Patents

Literature

30results about How to "Control punch depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

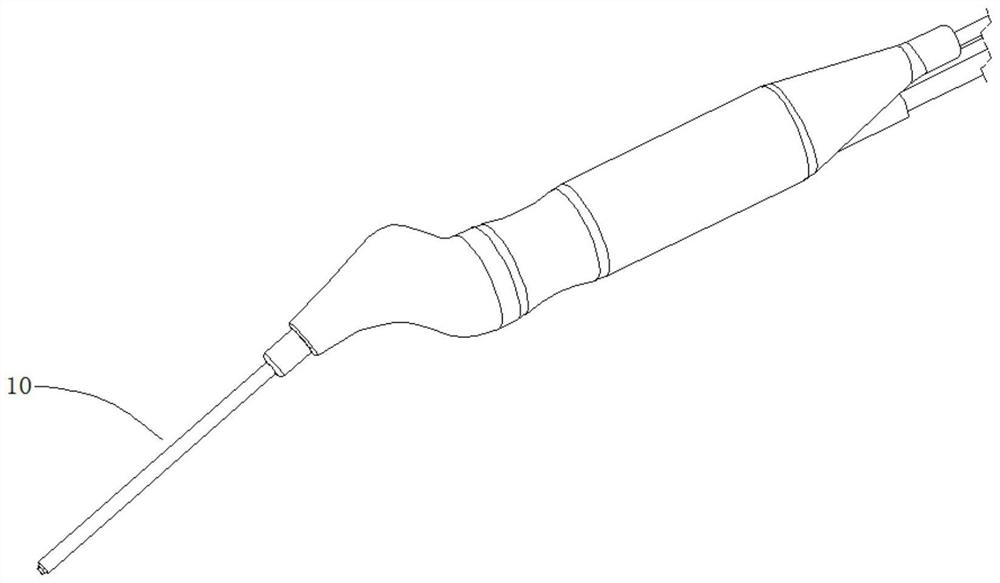

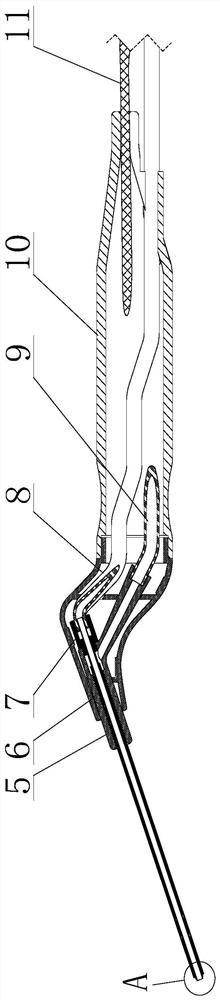

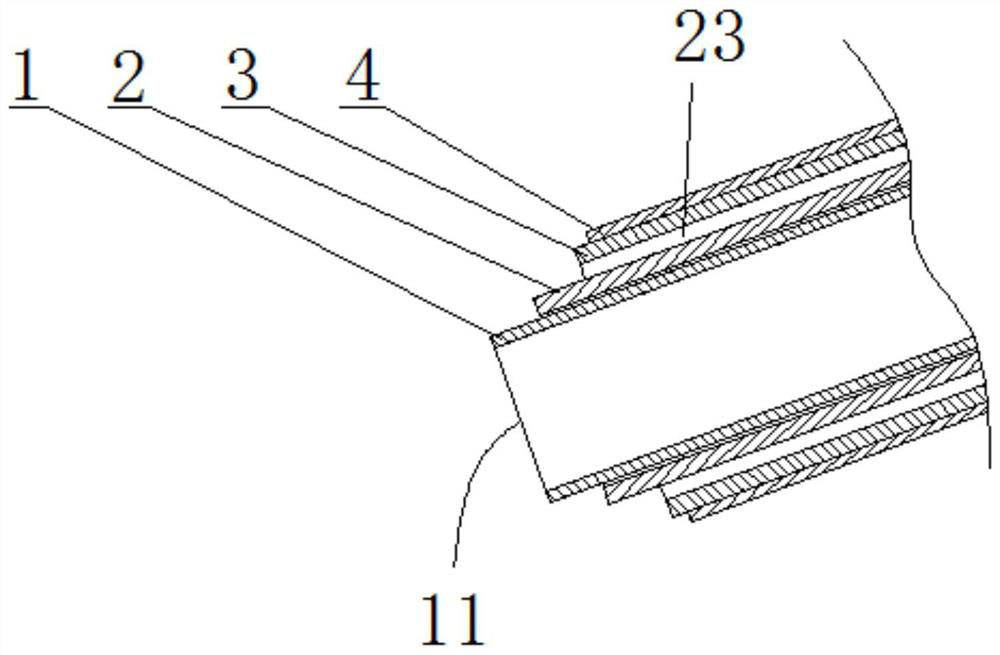

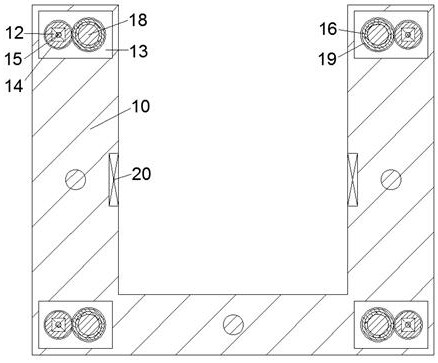

Radio frequency melting electrode for otitis media minimally invasive surgery and using method of radio frequency melting electrode

PendingCN111643176AReduce the difficulty of operationReduce surgical riskSurgical instruments for irrigation of substancesRf ablationEngineering

The invention provides a radio frequency melting electrode for an otitis media minimally invasive surgery and a using method of the radio frequency melting electrode. The radio frequency melting electrode comprises a handle and an electrode which are mutually connected, wherein the electrode adopts a tubular structure, and comprises an inner tube electrode and an outer tube electrode; the inner tube electrode and the outer tube electrode are connected with two poles of a power source; the tube body of the outer tube electrode sleeves the tube body of the inner tube electrode; the headend of the outer tube electrode and the headend of the inner tube electrode are in the same direction and are exposed to form the electrode headend of the electrode; the external surface of the inner tube electrode is an insulation surface; and the tube body of the inner tube electrode and the tube body of the outer tube electrode are mutually isolated, and the headends of the inner tube electrode and theouter tube electrode can be electrically conducted through normal saline, so that a plasma field is formed by the electrode headend to perform melting and drilling on tympanic membrane tissue. A thinking set of a conventional high-temperature puncturing surgery manner of mechanical puncturing, electric burning or laser and the like is broken through, low-temperature plasma principle is utilized toform the plasma field in the electrode headend, and melting and drilling are performed on the tympanic membrane tissue under a low temperature, so that the efficiency and the treatment effect of theotitis media minimally invasive surgery are improved.

Owner:SCANMED CHINA

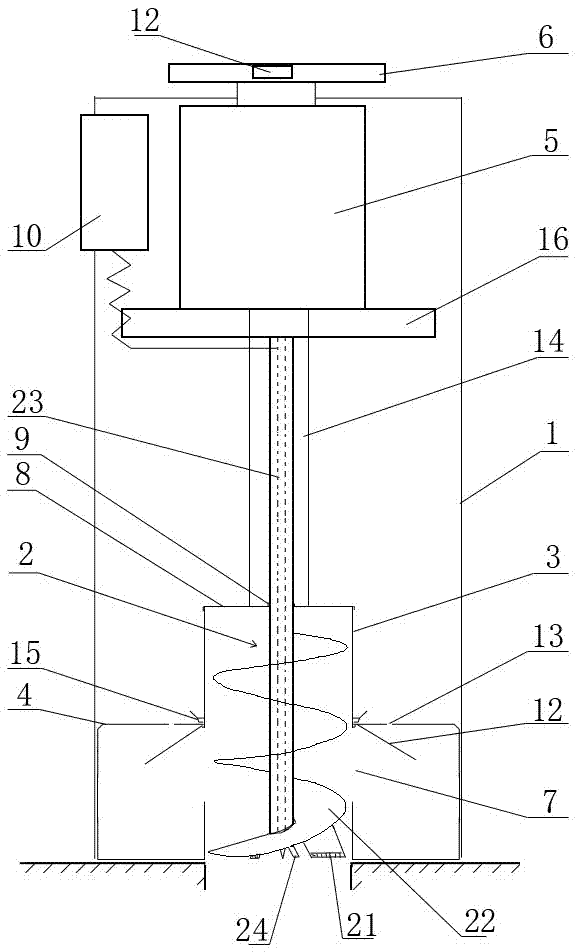

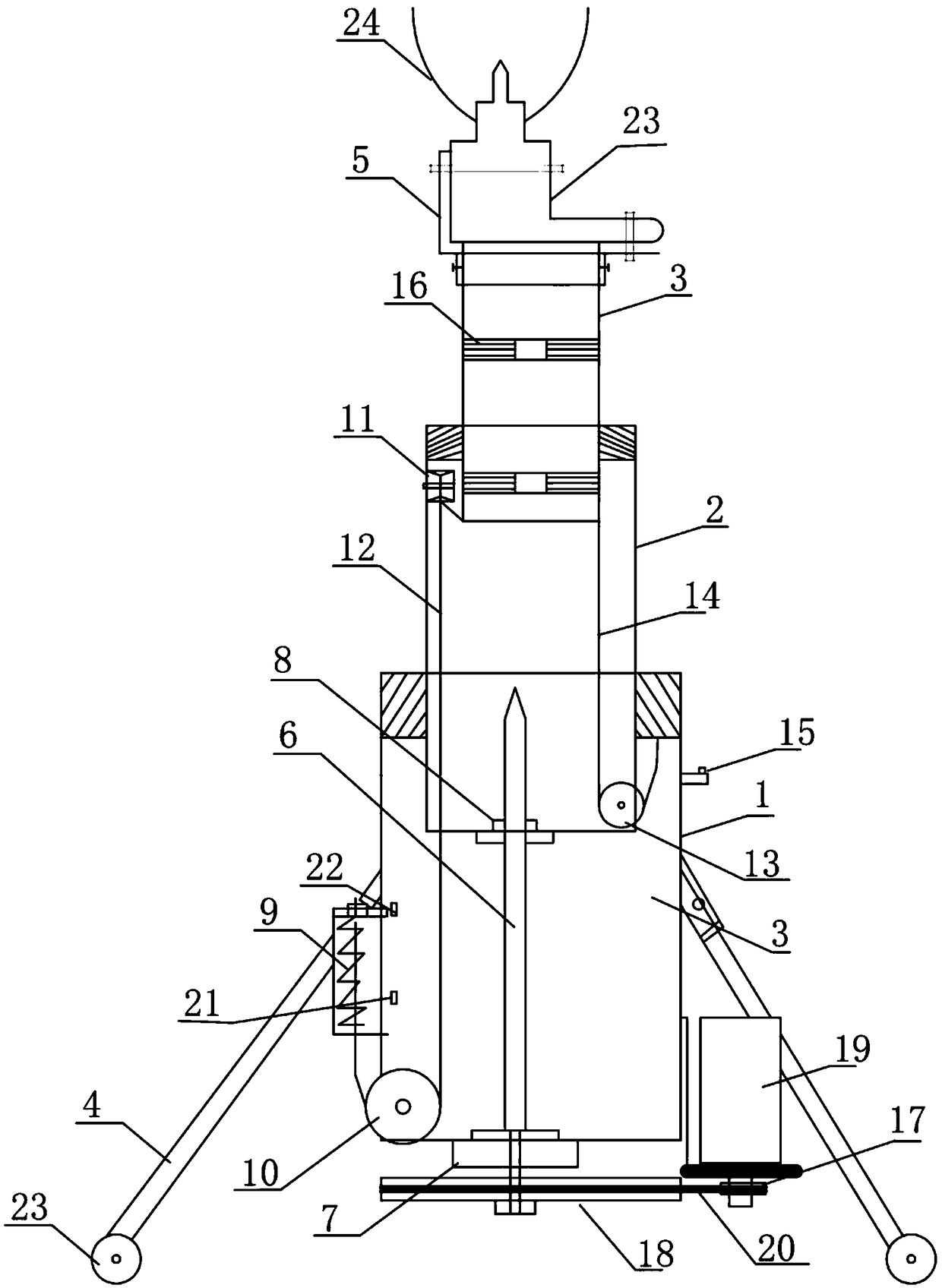

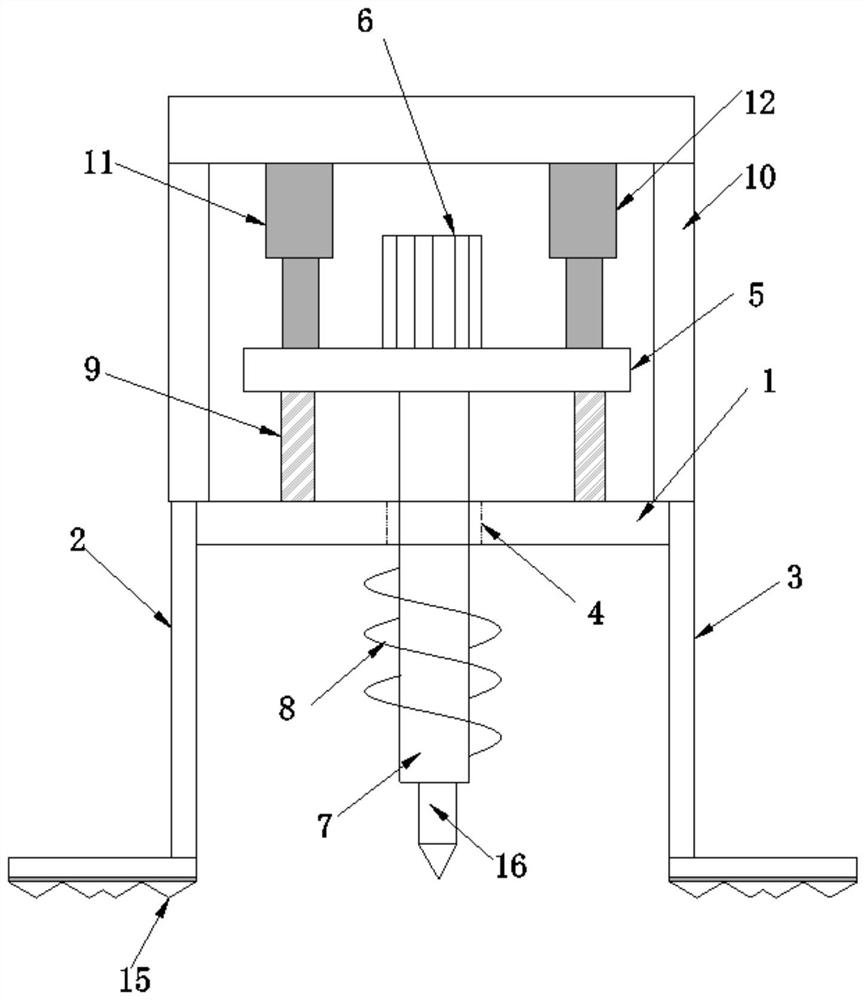

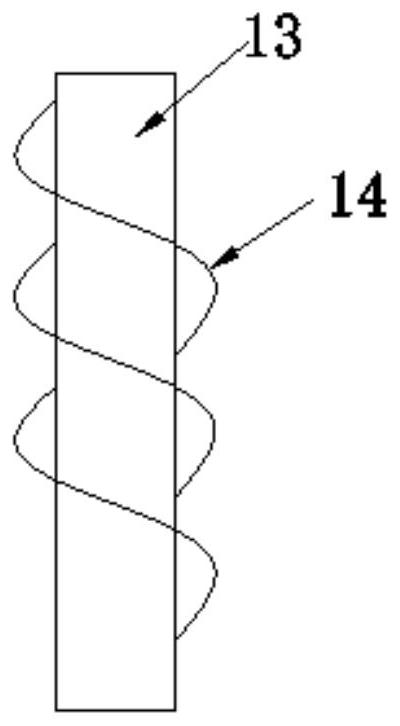

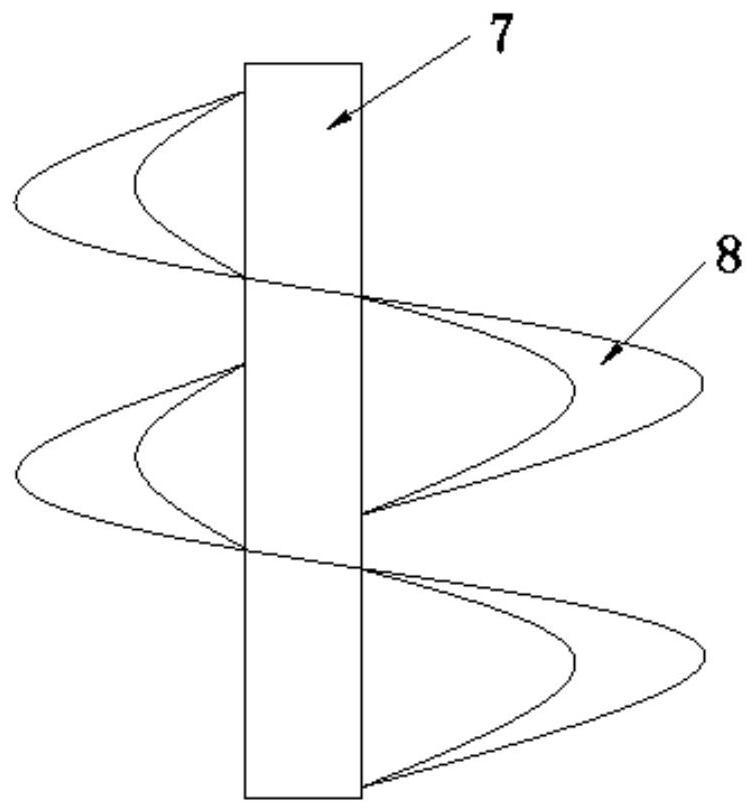

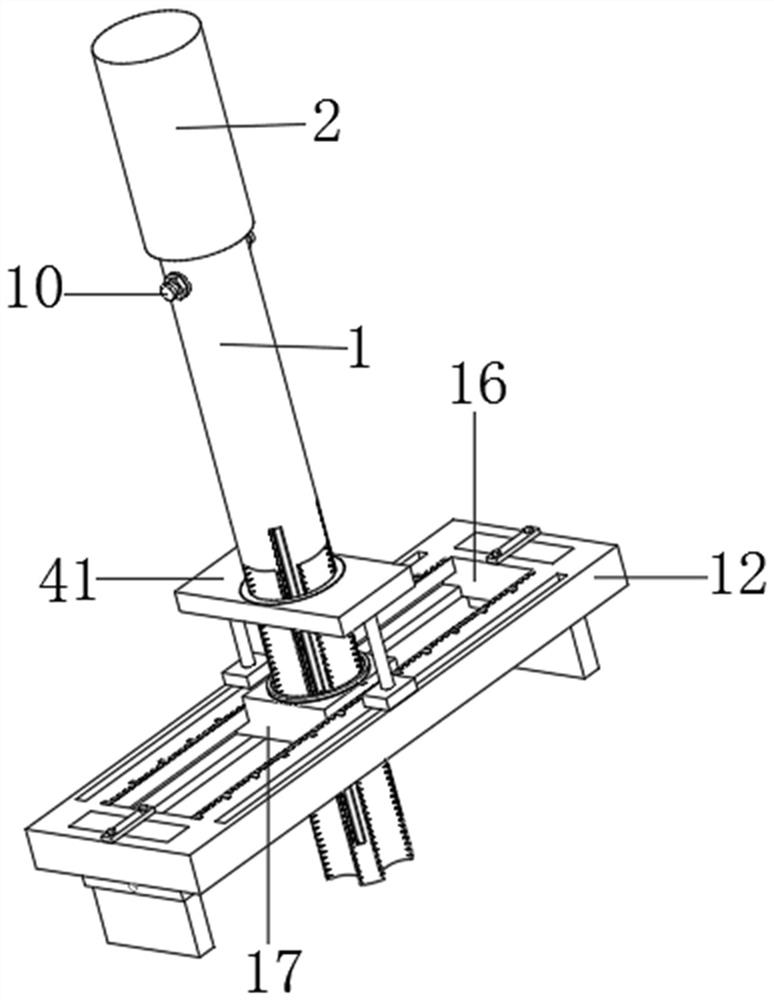

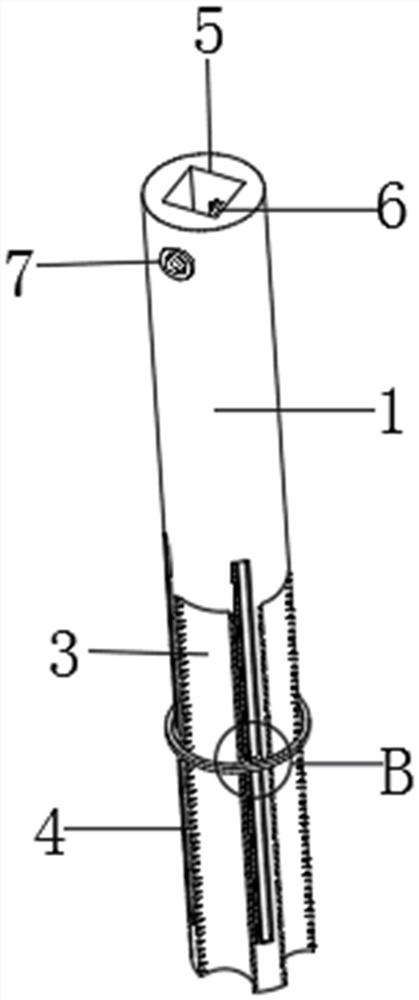

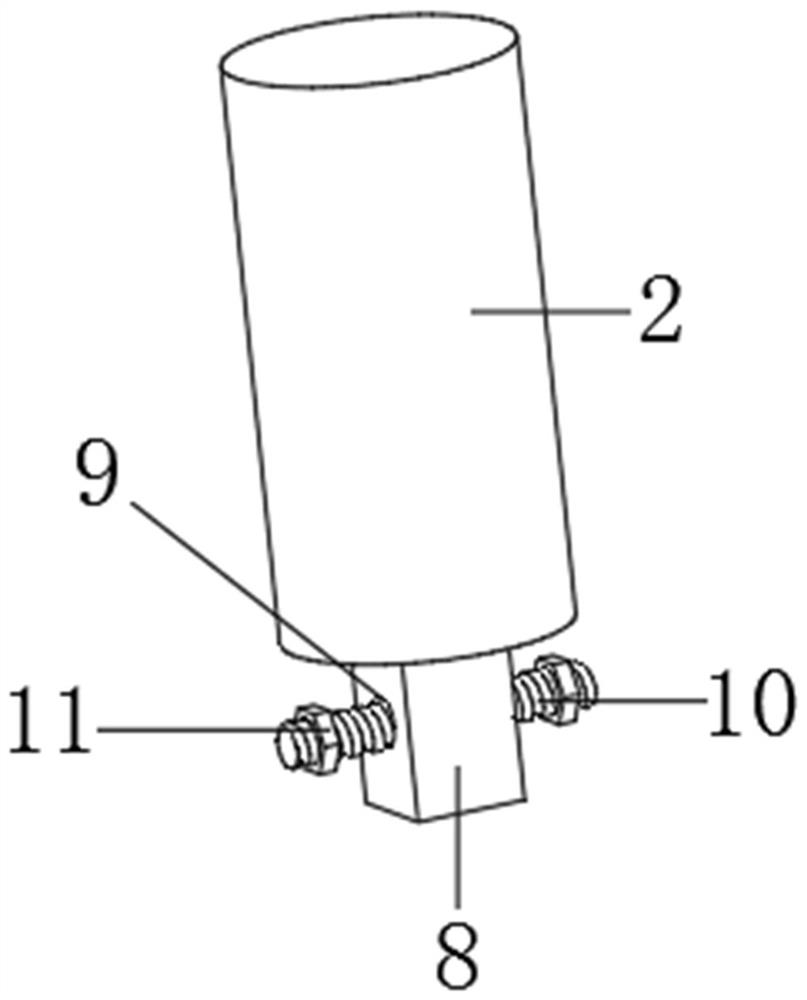

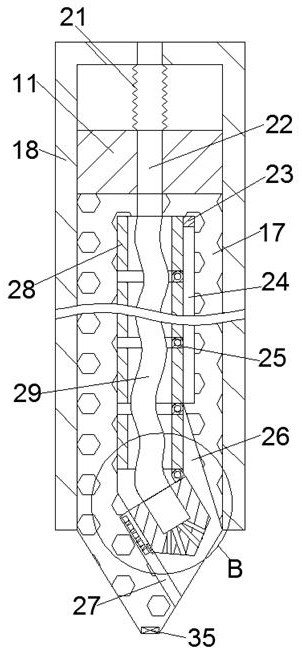

Sand cone method subgrade compaction degree detection rotary excavating and soil taking device

The invention provides a sand cone method subgrade compaction degree detection rotary excavating and soil taking device. The device comprises a device frame, a rotary excavating drill bit, a drill bit sleeve, a soil sample collecting sleeve, a motor driving device and an operation handle. The overall soil sample collecting sleeve is annular, the drill bit sleeve is located over the soil sample collecting sleeve, and an annular hollow part of the soil sample collecting sleeve communicates with the drill bit sleeve so that a hollow cylindrical cavity capable of allowing the rotary excavating drill bit to move up and down can be formed. The upper half portion of the inner wall of the soil sample collecting sleeve is in an open shape, and an opening serves as a soil throwing outlet. A sealing cover is arranged at the upper end of the drill bit sleeve. The bottom of the rotary excavating drill bit is provided with alloy tooth heads, and a spiral lifting sheet is arranged over the alloy tooth heads. The sand cone method subgrade compaction degree detection rotary excavating and soil taking device has the advantages of being simple in structure, high in excavating efficiency, capable of collecting all soil samples and convenient to use.

