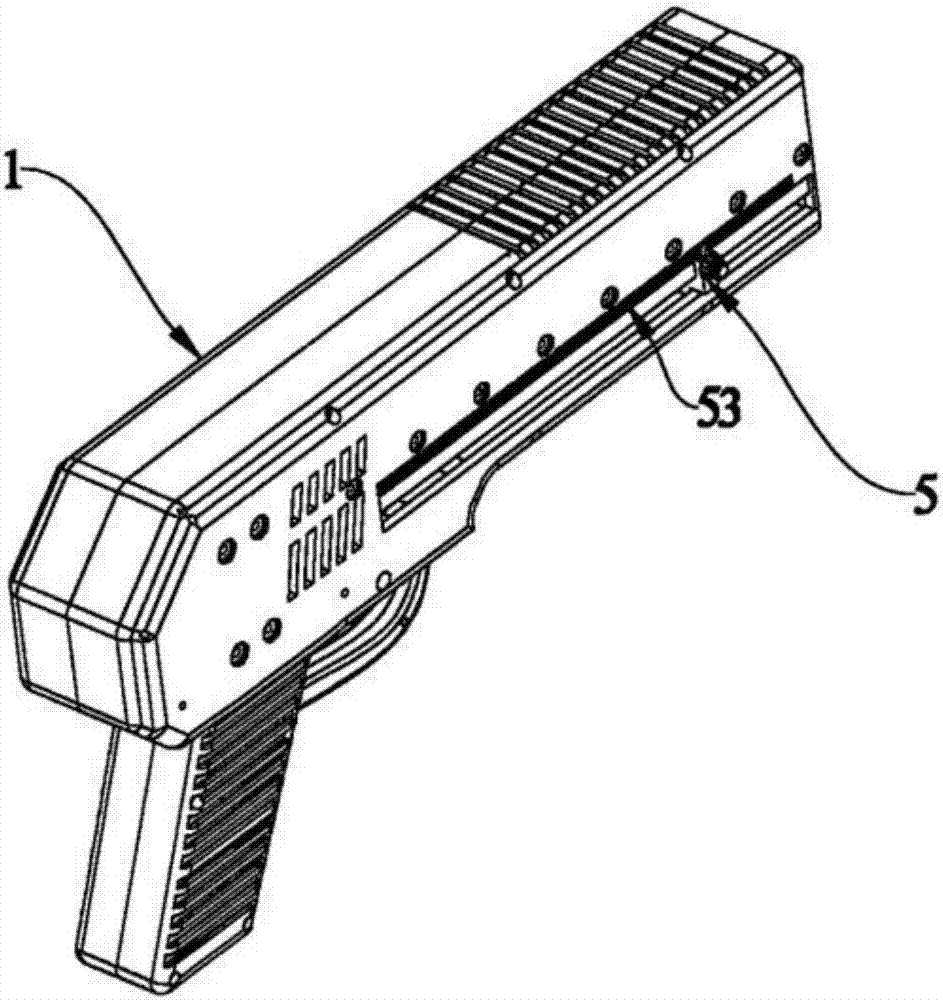

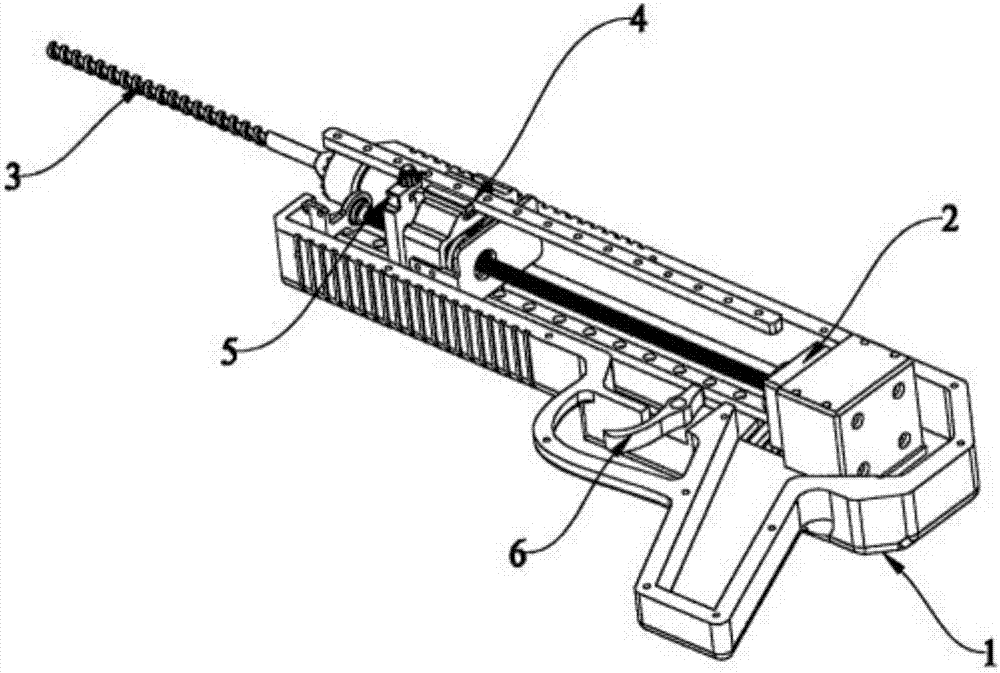

Novel electric drill

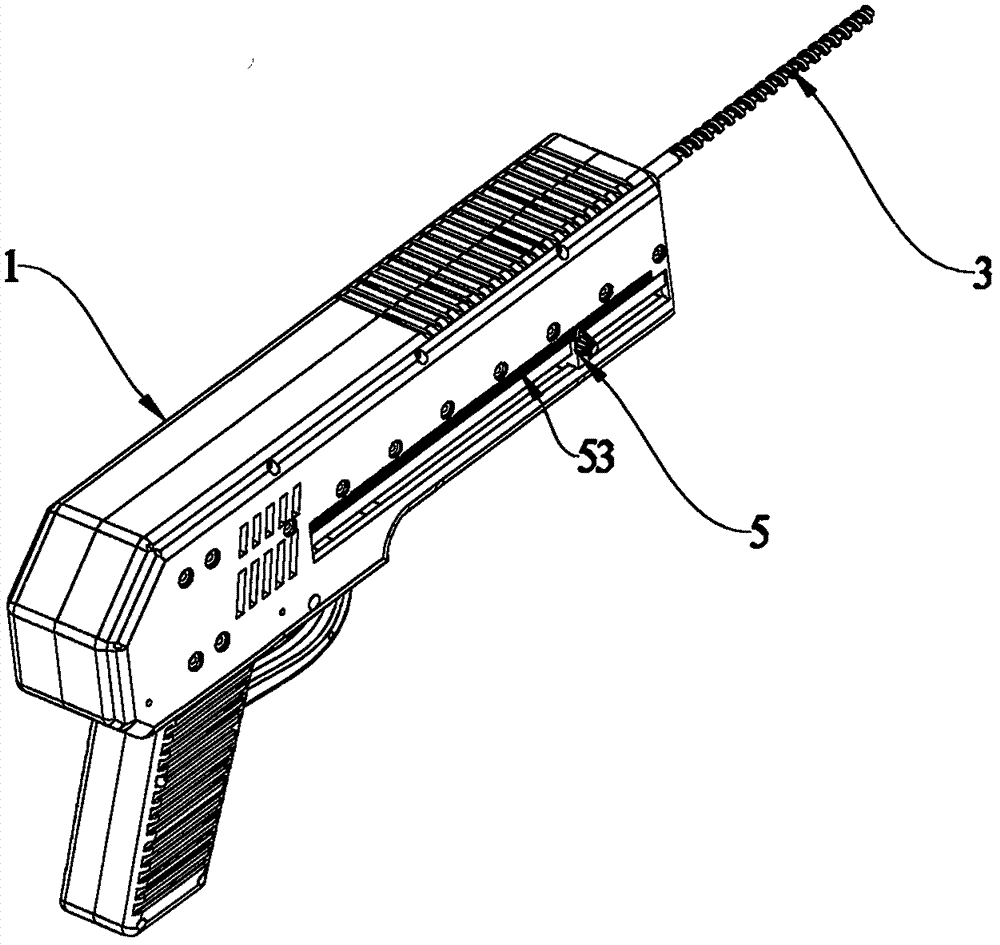

InactiveCN107999826AReduce frictionPrecise control of drilling depthPortable drilling machinesElectric machineryDrill bit

The invention discloses a novel electric drill. The novel electric drill comprises a shell body, a motor and a drill bit. The novel electric drill is characterized by further comprising a transmissionpart and a limit part, wherein the transmission part is connected with the motor and the drill bit in a transmissible manner, so as to realize the rotation of the drill bit with the motor, so that rotation in the circumferential direction of the drill bit and displacement in the axial direction of the drill bit can be carried out; and the limit part is movably arranged on the shell body, and usedfor limiting the displacement amount of the drill bit, so as to control a drilling depth. Therefore, the purposes that the drill bit gradually stretches out with the increasing of the drilling depthduring drilling, so that the drilling depth is accurately controlled, and the drill bit is located in the electric drill when the electric drill is not used, so that the drill bit is protected are achieved.

