Blank wax stone drilling machine for tissue chip

A tissue chip and drill technology, which is applied in the field of biochemistry, can solve the problems of disorderly arrangement of tissue samples, unbalanced movement, and reduced accuracy, and achieves the effect of facilitating automatic management, precise positioning, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

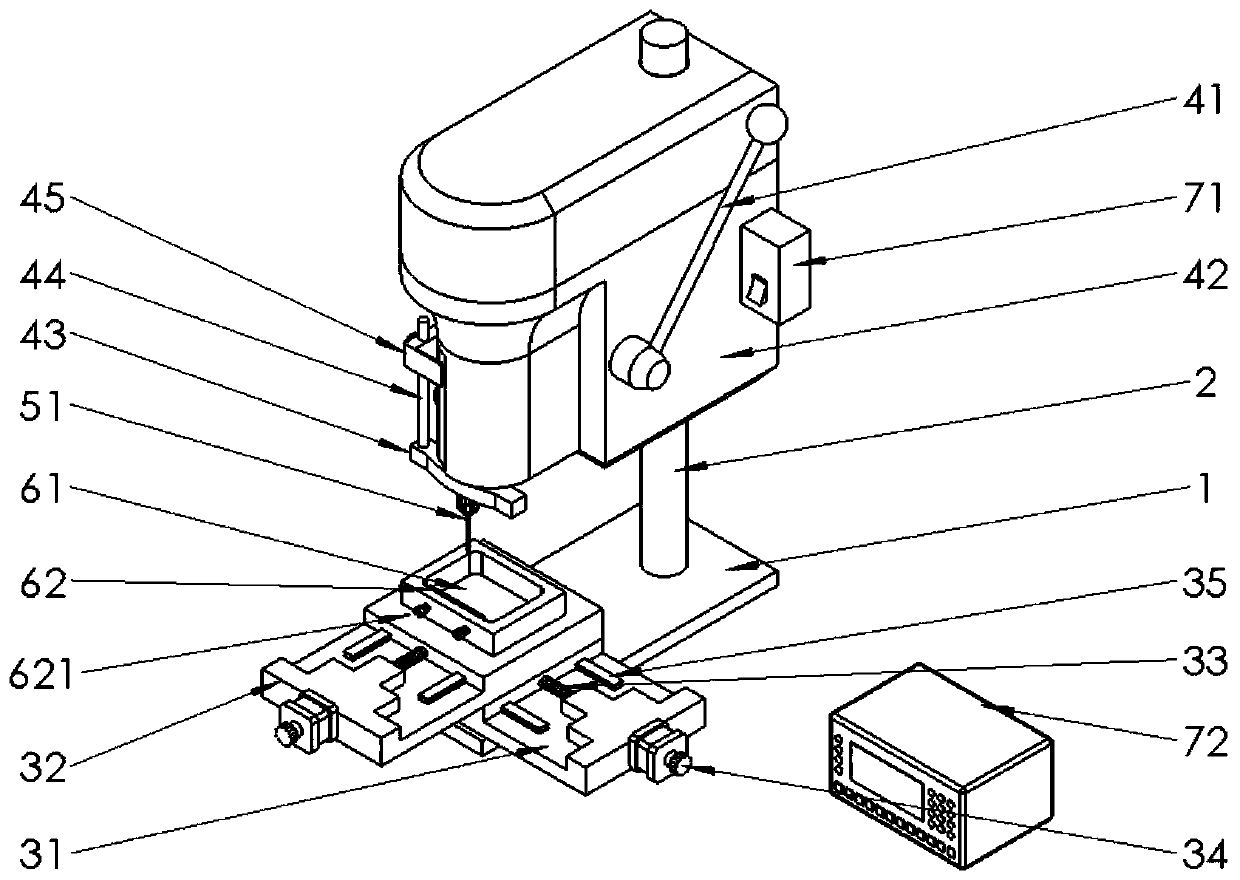

[0060] refer to figure 1 and figure 2 , this embodiment provides a tissue microarray blank wax block drilling instrument, including: a base 1, a bracket 2, a horizontal movement mechanism, a vertical movement mechanism, a drilling mechanism, and a wax block fixing seat;

[0061] The bracket 2 is connected to the base 1;

[0062] The horizontal movement mechanism includes two horizontal movement assemblies vertically connected to each other, namely an X-axis movement assembly 31 and a Y-axis movement assembly 32. The horizontal movement assembly is provided with scales, one of which is connected to the base 1, and the other is connected to the wax block holder;