Owner:HEBEI ROAD & BRIDGE GROUP +1

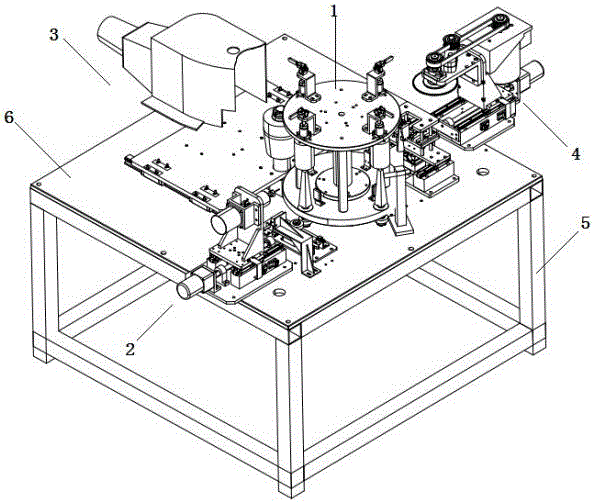

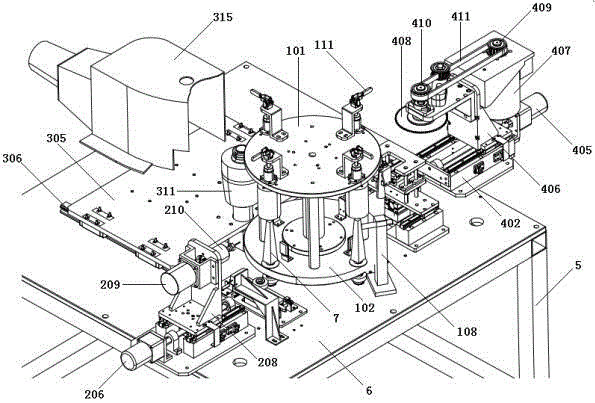

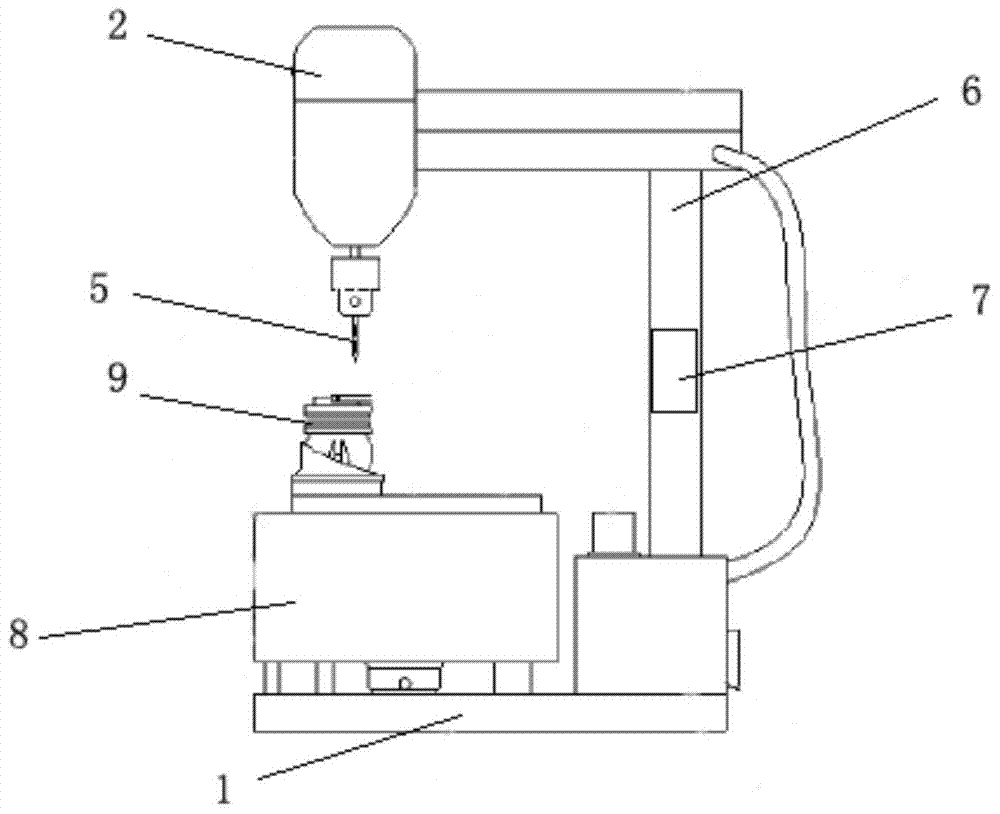

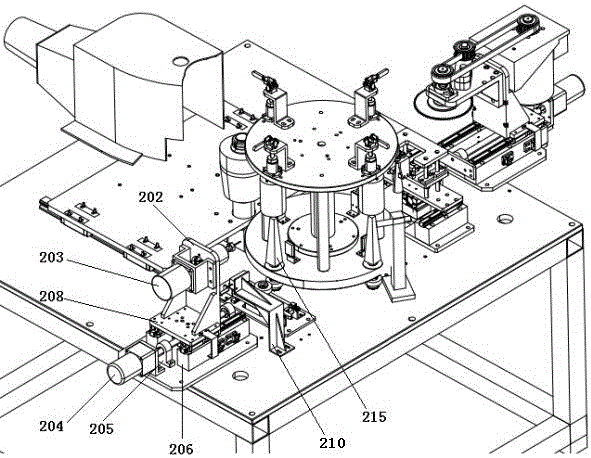

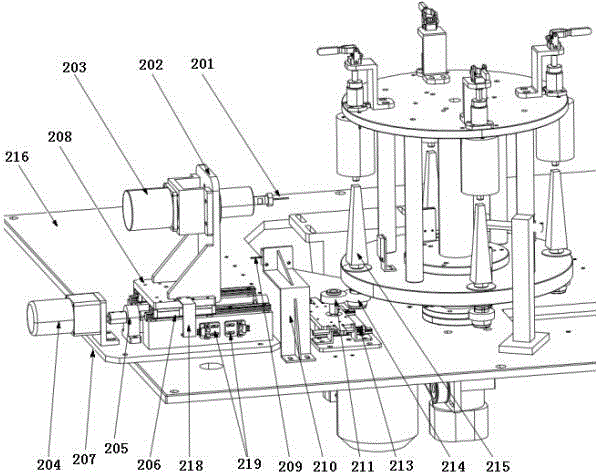

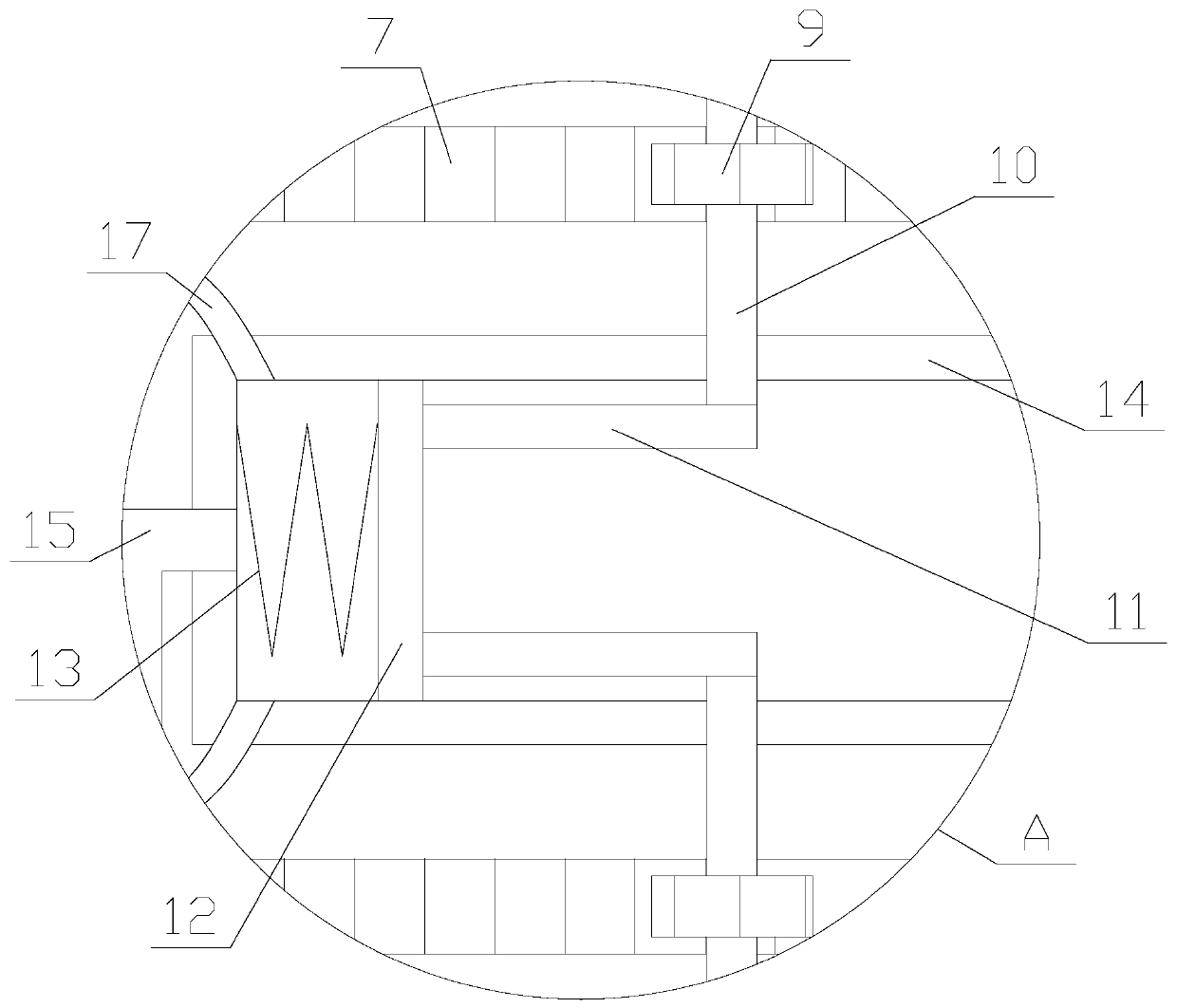

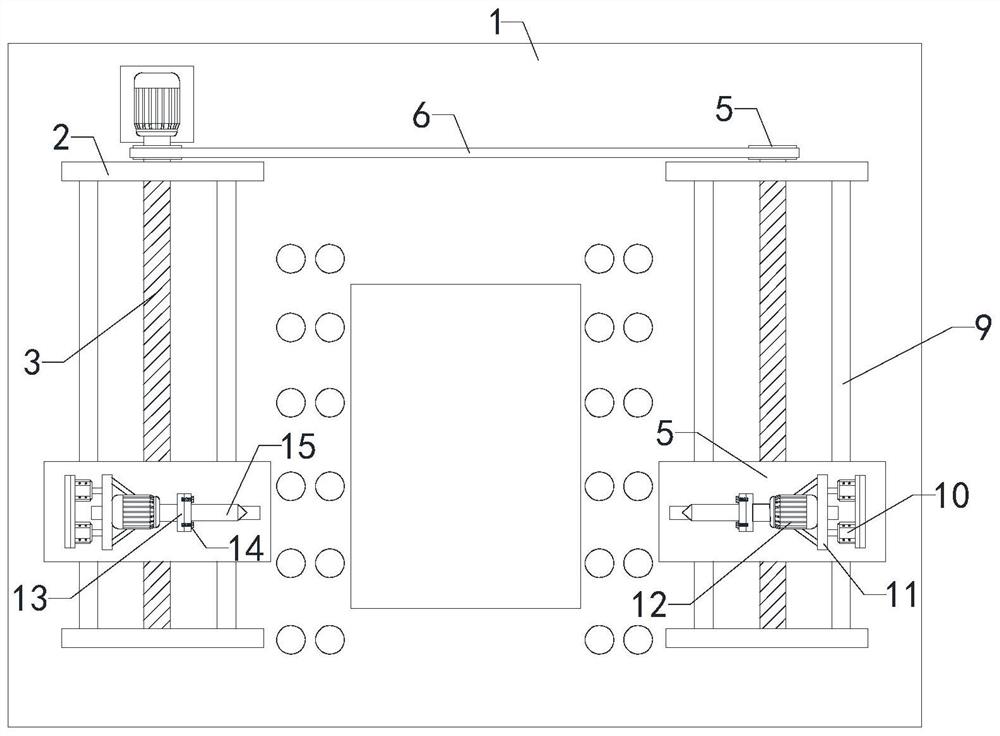

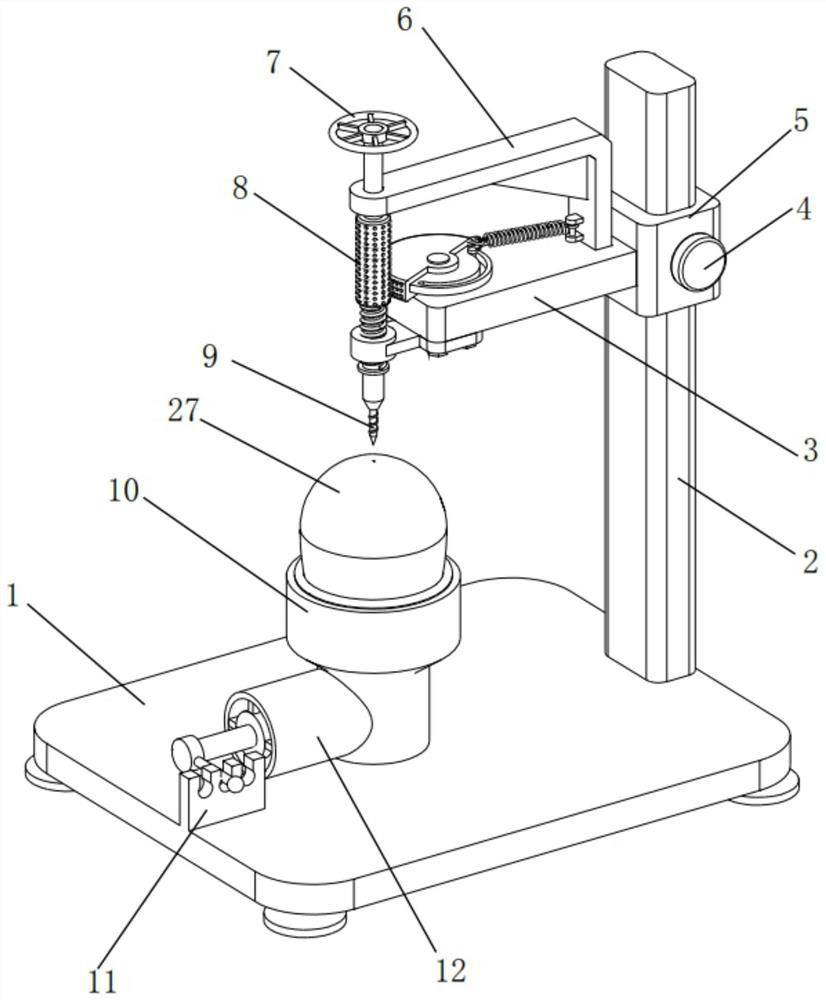

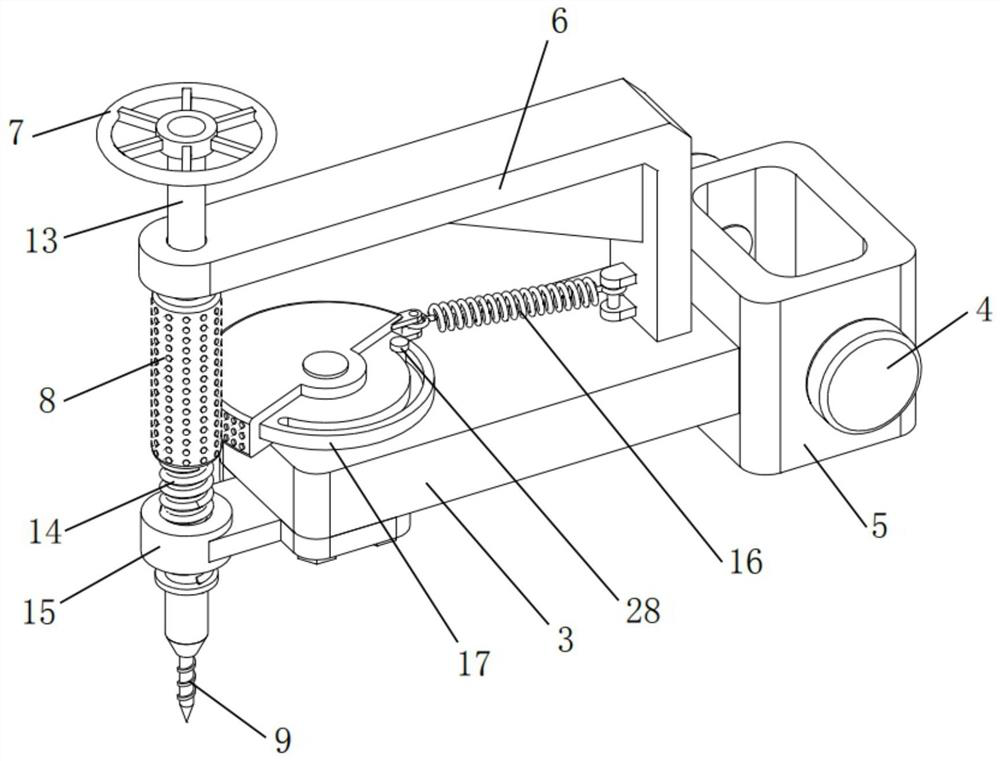

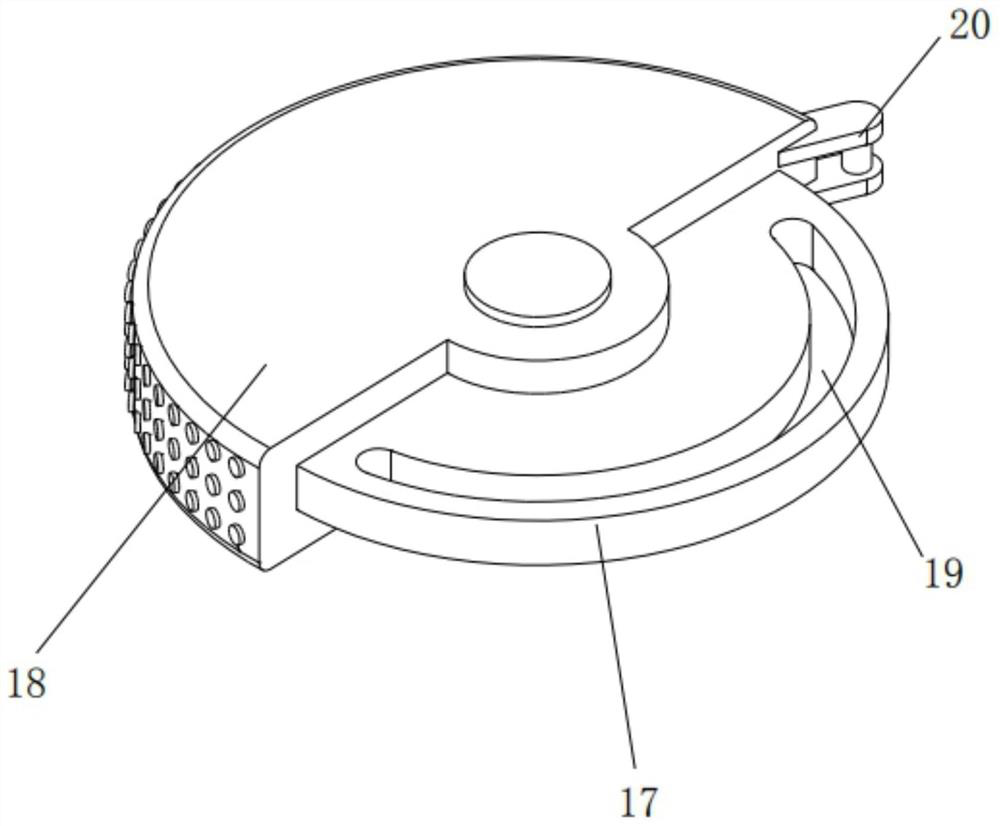

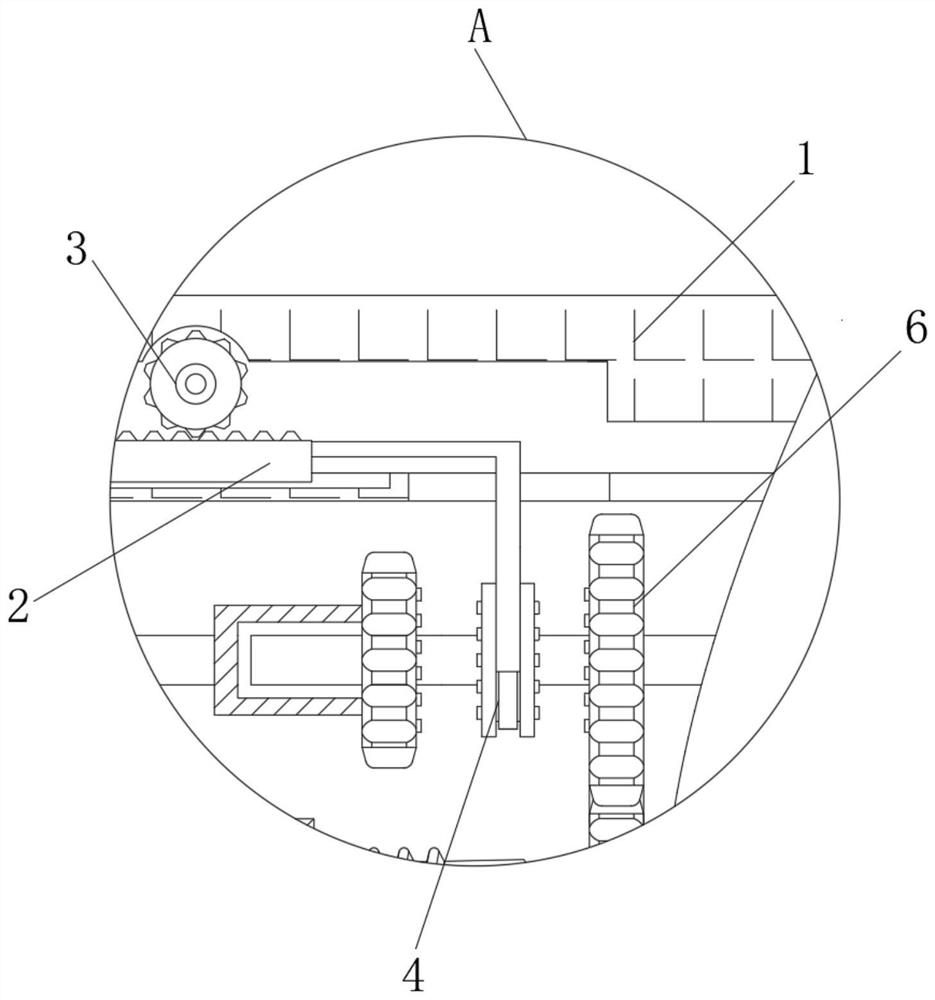

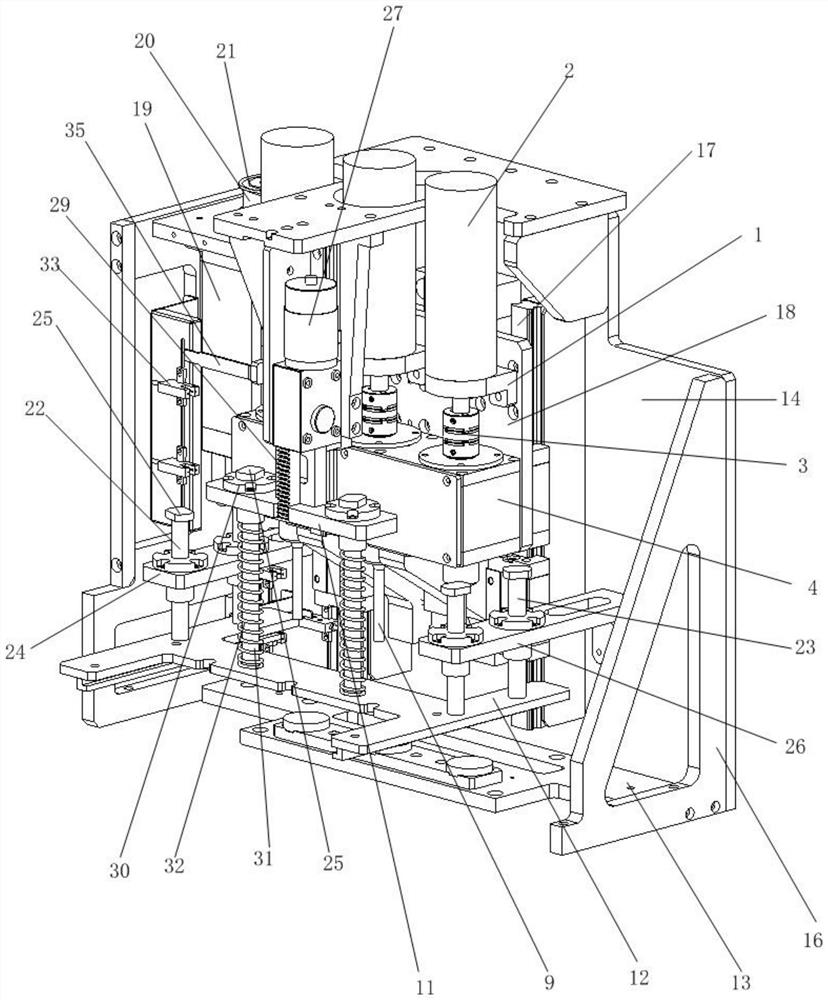

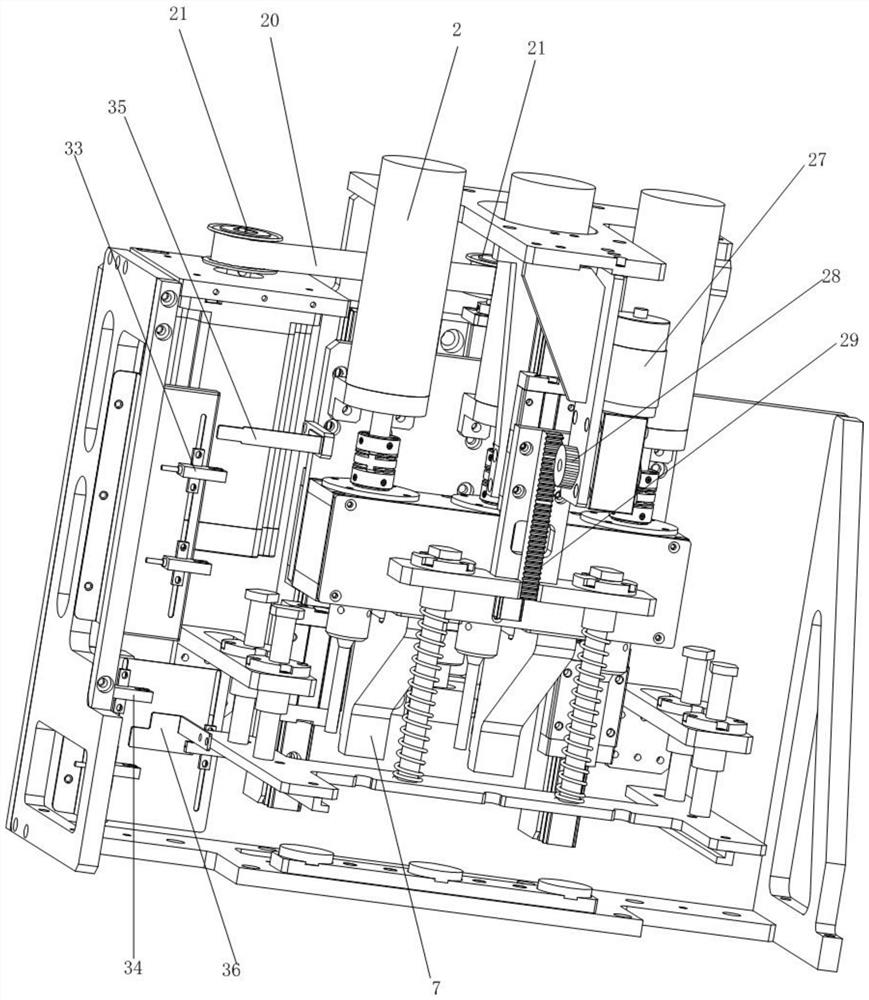

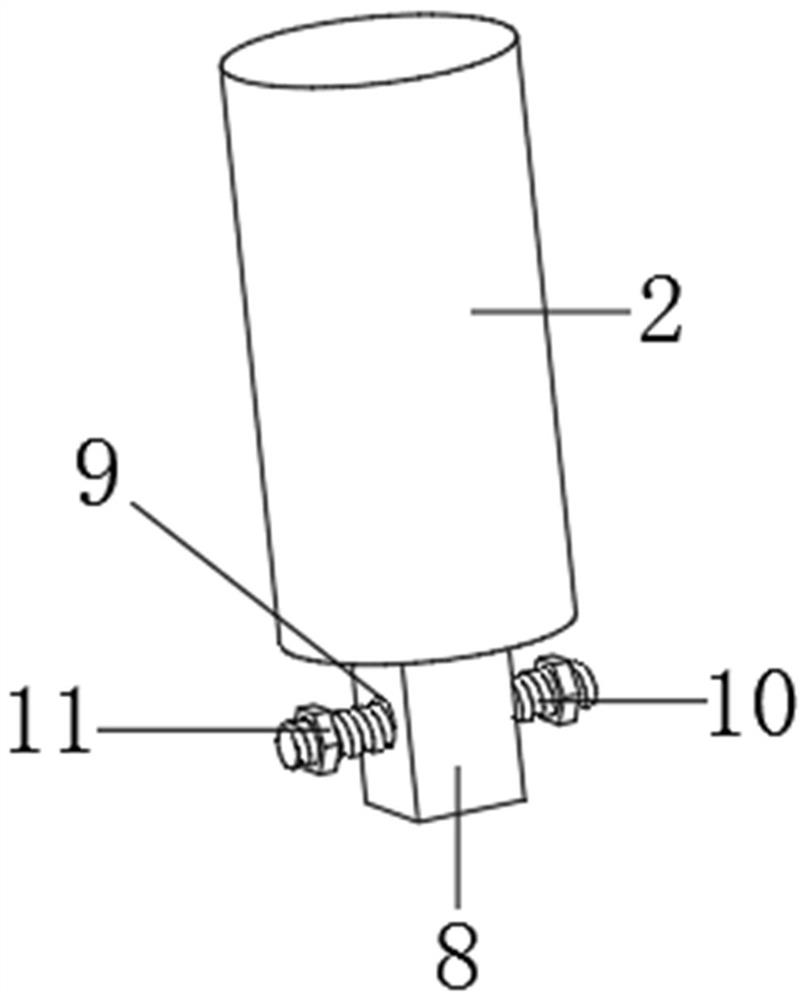

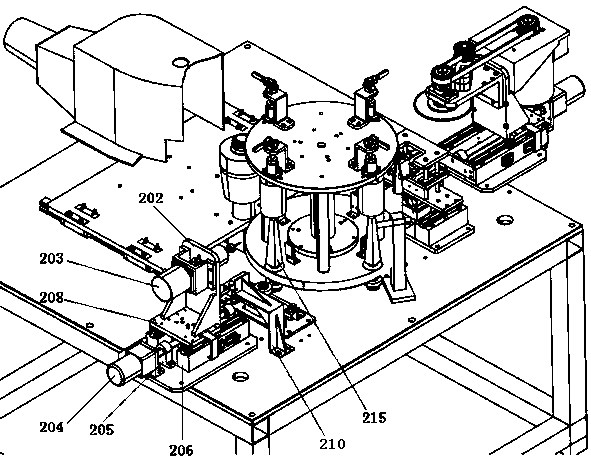

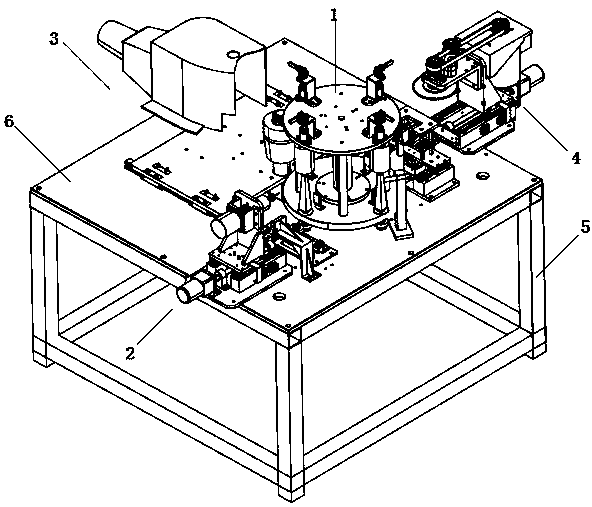

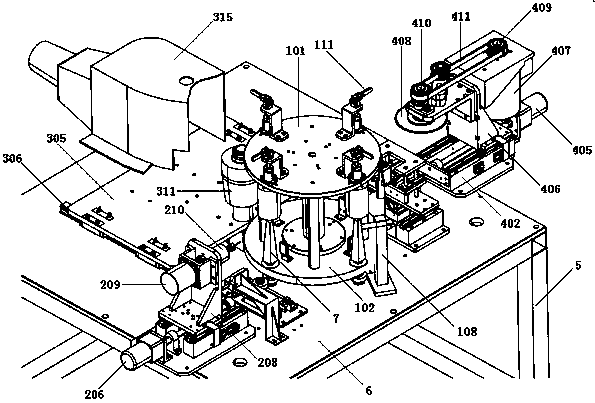

Automatic machining machine of tuning peg of erhu

ActiveCN106624815AErgonomicHigh strengthPrecision positioning equipmentOther manufacturing equipments/toolsAutomatic controlEngineering

The invention discloses an automatic machining machine of a tuning peg of an erhu. The automatic machining machine comprises a working table, wherein a clamping and indexing mechanism, a drilling mechanism, a grinding mechanism and a cutting mechanism are arranged on the machining tabletop of the working table; the clamping and indexing mechanism is located in the center of the machining tabletop; the drilling mechanism is located on the left side of the clamping and indexing mechanism; the grinding mechanism is located on the rear side of the clamping and indexing mechanism; and the cutting mechanism is located on the right side of the clamping and indexing mechanism. By the adoption of multi-station automatic machining, the automatic machining machine can complete three procedures of drilling, forming machining and sawing off of a tuning peg blank at each clamping, so that the machining efficiency is high, and the machining quality is reliable; furthermore, equipment of the automatic machining machine is easy to operate; and by full-automatic control, a worker only needs to clamp a tuning peg billet at the first station and press a start button, so that the automatic machining machine is low in labor intensity and low in manufacturing cost.