Owner:余姚市奥祥轴承有限公司

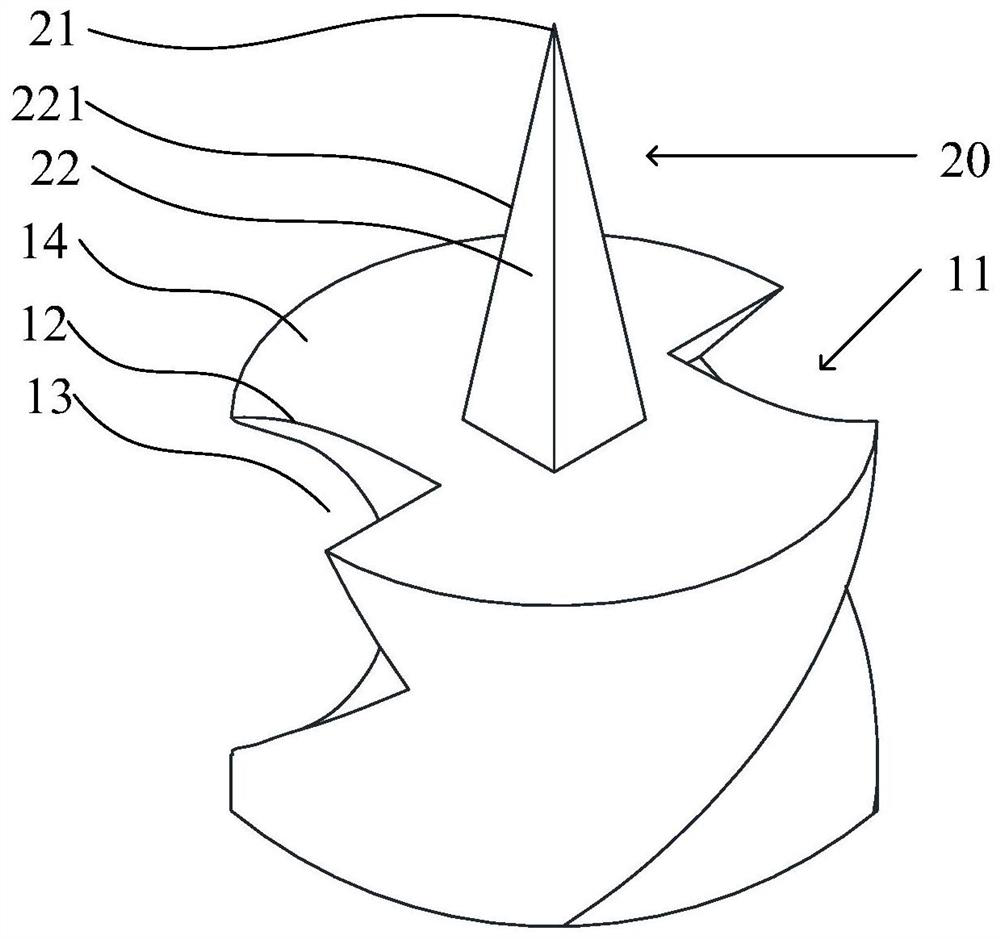

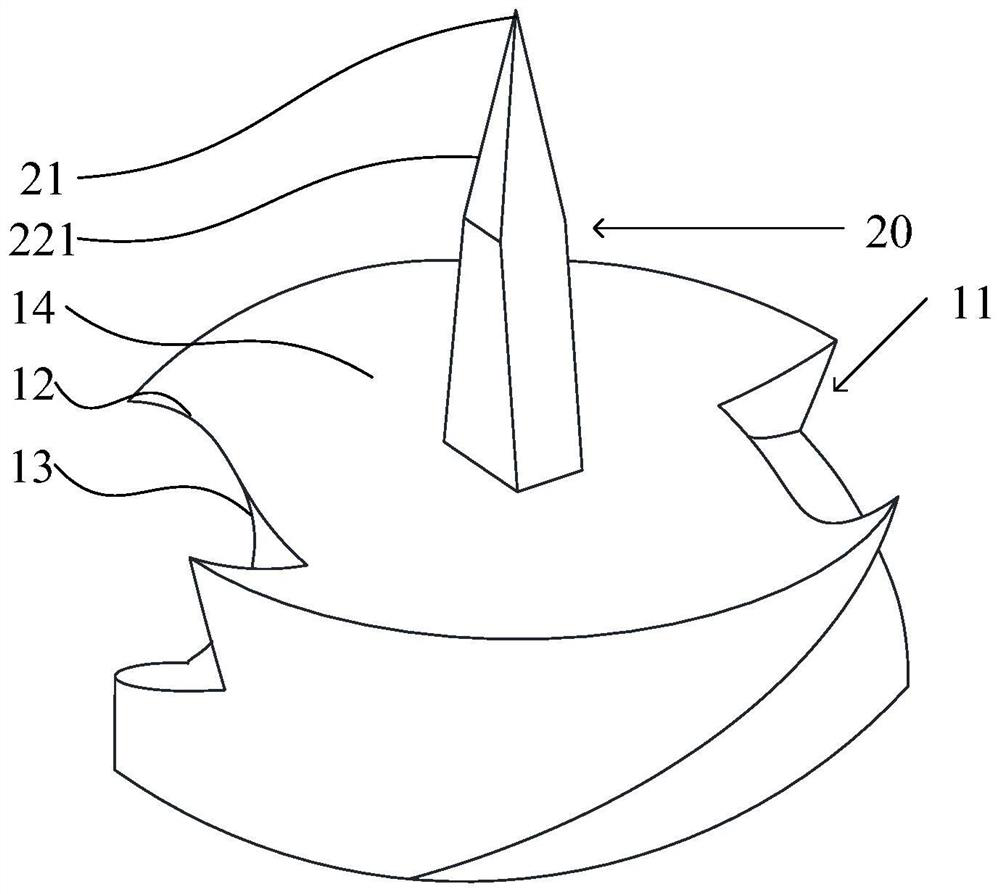

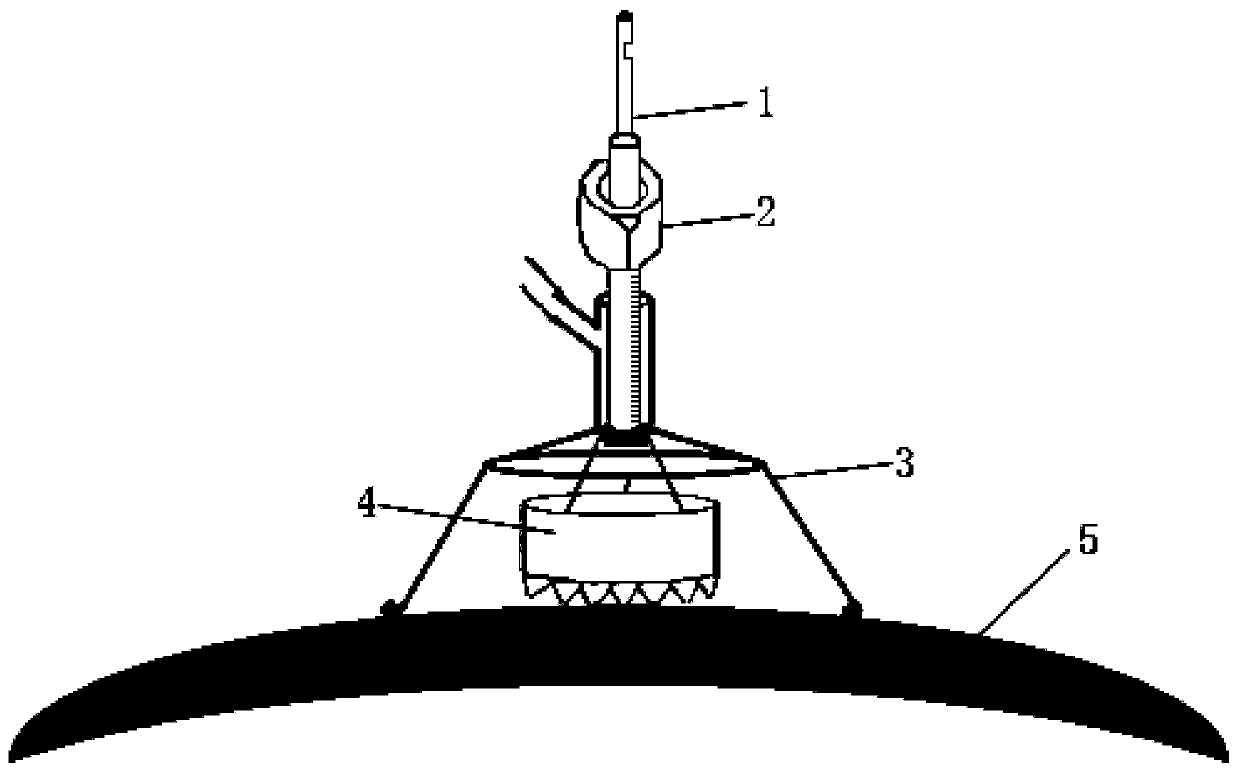

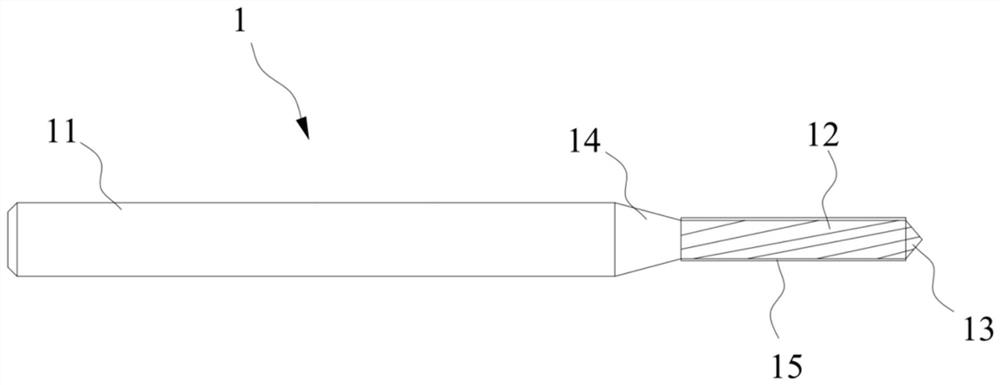

Orthopedic operation drill

InactiveCN111671490AImprove stabilityImprove the quality of follow-up surgeryDiagnosticsBone drill guidesSurgical drillOrthopedic Procedures

The invention discloses an orthopedic operation drill. The orthopedic operation drill comprises a drill body and a positioning part, wherein one end of the positioning part is connected to the end face of the drill body, the other end of the positioning part is provided with a tip, and the tip is used for determining the drilling position of the orthopedic operation drill in the cartilage or bone.According to the orthopedic operation drill, the orthopedic operation drill is simply and conveniently inserted into the cartilage or bone through the tip of the positioning part, so that sliding ofthe orthopedic operation drill on the cartilage or bone is avoided, and then the orthopedic operation drill can accurately perform drilling at a pre-designed implantation position. According to the orthopedic surgery drill, cartilage or bone drilling can be easily and conveniently achieved, the drilling efficiency can be improved, and the precision of the drilling position can be improved.

Owner:JIANGYIN STEMEASY BIOTECH LTD

Automatic feeding control method used for numerical control lathe tailstock and capable of controlling drilling depth

ActiveCN106180765ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlDrive motor

The invention provides an automatic feeding control method used for a numerical control lathe tailstock and capable of controlling the drilling depth. A connecting device for automatic connection and separation of a saddle and the tailstock of a numerical control lathe is adopted. The connecting device comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is mounted in a barrel sleeve of the numerical control lathe tailstock. The centering assembly comprises a centering shaft and a V-shaped block. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting press blocks. The driving assembly comprises a pair of belt drive parts, a drive motor, a reset switch and a controller, wherein the controller is mounted in a distribution box of the lathe, the reset switch is mounted in front of the saddle of the numerical control lathe, and the drive motor is fixedly connected with the numerical control lathe tailstock and electrically connected with the controller.

Owner:盐城市力真佳机电有限公司

Drilling device for processing doors and windows

InactiveCN112238235AAdjustable tilt anglePracticalMeasurement/indication equipmentsPositioning apparatusEngineeringMechanical engineering

The invention discloses a drilling device for processing doors and windows and belongs to the technical field of doors and windows processing. The drilling device comprises a bottom plate, a clampingand supporting mechanism and a drilling mechanism. The clamping and supporting mechanism comprises a clamping seat. Doors and windows of different dimensions can be supported by the clamping and supporting mechanism and the inclination angles of the doors and windows can be adjusted. The inclination angle of a drilling machine can be adjusted by the drilling mechanism. It is more precise to drillby adjusting the inclination angles of the doors and windows and the drilling machine. A connecting plate can be guided by means of a side supporting rod of a fixed rack II, so that the connecting rodis kept stable. A drilling depth can be mastered precisely by means of a scale mark, so that it is more precise to drill.

Owner:张锋凯

Punching machine capable of automatically controlling punching depth

InactiveCN104259510AControl punch depthPrecise control of drilling depthBoring/drilling componentsMaintainance and safety accessoriesAutomatic controlPunching

The invention provides a punching machine capable of automatically controlling punching depth. The punching machine comprises a base, a motor and a control device, a power output shaft of the motor is connected with an inner cooling joint, the inner cooling joint is connected with a hollow drill bit, a support is mounted on the base, a lifting air cylinder is disposed on the support, the lifting air cylinder is connected with the control device, the motor is fixedly connected with the support, a working table is disposed on the base, and a clamping mechanism is disposed on the working table. The punching machine capable of automatically controlling punching depth has the advantages that the lifting air cylinder is disposed on the support, the control device is connected with the lifting air cylinder, the height of the lifting air cylinder is controlled through the control device, thereby, the punching depth of the hollow drill bit is controlled, the punching depth is accurately controlled, the inner cooling joint is arranged and provided with a water inlet and a water outlet, tap water can flow in the hollow drill bit so as to cool the hollow drill bit, abrasion of the drill bit is reduced, and the service life of the drill bit is prolonged.

