Bone screw tap with anti-slip threads and using method thereof

A technology of anti-slip wire and tap, which is applied in bone drill guidance, medical science, surgery, etc. It can solve the problems of useless drilling, affecting the installation of medical components, and accurate control of the depth of tap rotation, so as to facilitate control and avoid rotational friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

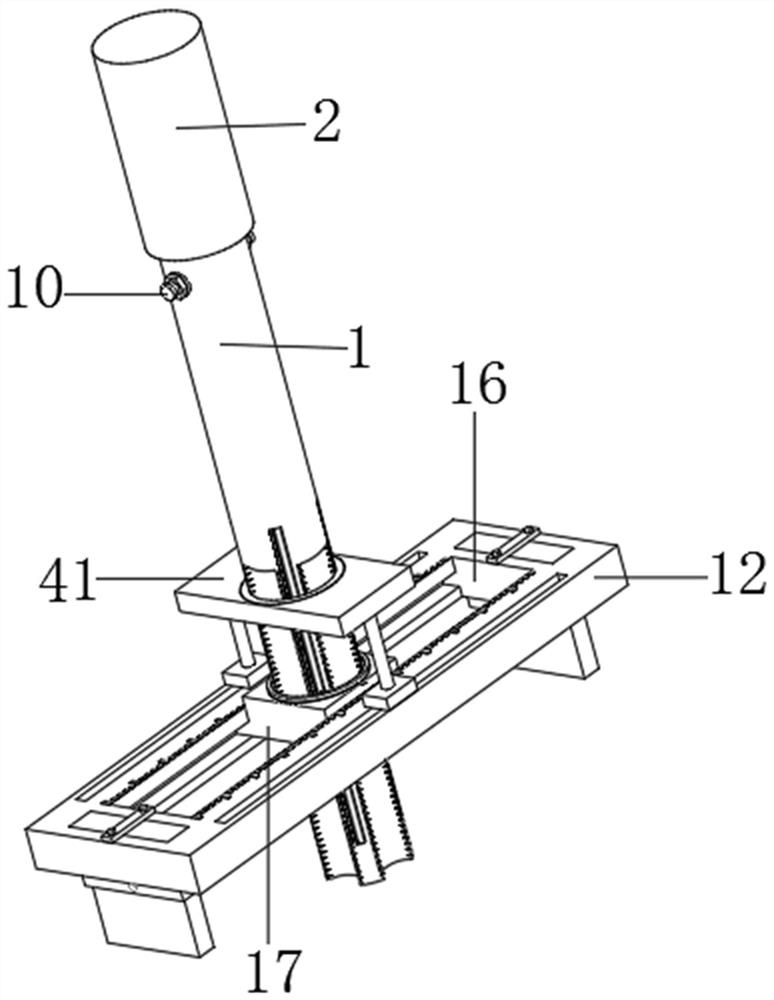

[0041] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides the following technical solutions:

[0042] Such as figure 1 and figure 2 As shown, a bone tap with an anti-slip wire includes a tap 1, a bone drill rod 2 and an anti-slip positioning assembly. tapping thread 4,