Owner:SUZHOU INST OF INDAL TECH

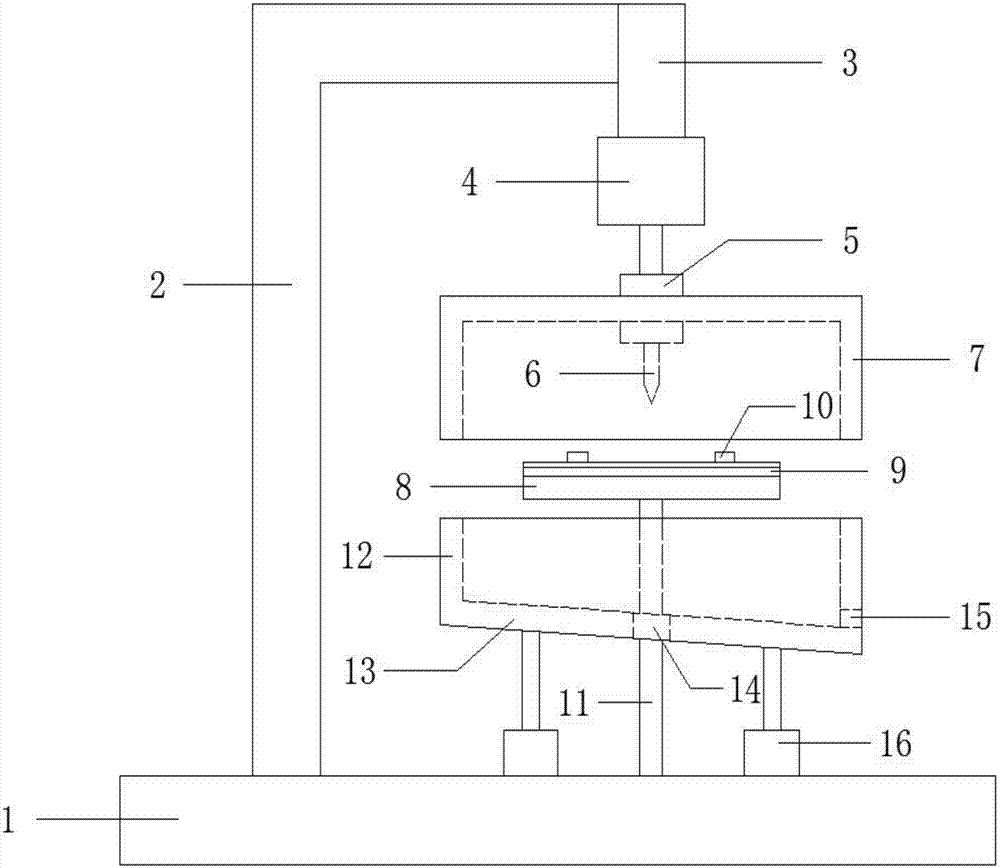

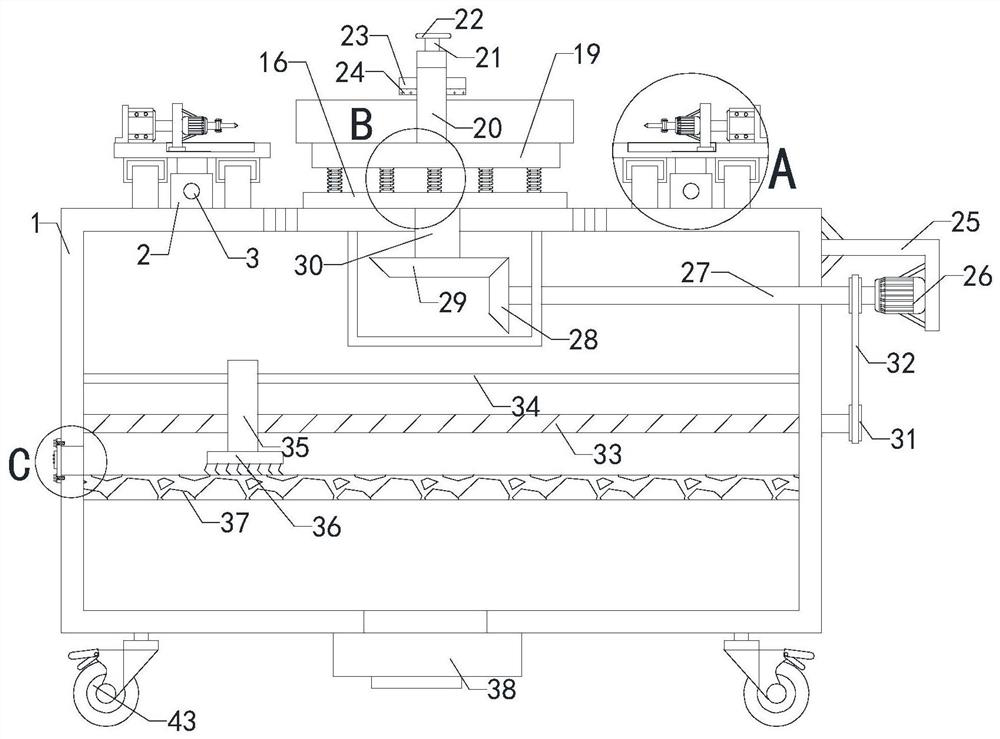

Drilling machine convenient for clearing scrap

InactiveCN107116251AAvoid splattering of debrisImprove cleanlinessDrilling/boring measurement devicesScrapDrill bit

The invention relates to a drilling machine, in particular to a drilling machine convenient for clearing scrap. The drilling machine comprises a base, wherein a supporting rod is fixedly arranged on the base; the supporting rod is fixed with one end of a connecting rod; the other end of the connecting rod is equipped with a first electric telescopic pole; the front end of the first electric telescopic pole is fixedly equipped with a drive mechanism; the drive mechanism is connected with a drill bit; an upper housing with an open bottom is arranged outside the drive mechanism; a processing table is arranged below the drill bit; a fixed device is arranged on the processing table; a reinforcing layer is arranged in the processing table; the bottom of the processing table is fixed with one end of a vertical rod; the other end of the vertical rod is fixed with the base; a lower housing with an open top sleeves the vertical rod; the lower housing is matched with the upper housing; the bottom of the lower housing is equipped with an inclined bottom plate and a through hole matched with the vertical rod; and an opening is formed in a position, close to the bottom of the side wall at the lower end of the inclined bottom plate, of the lower housing. According to the technical scheme provided by the invention, the drilling machine can effectively overcome the defects such as expanded bore diameter as scrap splashes everywhere during drilling and excessively deep punching is easily caused during drilling in the prior art.