Owner:TIANJIN QINGLONG INTELLIGENT SCI & TECHCO

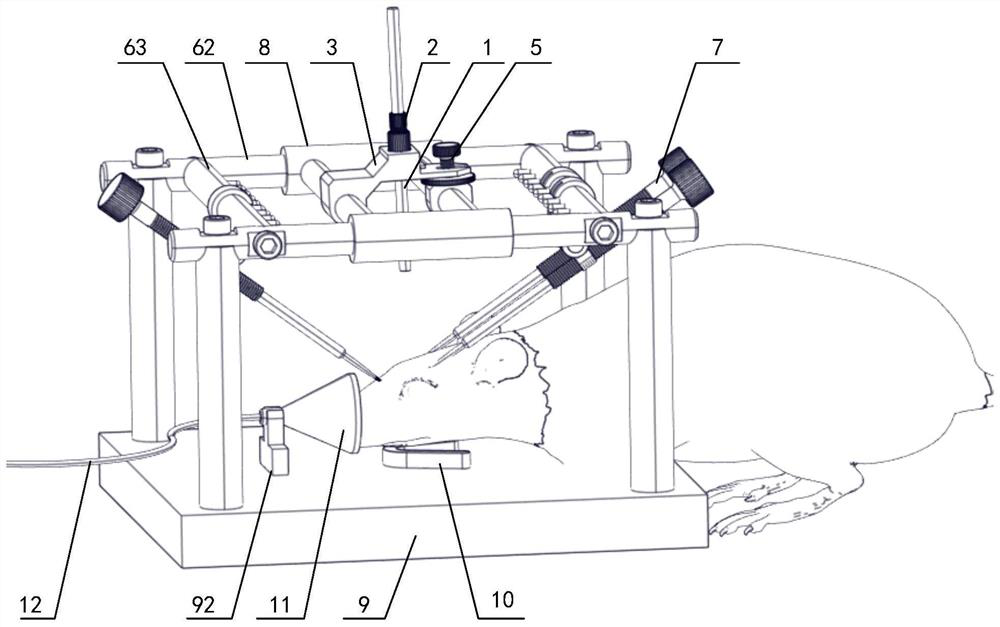

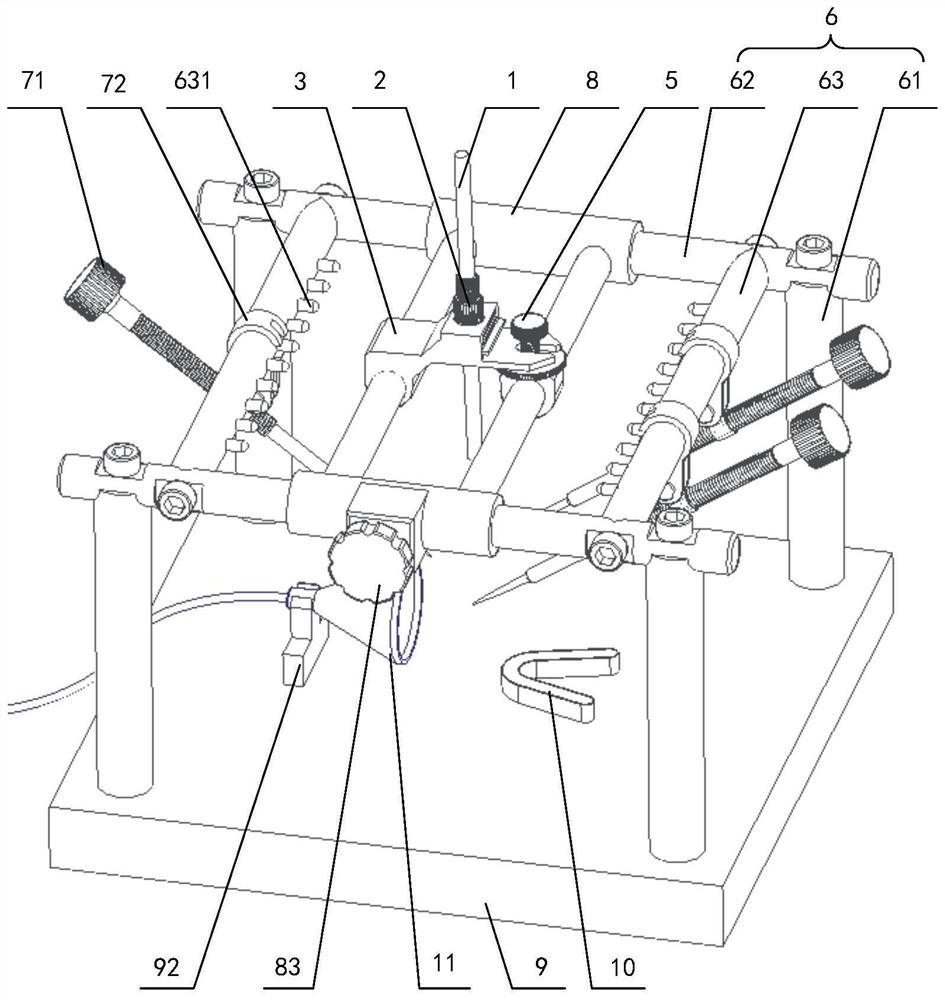

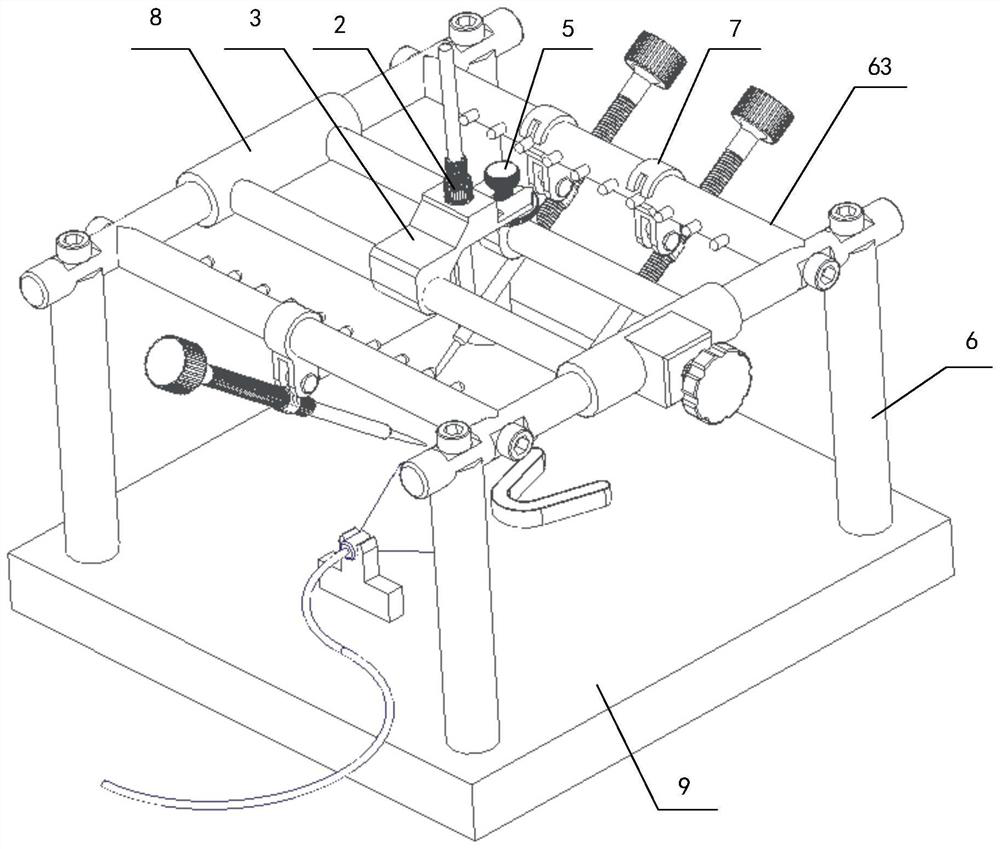

Modeling tool for animal skull defect models, and application method of modeling tool

PendingCN111467070APrecise control of drilling depthSolve the problem of verticalitySurgical veterinaryStructural engineeringSkull bone

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Wall installation dust-free visual rapid construction system

ActiveCN103537731BNo damage pointsReduce dustDirt cleaningPortable power-driven toolsDirect observationEngineering

The invention discloses a dust-free, visual and quick construction system for installing walls. The dust-free, visual and quick construction system comprises a large hole perforating device and a slim hole perforating device. According to the technical scheme, the dust-free, visual and quick construction system has the advantages that large holes are directionally perforated by the large hole perforating device, slim holes are perforated on the basis of the large holes, a same-hole adhesion technology is adopted, accordingly, increase of damage points of wall surfaces is prevented, dust in air can be reduced by a combination of a hollow drill bit and a dust collection technology, the perforation depths can be accurately controlled by the aid of a depth controllable technology, the insides of the holes can be directly observed by the aid of a camera and an illuminating device, accurate perforation, speediness, dust-free and noiseless effects can be realized integrally, and the dust-free, visual and quick construction system can assist investigators to effectively protect the country and personal lives and properties. The dust-free, visual and quick construction system for installing the walls can be widely applied to the field of perforation.

Owner:GUANGZHOU WAVE SCI & TECH DEVCO

Automatic numerical control lathe tailstock control method

ActiveCN106001633ARealize synchronized movementRealize finishingTailstocks/centresAuxillary equipmentMagnetic exchangeAutomatic control

The invention provides an automatic numerical control lathe tailstock control method. A connection device for achieving automatic connection and disconnection between a lathe saddle and a tailstock of a numerical control lathe through an air cylinder is utilized. The connection device comprises a connection pillar, a rotating arm assembly, a drive assembly and a drill bit assembly, the middle of the connection pillar is provided with an annular groove, the shaft end of the connection pillar and the side face of the tailstock are provided with a pair of sensors, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and a big gear, the shaft sleeve is fixed to the front side face of the tailstock of the numerical control lathe, the rotating shaft penetrates through the shaft sleeve, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the big gear, the front end of the rotating arm is provided with a hook portion capable of being clamped into an annular groove, the drive assembly comprises a rack, an air cylinder, a magnetic exchange valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the magnetic exchange valve, and the rest switch is mounted in front of the lathe saddle of the numerical control lathe and electrically connected with the controller.

Owner:三星智能科技盐城有限公司

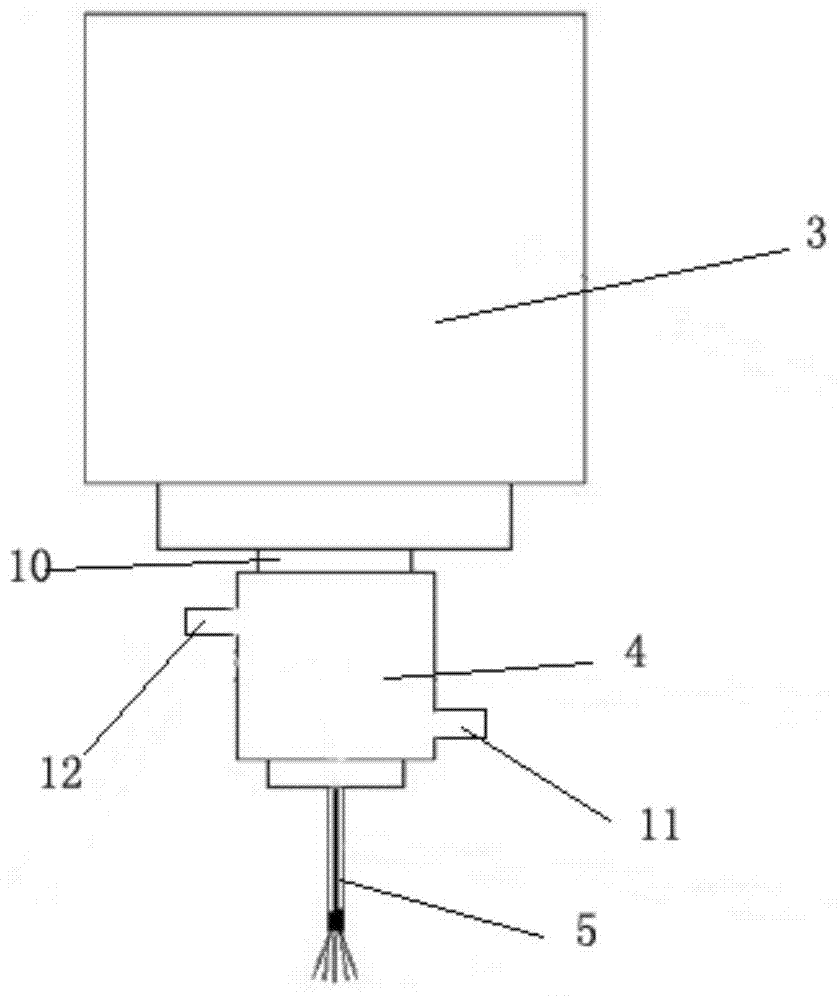

Rat craniocerebral model preparation device

ActiveCN113456284APrecise control of drilling depthAvoid damageAnimal fetteringSurgical veterinaryPilot holeStructural engineering

The invention discloses a rat craniocerebral model preparation device which comprises a sliding block, a drill rod, at least two limiting insertion holes and limiting insertion pieces, wherein the sliding block is arranged in a sliding mode and provided with a guide hole, the drill rod is sleeved with a locking sleeve, the limiting insertion holes are distributed in one side of the sliding block in the axial direction of the guide hole and communicated with the guide hole in the radial direction, and the limiting insertion piece is inserted into one limiting insertion hole. When the sliding block slides to a designated area, the limiting insertion piece is inserted into the limiting insertion hole in the uppermost layer, the drill rod moves downwards along the guide hole until the drill rod abuts against the skull, the locking sleeve which is not locked moves downwards along the drill rod to abut against the limiting insertion piece when the drill rod moves downwards along the guide hole to abut against the skull, the locking sleeve is locked on the drill rod, and the limiting insertion piece is pulled out; when the limiting insertion pieces are sequentially inserted into the limiting insertion holes of the subsequent layers from top to bottom, the locked locking sleeve drills into the skull along with the drill rod till the locking sleeve abuts against the limiting insertion pieces again, the drilling depth of the drill rod is equal to the distance between all the limiting insertion holes, the drilling depth of the drill rod is accurately controlled, and the situation that the drill rod damages the brain is avoided.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

Numerically-controlled lathe tailstock automatic feeding control method capable of controlling finishing of hole bottoms

