A CNC lathe tailstock automatic feed control method capable of controlling drilling depth

A CNC lathe tailstock, CNC lathe technology, applied in the direction of tailstock/top, drilling/drilling equipment, turning equipment, etc., can solve the problems of low processing efficiency, time-consuming and laborious, difficult to guarantee the depth of drilling, etc., to achieve Improve the degree of automation and the effect of precise drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

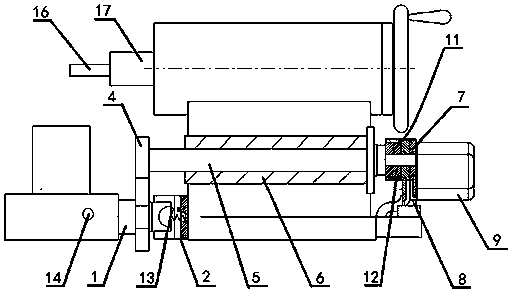

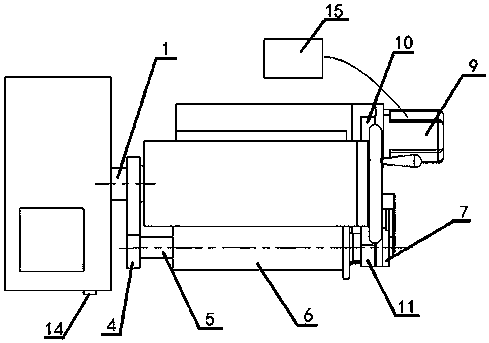

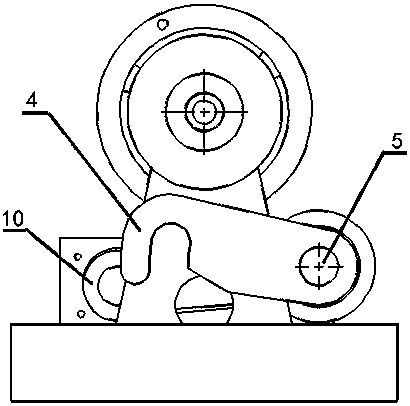

[0017] A CNC lathe tailstock automatic feed control method that can control the drilling depth, which uses a CNC lathe bed saddle and a tailstock coupling and disengagement connection device, including a centering component, a rotating arm component, and a driving component And a drill bit assembly, the centering assembly includes a pair of center shafts 1 and a centering sleeve 2 with an inner taper hole, a ring groove 3 is provided in the middle of the centering shaft 1, and the centering shaft 1 is fixedly connected with the saddle of the CNC lathe, The centering sleeve 2 is fixedly connected with the tailstock of the CNC lathe. The front end of the centering shaft 1 and the inner taper hole of the centering sleeve 2 form a conical surface fit. The shaft end of the centering shaft 1 and the bottom of the tapered hole of the centering sleeve 2 are provided with a The sensor 13 can be a magnetic effect sensor or a Hall effect sensor, or a photoelectric sensor.

[0018] The rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com