Owner:HEFEI DINGXIN MOLD

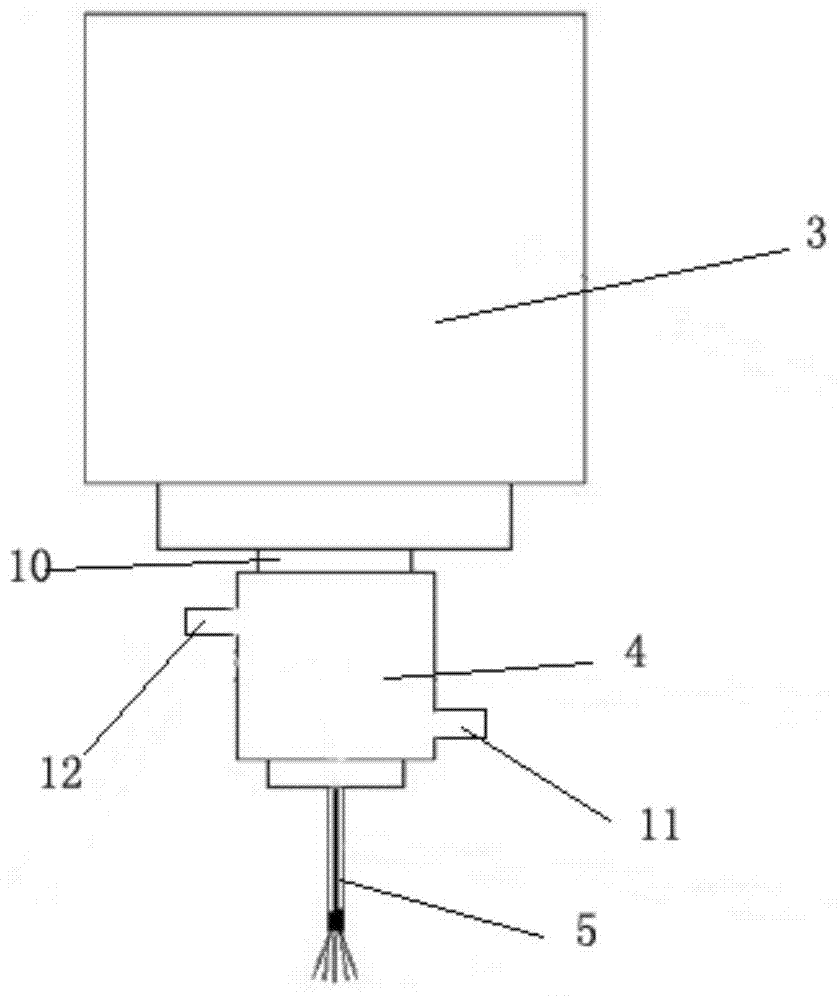

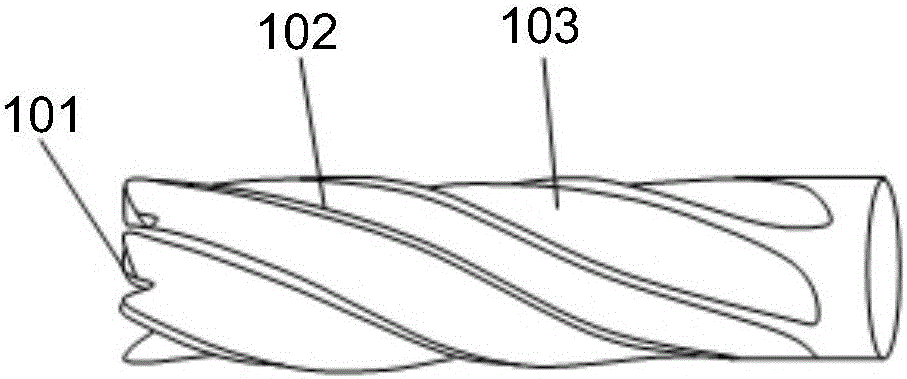

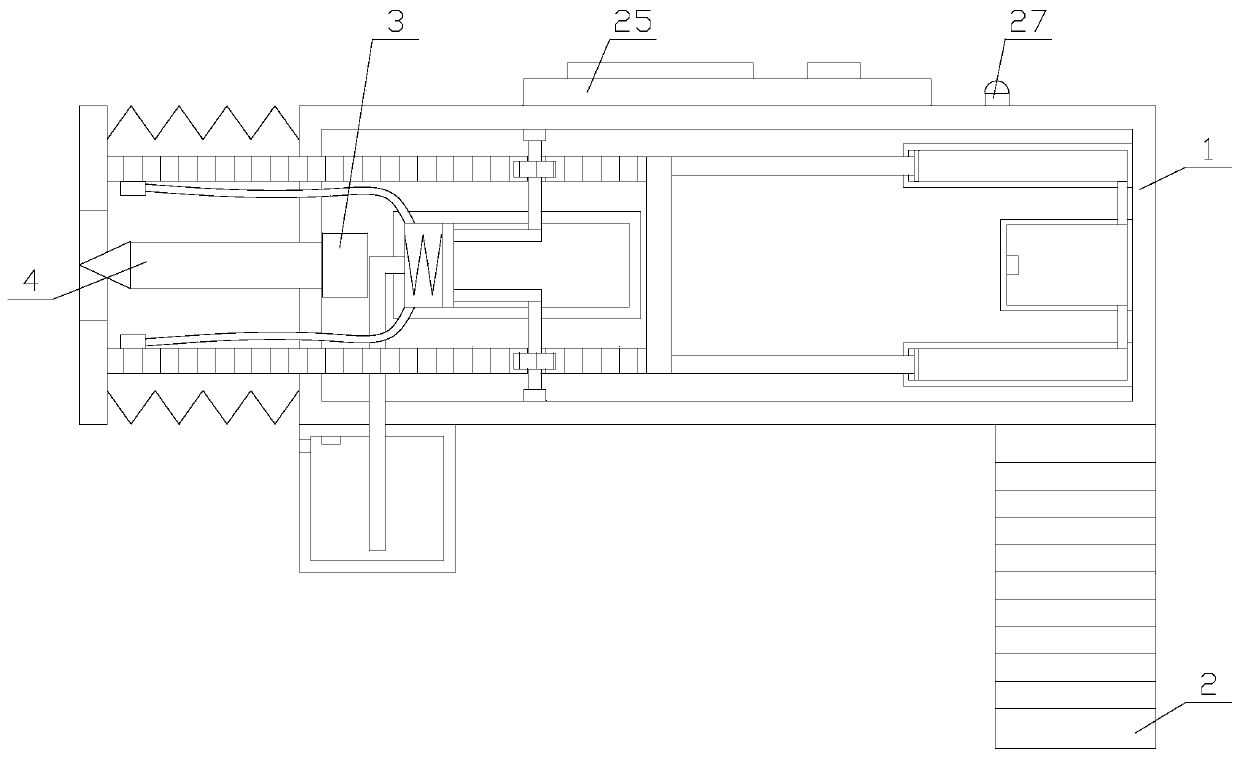

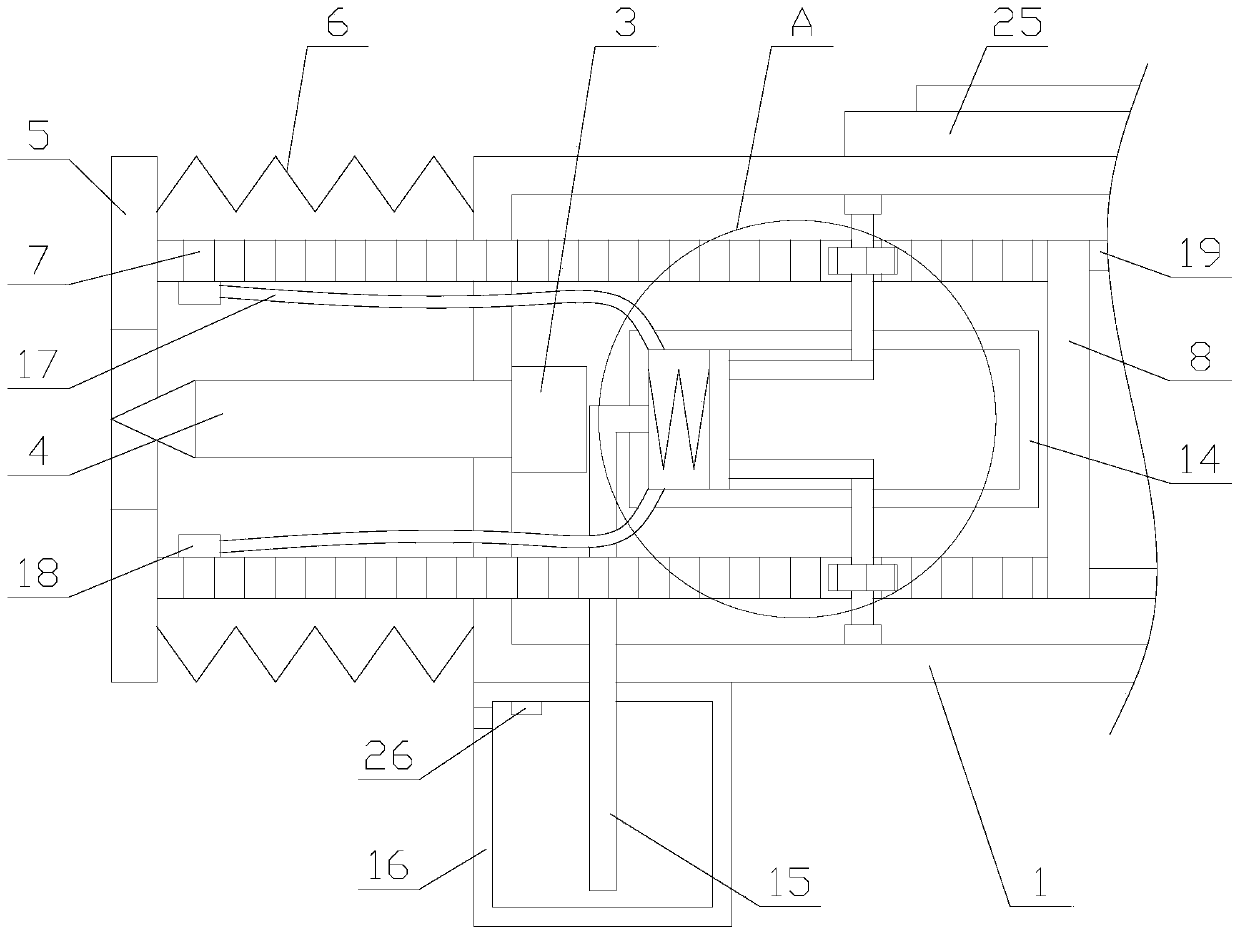

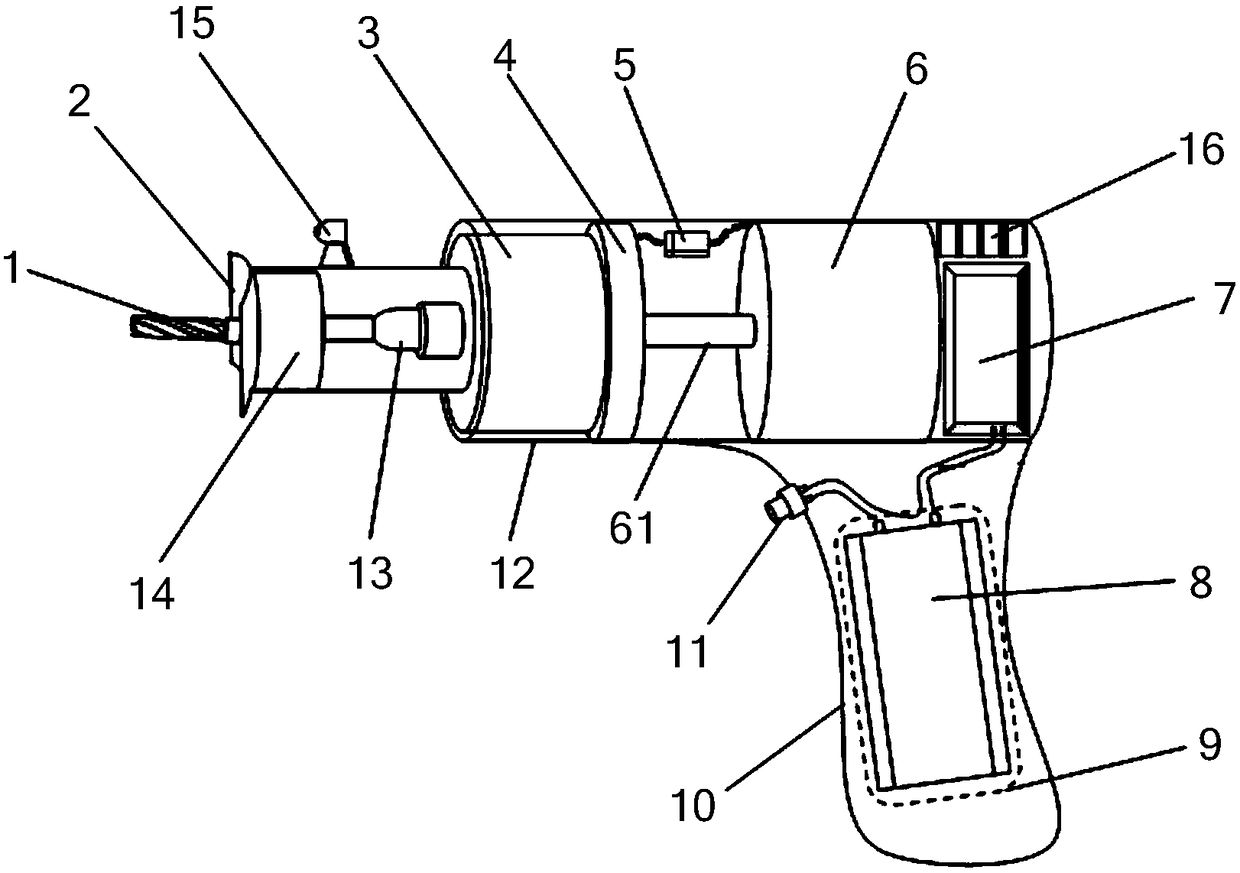

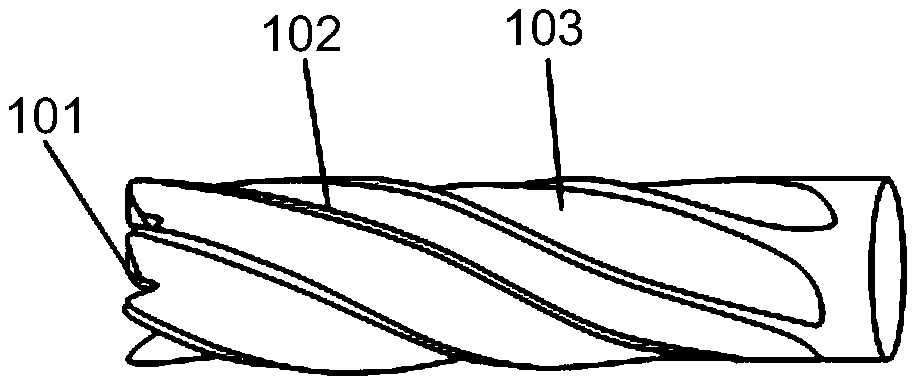

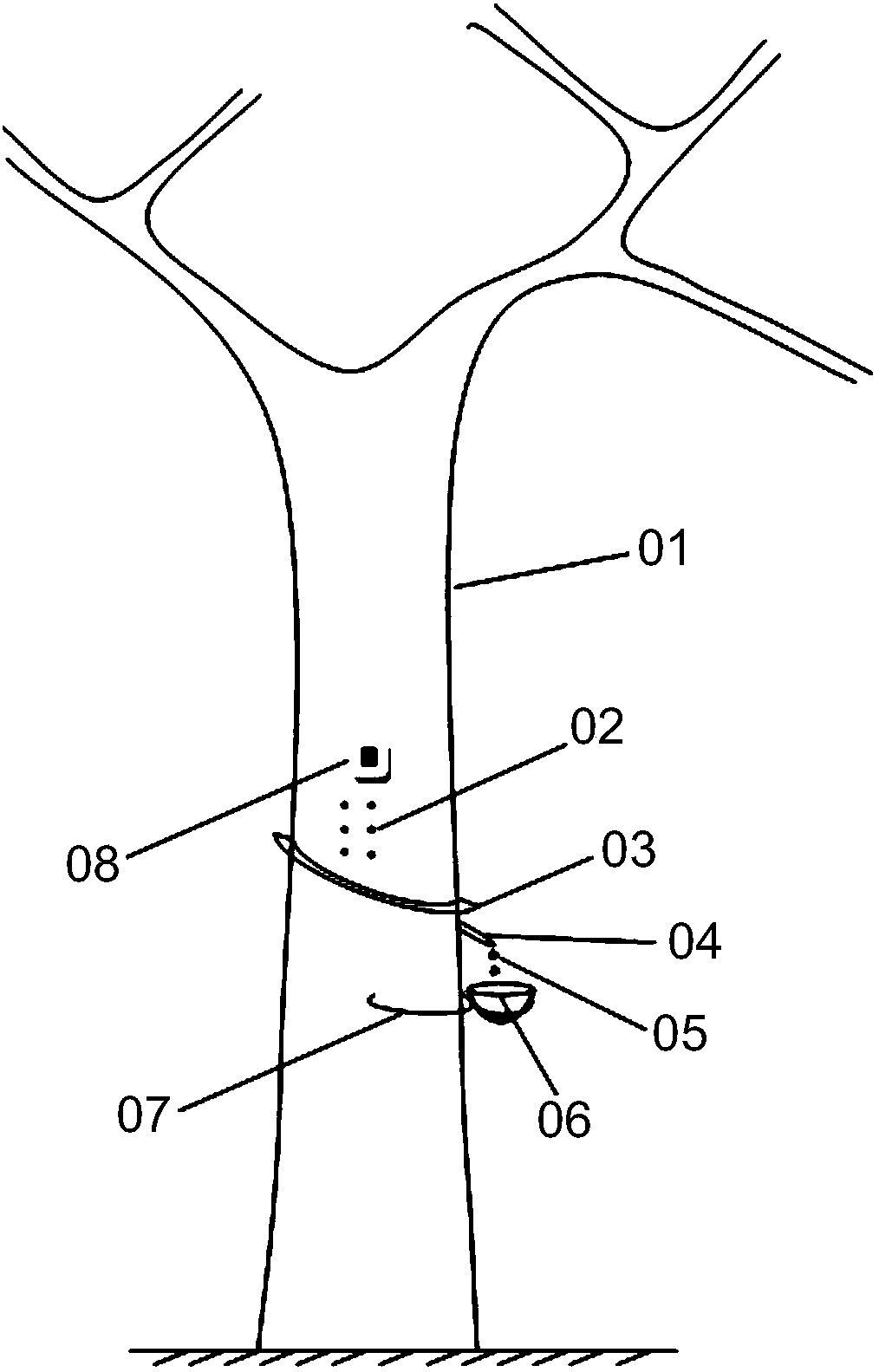

Latex exploration method, latex exploration controller, latex exploration drilling machine, and latex collection system

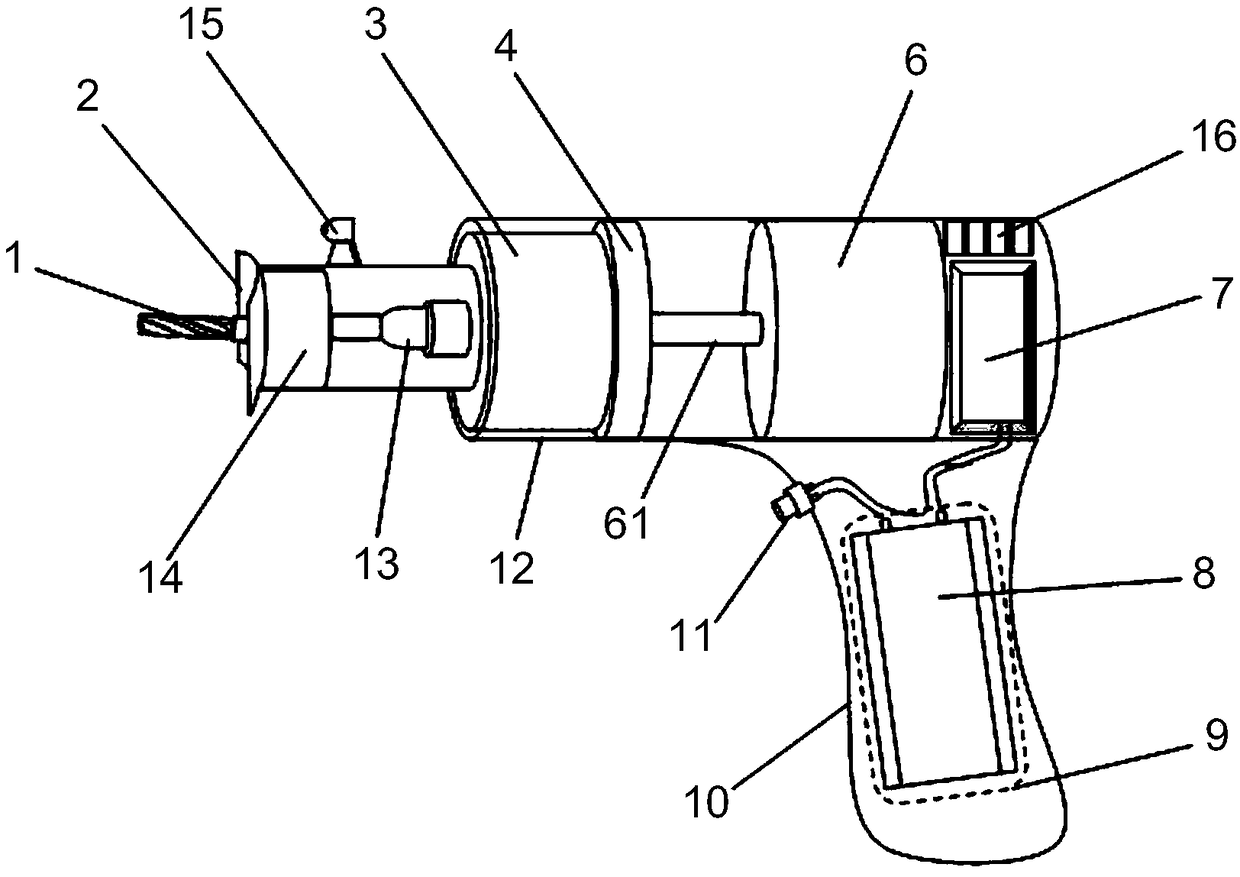

ActiveCN106034977AAvoid breakingNot hurtForestryMaterial dimension controlMotor driveCollection system

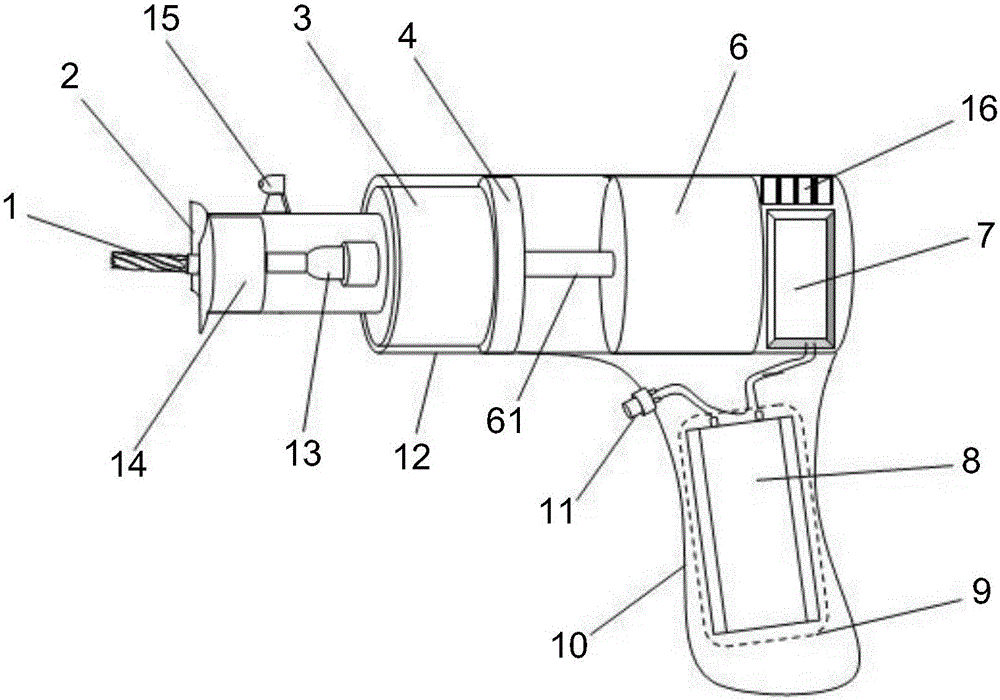

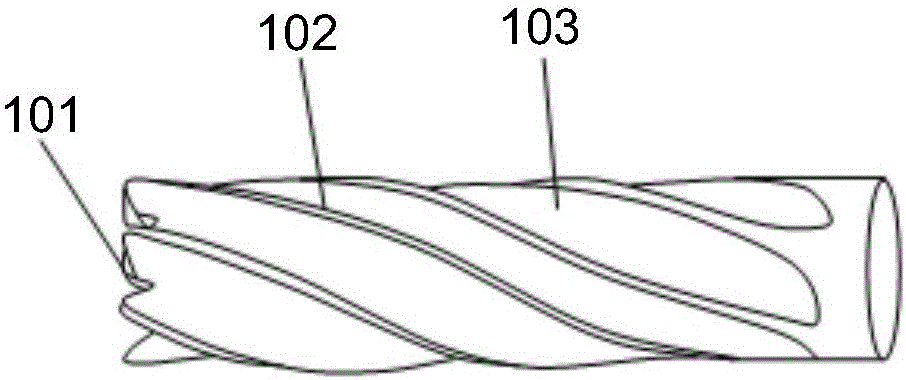

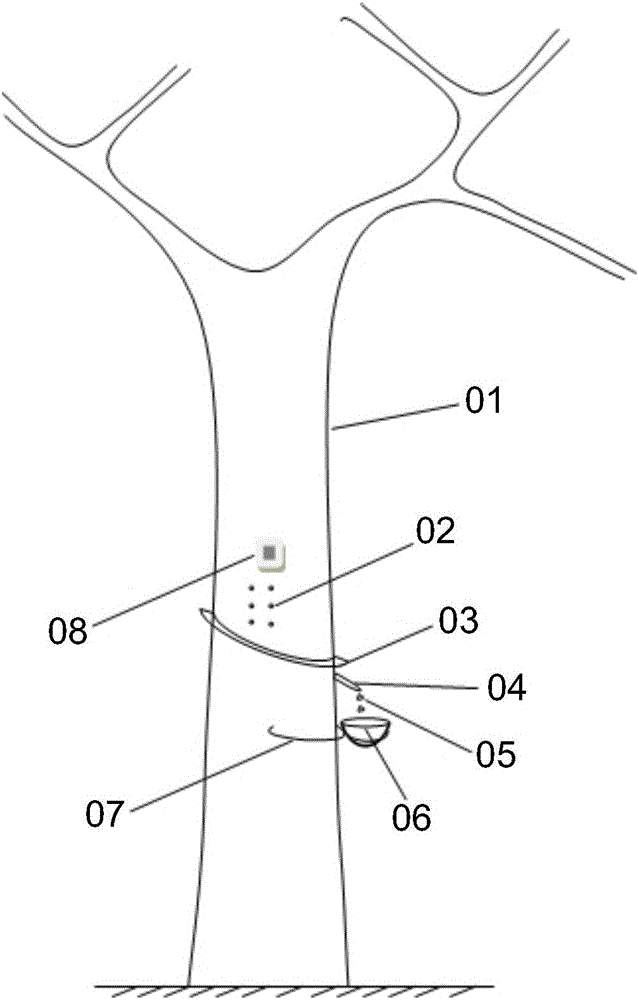

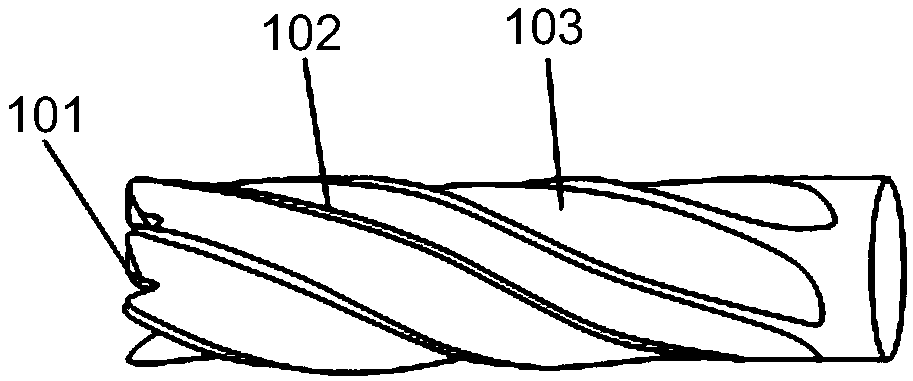

The invention discloses a latex exploration method, a latex exploration controller, a latex exploration drilling machine, and a latex collection system. The latex exploration drilling machine comprises a motor case, a needle drill, a rotating motor, a push motor, thickness information obtaining devices, and the latex exploration controller. The rotating motor drives the needle drill to rotate, and the push motor drives the needle drill to move back and forth. The thickness information obtaining devices are respectively used for reading the thickness information stored in the thickness information obtaining device corresponding to each rubber tree, converting the thickness information into a pulse signal of the push motor, and controlling the push depth of the push motor according to the pulse signal, thereby protecting a forming layer from being damaged. Moreover, the latex exploration drilling machine is easier to drill into the skin of the rubber tree in a rotating manner, reduces the compression on a latex tube, and guarantees the discharging of a larger volume of latex.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