ActiveCN106112024ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

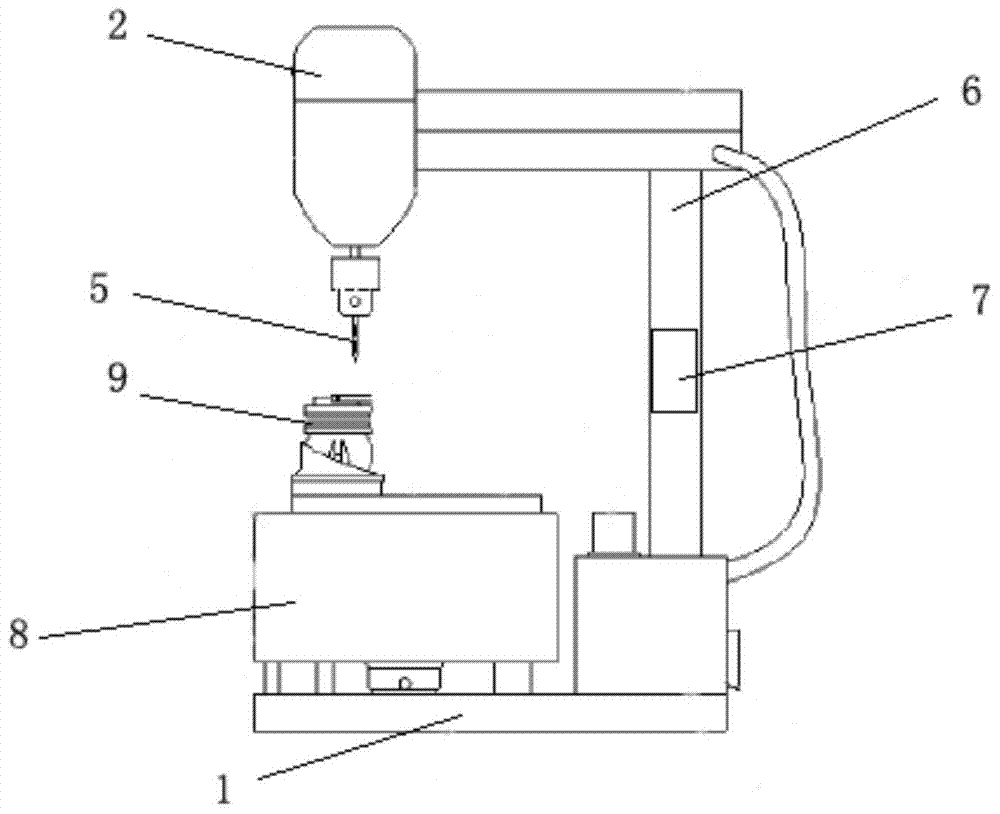

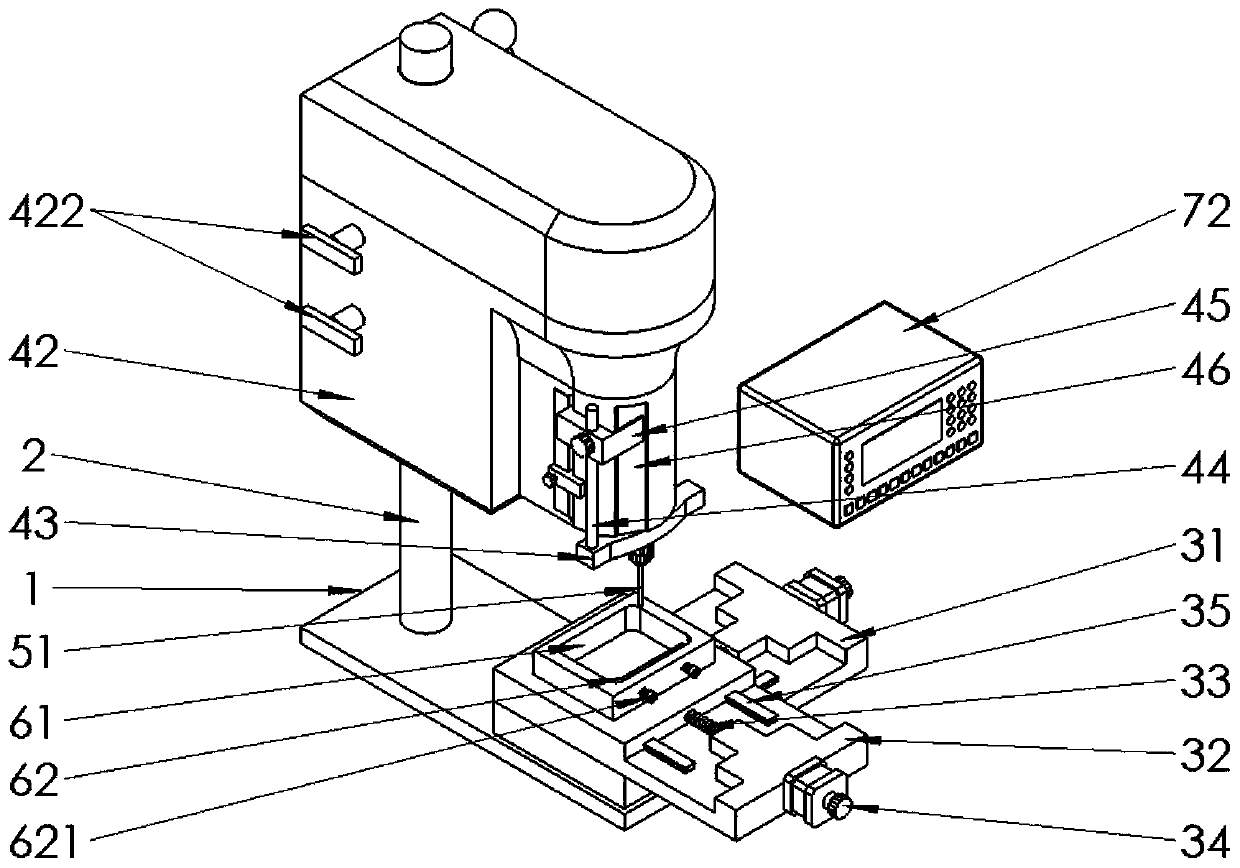

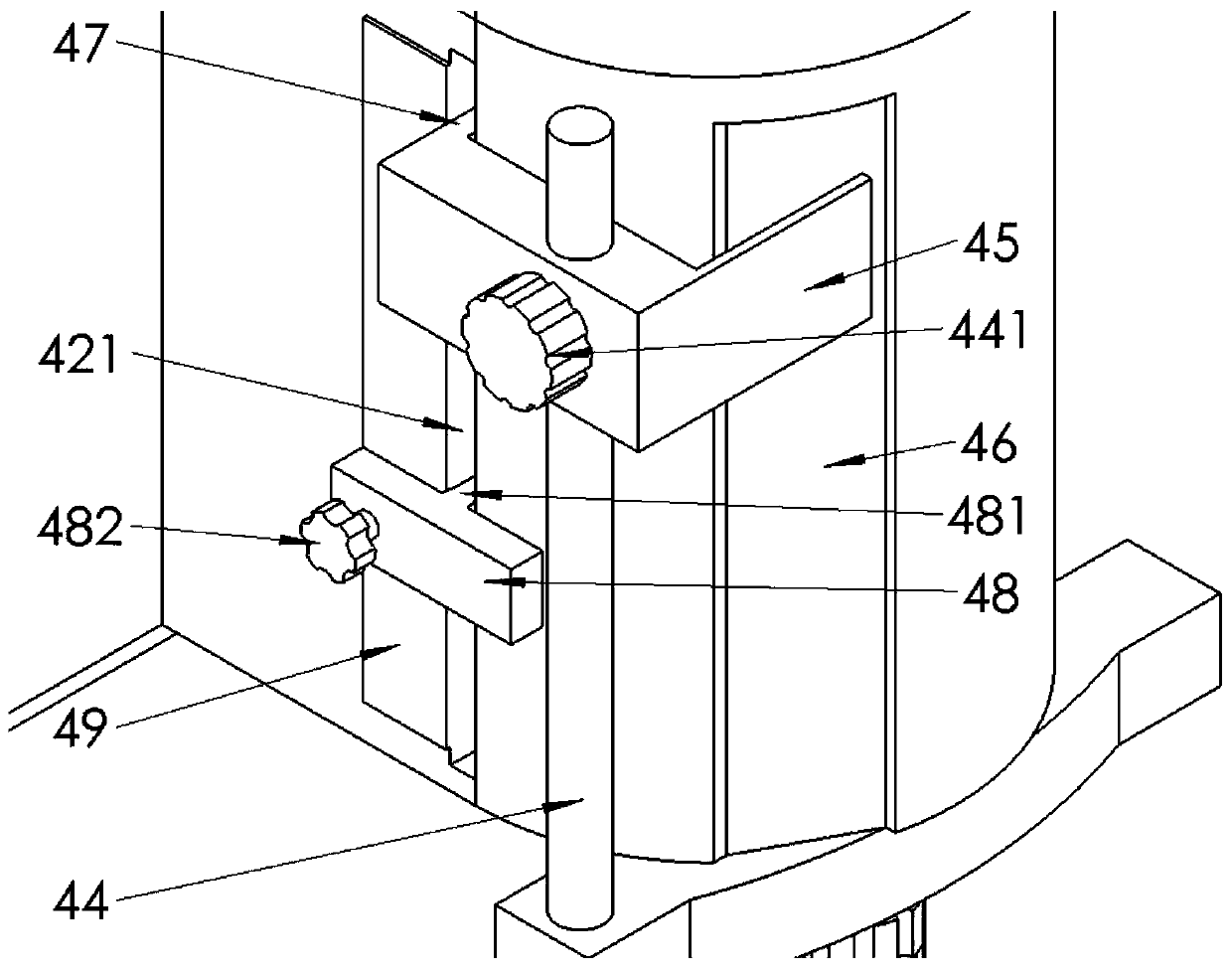

Blank wax stone drilling machine for tissue chip

PendingCN110614673AAccurately control the punching positionEasy to movePreparing sample for investigationMetal working apparatusWaxEngineering

The invention provides a blank wax stone drilling machine for a tissue chip. The drilling machine includes a base, a bracket, a horizontal movement mechanism, a vertical movement mechanism, a drillingmechanism and a wax stone fixing seat. The bracket is connected with the base; the horizontal movement mechanism comprises two horizontal movement components which are mutually vertically connected,namely, the X-axis movement component and the Y-axis movement component; scales and / or grating rulers are arranged on the horizontal movement components, one horizontal movement component is connectedwith the base, and the other horizontal movement component is connected with the wax block fixing seat; the vertical movement mechanism includes a Z-axis movement component and a Z-axis limiting component, the Z-axis movement component is connected with the bracket and the drilling mechanism respectively, and the Z-axis limiting component is arranged on the Z-axis movement component for limitingthe maximum displacement of the Z-axis movement component. The drilling mechanism includes a drill bit, a first transmission device and a first motor, wherein the first motor is connected with the drill bit through the first transmission device.

Owner:北京龙迈达斯科技开发有限公司

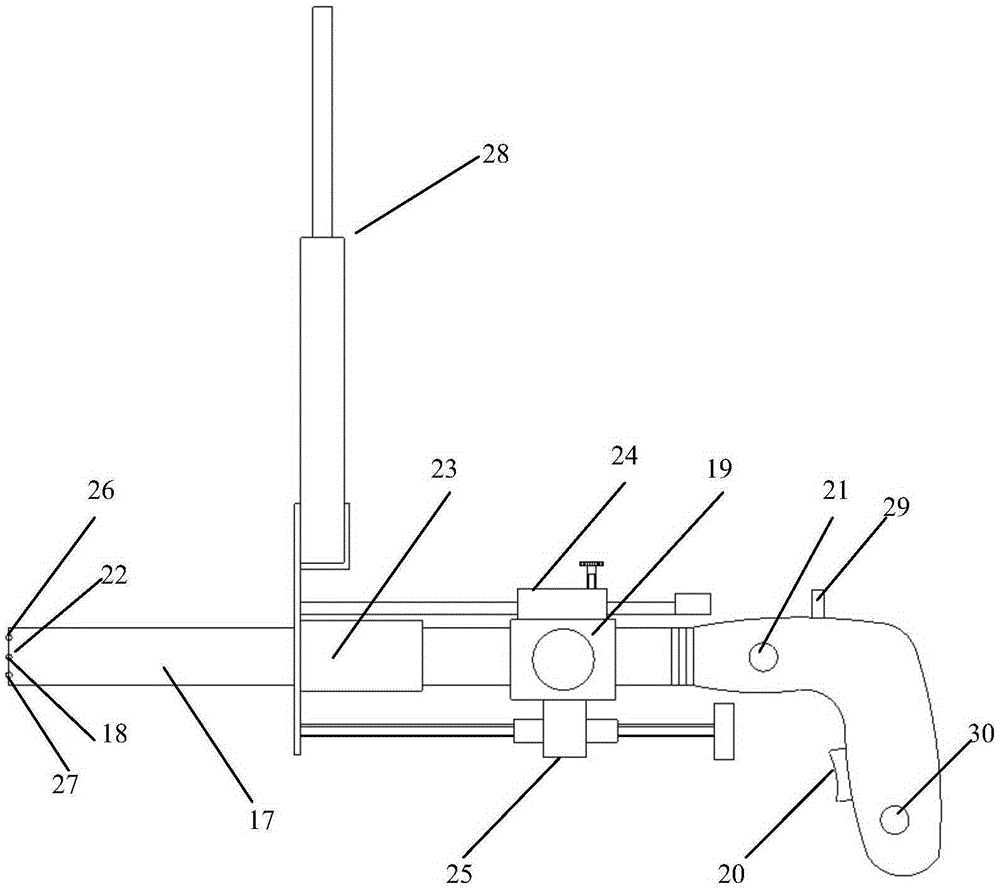

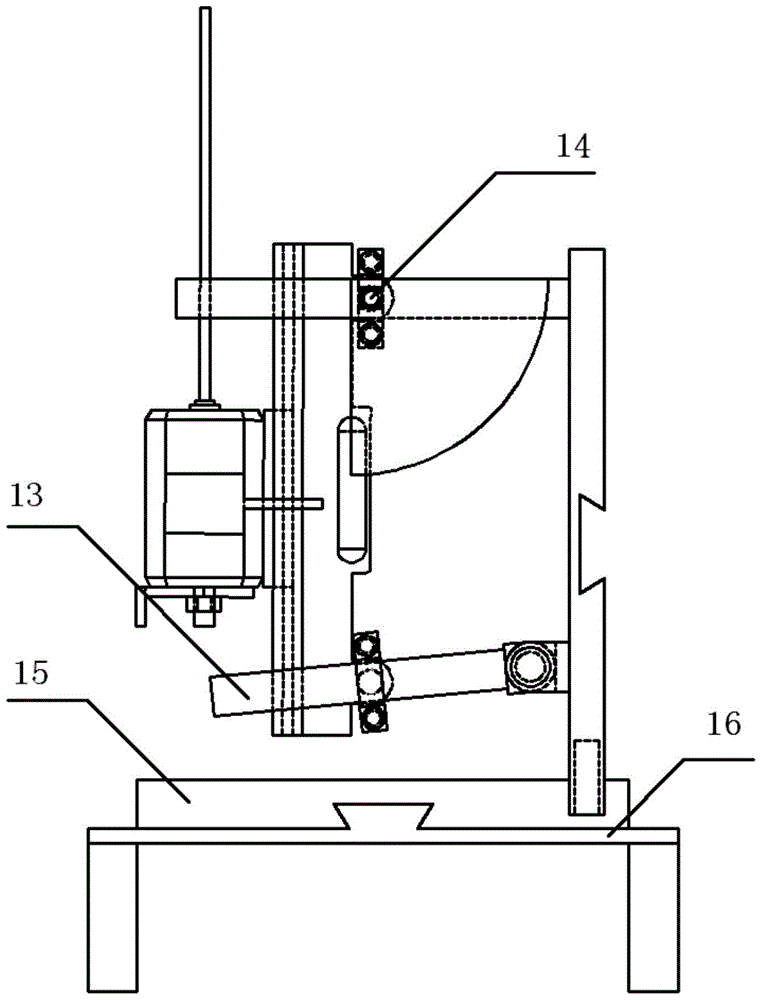

Punching device and punching method for foundation horizontal bar planting

InactiveCN114042967AControl depthPrecise punchingMeasurement/indication equipmentsPortable drilling machinesPunchingArchitectural engineering

The invention relates to the technical field of building construction, in particular to a punching device and a punching method for foundation horizontal bar planting. The punching device comprises an adjustable base support, a sliding frame and a stroke control mechanism, wherein height of the adjustable base support can be adjusted, and the adjustable base support can be used for being placed on the ground or a surface of a building foundation; the sliding frame is installed on the adjustable base support in a sliding mode, and a handheld electric drill is detachably connected with the sliding frame; and the stroke control mechanism is connected with the adjustable base support and the sliding frame, and the stroke control mechanism is used for controlling a moving distance of the sliding frame relative to the adjustable base support. The punching method comprises the steps that S1, height and levelness of the adjustable base support are adjusted; S2, the handheld electric drill is installed; S3, the handheld electric drill is started; and S4, a driving push rod pushes the handheld electric drill to accurately drill holes. According to the invention, the operation efficiency can be improved, the safety risk is reduced, the punching depth is accurately controlled, and the construction quality is guaranteed.