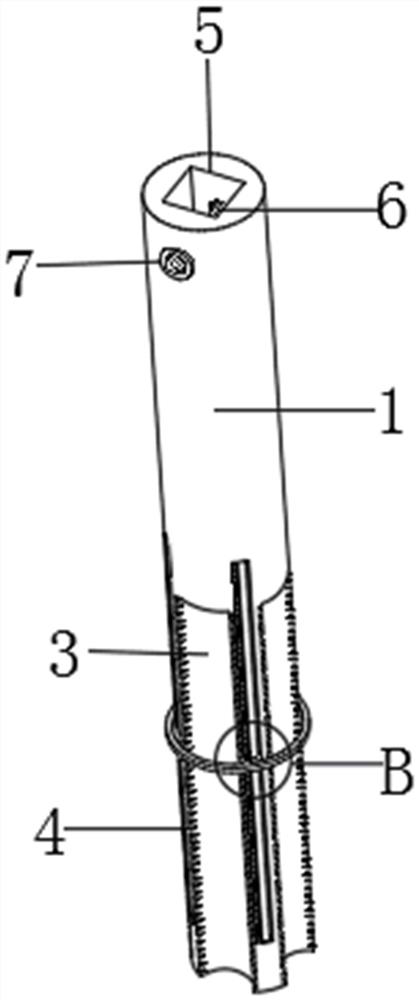

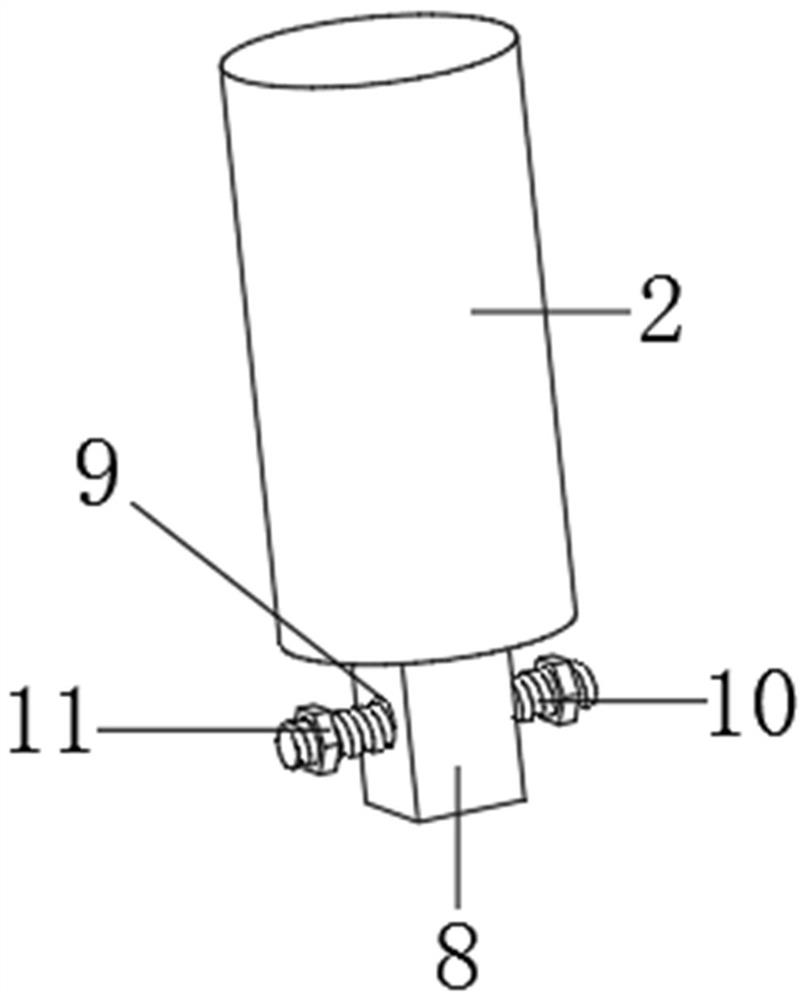

[0043] Such as figure 2 and image 3 As shown, the top end of the tap 1 and the bottom end of the bone drill rod 2 are provided with a mounting assembly, the mounting assembly includes a mounting groove 5, a connecting screw hole 6, an auxiliary gasket 7, a mounting block 8, a through screw hole 9, and a stud bolt 10 and auxiliary nut 11,

[0044] Specifically, the installation groove 5 is set at the center of the top of the tap 1, the connecting screw hole 6 is arranged at the center of the two opposite inner walls of the installation groove 5 and runs through the tap 1, and the auxiliary gasket 7 is fixed on the side wall of the tap 1 at the end...

Embodiment 2

[0053] On the basis of Example 1, refer to Figure 7 , Figure 8 and Figure 9 As shown, a bone tap with non-slip wire:

[0054] A depth control assembly is arranged on the side wall of the screw tap 1, and the depth control assembly includes a vertical chute 27, a vertical slider 28, an electromagnet rod 29, a limit ring 30, an indicator scale 31, a transition ring groove 32, a spring 33 and a transition ring 34 ,

[0055] Specifically, the vertical chute 27 is arranged on the side wall of the tap 1, the vertical slider 28 slides in the vertical chute 27, the electromagnet rod 29 is fixed between the two ends of the vertical chute 27, and the electromagnet rod 29 moves through the vertical slider 28. , the limit ring 30 is fixed on the side of the vertical slider 28, the indicating scale 31 is arranged on the edge of the vertical chute 27, the transition ring groove 32 is opened in the center of the top end of the positioning slider 17, the spring 33 is fixed in the center...

Embodiment 3

[0061] On the basis of Example 2, refer to Figure 5 , Figure 6 and Figure 10 As shown, a bone tap with anti-slip wire: connecting grooves 22 are symmetrically opened on both sides of the center of the top of the positioning bar 12, the expansion plate 13 is installed in the connecting groove 22, and the top of the positioning bar 12 is symmetrical with the connecting groove 22 Two sets of positioning screw holes 23 are symmetrically arranged, and a positioning plate 24 is fixed at the center of the top of the telescopic plate 13. The positioning plate 24 is provided with a matching screw hole 25 that cooperates with the positioning screw hole 23, and the internal thread of the matching screw hole 25 and the positioning screw hole 23 Positioning screws 26 are connected, and auxiliary positioning components are also arranged on the positioning bar 12. The auxiliary positioning components include auxiliary chute 35, auxiliary slider 36, connecting block 37, connecting hole 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com