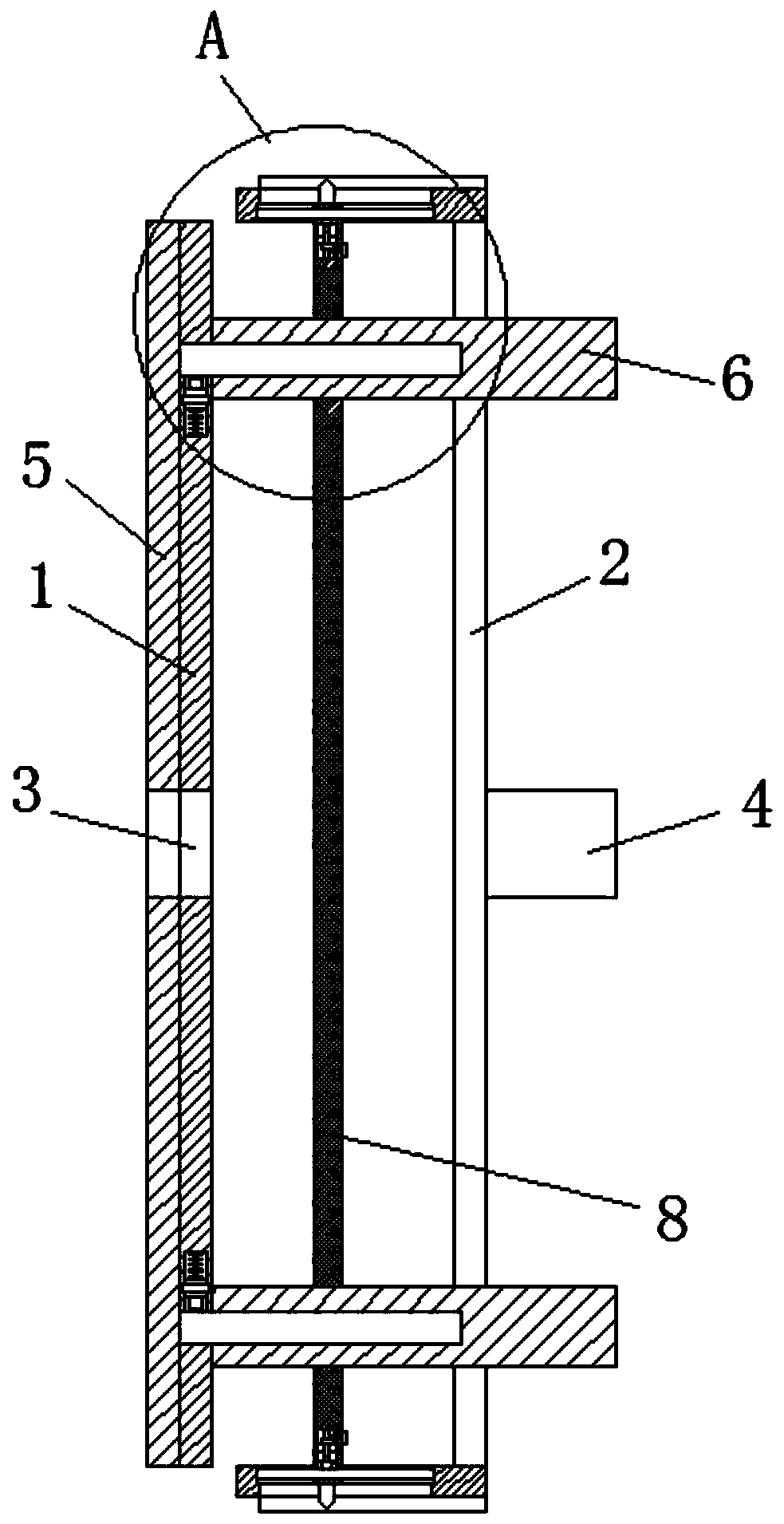

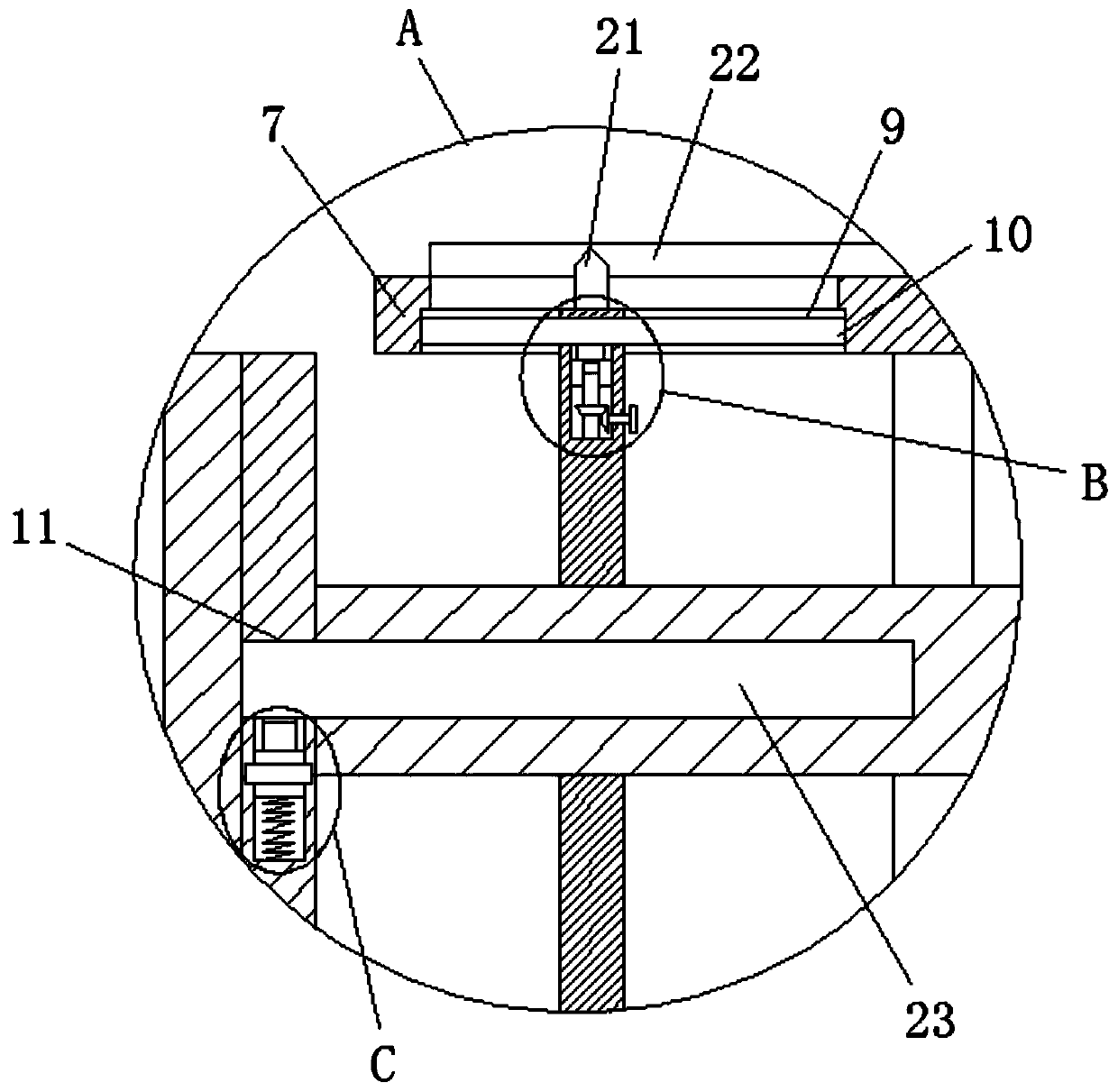

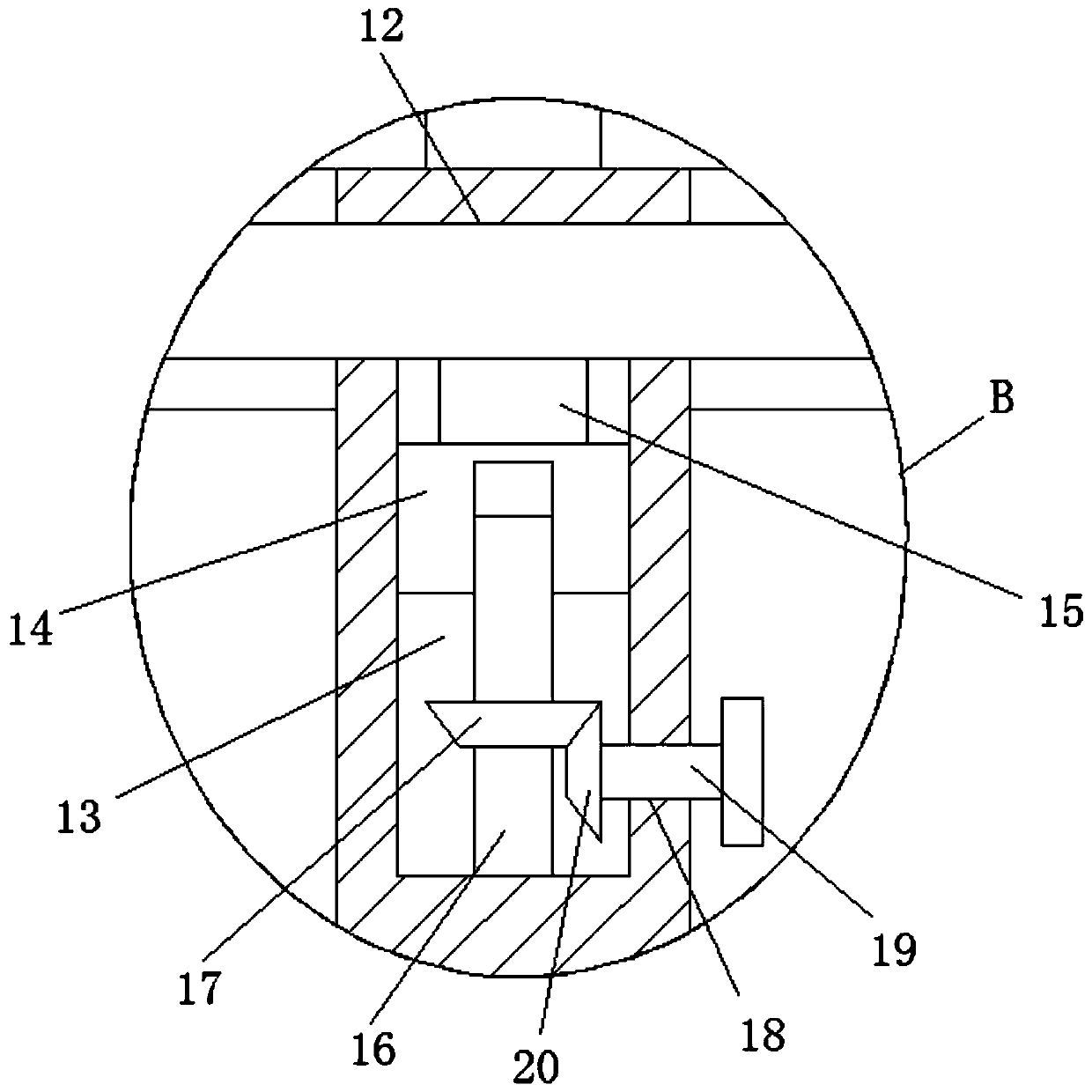

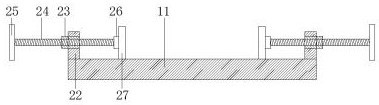

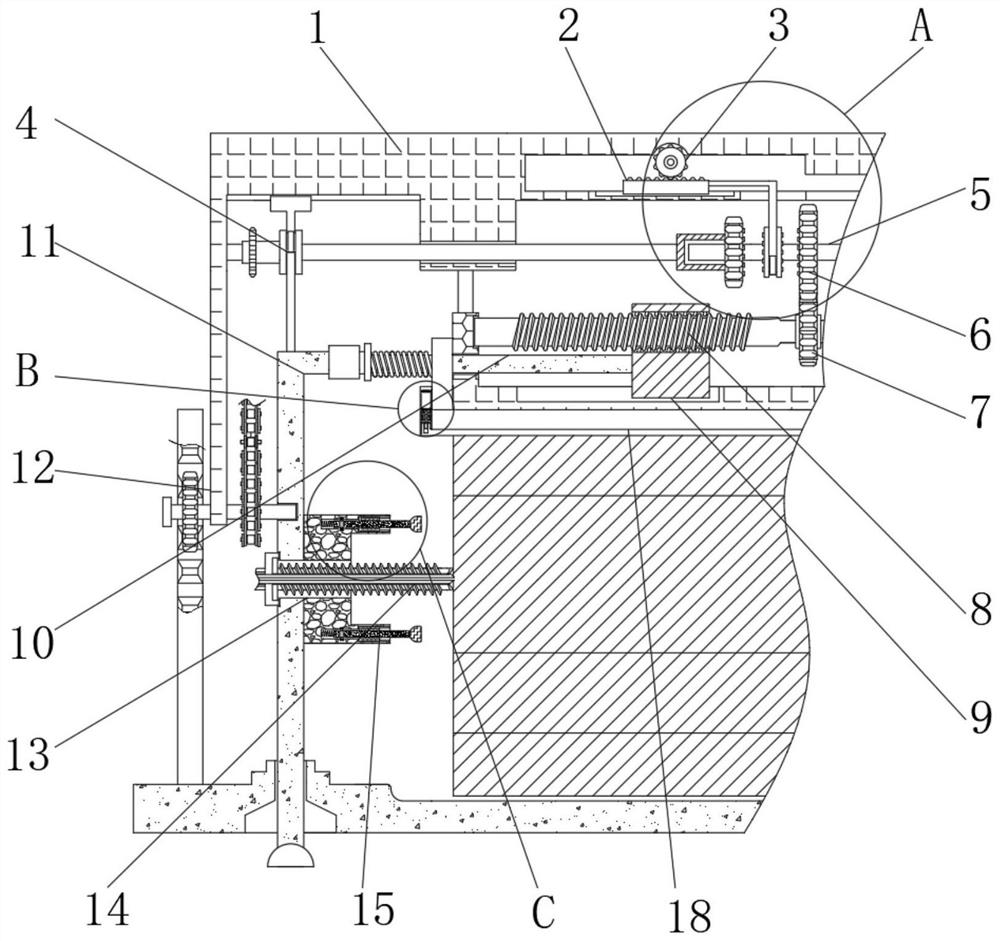

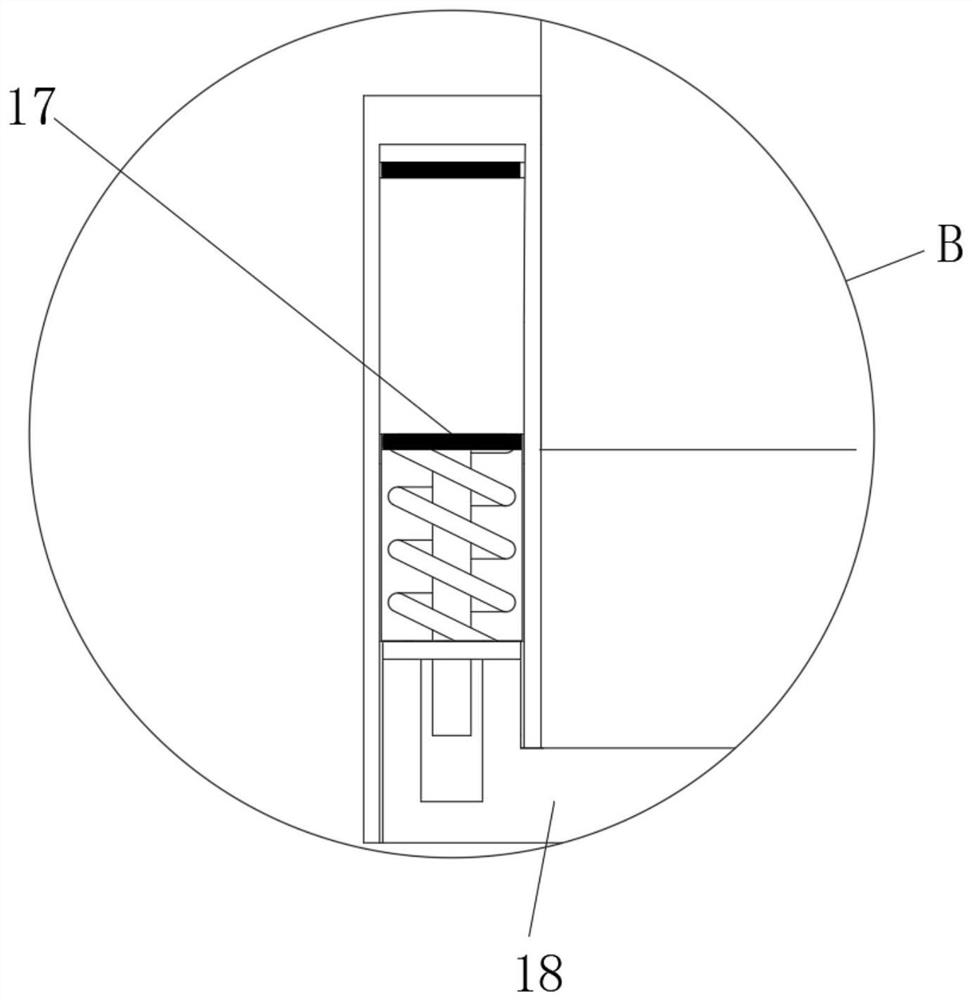

Perforating device capable of adjusting perforating depth

InactiveCN112045224AImprove stabilityExtended service lifeAutomatic control devicesFeeding apparatusEngineeringElectronic component

The invention relates to a perforating device capable of adjusting the perforating depth. The perforating device comprises a base, a supporting rod, a transverse rod, a perforating mechanism and a pushing mechanism, wherein the transverse rod is arranged above the base through the supporting rod; the perforating mechanism is arranged above the base, and the pushing mechanism is arranged on the base. According to the perforating device capable of adjusting the perforating depth, perforating and perforating depth adjustment are achieved through the perforating mechanism, and feeding of workpieces is achieved through the pushing mechanism; compared with an existing perforating device, the perforating depth can be controlled by adjusting the moving distance of a drill bit, the perforating precision is improved, the linkage is adopted between the perforating mechanism and the pushing mechanism, the automatic feeding and perforating are achieved, the labor is saved and the working efficiencyis improved; and meanwhile, the linkage adopts a pure mechanical structure, so that the use of sensors and other electronic elements is avoided, the stability of the mechanism is improved, and the service life of the mechanism is prolonged.

Owner:杨龙兵

Electric quick lifting bracket of electric hammer and electric hammer module thereof

InactiveCN108656032AEasy to returnQuick and easy homing backPortable percussive toolsWork benchesPunchingArchitectural engineering

The invention relates to the technical field of architectural engineering construction equipment, in particular to an electric quick lifting bracket of an electric hammer and an electric hammer modulethereof. The electric quick lifting bracket of the electric hammer comprises a first sleeve, a second sleeve and a third sleeve sleeved in sequence; a bracket is arranged on the first sleeve; and anelectric hammer base is arranged on the third sleeve. The electric quick lifting bracket of the electric hammer has the following beneficial effects: through ascending or descending of a special climblifting structure, an auxiliary support device can be suitable for the punching operation in different height ranges, the construction safety and the working efficiency are effectively improved, thequick punching is realized, and the punching accuracy is improved; after the construction operation is finished, each mechanism can be conveniently and quickly returned to an initial state; and the electric quick lifting bracket of the electric hammer is reasonable in structure, reliable in principle, accurate in positioning, convenient to operate, light, convenient, low in preparation cost, excellent in punching effect, high in construction safety and environment-friendly.

Owner:栾仁卫

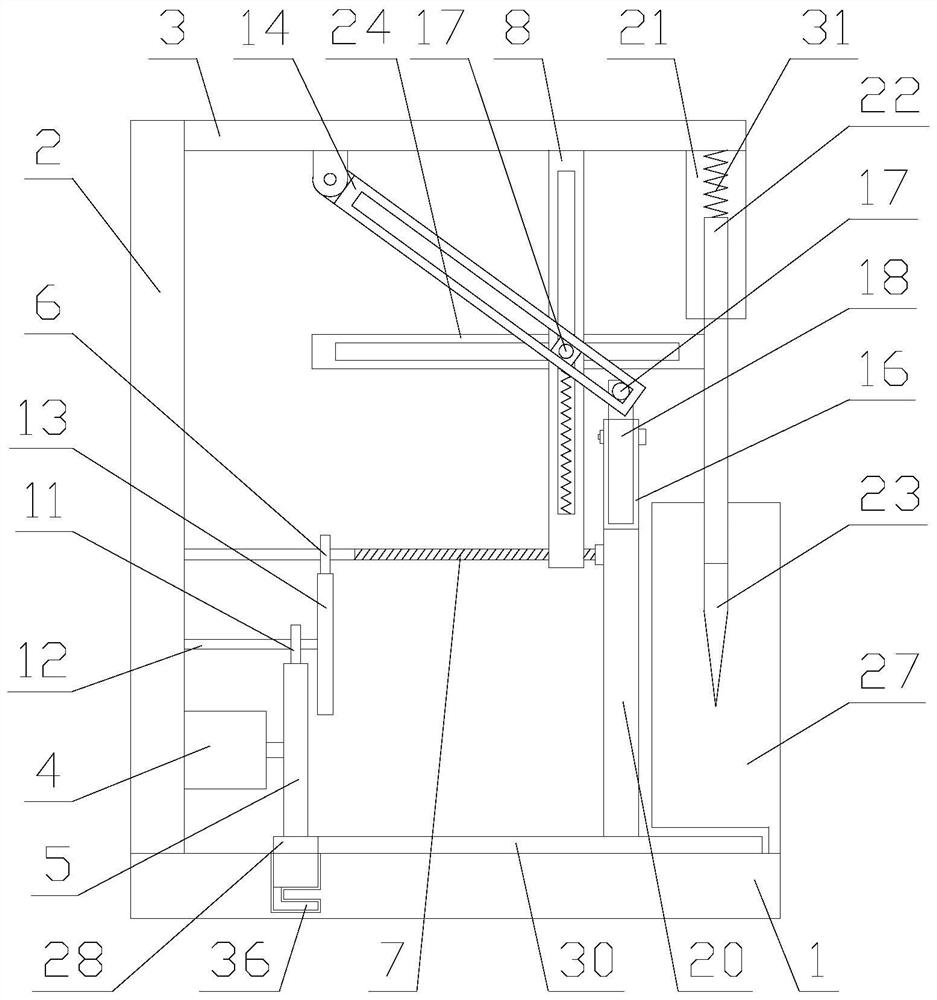

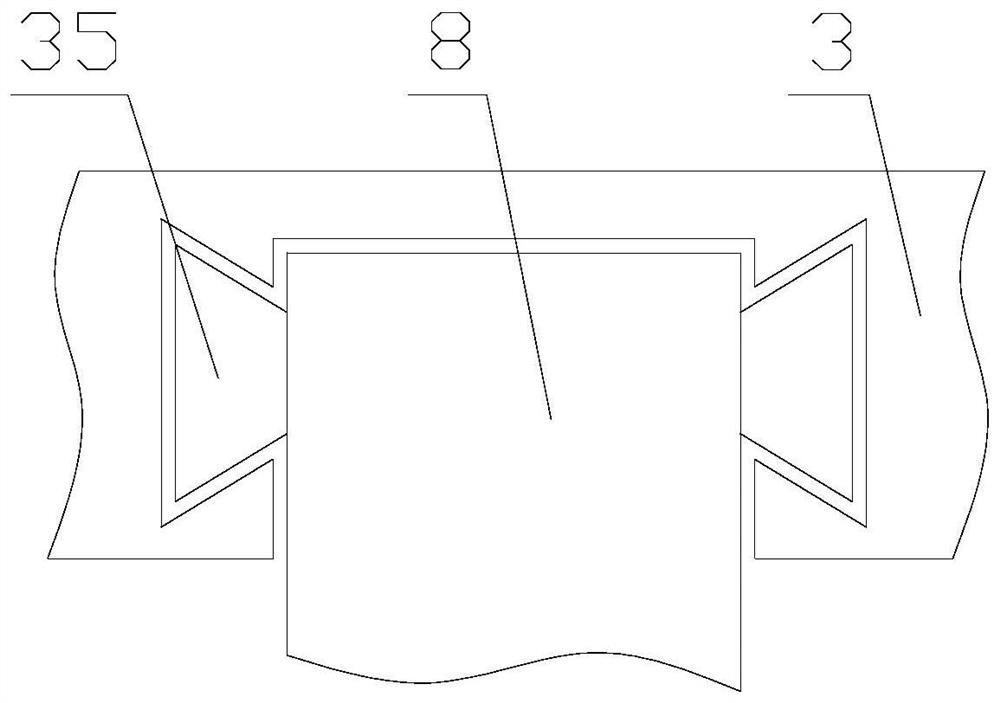

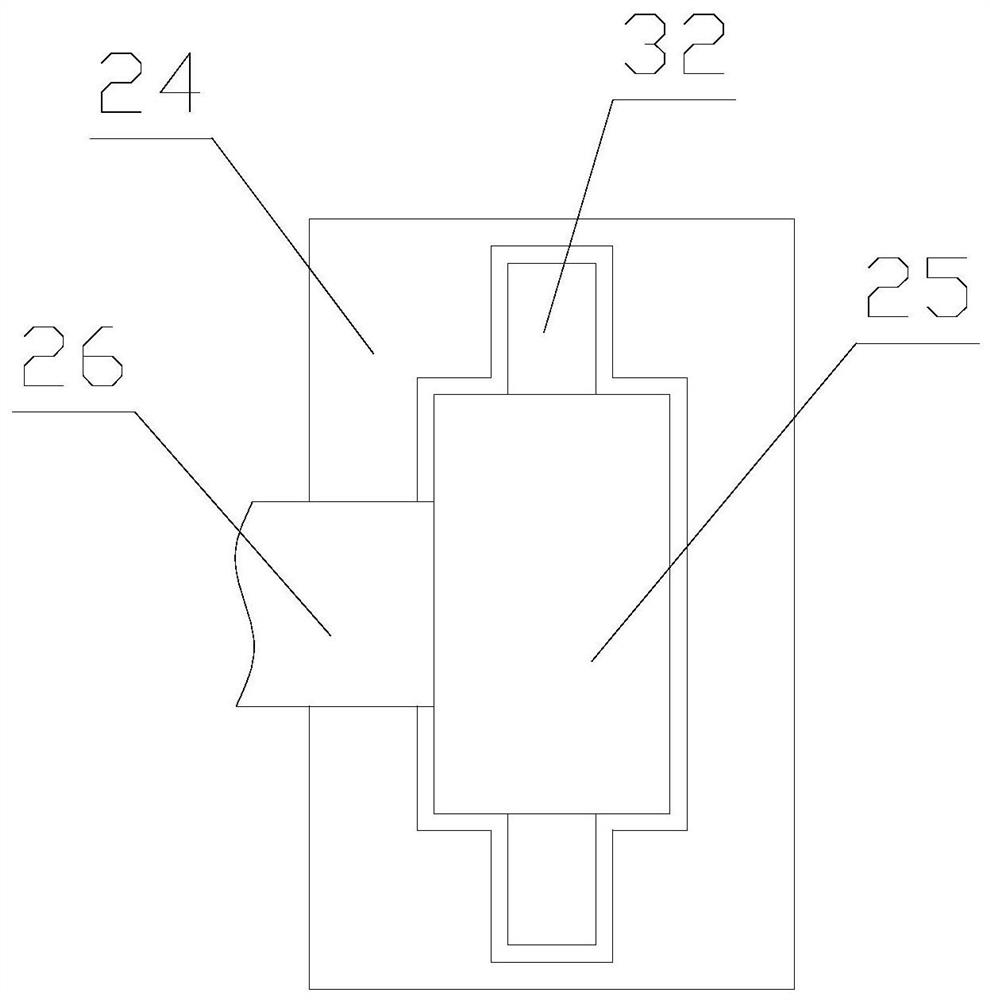

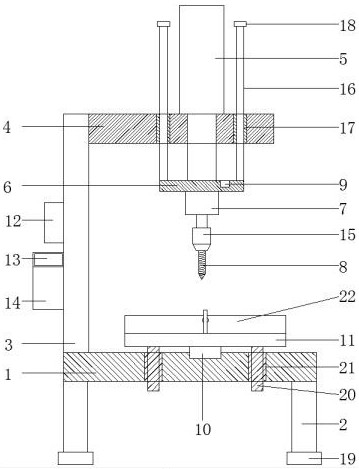

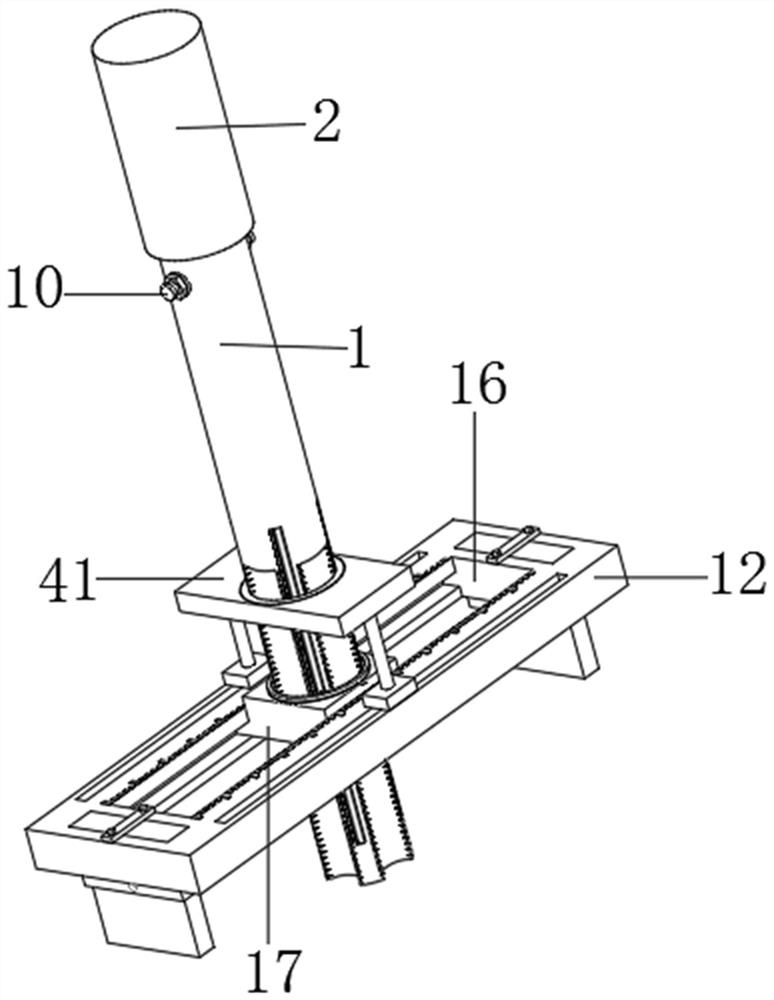

Punching machine capable of automatically controlling punching depth

InactiveCN104259510AControl punch depthPrecise control of drilling depthBoring/drilling componentsMaintainance and safety accessoriesAutomatic controlPunching

The invention provides a punching machine capable of automatically controlling punching depth. The punching machine comprises a base, a motor and a control device, a power output shaft of the motor is connected with an inner cooling joint, the inner cooling joint is connected with a hollow drill bit, a support is mounted on the base, a lifting air cylinder is disposed on the support, the lifting air cylinder is connected with the control device, the motor is fixedly connected with the support, a working table is disposed on the base, and a clamping mechanism is disposed on the working table. The punching machine capable of automatically controlling punching depth has the advantages that the lifting air cylinder is disposed on the support, the control device is connected with the lifting air cylinder, the height of the lifting air cylinder is controlled through the control device, thereby, the punching depth of the hollow drill bit is controlled, the punching depth is accurately controlled, the inner cooling joint is arranged and provided with a water inlet and a water outlet, tap water can flow in the hollow drill bit so as to cool the hollow drill bit, abrasion of the drill bit is reduced, and the service life of the drill bit is prolonged.