Owner:HEBEI INSTALLATION ENG

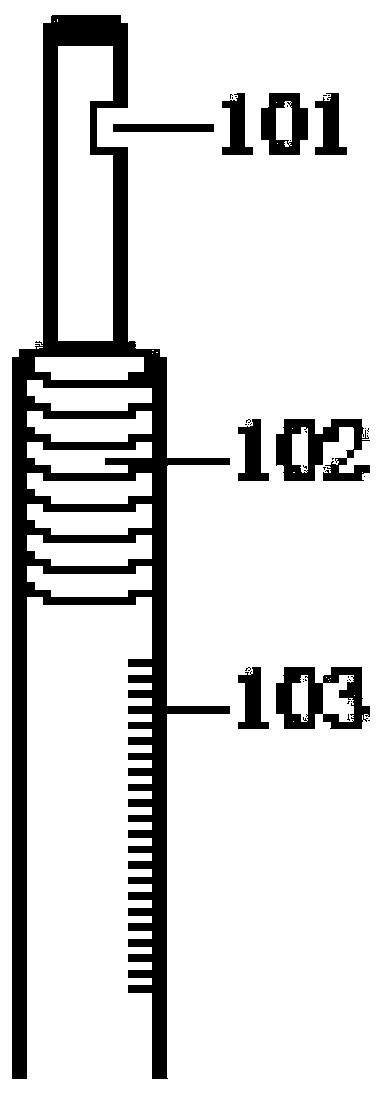

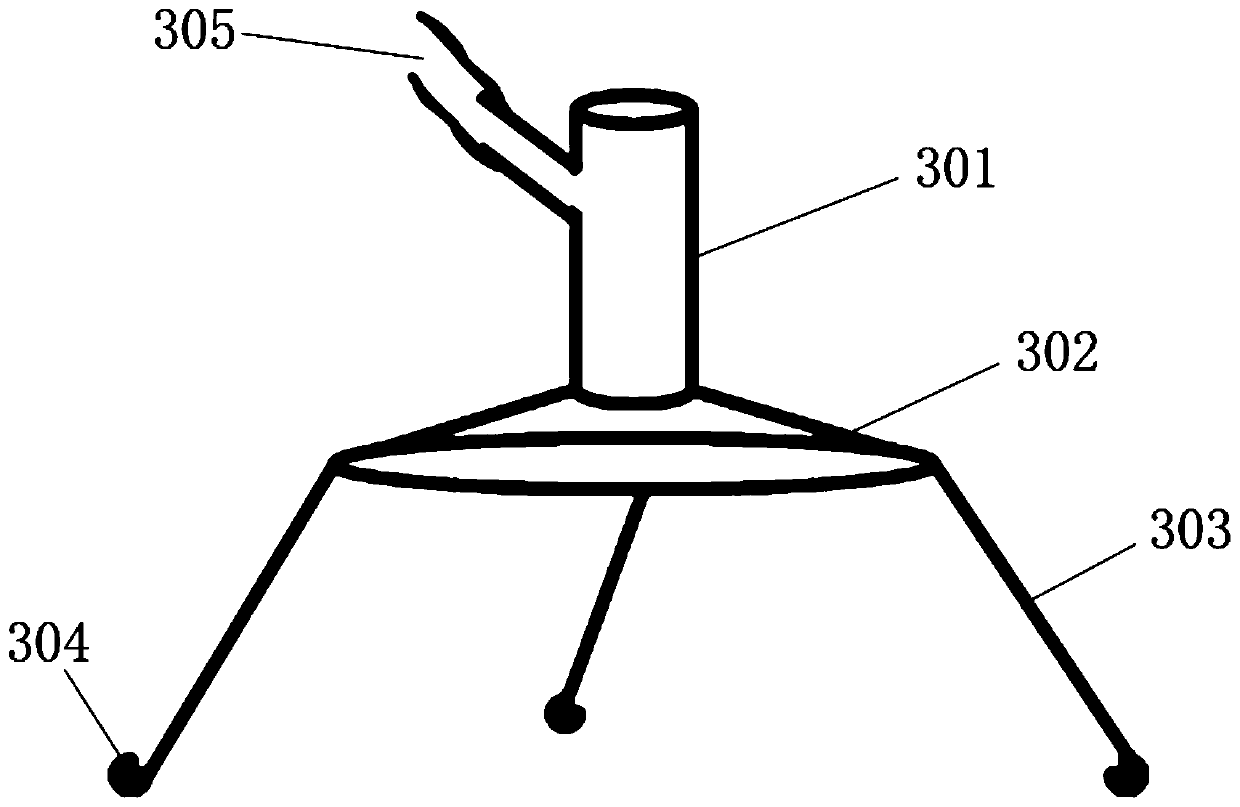

Thermal control multilayer puncher for spacecraft

ActiveCN109571636ALightweight and easy to handleImprove handlingMetal working apparatusSelf lockingScrew thread

The invention provides a thermal control multilayer puncher for a spacecraft, which is characterized by comprising a handle, a screw rod, a butterfly nut, a cylindrical base, a needle head and a scale; wherein one end of the screw rod is wrapped by the handle, the other end of the screw rod is provided with a central hollow area, the surface of the other end of the screw rod is provided with threads; the needle head is inserted into the central hollow area; the butterfly nut and the cylindrical base are fixedly connected with the screw rod through the threads, and the scale is arranged on thethreads. The puncher provided by the invention is light, easy to hold, simple in structure, convenient to operate and easy to popularize; the head of the screw rod is hollow to realize the design of the replaceable needle head; the head of the screw rod convenient for maintenance; the needle head is made of stainless steel and has high strength and corrosion resistance; the point of the needle head has various specifications and can punch holes of any aperture; the threads of the screw rod are fine threads with self-locking property; the depth of the point can be adjusted; the cylindrical baseis made of brass material and has a large bottom area, so the cylindrical base can meet the requirement of pressure dispersion, and the bottom surface is stressed evenly; and the cylindrical base iscapable of finding perpendicularity during drilling.

Owner:SHANGHAI INST OF SPACE PROPULSION

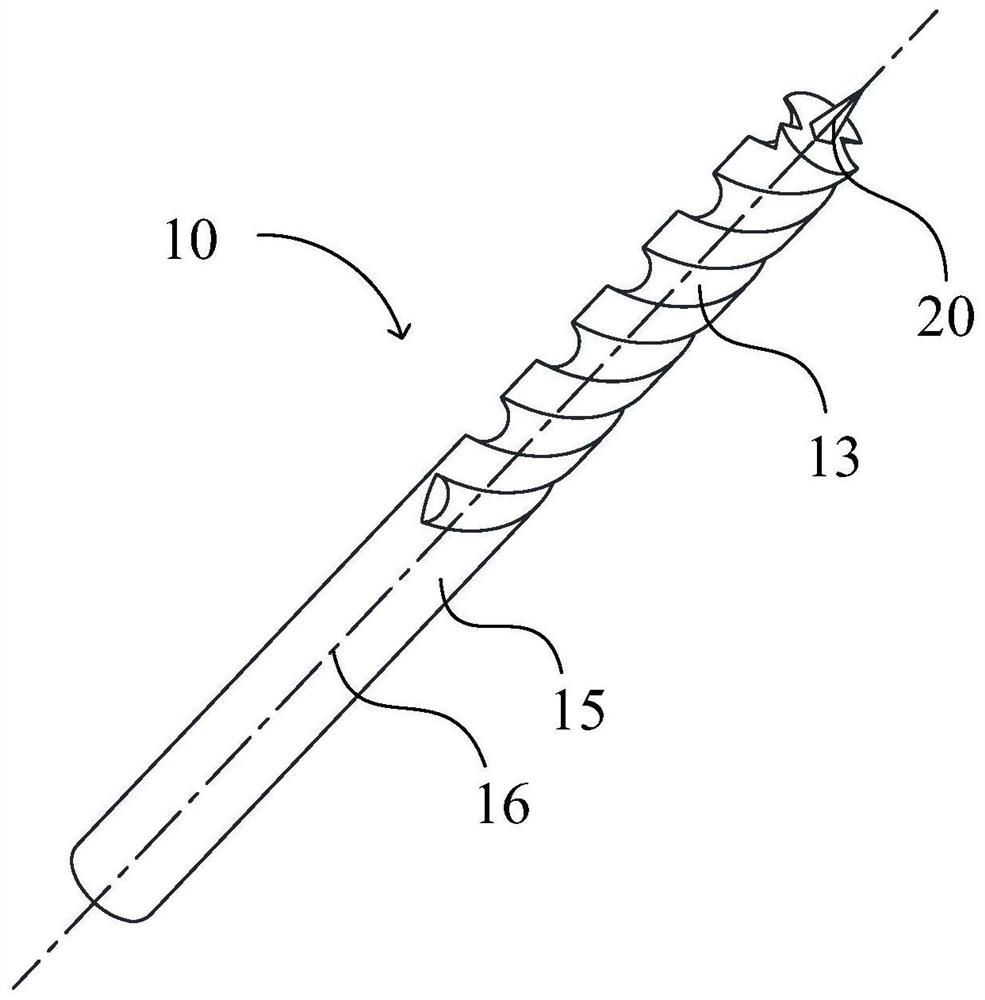

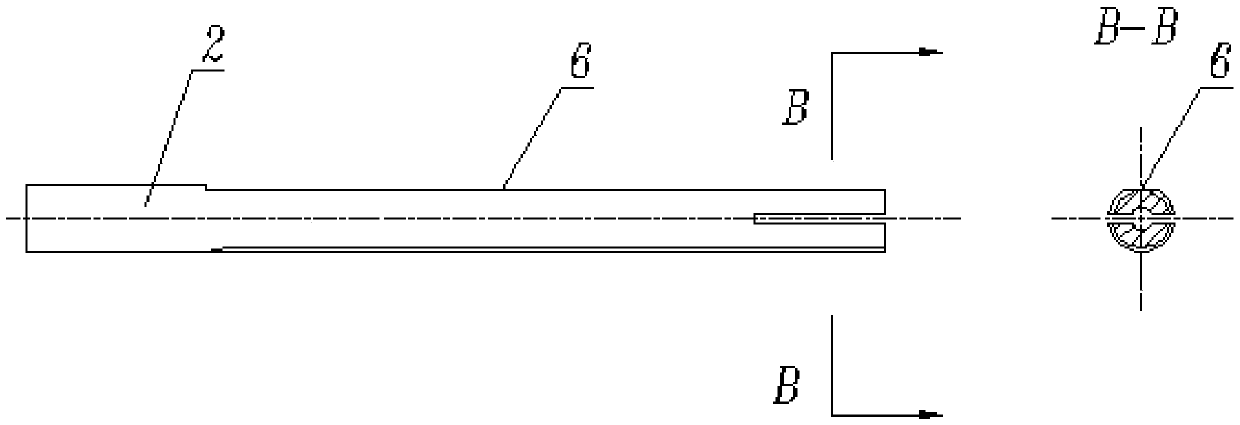

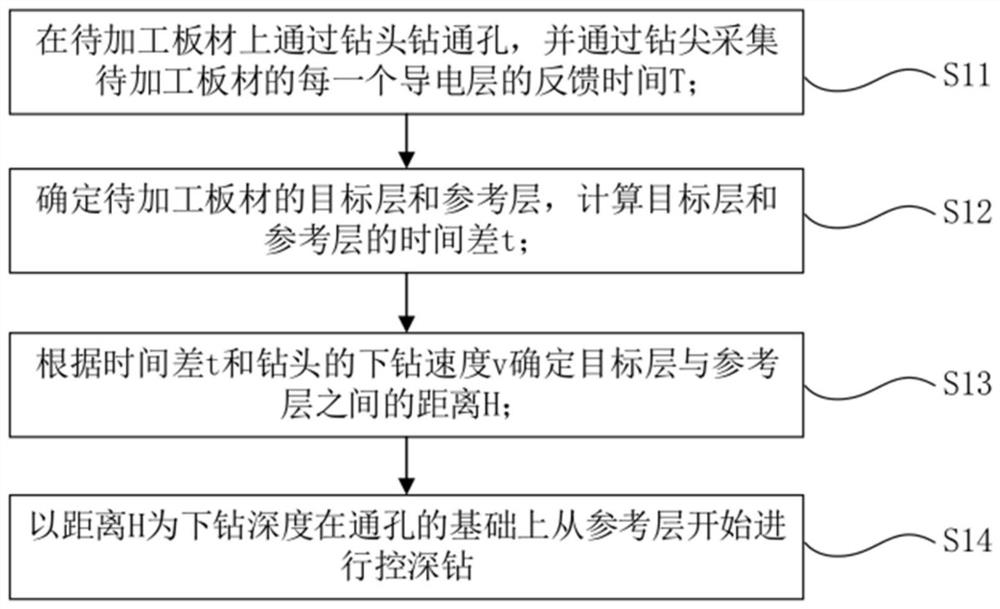

Use method and preparation method of drill bit

ActiveCN112372739AGet rid of dependencyPrecise control of drilling depthMetal working apparatusWorkpiecesEngineeringMachine tool