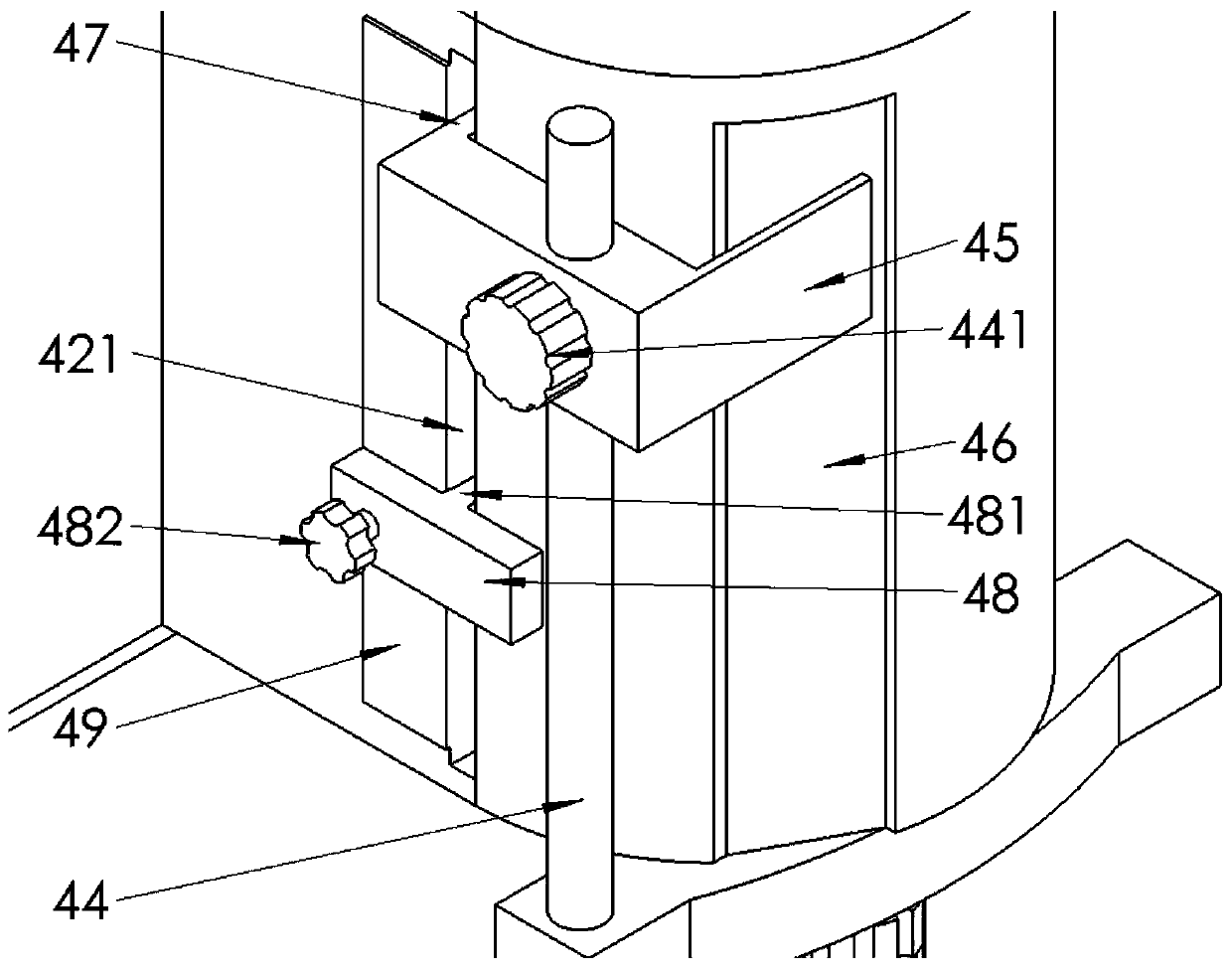

[0063] The vertical moving mechanism includes a Z-axis moving assembly and a Z-axis limiting assembly, the Z-axis moving assembly is respectively connected to the bracket 2 and the drilling mechanism, and the Z-axis limiting assembly is arranged on the Z-axis moving assembly for limiting The maximum displacement of...