Owner:TIANJIN QINGLONG INTELLIGENT SCI & TECHCO

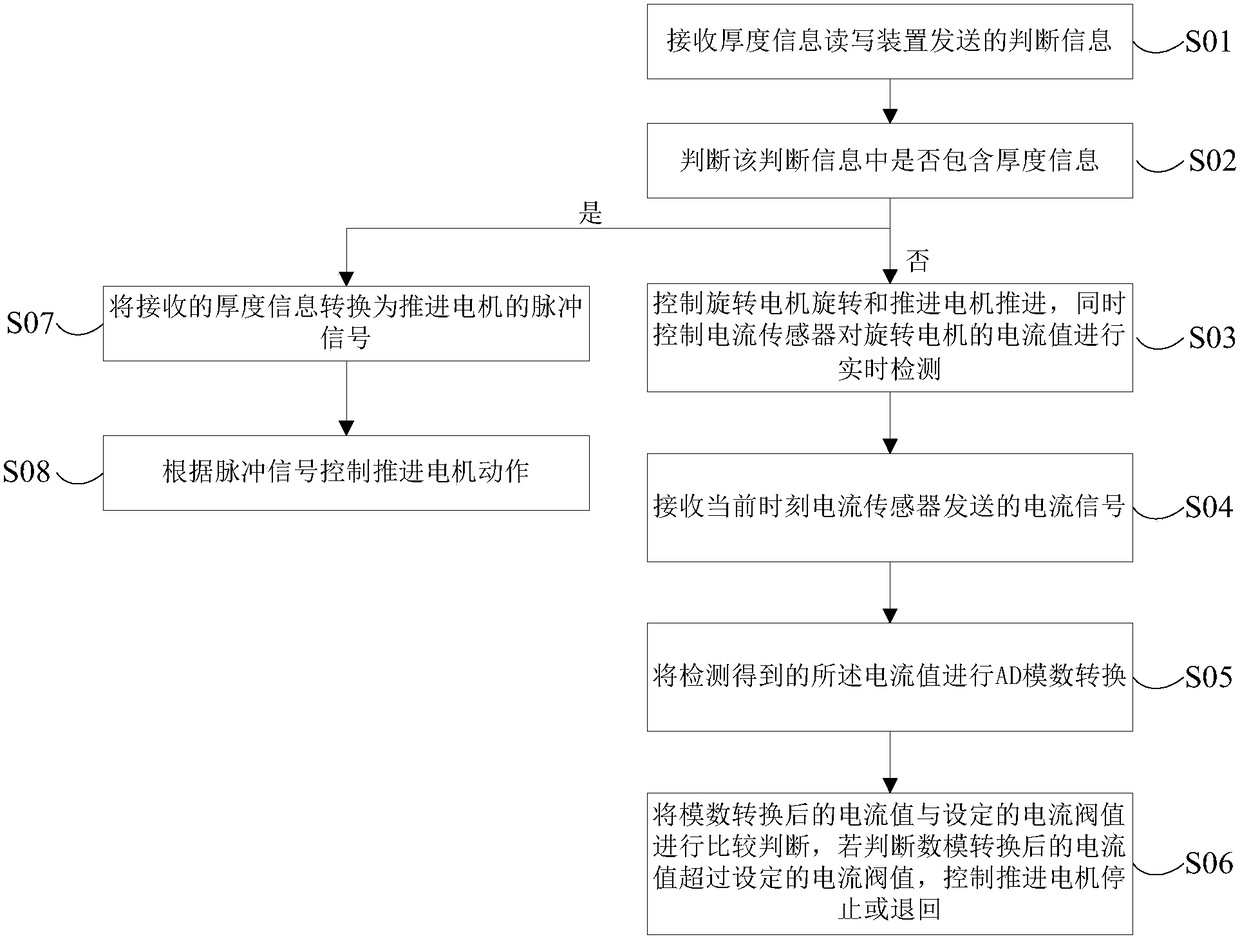

Latex collecting method, latex collection processor and latex collector

The application discloses a latex collecting method, a latex collection processor and a latex collector; the latex collector comprises a casing, a needle drill, a rotation motor, a propulsion motor, a current sensor and a latex collection processor; the rotation motor drives the needle drill to rotate; the propulsion motor drives the needle drill to move back and forth; the current sensor is used for detecting the current value of the rotation motor; the latex collection processor can carry out analog-to-digital conversion according to the current value detected by the current sensor; the converted current value is compared with a set current threshold value, if the converted current value exceeds the set current threshold value, the propulsion motor is controlled to stop or fall back. The rotation motor drives the needle drill to work, and uses different current values for drilling into the bark and xylem; the current threshold value is determined by said current values used by the rotation motor; the needle drill drills into the xylem and stops to propel and drill, thus protecting the cambium layer from being damaged; the needle drill can easily drill into the rubber tree bark, so the latex tube can be less extruded, thus ensuring more latex flow amount.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

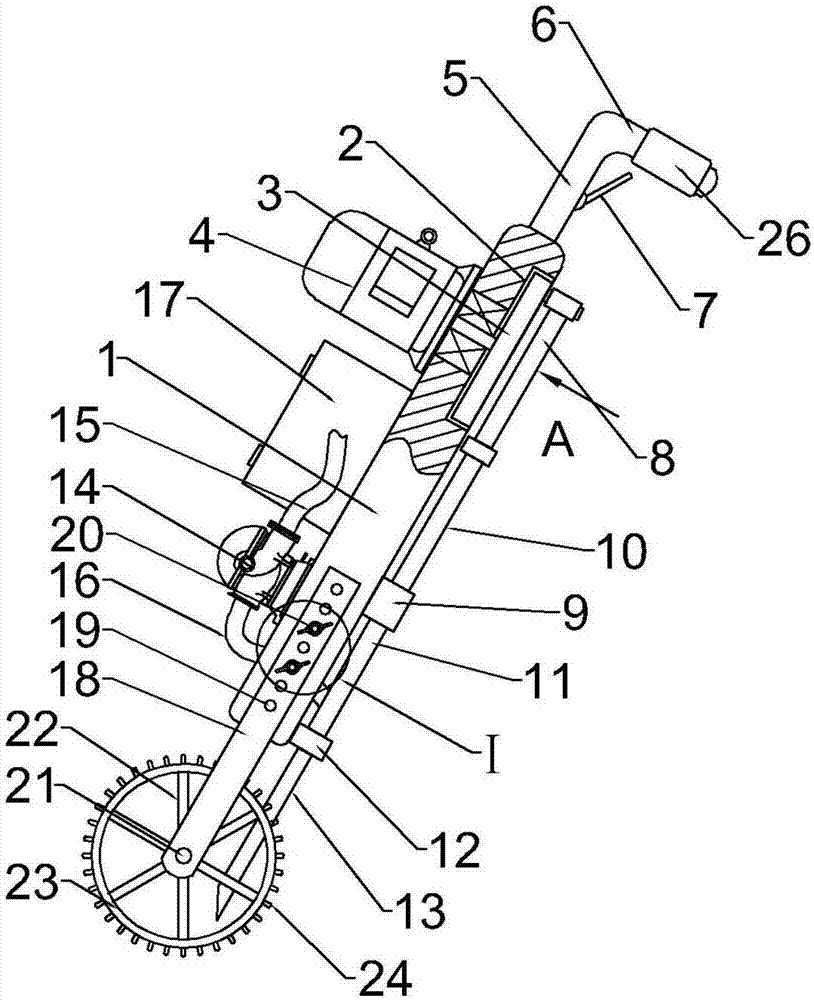

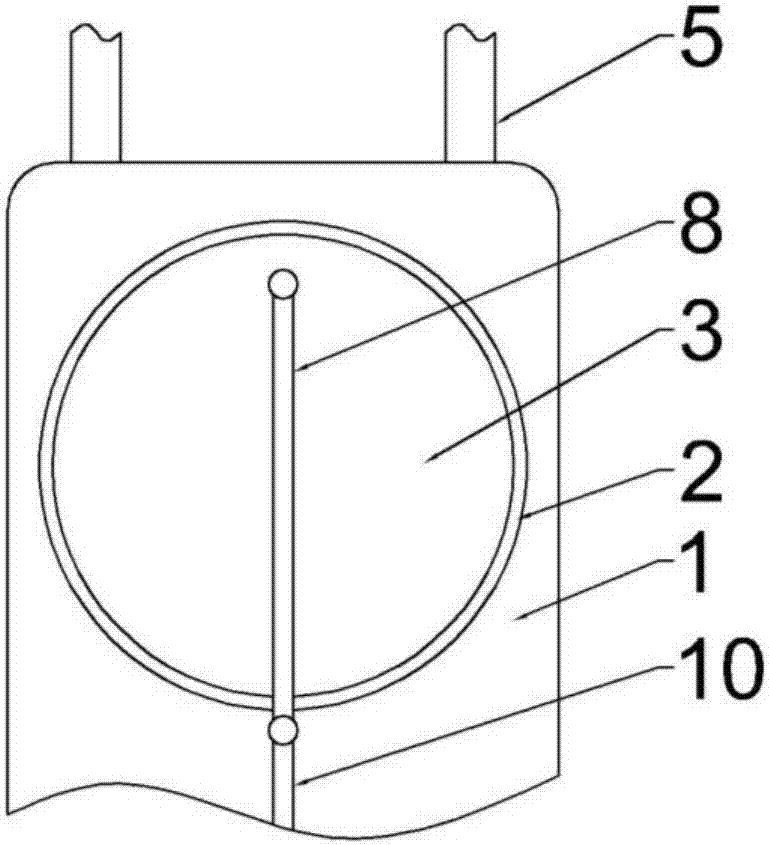

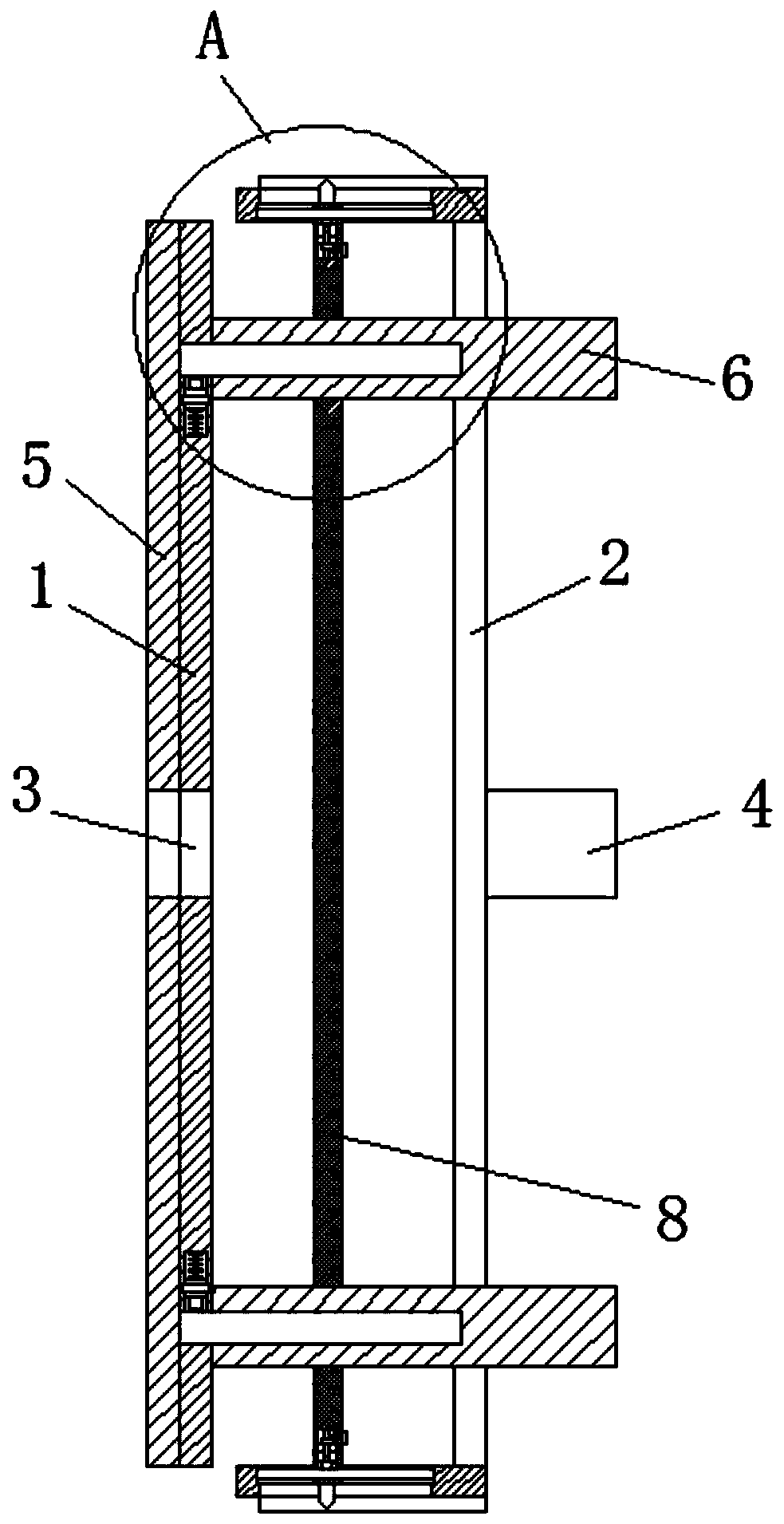

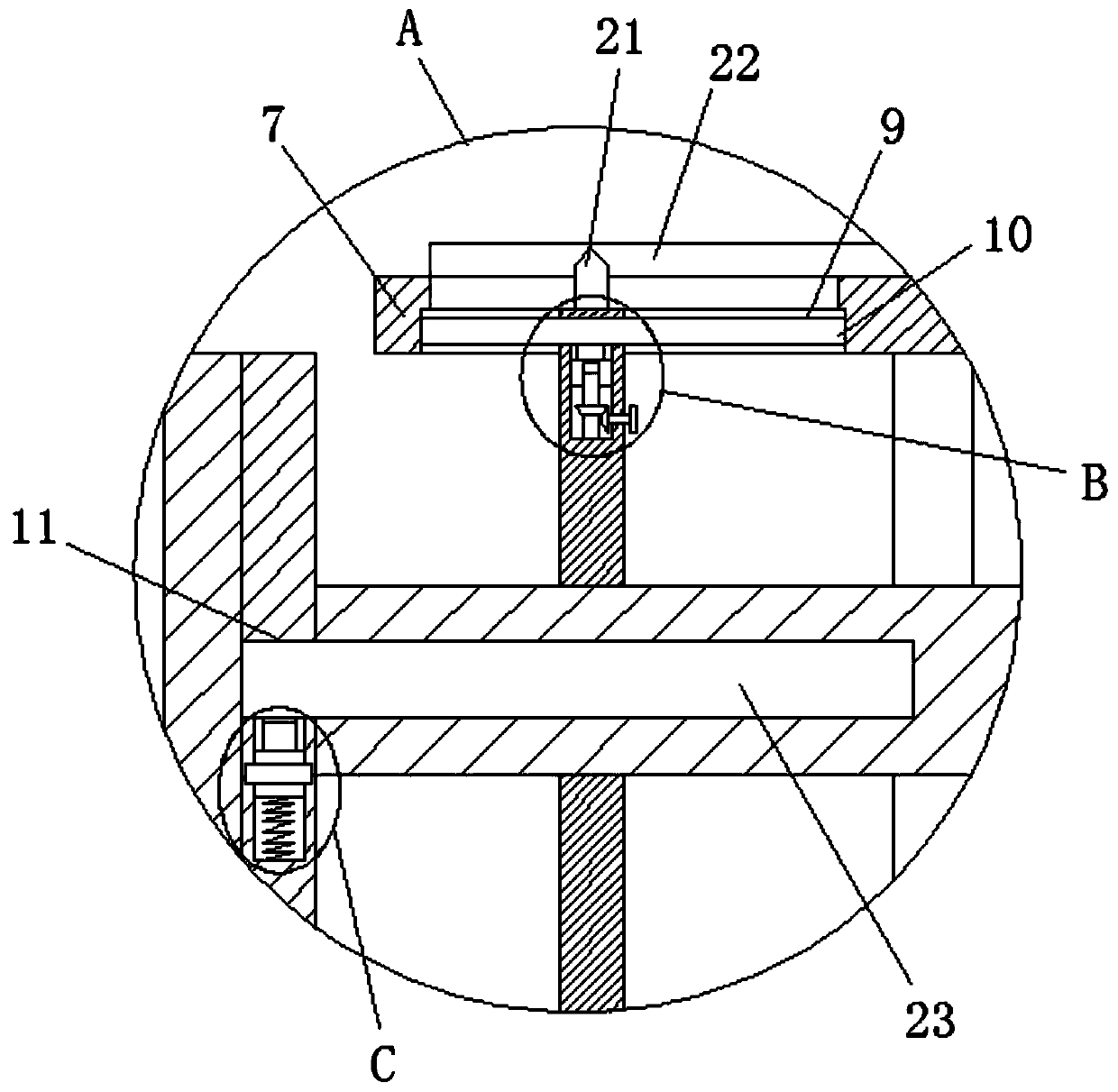

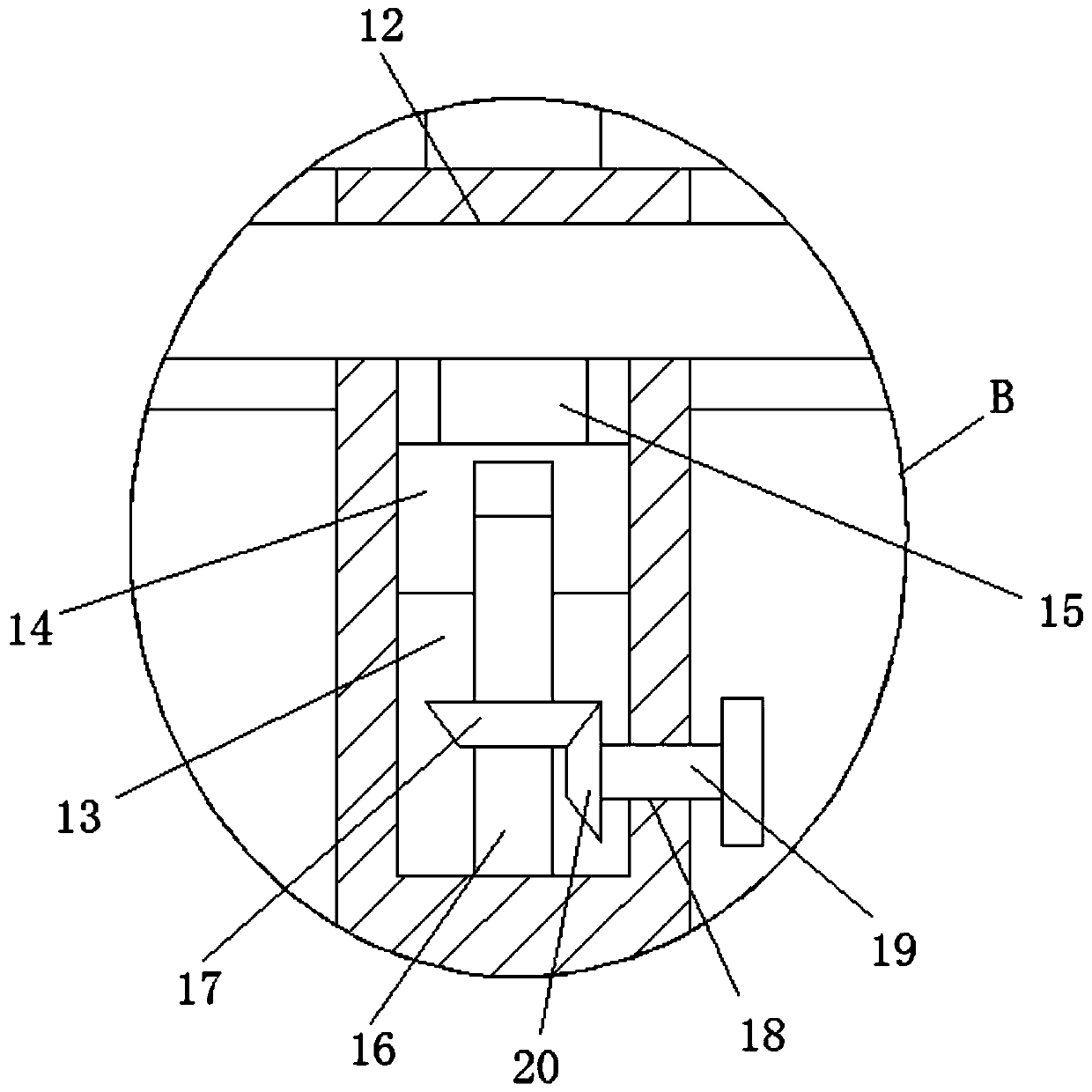

Handheld lawn aerator device used for garden

The invention discloses a hand-held lawn punching device for gardening, comprising a longitudinal support plate, a turntable slot is opened on the right side of the longitudinal support plate, a rotating disc is rotatably connected inside the turntable slot, and the upper left side of the longitudinal support plate is A motor is fixedly connected, the output end of the motor is fixedly connected to the rotating disc through a longitudinal support plate, a longitudinal connection handle is fixedly connected to the top of the longitudinal support plate, and a horizontal handle is fixedly connected to the right side of the top of the longitudinal connection handle. A start switch is fixedly connected to the right side of the handle. Compared with the prior art, the beneficial effects of the present invention are as follows: the present invention has a simple structure, is convenient to use, and is more convenient to operate the punching hole by using a hand-held type, and can control the punching depth. Irrigating the lawn also makes it easier to drill holes, allowing the roots of the lawn to breathe more air, which in turn can lead to better lawn growth and is worth promoting.

Owner:武汉中智德远科技开发有限公司

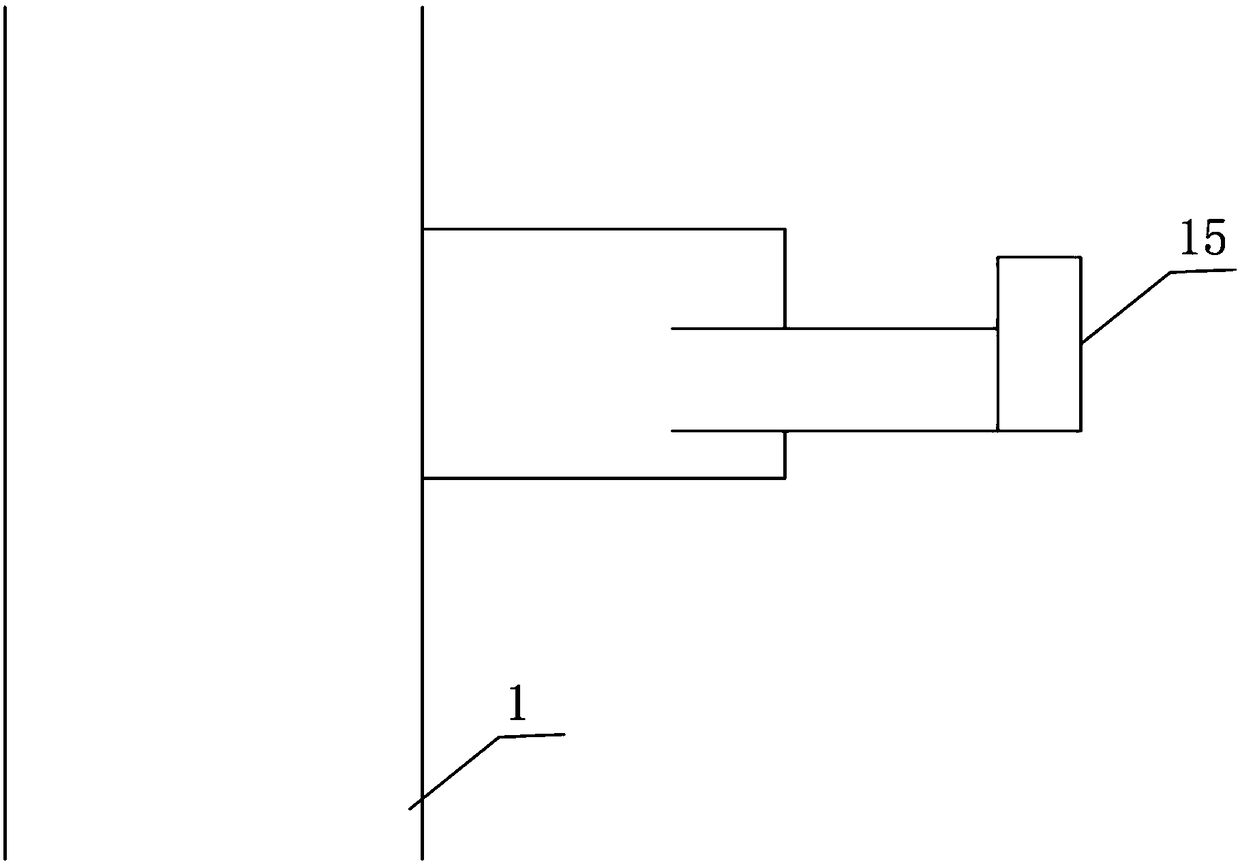

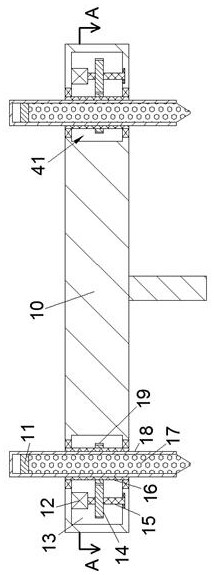

Tunnel drilling device capable of controlling drilling depth and method of use

ActiveCN109826560BControl punch depthEasy to adjustSurveyDrilling rodsPunchingStructural engineering

The invention discloses a tunnel drilling device capable of controlling drilling depth and a using method thereof, wherein a first baffle plate capable of adjusting position is arranged on a second plate in a control device in a direct or indirect sliding mode; the first baffle plate is positioned at one side of a second plate, away from a fixing rod; three fourth fixing holes are formed in the first baffle plate; the positions of the three fourth fixing holes correspond to those of the three third fixing holes one by one; a second baffle plate capable of adjusting position is arranged on a first plate in a direct or indirect sliding mode; the second baffle plate is positioned at one side of the first plate, away from a detection rod; the third baffle plate is provided with three second fixing holes which correspond to three first fixing holes one by one. According to the control device, the position of the first baffle plate can be accurately adjusted, so that the punching depth can be accurately controlled conveniently, the position of the second baffle plate can be conveniently adjusted, and the punching depth can be accurately controlled according to the length of the fixing rod.

Owner:何一当

Tunnel drilling device capable of controlling drilling depth and using method thereof

The invention discloses a tunnel drilling device capable of controlling drilling depth and a using method thereof, wherein a first baffle plate capable of adjusting position is arranged on a second plate in a control device in a direct or indirect sliding mode; the first baffle plate is positioned at one side of a second plate, away from a fixing rod; three fourth fixing holes are formed in the first baffle plate; the positions of the three fourth fixing holes correspond to those of the three third fixing holes one by one; a second baffle plate capable of adjusting position is arranged on a first plate in a direct or indirect sliding mode; the second baffle plate is positioned at one side of the first plate, away from a detection rod; the third baffle plate is provided with three second fixing holes which correspond to three first fixing holes one by one. According to the control device, the position of the first baffle plate can be accurately adjusted, so that the punching depth can be accurately controlled conveniently, the position of the second baffle plate can be conveniently adjusted, and the punching depth can be accurately controlled according to the length of the fixing rod.