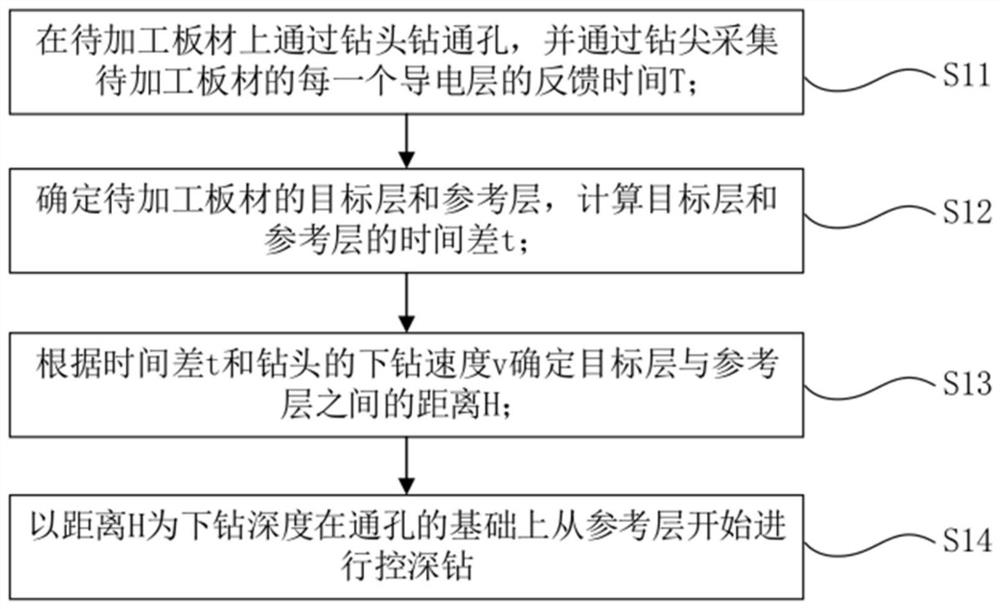

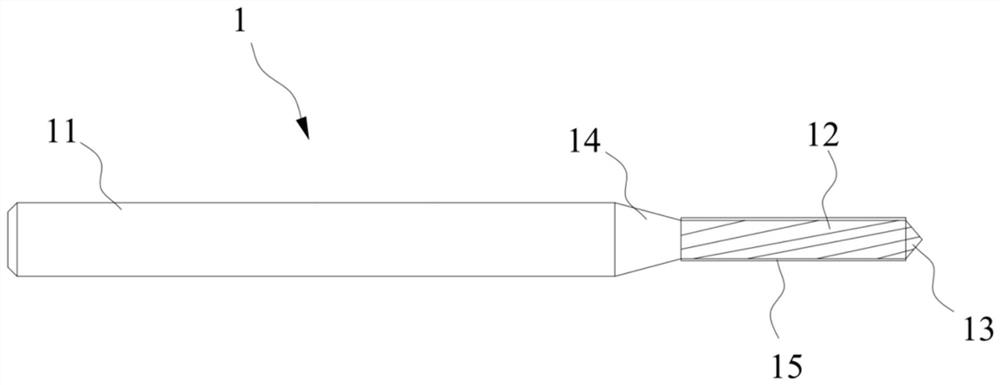

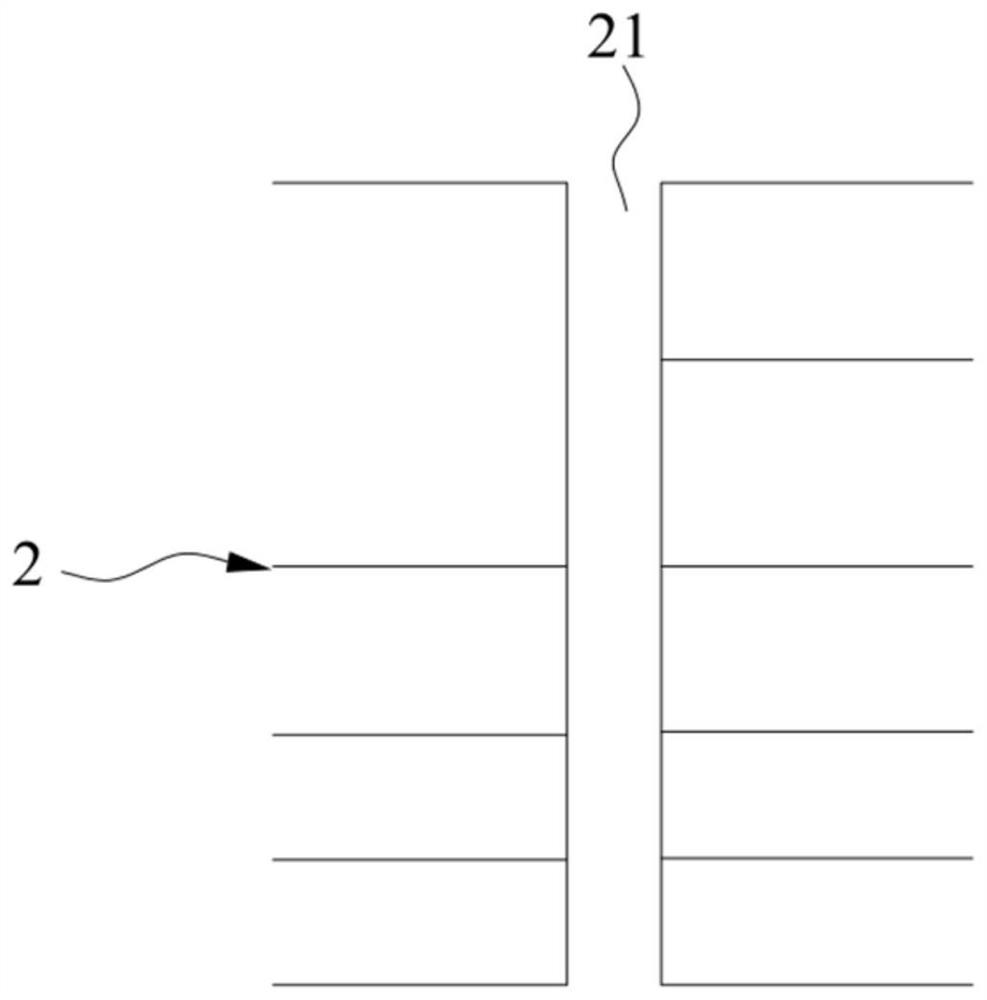

The invention discloses a use method and a preparation method of a drill bit, and relates to the technical field of machining tools. The drill bit comprises a drill handle, a drill blade and a drill tip which are connected in sequence; the drill tip can conduct electricity; and the drill blade is covered with a non-conducting film layer. The use method of the drill bit comprises the following steps that S11, a through hole is drilled in a to-be-machined plate through the drill bit, and the feedback time T of each conducting layer of the to-be-machined plate is collected through the drill tip;S12, a target layer and a reference layer of the to-be-processed plate are determined, and a time difference t between the target layer and the reference layer is calculated; S13, the distance H between the target layer and the reference layer is determined according to the time difference t and the drilling speed v of the drill bit; and S14, the distance H is used as the drilling depth, and depth-controlled drilling is performed from the reference layer on the basis of the through hole. By means of the method, when the drill bit is used for depth-controlled drilling, the drilling depth can beaccurately controlled, meanwhile, the method does not depend on procedures, and the machining efficiency and the machining precision can be improved.

Owner:GUANGDONG DTECH TECH CO LTD

A device for punching holes at a specified depth on a rubber product production line

ActiveCN109079907BAvoid the phenomenon of piercingPrecise control of drilling depthMetal working apparatusPunchingGear wheel

The invention relates to the field of rubber punching, more specifically, a device for punching holes at a specified depth on a rubber product production line, including a support base, a driver, an adjustment gear and a drill, and the support base includes a horizontal Plate, four legs, vertical plate, fixed shaft, rotating slot, replacement threaded hole, left support plate, two through slots, right support plate, fixed plate, fixed round hole, loading plate, rack plate, slider , chute, multiple object troughs and multiple through troughs, the four legs are respectively fixedly connected to the four bottom corners of the lower end of the horizontal plate, the vertical plate is fixedly connected to the front end of the horizontal plate, and the front end of the fixed shaft is fixedly connected to the On the vertical plate, the rotating groove is arranged on the fixed shaft, and the replacement screw hole is arranged on the rear end of the fixed shaft; the beneficial effect of the present invention is that the rubber products such as rubber tubes can be drilled in batches, and the drilling depth can be precisely controlled to avoid Phenomenon that the rubber tube is double-punched.

Owner:威海恒兴汽车配件有限公司

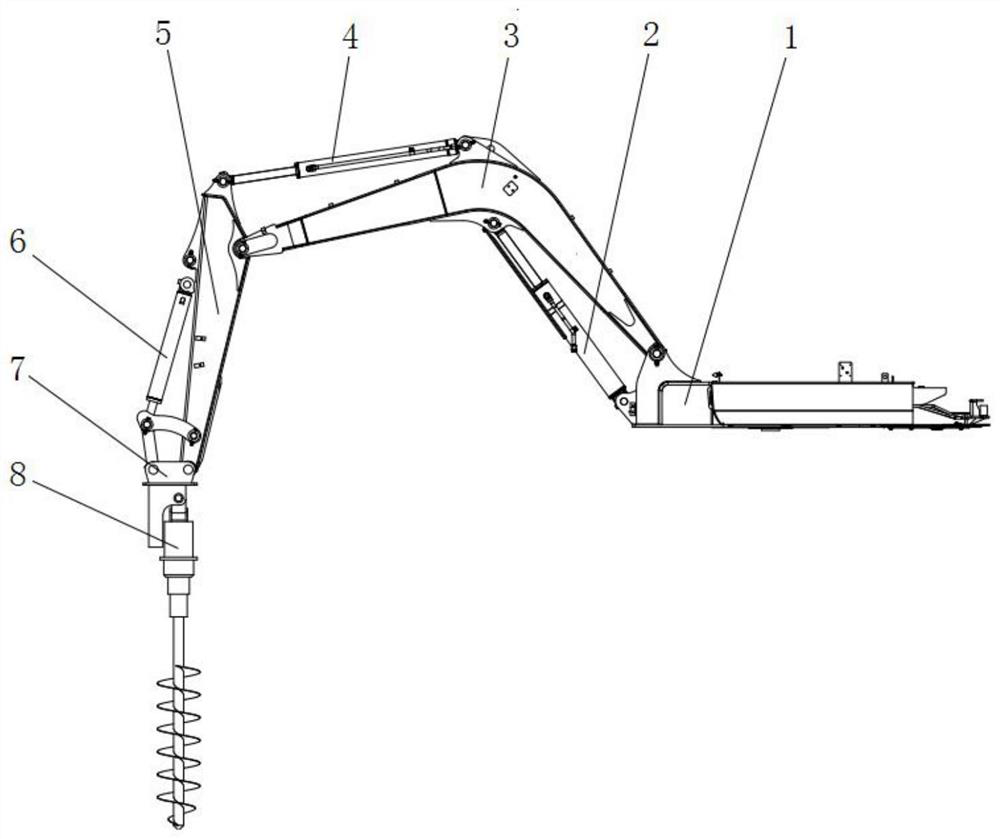

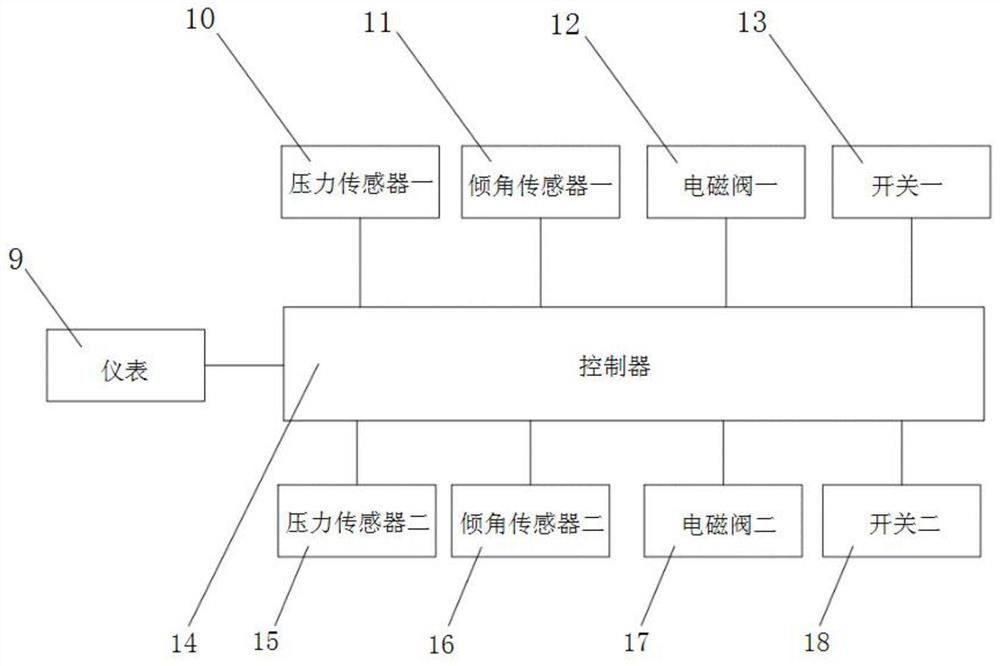

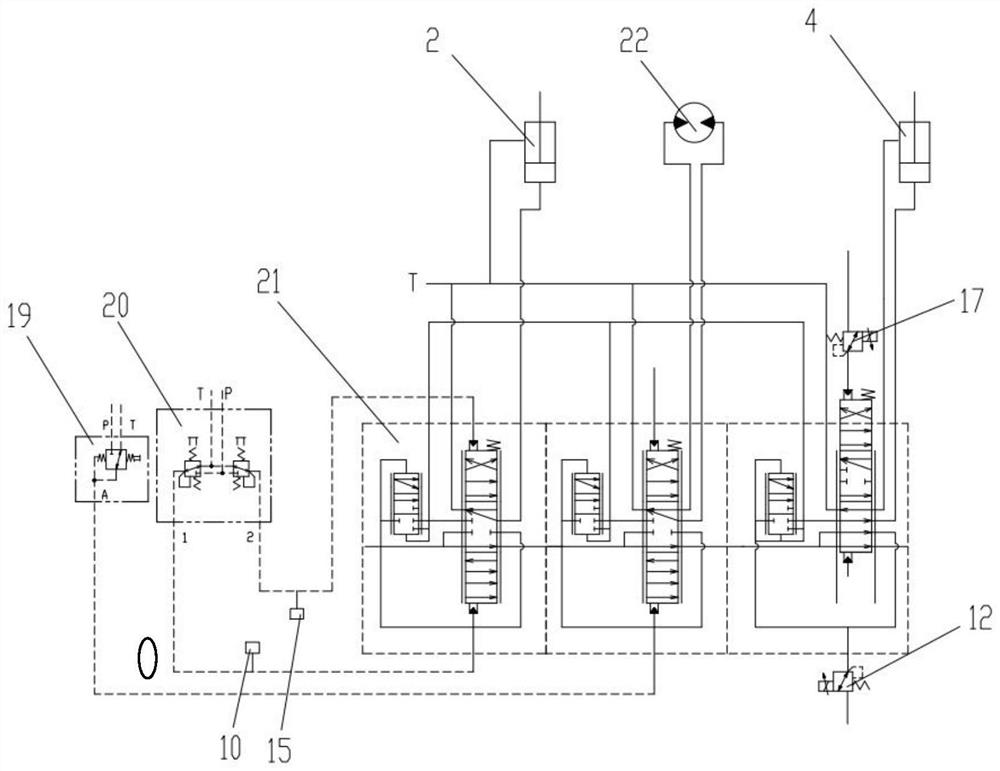

Control system and control method for auger stem machine tool of hydraulic excavator

PendingCN114215500AReduce processEliminate the operation of stick controlAutomatic control for drillingAutomatic controlControl system

The control system comprises a rotary table, a movable arm oil cylinder, a movable arm, a bucket rod oil cylinder, a bucket rod, a bucket oil cylinder, a spiral drill rod connecting mechanism and a spiral drill rod, and further comprises a controller, an instrument, a pressure sensor, a tilt angle sensor, an electromagnetic valve and a switch. The controller is electrically connected with the instrument, the pressure sensor, the tilt angle sensor, the electromagnetic valve and the switch. The electromagnetic valve is used for controlling the bucket rod linkage valve element to achieve inward retracting and outward swinging of the bucket rod. The tilt angle sensor is mounted on the movable arm and the bucket rod and used for identifying postures of the movable arm and the bucket rod; the switches comprise the first switch and the second switch, the first switch is used for triggering and recognizing the position of the spiral drill rod and triggering and recognizing the horizontal and vertical distance between a connecting shaft between the spiral drill rod and the bucket rod and a connecting shaft between the movable arm and the rotary table, and the second switch is used for triggering and starting the automatic control function of a spiral drill rod machine tool. According to the invention, inclination of a drilling pit is effectively avoided, perpendicularity of the drilling pit is ensured, operation difficulty is greatly reduced, and working efficiency is improved.