Embodiment 2

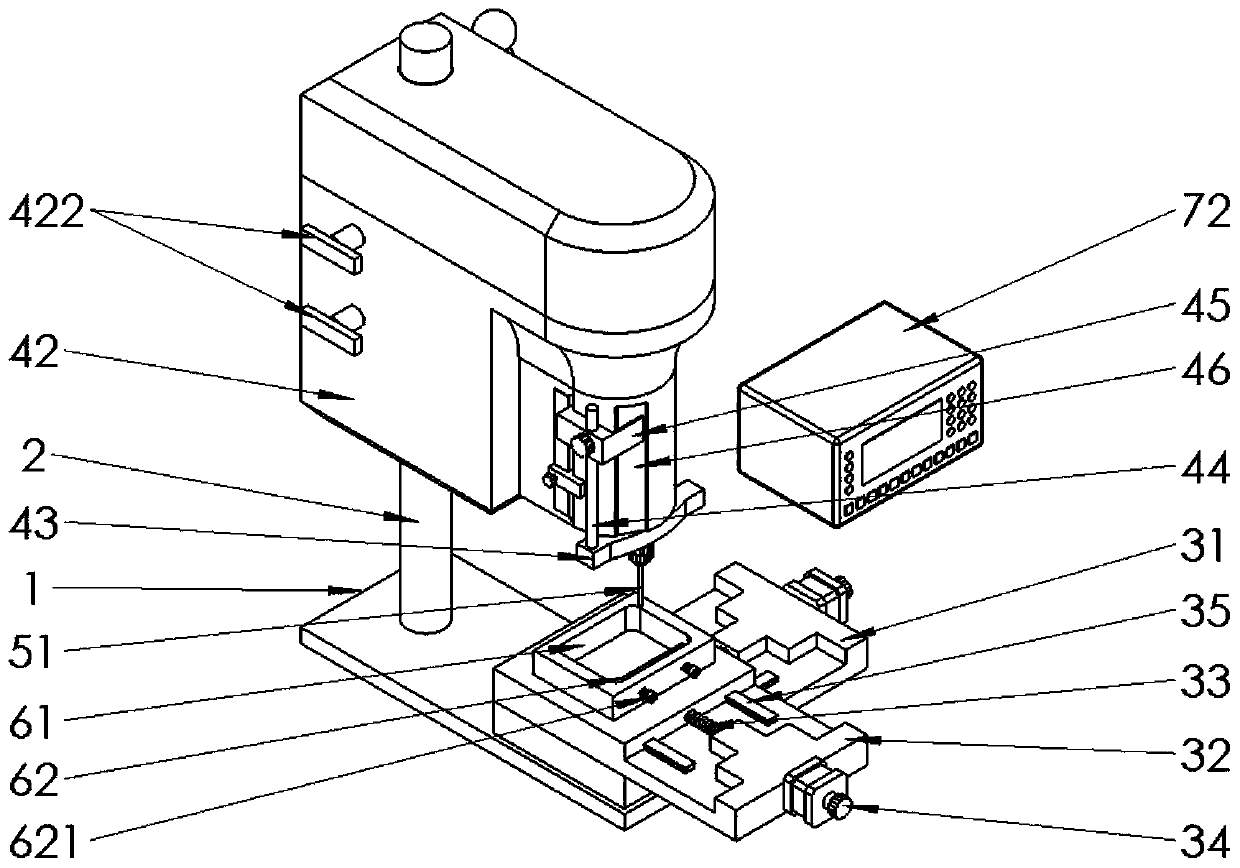

[0093] refer to figure 1 and figure 2 , this embodiment provides a tissue microarray blank wax block drilling instrument, including: a base 1, a bracket 2, a horizontal movement mechanism, a vertical movement mechanism, a drilling mechanism, and a wax block fixing seat;

[0094] The bracket 2 is connected to the base 1;

[0095] The horizontal movement mechanism includes two horizontal movement assemblies vertically connected to each other, namely the X-axis movement assembly 31 and the Y-axis movement assembly 32. The horizontal movement assembly is provided with a grating scale, one of which is connected to the base 1 and the other is connected to the Wax block holder;

[0096] The vertical moving mechanism includes a Z-axis moving assembly and a Z-axis limiting assembly, the Z-axis moving assembly is respectively connected to the bracket 2 and the drilling mechanism, and the Z-axis limiting assembly is arranged on the Z-axis moving assembly for limiting The maximum disp...

Embodiment 3

[0111] Such as Figure 1-Figure 2 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that: the horizontal movement assembly also includes a second motor and a first grating scale, and the second The motor is connected with the ball moving screw 33, and the first grating scale is used to measure the displacement of the horizontal moving assembly.

[0112] By adopting the above solution, the horizontal moving mechanism can realize automatic control, precise positioning, and improve efficiency.

[0113] In a preferred implementation of this embodiment, the Z-axis moving assembly is provided with a third motor and a second grating ruler, the third motor is connected to a gear, and the second grating ruler is used to measure the Z-axis moving assembly displacement.

[0114] By adopting the above solution, the vertical moving mechanism can realize automatic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com