Owner:何一当

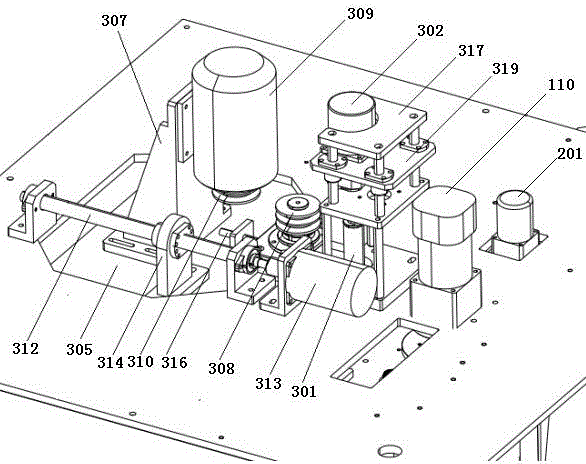

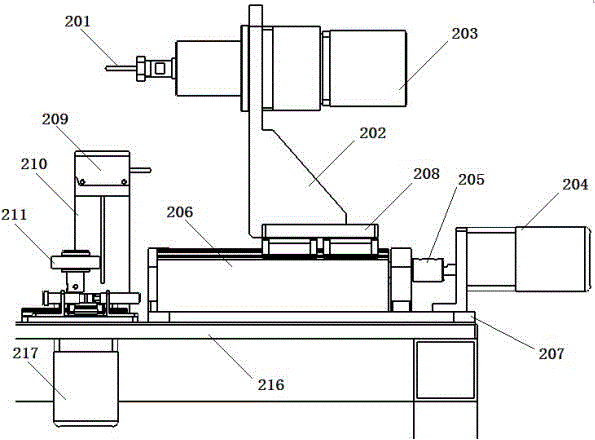

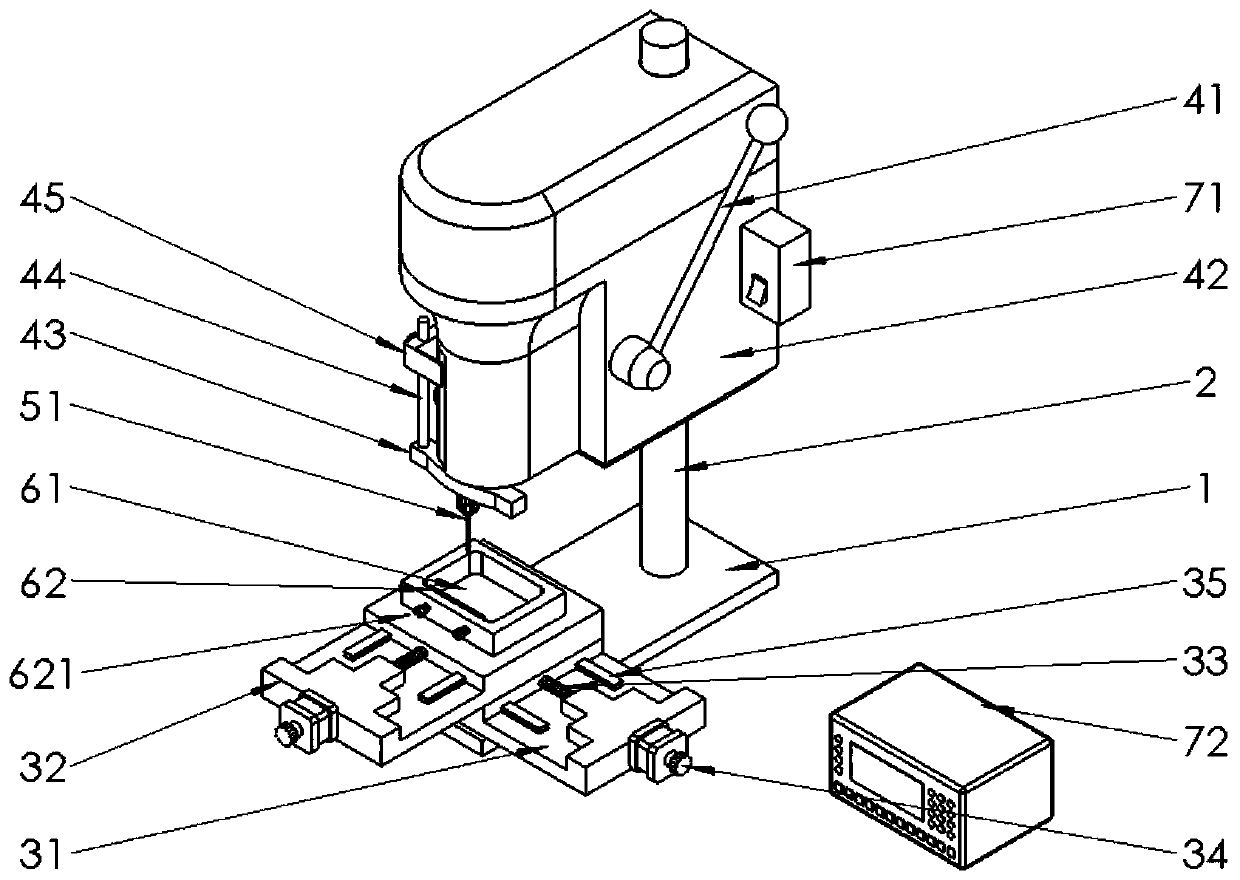

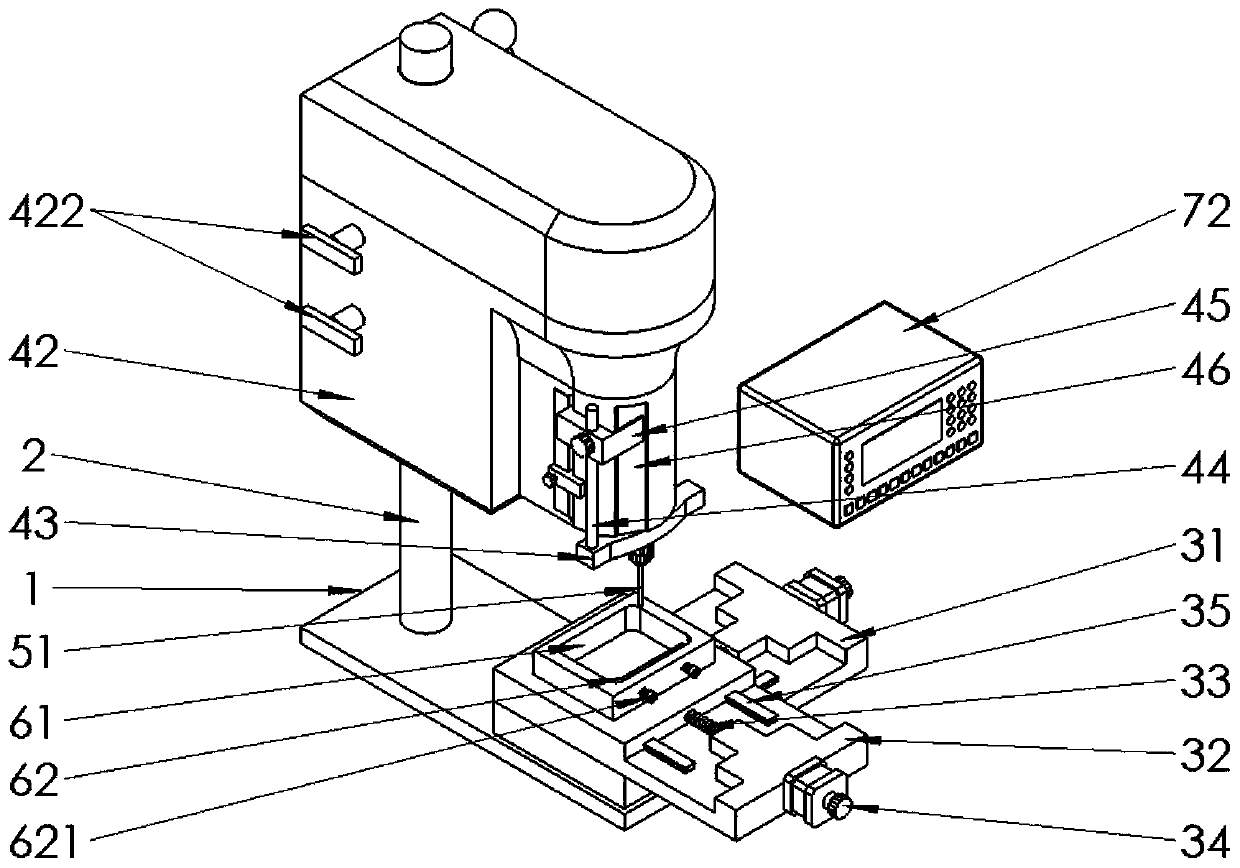

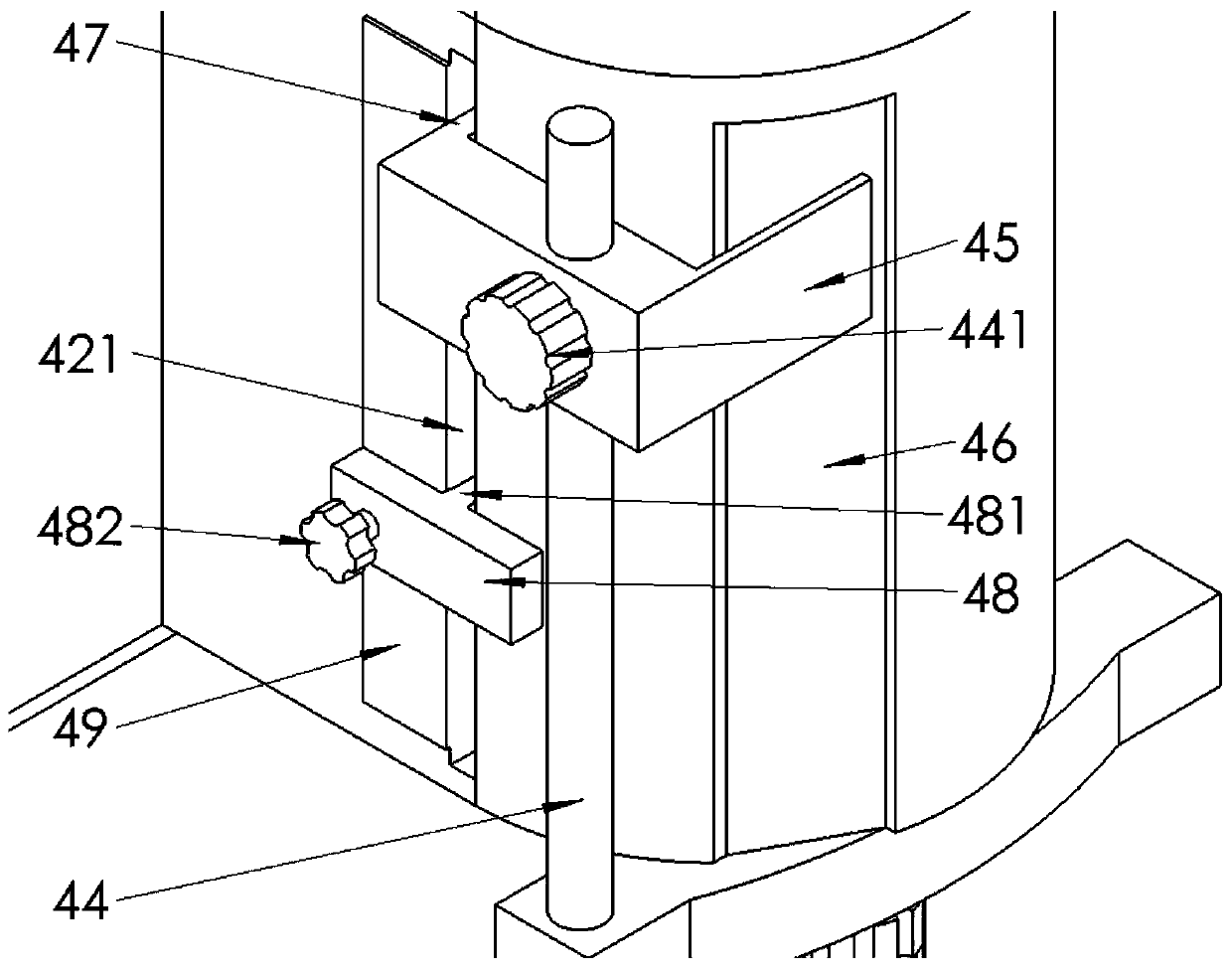

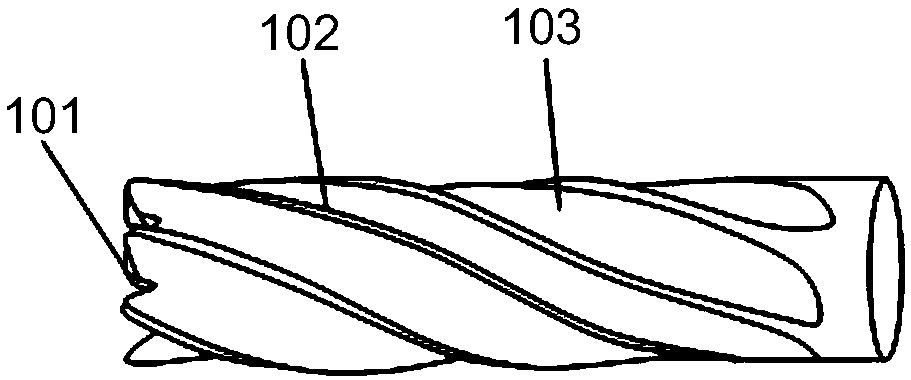

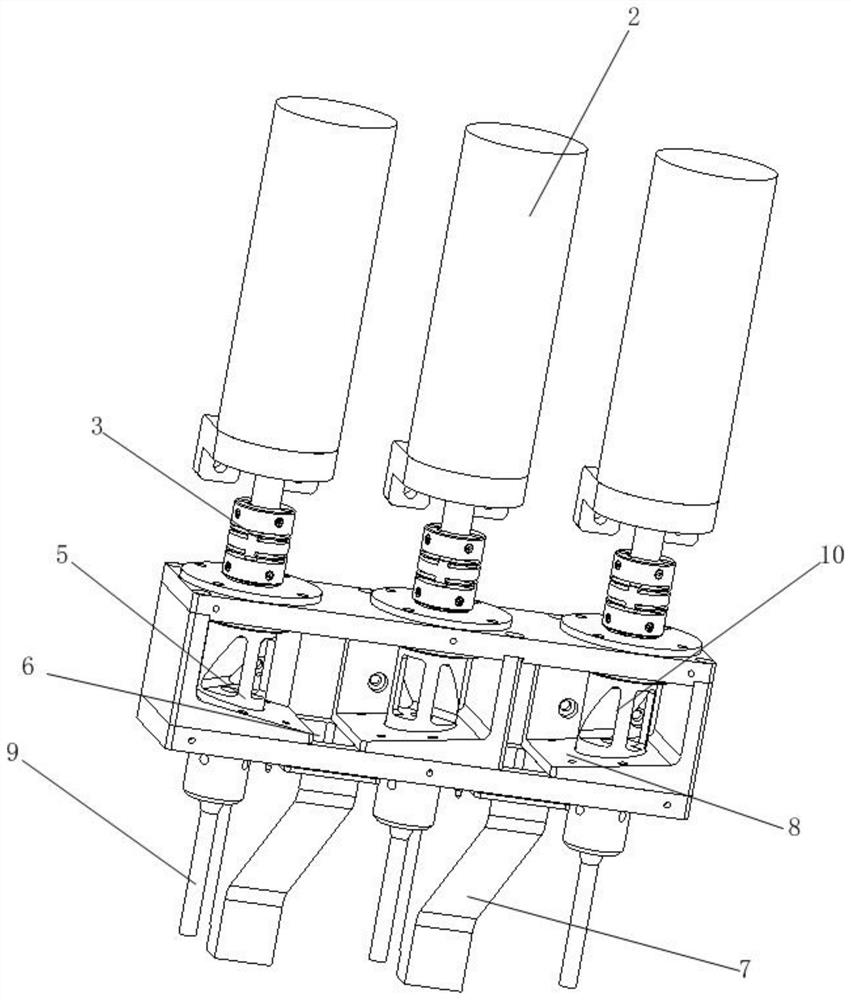

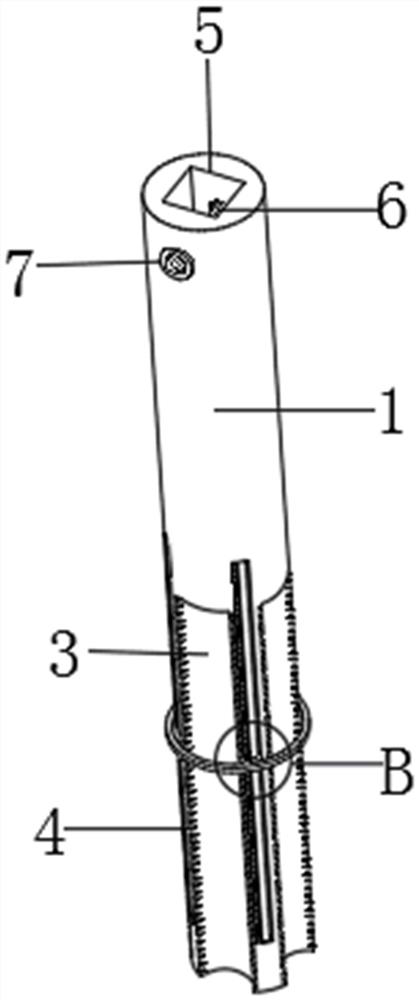

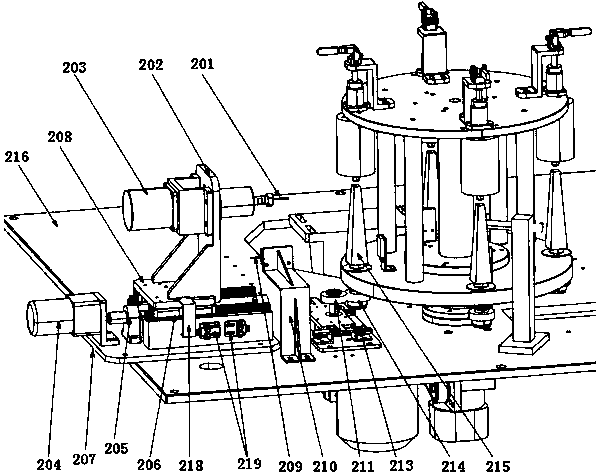

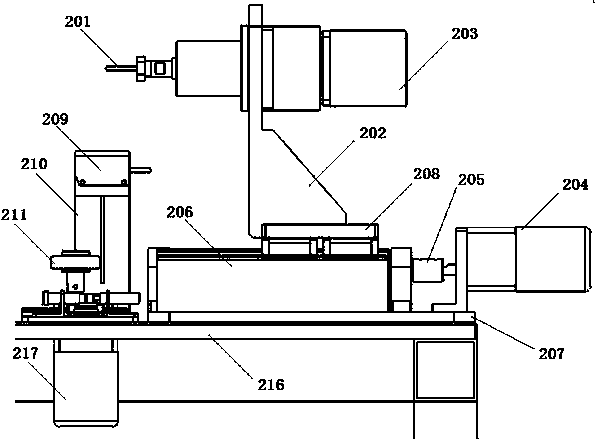

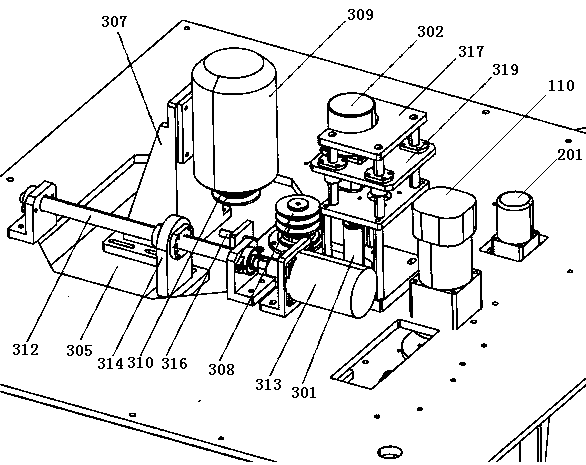

Drilling mechanism for automatic processing machine for erhu tuning pegs

ActiveCN106424821AImprove efficiencyReduce labor intensityPrecision positioning equipmentFeeding apparatusAutomatic controlAutomatic processing

The invention discloses a drilling mechanism for an automatic processing machine for erhu tuning pegs. The mechanism comprises friction wheel equipment, drilling equipment and detection equipment; the friction wheel equipment comprises a friction wheel driving motor and a driving friction wheel; the drilling equipment comprises a drilling equipment mounting plate, two linear guide rails, a screw nut and a drilling equipment feeding motor are arranged on the drilling equipment mounting plate, the drilling equipment feeding motor can drive the screw nut to drive a support mounting seat to move on the two linear guide rails, and a bit driving motor provided with a bit is arranged on the support mounting seat through a bit driving motor support; and the detection equipment comprises a photoelectric reflection sensor fixed through a sensor support. With the mechanism, tuning peg blanks can be drilled automatically, manual operation is not required, and the labor intensity is low; angles of the tuning peg blanks can be detected and adjusted automatically, tuning peg planes are perpendicular to the bit, and the bit is prevented from being damaged; and the drilling depth can be controlled automatically, drilling actions are reliable, positions are accurate, and the precision is high.

Owner:SUZHOU INST OF INDAL TECH

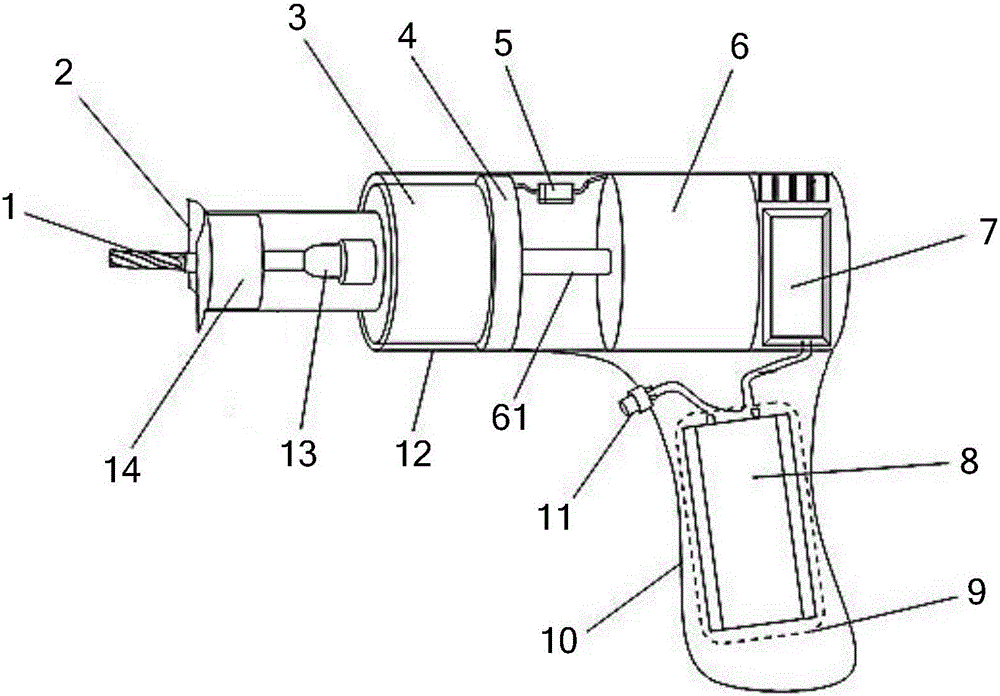

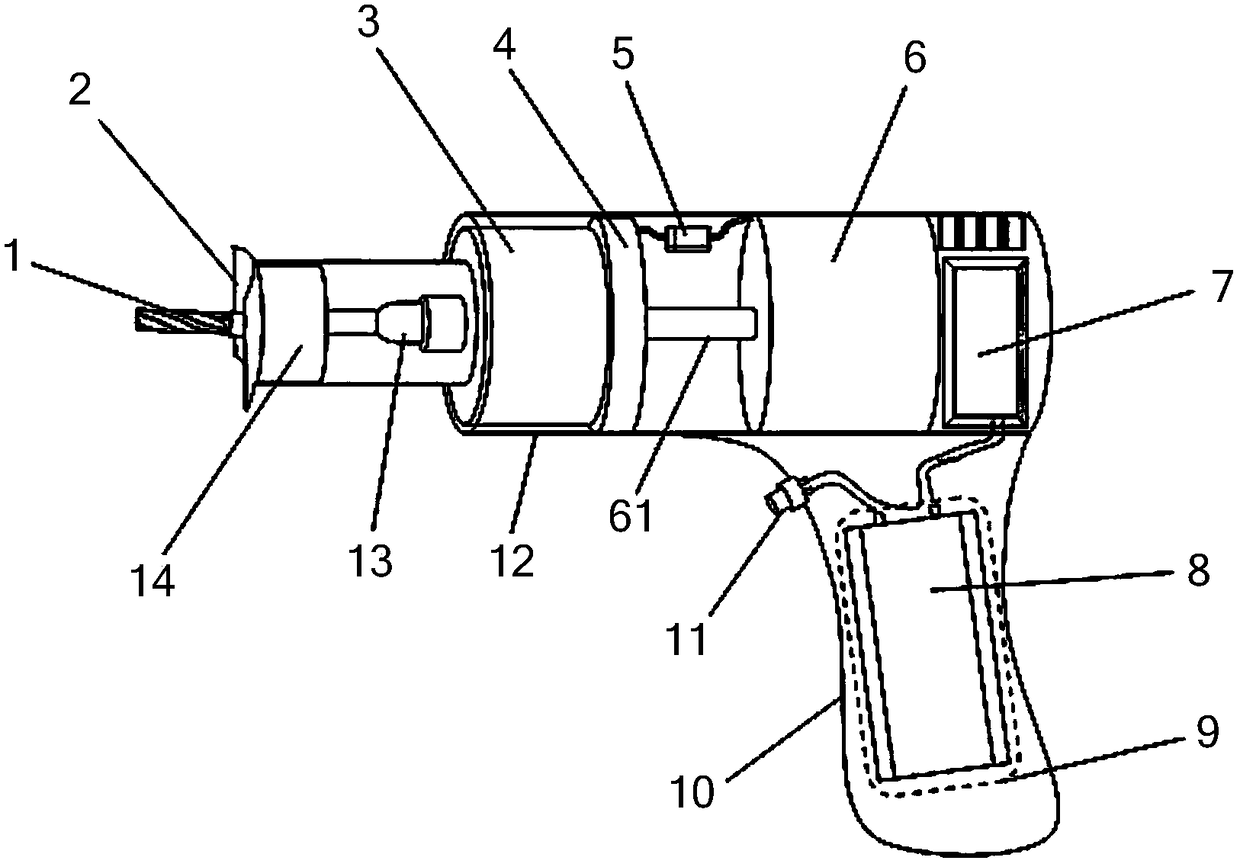

Electric drill with dustproof function

InactiveCN111570865AAvoid pollutionAvoid damagePortable power-driven toolsPortable drilling machinesElectric machineSpray nozzle

The invention relates to an electric drill with a dustproof function. The electric drill comprises a main body, a grip, a motor and a drill rod, and further comprises a dustproof mechanism and a control mechanism, wherein the dustproof mechanism comprises a baffle plate, a water tank, a connecting rod, a fixed box, a movable plate, a first spring, a communicating pipe, two second springs, two pushrods, two power assemblies and two dustproof assemblies; each dustproof assembly comprises a spray nozzle and a connecting pipe; the control mechanism comprises a control box, an air pressure sensorand two connecting assemblies; and each connecting assembly comprises an air rod, a piston, an air cylinder and an air pipe. According to the electric drill with the dustproof function, water can be sprayed during drilling through the dustproof mechanism, so that the dust falling function is realized, dust is prevented from scattering to pollute the surrounding air environment, and the practicability is higher; and the drilling depth can be controlled through the control mechanism, so that the drilling precision is improved.