Owner:XCMG EXCAVATOR MACHINERY

Thermally controlled multi-layer hole puncher for spacecraft

ActiveCN109571636BLightweight and easy to handleImprove handlingMetal working apparatusScrew threadCorrosion resistant

The invention provides a thermal control multi-layer puncher for spacecraft, which is characterized in that it includes a handle, a screw, a butterfly nut, a cylindrical base, a needle, and a scale; one end of the screw is wrapped by the handle, and the other end of the screw is set There is a central hollow area, the other end surface of the screw is provided with threads, the needle is inserted into the central hollow area, the wing nut and the cylindrical base are tightly connected with the screw through the threads, and a scale is provided on the threads. The invention is light and easy to hold, simple in structure, convenient in operation, and easy to popularize; the head of the screw is hollowed out to realize the design of replaceable needles, which is convenient for maintenance; the needles are made of stainless steel, high-strength and corrosion-resistant; Arbitrary aperture; the screw thread adopts fine thread, which has self-locking characteristics, and the depth of the needle hole can be adjusted; the cylindrical base is made of brass material with a large bottom area, which meets the requirements of dispersing pressure and the bottom surface is evenly stressed, and has self-seeking verticality when drilling. ability.

Owner:SHANGHAI INST OF SPACE PROPULSION

An automatic feed control method for the tailstock of a CNC lathe that can control the finishing of the bottom of the hole

ActiveCN106112024BRealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesGear wheelEngineering

The invention provides a numerically-controlled lathe tailstock automatic feeding control method capable of controlling the finishing of hole bottoms. A connecting device for realizing the automatic connection and disconnection of a saddle and a tailstock of a numerically-controlled lathe by using a cylinder, used in the invention, comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly, wherein the centering assembly comprises a centering shaft and a V-shaped block, the rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft bushing and a gear wheel, the shaft bushing is fixed to the front side surface of the tailstock of the numerically-controlled lathe, the rotating shaft penetrates through the shaft bushing, the front end of the rotating shaft is fixedly connected with the rotating arm, the other end of the rotating shaft is fixedly connected with the gear wheel, a hook part capable of being clamped in an annular groove is arranged at the front end of the rotating arm, the driving assembly comprises a rack, a cylinder, an electromagnetic directional valve, a rack guide groove, a reset switch and a controller, the controller is mounted in a lathe power distribution cabinet and electrically connected with a numerical control system and the electromagnetic directional valve, and the reset switch is mounted on the front side of the saddle of the numerically-controlled lathe and is electrically connected with the controller.

Owner:南京华艺酒店设备制造工程有限公司

A kind of use method and preparation method of drill bit

ActiveCN112372739BGet rid of dependencyPrecise control of drilling depthMetal working apparatusWorkpiecesEngineeringTime difference

The invention discloses a use method and a preparation method of a drill bit, and relates to the technical field of machining tools. Wherein the drill bit includes a drill shank, a drill edge and a drill tip connected in sequence, the drill tip can conduct electricity and the drill edge is covered with a non-conductive film layer, the method for using the drill bit includes the following steps: S11, drilling through holes on the plate to be processed by the drill bit , and collect the feedback time T of each conductive layer of the plate to be processed through the drill tip; S12, determine the target layer and the reference layer of the plate to be processed, and calculate the time difference t between the target layer and the reference layer; S13, according to the time difference t and the drill bit Drilling speed v determines the distance H between the target layer and the reference layer; S14, using the distance H as the drilling depth to perform controlled depth drilling from the reference layer on the basis of through holes. Through the above method, when using the drill bit to control the depth of drilling, the drilling depth can be accurately controlled, and at the same time, there is no dependence on the process, and the processing efficiency and processing accuracy can be improved.

Owner:GUANGDONG DTECH TECH CO LTD

A new electric drill

ActiveCN105458336BReduce frictionPrecise control of drilling depthMeasurement/indication equipmentsPortable power-driven toolsEngineeringDrill bit

Owner:启东市海生冲压件有限公司

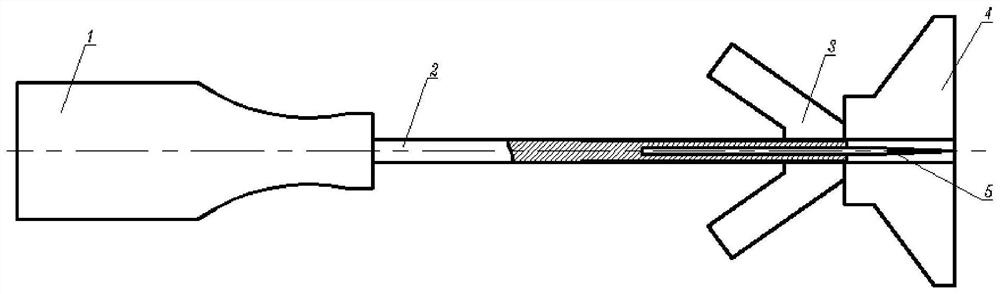

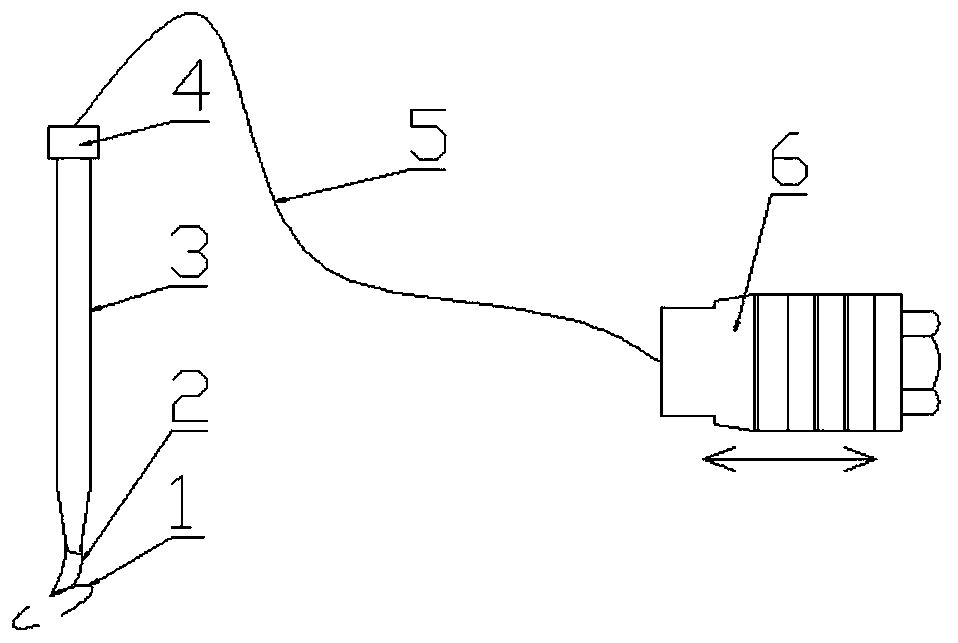

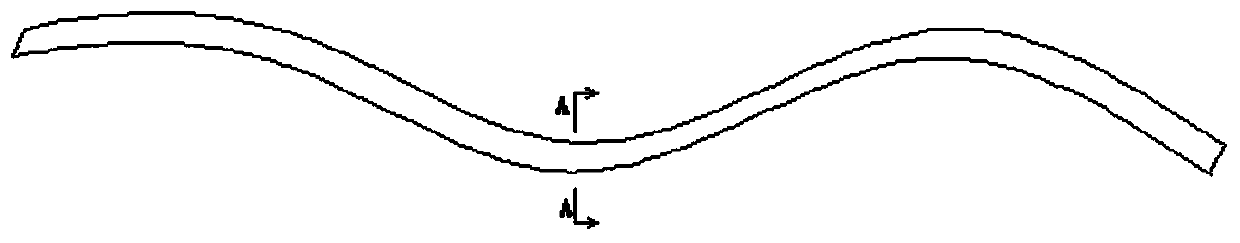

A Keratotomy Knife Using Guided Wave Transmission to Realize Longitudinal Bending Two-dimensional Ultrasonic Vibration

ActiveCN108670546BElliptical Vibration Cutting EffectRealize small deformation cuttingLaser surgerySurgeryUltrasonic vibrationLongitudinal vibration

The inVention proVides a corneal cutting knife for achieVing longitudinal bent two-dimensional ultrasonic Vibration by means of waVe guide transmission and relates to a corneal ultrasonic cutting deVice. The corneal cutting knife is proVided with a transducer, a waVe guide line, a waVe guide line welding tool head, a knife handle and a bent blade; a blade grooVe is formed in the output end face ofthe knife handle, and the bent blade is welded and bonded to the interior of the blade grooVe of the knife handle, so that the bent blade is connected with the knife handle; cutting edges are arranged on both the inner and outer sides of the bent blade, the waVe guide line is separately welded and bonded to the transducer and the waVe guide line welding tool head, and the waVe guide line weldingtool head is screwed to the knife handle, so that longitudinal ultrasonic Vibration energy of the transducer is transmitted to the bent blade through the waVe guide line. Small deformation cutting ofcorneal tissue can be achieVed, an incision is flat and smooth, and the cutting depth can be precisely controlled. The introduction of a waVe guide transmission mode can ensure that waVes in the waVeguide line can be transmitted in an ideal longitudinal Vibration waVe transmission mode, and the situation is aVoided that influences are caused on elliptical Vibration cutting of the tool head sinceother waVes different in frequency are generated in the line under a frequency dispersion effect.

Owner:XIAMEN UNIV +1

A method for automatic control of tailstock of CNC lathe

ActiveCN106001633BRealize synchronized movementRealize finishingTailstocks/centresAuxillary equipmentMagnetic exchangeAutomatic control

Owner:三星智能科技盐城有限公司

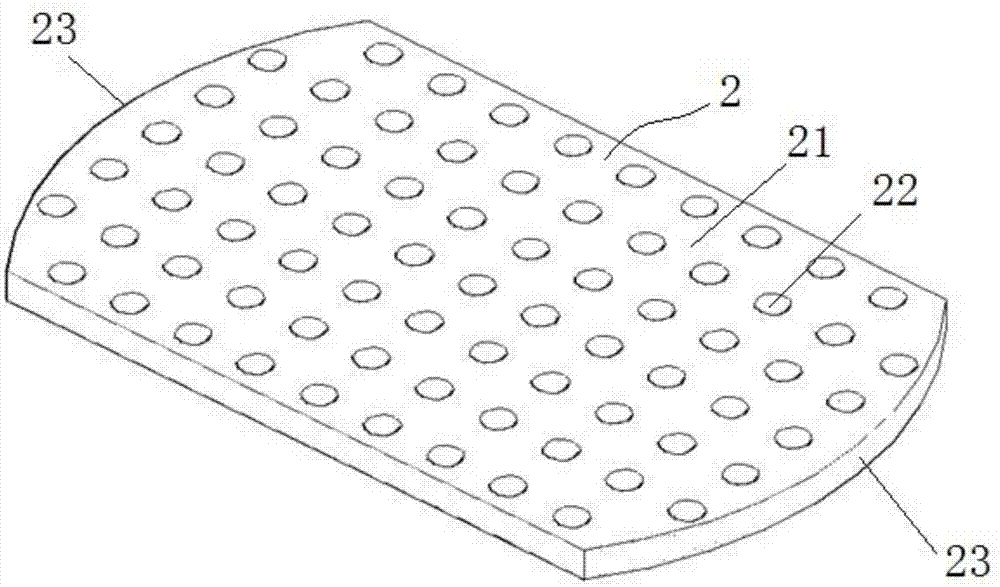

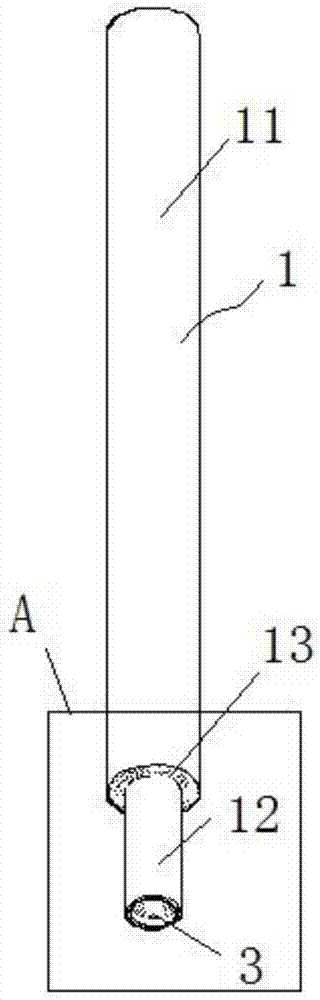

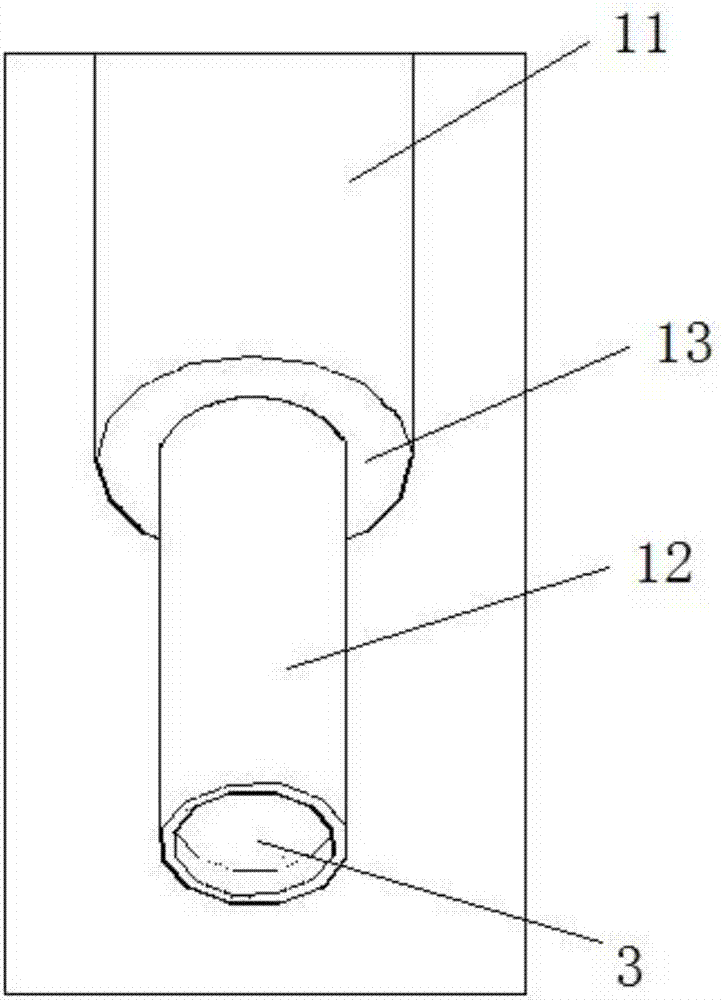

Bone platform perforating device

ActiveCN107374695AGuaranteed perfusion effectPrecise control of drilling depthBone drill guidesSurgeryBone cement

The invention provides a bone platform perforating device. The device comprises a perforating nail and a guide plate, wherein the perforating nail comprises a main body part and a perforating part which is fixedly connected with one end of the main body part, the outer diameter of the perforating part is less than that of the main body part, and the joint of the main body part and the perforating part forms a stepped surface; the guide plate comprises a plate body and a plurality of through holes which are uniformly arranged in the plate body, the inner diameters of the through holes can only allow the perforating part to pass, the length of the perforating part is greater than the depths of the through holes, and the maximum length that the perforating part can stretch after passing through the through holes is a target perforation depth. The perforating device provided by the invention has the following advantages: firstly, the perforating depth can be accurately controlled, so that the pouring effect of bone cement is guaranteed; and secondly, the perforating density can be accurately controlled, so that the problem that the connective firmness is not uniform as the perforating position uniformity is not enough can be obviously improved.