Owner:南京捷达威机电科技有限公司

Blank wax stone drilling machine for tissue chip

PendingCN110614673AAccurately control the punching positionEasy to movePreparing sample for investigationMetal working apparatusWaxEngineering

The invention provides a blank wax stone drilling machine for a tissue chip. The drilling machine includes a base, a bracket, a horizontal movement mechanism, a vertical movement mechanism, a drillingmechanism and a wax stone fixing seat. The bracket is connected with the base; the horizontal movement mechanism comprises two horizontal movement components which are mutually vertically connected,namely, the X-axis movement component and the Y-axis movement component; scales and / or grating rulers are arranged on the horizontal movement components, one horizontal movement component is connectedwith the base, and the other horizontal movement component is connected with the wax block fixing seat; the vertical movement mechanism includes a Z-axis movement component and a Z-axis limiting component, the Z-axis movement component is connected with the bracket and the drilling mechanism respectively, and the Z-axis limiting component is arranged on the Z-axis movement component for limitingthe maximum displacement of the Z-axis movement component. The drilling mechanism includes a drill bit, a first transmission device and a first motor, wherein the first motor is connected with the drill bit through the first transmission device.

Owner:北京龙迈达斯科技开发有限公司

Punching device automatically controlled by PLC

InactiveCN112453465AControl punch depthPunching quality is stableDrilling/boring measurement devicesPositioning apparatusElectric machineryDrill bit

The invention discloses a punching device automatically controlled by a PLC. The punching device comprises a workbench, supporting columns are fixedly arranged below the four corners of the workbench,a supporting plate is fixedly arranged on one side of the workbench, a top plate is fixedly arranged on the inner wall of the upper end of the supporting plate, a hydraulic cylinder is fixedly arranged on the top plate, a piston rod of the hydraulic cylinder penetrates through the top plate, a mounting plate is fixedly arranged at the lower end of the piston rod, a motor is fixedly arranged belowthe mounting plate, a drill bit is fixedly arranged below a rotating shaft of the motor, an infrared distance measuring sensor is fixedly embedded in the mounting plate, a limiting device is arrangedon the mounting plate, and a pressure sensor is fixedly embedded in the workbench. The punching device has the beneficial effects that automatic punching operation can be completed through the PLC, the punching depth can be accurately controlled, the punching quality is stable, and the punching efficiency is high.

Owner:XIAN LANXIN IND AUTOMATION ENG CO LTD

Timber side hole punching machine

InactiveCN112606112AQuickly adjust the punching positionControl punch depthStationary drilling machinesBark-zones/chip/dust/waste removalPunchingElectric machinery

The invention relates to the technical field of punching equipment, in particular to a timber side hole punching machine which facilitates rapid adjustment of the front and rear punching positions of timber, meanwhile facilitates control cover the punching depth of the timber, replaces manual timber punching, saves time and labor and improves the punching speed of the timber. The timber side hole punching machine comprises a supporting box, multiple sets of fixing blocks, two sets of first lead screw shafts, two sets of first sliding blocks, a first motor, two sets of first belt wheels, a first belt, two sets of mounting plates, multiple sets of C-shaped sliding blocks, multiple sets of sliding rails, multiple sets of electric push rods, two sets of T-shaped sliding blocks, two sets of second motors, multiple sets of connecting blocks, multiple sets of connecting bolts and two sets of drill bits; and the multiple sets of fixing blocks are symmetrically fixed to the left side and the right side of the top end of the supporting box with two sets as a unit, the first lead screw shafts are rotationally connected with the fixing blocks, the output end of the first motor is connected with the rear end of the first lead screw shaft located at the left side of the supporting box, and the first motor is fixed to the supporting box.

Owner:山东珍木园家居有限公司

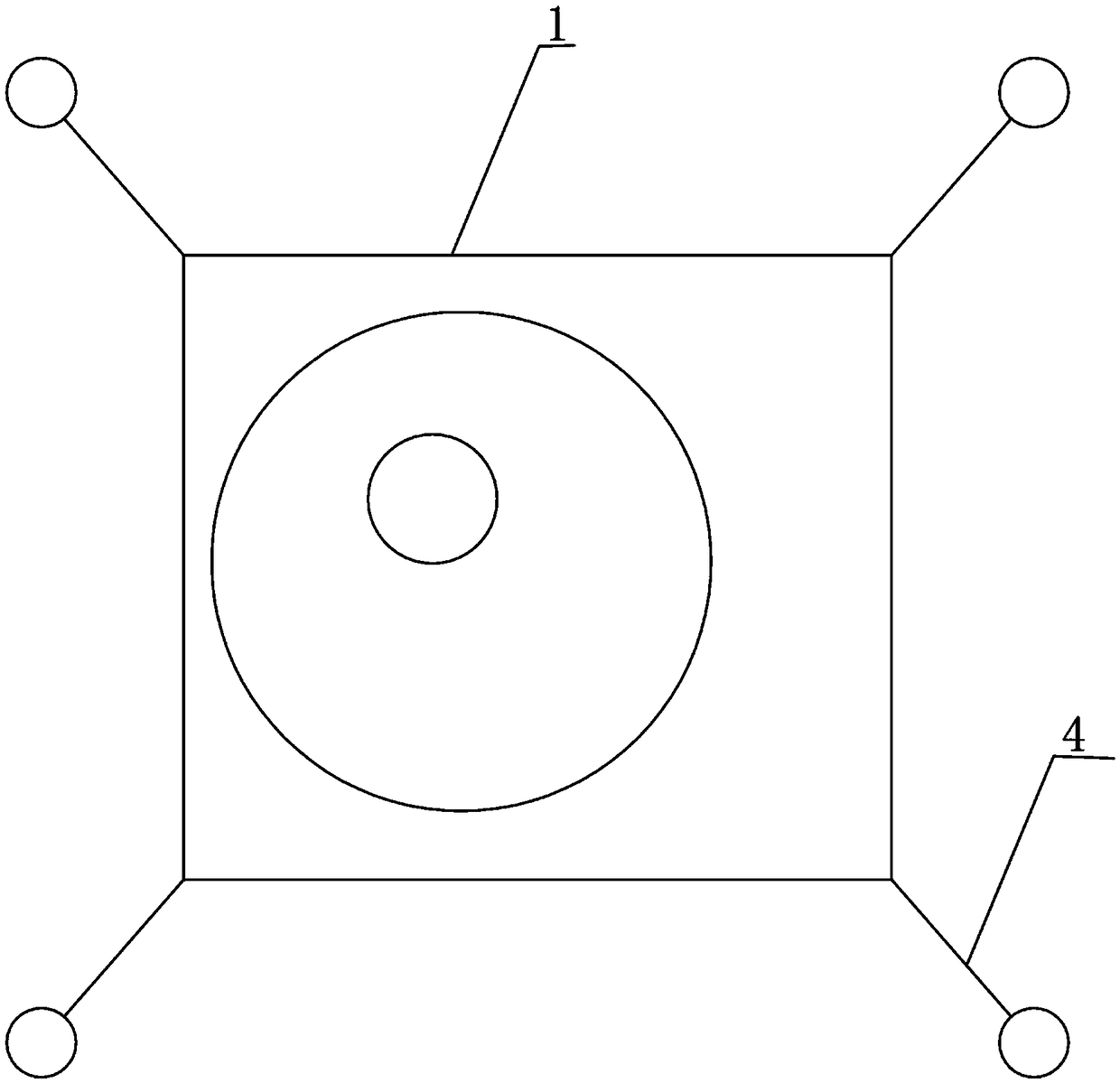

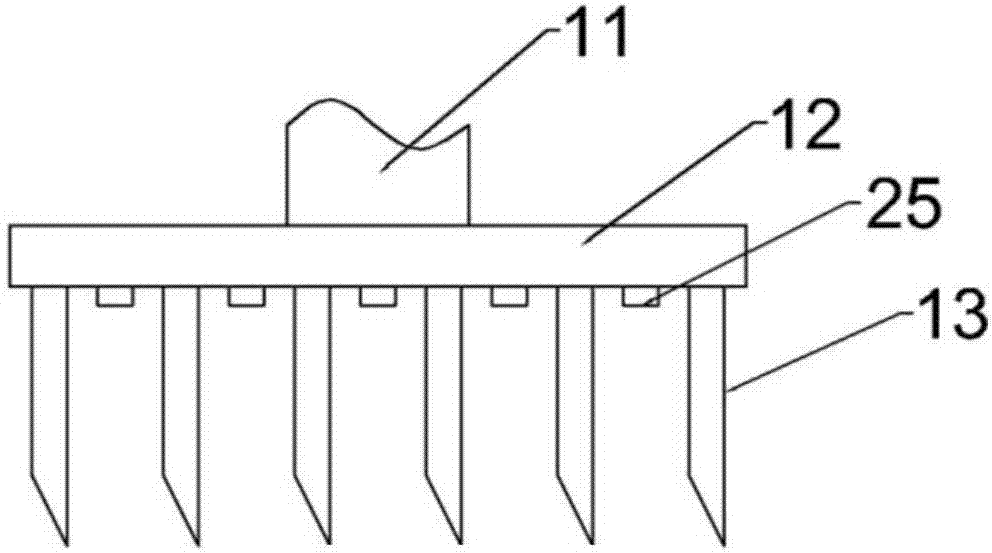

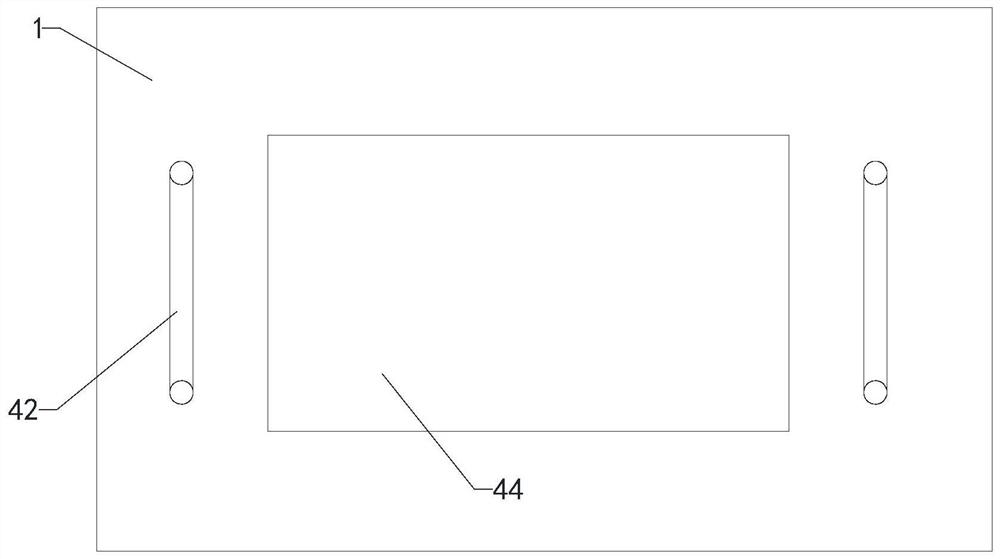

Punching device for tea planting

InactiveCN112075165AAchieve precise positioningNo deviationPlantingFurrow making/coveringPunchingSpiral blade

The invention discloses a punching device for tea planting. The punching device comprises a supporting assembly and a punching assembly; the supporting assembly comprises a top plate, a left L-shapedsupporting plate and a right L-shaped supporting plate, the left L-shaped supporting plate and the right L-shaped supporting plate are arranged on the two sides of the top plate correspondingly, and athrough hole is formed in the center of the top plate; and the punching assembly comprises a mounting plate, a servo motor, a rotating shaft, a spiral blade and a lifting control assembly. The punching device for tea planting is novel in structural design and convenient to operate, tea planting ground can be rapidly punched, the punching depth can be controlled, the punching stability is good, and the punching efficiency is improved.

Owner:湖南瑶园生态农业科技发展有限公司

A rubber picking method, a rubber picking processor, a rubber picking needle drill, and a glue collecting system

The invention discloses a latex exploration method, a latex exploration processor, a latex exploration pin drill and a latex collecting system. The latex exploration pin drill comprises a shell, a pin drill, a rotating motor, a propulsion motor, a current sensor, a thickness information read-write device and the latex exploration processor, wherein the rotating motor drives the pin drill to rotate, the propulsion motor drives the pin drill to move front and back, the current sensor is used for detecting the current value of the rotating motor, and the thickness information read-write device is used for reading judgment information in corresponding thickness information storage devices on all rubber trees. When no thickness information exists in the thickness information read-write device, the current sensor detects different current signals of the rotating motor to obtain the thickness information of the rubber trees, when thickness information exists in the thickness information read-write device, the thickness information is converted into pulse signals of the propulsion motor, propulsion depth of the propulsion motor is controlled according to the pulse signals to protect a cambium against damage, it is easier to rotationally drill into the rubber tree bark without extruding a latex pipe, and large latex discharge amount is ensured.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

A kind of bone tap with anti-slip wire and using method thereof

The invention belongs to the technical field of bone taps, in particular to a bone tap with anti-slip wires, including a tap, a bone drill rod and an anti-slip positioning assembly. Anti-slip tapping threads are provided, and the top end of the tap and the bottom end of the bone drill rod are provided with installation components. The installation components include installation grooves, connecting screw holes, auxiliary gaskets, installation blocks, through screw holes, stud bolts and auxiliary nuts. The anti-slip positioning assembly includes positioning bars, telescopic plates, piston plates, adjustment buttons, positioning chute, positioning sliders, positioning scales, scale indicator strips, positioning holes and electromagnet plates, and depth control components are arranged on the side wall of the tap. The depth control assembly includes a vertical chute, a vertical slider, an electromagnet rod, a limit ring, an indicator scale, a transition ring groove, a spring and a transition ring.

Owner:东莞市金名医疗器械有限公司

A rubber picking method, a rubber picking controller, a rubber picking drilling rig, and a glue collecting system

ActiveCN106034977BAvoid breakingNot hurtForestryMaterial dimension controlMotor driveCollection system

The invention discloses a latex exploration method, a latex exploration controller, a latex exploration drilling machine, and a latex collection system. The latex exploration drilling machine comprises a motor case, a needle drill, a rotating motor, a push motor, thickness information obtaining devices, and the latex exploration controller. The rotating motor drives the needle drill to rotate, and the push motor drives the needle drill to move back and forth. The thickness information obtaining devices are respectively used for reading the thickness information stored in the thickness information obtaining device corresponding to each rubber tree, converting the thickness information into a pulse signal of the push motor, and controlling the push depth of the push motor according to the pulse signal, thereby protecting a forming layer from being damaged. Moreover, the latex exploration drilling machine is easier to drill into the skin of the rubber tree in a rotating manner, reduces the compression on a latex tube, and guarantees the discharging of a larger volume of latex.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Handheld hole puncher for chick embryo eggshell

The invention discloses a handheld hole puncher for a chick embryo eggshell. The hole puncher comprises a bottom plate, an egg, a fixing assembly, a punching assembly and a reset assembly, a fixing column is fixedly connected to one side of the upper end face of the bottom plate, a sliding seat is slidably connected to the fixing column, fixing rotary knobs used for fixing the sliding seat are arranged on the two sides of the sliding seat, and a mounting plate is fixedly connected to one side of the sliding seat. Through the arrangement of a placing cylinder and a sealing ring arranged at an upper end opening of the placing cylinder, the egg can be conveniently placed, meanwhile, through a connecting buckle arranged in a drawing pipe, after the egg is placed, a drawing rod and a piston block can be pulled out by drawing a drawing handle, and after being pulled out, the drawing rod is hung and buckled in a groove in the side of a groove plate. A negative pressure state can be formed in a fixing barrel, an adsorption effect on the egg is achieved, the situation that the egg shakes during perforating is effectively avoided, and the arranged sealing ring has a sealing effect and can prevent the egg from being collided during placement.

Owner:JILIN ZHENGYE BIOLOGICAL PROD

Energy-saving and environment-friendly multi-layer steel plate rolling and automatic punching device

InactiveCN112518333ASimple working processControl punch depthOther manufacturing equipments/toolsPunchingGear wheel

The invention relates to the technical field of hardware mechanical equipment, and discloses an energy-saving and environment-friendly multi-layer steel plate rolling and automatic punching device which comprises a box body. Sliding clamping teeth are movably connected to the inner part of the box body, sliding wheels are movably connected to the lower ends of the sliding clamping teeth, and a driving shaft is connected to the inner parts of the sliding wheels in a sleeved mode; the outer portion of the driving shaft is sleeved with a first gear, the lower end of the first gear is connected with a driving gear in a meshing mode, the driving gear sleeves a threaded lead screw, the exterior of the threaded lead screw is sleeved with a threaded sliding block, and the lower end of a supportingrod is movably connected with a lifting device; and a hollow drill bit is movably sleeved with a punching device, a triggering device is movably connected with the inner part of the punching device,and a triggering block is fixedly connected with the outer part of the triggering rod. The energy-saving and environment-friendly multi-layer steel plate rolling and automatic punching device has theadvantages of being simple and convenient to work, capable of achieving automation, capable of achieving automatic punching after completing of rolling, capable of saving energy and environmentally friendly.

Owner:南京星全电子商务有限公司

A rubber picking method, a rubber picking processor and a rubber picking device

The application discloses a latex collecting method, a latex collection processor and a latex collector; the latex collector comprises a casing, a needle drill, a rotation motor, a propulsion motor, a current sensor and a latex collection processor; the rotation motor drives the needle drill to rotate; the propulsion motor drives the needle drill to move back and forth; the current sensor is used for detecting the current value of the rotation motor; the latex collection processor can carry out analog-to-digital conversion according to the current value detected by the current sensor; the converted current value is compared with a set current threshold value, if the converted current value exceeds the set current threshold value, the propulsion motor is controlled to stop or fall back. The rotation motor drives the needle drill to work, and uses different current values for drilling into the bark and xylem; the current threshold value is determined by said current values used by the rotation motor; the needle drill drills into the xylem and stops to propel and drill, thus protecting the cambium layer from being damaged; the needle drill can easily drill into the rubber tree bark, so the latex tube can be less extruded, thus ensuring more latex flow amount.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Synchronous punching mechanism

PendingCN113787569ARealize automatic multi-hole punchingControl thicknessMetal working apparatusCardboardPunching

The invention relates to a synchronous punching mechanism. The mechanism comprises a frame, a paper pressing device erected in the frame and a punching device erected on a back plate in the frame, and the punching device comprises a vertical plate fixed to the back plate and a plurality of direct current motors erected on the vertical plate. Each direct-current motor is connected with a hollow punching shaft located in a paper scrap collecting box through a coupler, paper scrap collecting openings are formed in the inner bottom face, between every two adjacent punching shafts, in the paper scrap collecting box, and each paper scrap collecting opening is connected with a flow guiding device. A bottom bearing of each punching shaft is fixed to a drainage block which is located at one side of the paper scrap collecting opening and guides paper scraps to the paper scrap collecting opening, the bottom end of each punching shaft is connected with a hollow drilling tool, and a plurality of connecting holes which are communicated with the drilling tools through inner cavities of the punching shafts are formed in the outer walls of the punching shafts. The paper pressing device comprises a lifting device and a transverse plate controlled by the lifting device to ascend and descend, and a paper pressing plate is elastically connected to the transverse plate. The invention provides the synchronous punching mechanism capable of realizing high-efficiency punching.

Owner:SUZHOU DEQI INTELLIGENT TECH CO LTD

Bone screw tap with anti-slip threads and using method thereof

The invention belongs to the technical field of bone screw taps, and particularly relates to a bone screw tap with anti-skid threads, which comprises a screw tap, a bone drill connecting rod and an anti-skid positioning assembly, wherein a chip collecting groove is formed in the circumference of the bottom end of the side wall of the screw tap, anti-skid tapping threads are arranged at the edge of the chip collecting groove, and mounting assemblies are arranged at the top end of the screw tap and the bottom end of the bone drill connecting rod. The mounting assembly comprises a mounting groove, a connecting screw hole, an auxiliary gasket, a mounting block, a penetrating screw hole, a stud and an auxiliary nut, the anti-skid positioning assembly comprises a positioning transverse strip, a telescopic plate, a piston plate, an adjusting knob, a positioning sliding groove, a positioning sliding block, positioning scales, a scale indication strip, a positioning hole and an electromagnet plate, and the depth control assembly is arranged on the side wall of the screw tap. The depth control assembly comprises a vertical sliding groove, a vertical sliding block, an electromagnet rod, a limiting ring, indication scales, a transition ring groove, a spring and a transition ring.

Owner:东莞市金名医疗器械有限公司

Street tree punching and fertilizing device capable of preventing tree roots from being damaged

InactiveCN112930769AGuaranteed normal growthAvoid harmPlantingRoot feedersTree rootAgricultural engineering

The invention relates to the technical field of fertilization, in particular to a street tree punching and fertilizing device capable of preventing tree roots from being damaged. The street tree punching and fertilizing device capable of preventing the tree roots from being damaged aims to solve the problem that a street tree root system fertilizer is non-uniformly absorbed or a root system is easily damaged during fertilization. The disclosed street tree punching and fertilizing device capable of preventing the tree roots from being damaged comprises a U-shaped punching and fertilizing machine with three supporting legs; the U-shaped punching and fertilizing machine is internally provided with four driving cavities which are in central symmetry by taking a tree as the center; the driving cavities are internally and rotatably provided with hollow rotating shafts which are through in the vertical direction; an electric push rod which is close to the ground side and communicated with the outside is fixedly installed in each hollow rotating shaft; and an electric push block is slidably arranged in each electric push rod.

Owner:深圳市创志品实业有限公司

A drilling mechanism for automatic processing machine of erhu pegs

ActiveCN106424821BImprove efficiencyNo action requiredPrecision positioning equipmentFeeding apparatusAutomatic controlDrive motor

The invention discloses a drilling mechanism for an automatic processing machine for erhu tuning pegs. The mechanism comprises friction wheel equipment, drilling equipment and detection equipment; the friction wheel equipment comprises a friction wheel driving motor and a driving friction wheel; the drilling equipment comprises a drilling equipment mounting plate, two linear guide rails, a screw nut and a drilling equipment feeding motor are arranged on the drilling equipment mounting plate, the drilling equipment feeding motor can drive the screw nut to drive a support mounting seat to move on the two linear guide rails, and a bit driving motor provided with a bit is arranged on the support mounting seat through a bit driving motor support; and the detection equipment comprises a photoelectric reflection sensor fixed through a sensor support. With the mechanism, tuning peg blanks can be drilled automatically, manual operation is not required, and the labor intensity is low; angles of the tuning peg blanks can be detected and adjusted automatically, tuning peg planes are perpendicular to the bit, and the bit is prevented from being damaged; and the drilling depth can be controlled automatically, drilling actions are reliable, positions are accurate, and the precision is high.

Owner:SUZHOU INST OF INDAL TECH

An automatic processing machine for erhu pegs

ActiveCN106624815BErgonomicHigh strengthPrecision positioning equipmentOther manufacturing equipments/toolsAutomatic controlEngineering

Owner:SUZHOU INST OF INDAL TECH

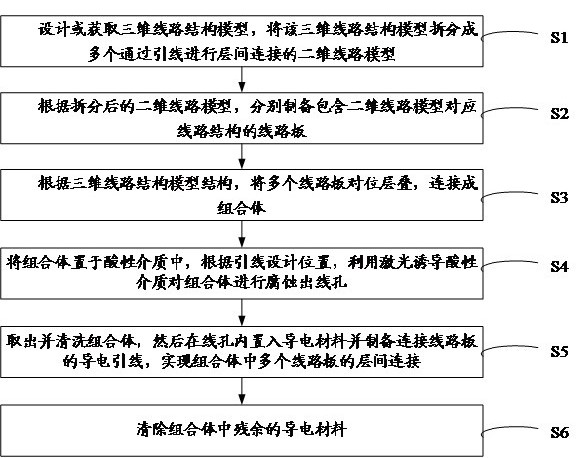

Method for forming three-dimensional structure of multi-layer conductive sheet

ActiveCN113347811AEasy to manufactureGentle formationAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringCircuit models

The invention provides a method for forming a three-dimensional structure of a multi-layer conductive sheet. The method comprises the following steps of: designing or acquiring a three-dimensional circuit structure model, and splitting the three-dimensional circuit structure model into a plurality of two-dimensional circuit models which are in interlayer connection through leads; according to the split two-dimensional circuit models, respectively preparing circuit boards comprising circuit structures corresponding to the two-dimensional circuit models; according to the structure of the three-dimensional circuit structure model, aligning and stacking the plurality of circuit boards so as to connect the circuit boards into a combined body; and placing the combined body in an acid medium, and conducting wire outgoing hole corrosion on the combined body through the acid medium induced by laser according to lead design positions. According to the forming method, the preparation process of the conductive sheet of the three-dimensional structure is effectively simplified, meanwhile, wire holes are obtained through corrosion of the acid medium induced by the laser. Compared with a traditional laser drilling mode, the wire hole forming process is milder and can effectively control the drilling depth, the focusing temperature requirement is far lower than the laser drilling temperature requirement, and the equipment threshold is effectively lowered.

Owner:JIHUA LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com