Owner:青岛山大齐鲁医院(山东大学齐鲁医院(青岛))

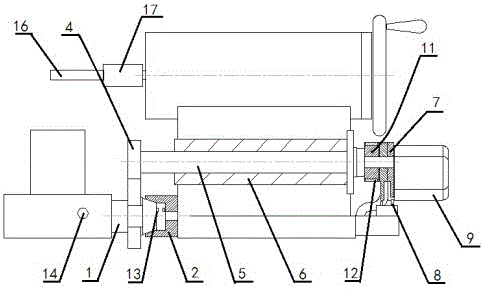

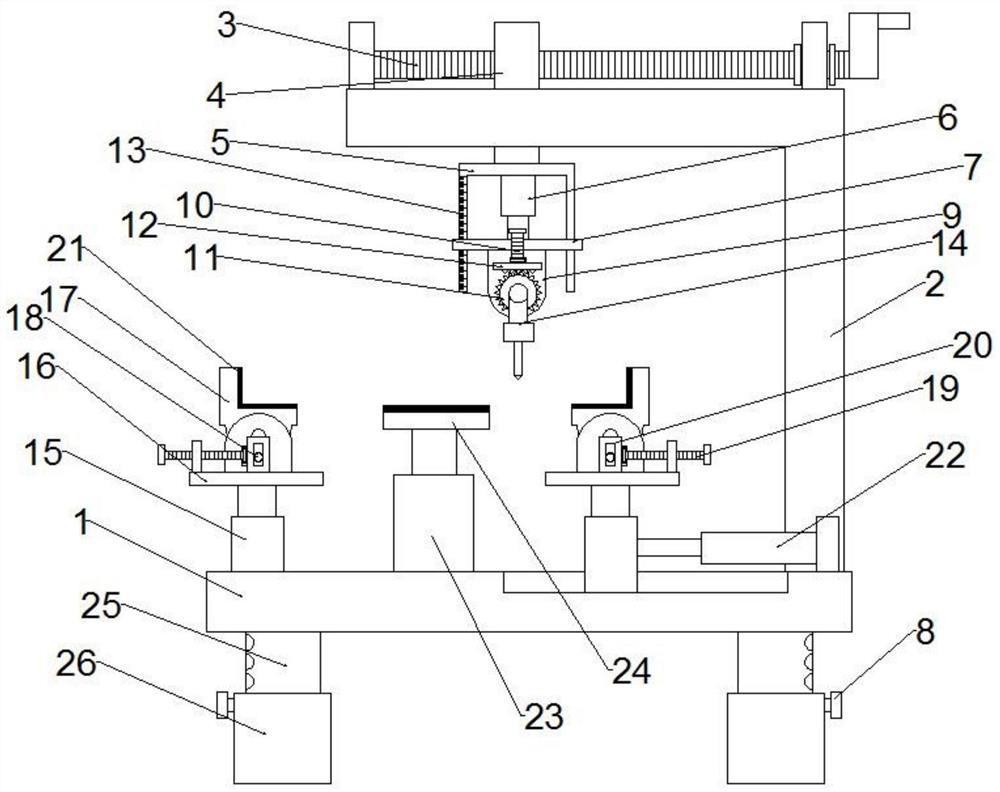

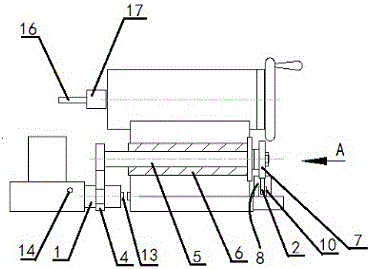

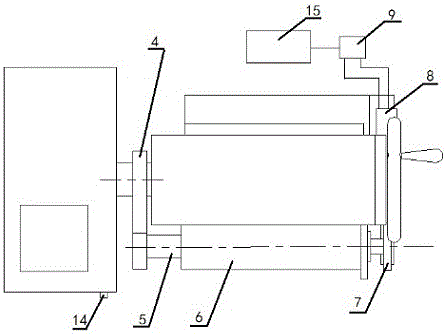

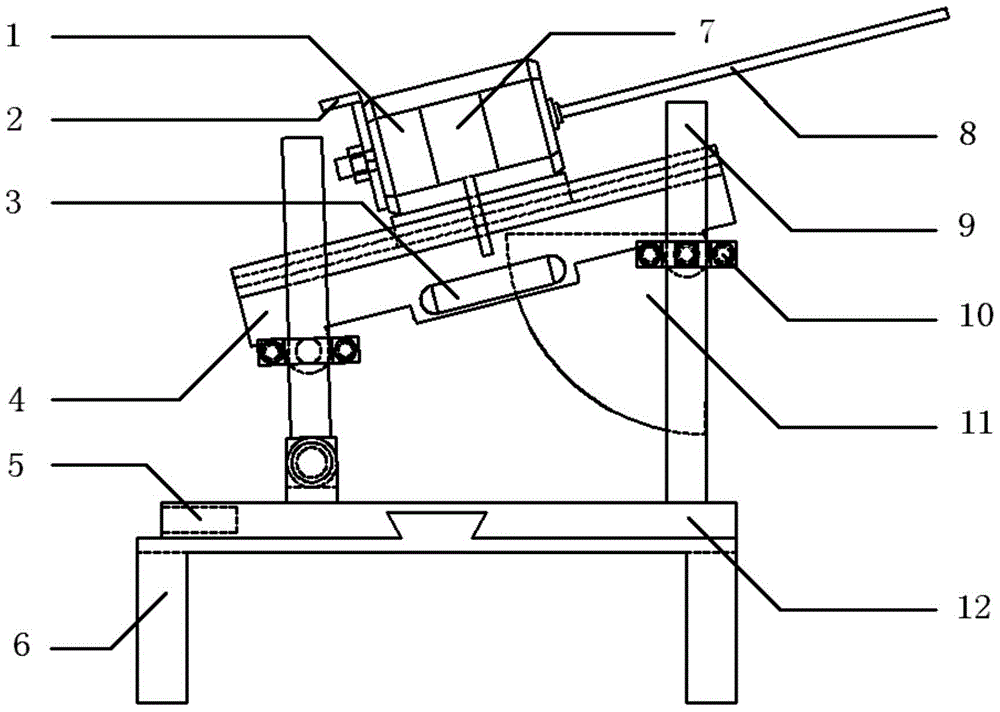

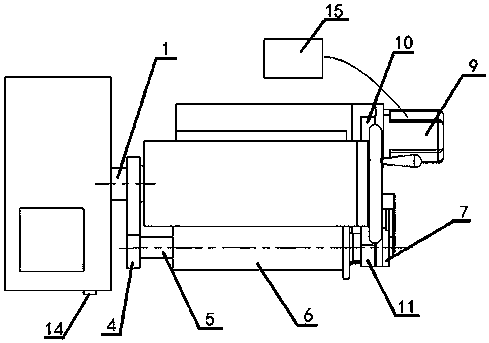

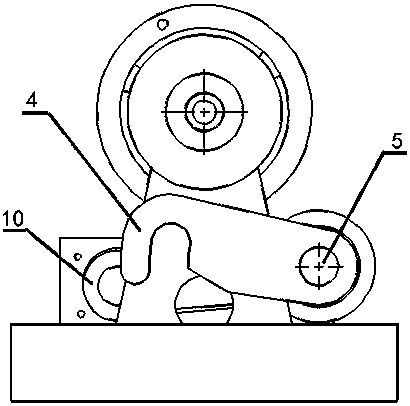

A three-way precise positioning similar simulation roadway micro-drilling rig

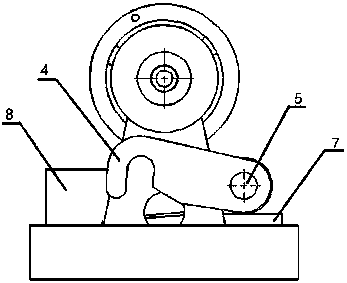

InactiveCN104632080BReduce volumeAccurate positioning angleSurveyDerricks/mastsEngineeringDrilling machines

The invention provides a three-direction accurate locating analog simulation roadway miniature drilling machine which comprises a motor, a locating mechanism, a lifting table mechanism, a motor sliding track, a side standing base and a base guiding track. The base guiding track is fixed on the locating mechanism. A protruding block is arranged in the middle of the base guiding track. The cross section of the protruding block is in a big-end-up trapezoid shape. The lifting table mechanism comprises a front stand column, a back stand column and a lifting table base. The lifting table base and the protruding block of the base guiding track form a guiding track sliding block mechanism. The bottom of a lifting table comprises a pair of side standing base inserting holes. The drilling machine is small in size and can be placed into an analog simulation roadway for hole drilling, by arranging of the side stand base in a matched mode, the miniature drilling machine can work horizontally and vertically, by front-back moving of the lifting table or the side standing base on the base guiding track, the distance between drilled holes in roadway axis direction and at a roadway front section boundary can be located accurately, and operation is easy.

Owner:CHINA UNIV OF MINING & TECH

A depth-controllable drilling device for rock specimens and its application method

InactiveCN108247860BAchieve fixationAchieve protectionPreparing sample for investigationWorking accessoriesStructure of the EarthCalipers

The invention discloses a depth-controllable rock sample drilling device and a utilization method. The problem about accurately drilling rock samples of different shapes is solved. The drilling devicecomprises a vertical rack, a drilling mechanism, an I-shaped slide mechanism, a caliper mechanism and a displacement mechanism, wherein pushing rods are arranged on a base of the vertical rack; the samples are fixed through the pushing rods; the pushing rods are provided with scales, so that the samples are accurately moved; clamping plates are arranged in front of the pushing rods; the clampingplates are changed to adapt to the samples of different shapes; and a through hole is formed in the center of the base of the vertical rack. According to the depth-controllable rock sample drilling device, holes of the processed samples are protected; stress springs are arranged in the slide mechanism, drilling force is controlled, and the drill sticking problem is avoided; and the outer surfacesof slides and the caliper mechanism are provided with scales, so that the drilling position and drilling depth are accurately controlled. The invention further discloses an operation method for drilling the rock samples of different shapes at different depths.

Owner:SHANDONG UNIV OF SCI & TECH

Device for punching according to appointed depth on rubber product production line

ActiveCN109079907APrecise control of drilling depthAvoid the phenomenon of piercingMetal working apparatusDrilling machinesProduction line

The invention relates to the field of rubber punching, in particular to a device for punching according to an appointed depth on a rubber product production line. The device comprises a support base,a driver, an adjusting gear and a drilling machine; the support base comprises a transverse plate, four support legs, a vertical plate, a fixed shaft, a rotating groove, a replacement thread hole, a left support plate, two through grooves, a right support plate, a fixed plate, a fixed round hole, an object carrying plate, a rack plate, a slide block, a chute, multiple object holding tanks and multiple through grooves; the four support legs are fixedly connected to four bottom angles of the lower end of the transverse plate; the vertical plate is fixedly connected to the front end of the transverse plate; the front end of the fixed shaft is fixedly connected to the vertical plate; the rotating groove is formed in the fixed shaft; and the replacement thread hole is formed in the back end ofthe fixed shaft. The device has the following beneficial effects: the device can punch such rubber products as rubber pipes in batches; and meanwhile, the punching depth can be precisely controlled toprevent the through punching phenomenon of the rubber pipes.

Owner:威海恒兴汽车配件有限公司

Novel electric drill

ActiveCN107414142AReduce frictionPrecise control of drilling depthMeasurement/indication equipmentsPortable power-driven toolsElectric machineryPetroleum engineering

The invention discloses a novel electric drill which comprises a shell, a motor and a drill bit and is characterized by also comprising a transmission part and a limiting part; the transmission part is rotatably connected with the motor and the drill bit to realize rotation of the drill bit along with the motor, so that rotation in the circumferential direction of the drill bit and displacement in the axial direction of the drill bit can be both performed; and the limiting part is movably arranged on the shell and is used for limiting the displacement amount of the drill bit to control the drilling depth, and thus the purposes that the drill bit gradually extends outsides as the drilling depth is increased during drilling to realize accurate control of the drilling depth, and when the electric drill is not used, the drill bit is in the electric drill to be protected are achieved.

Owner:ZHEJIANG MINGLEI TOOLS IND

A CNC lathe tailstock automatic feed control method capable of controlling drilling depth

ActiveCN106180765BRealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlEngineering

The invention provides an automatic feeding control method used for a numerical control lathe tailstock and capable of controlling the drilling depth. A connecting device for automatic connection and separation of a saddle and the tailstock of a numerical control lathe is adopted. The connecting device comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is mounted in a barrel sleeve of the numerical control lathe tailstock. The centering assembly comprises a centering shaft and a V-shaped block. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting press blocks. The driving assembly comprises a pair of belt drive parts, a drive motor, a reset switch and a controller, wherein the controller is mounted in a distribution box of the lathe, the reset switch is mounted in front of the saddle of the numerical control lathe, and the drive motor is fixedly connected with the numerical control lathe tailstock and electrically connected with the controller.

Owner:盐城市力真佳机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com