Tunnel drilling device capable of controlling drilling depth and method of use

A drilling device and depth technology, applied in the direction of drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of control, inconvenient drilling accuracy, etc., and achieve the effect of easy and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

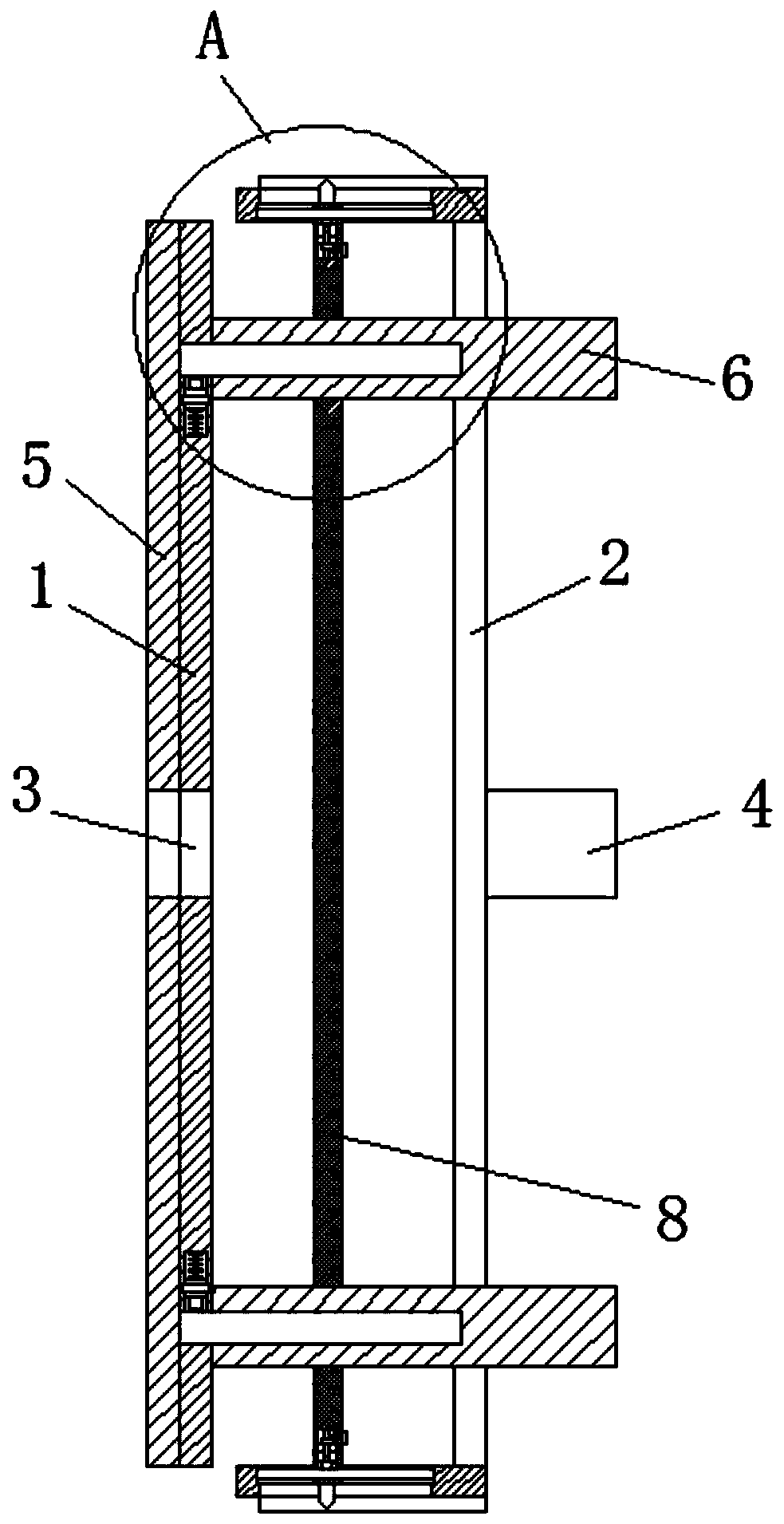

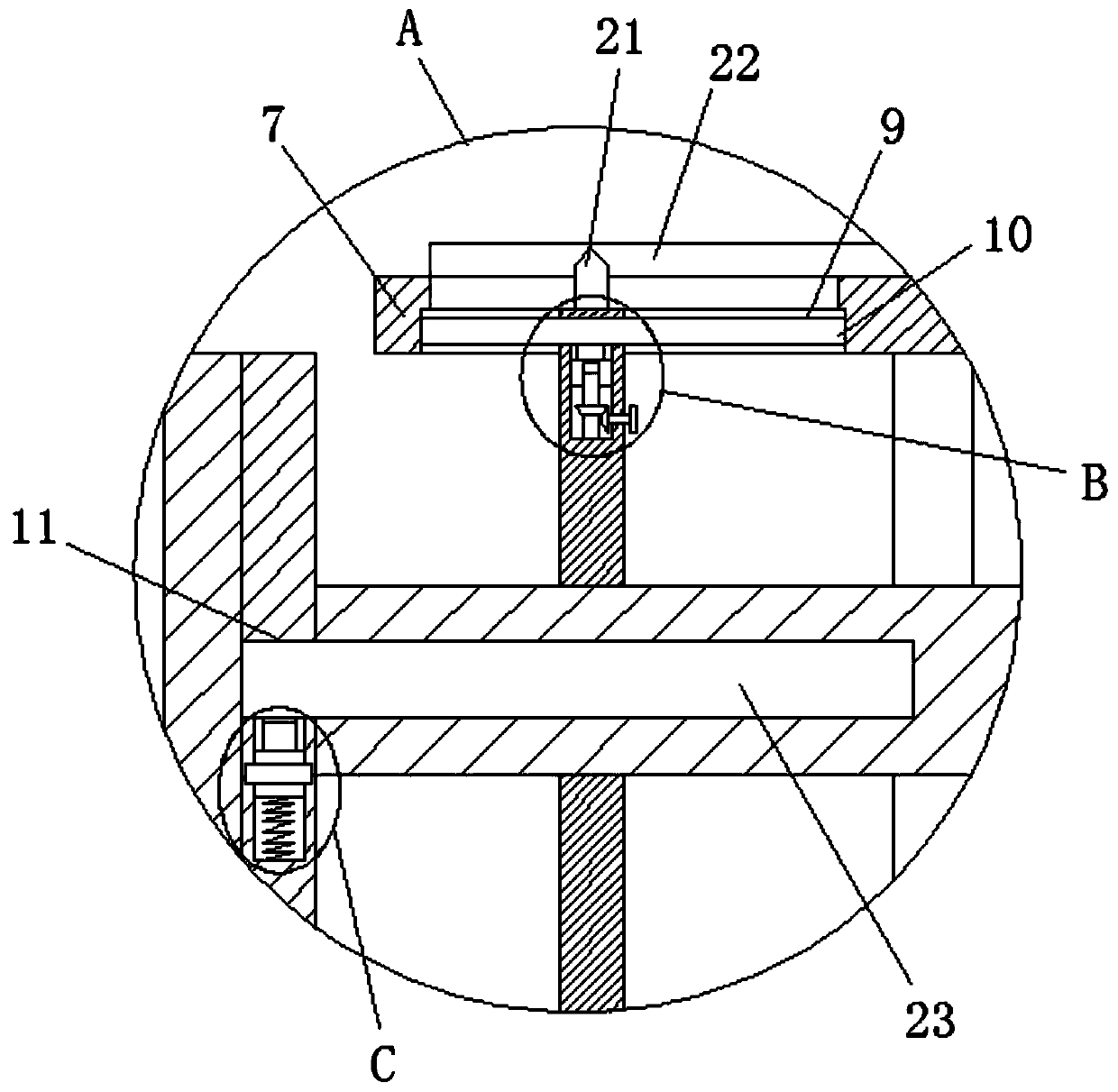

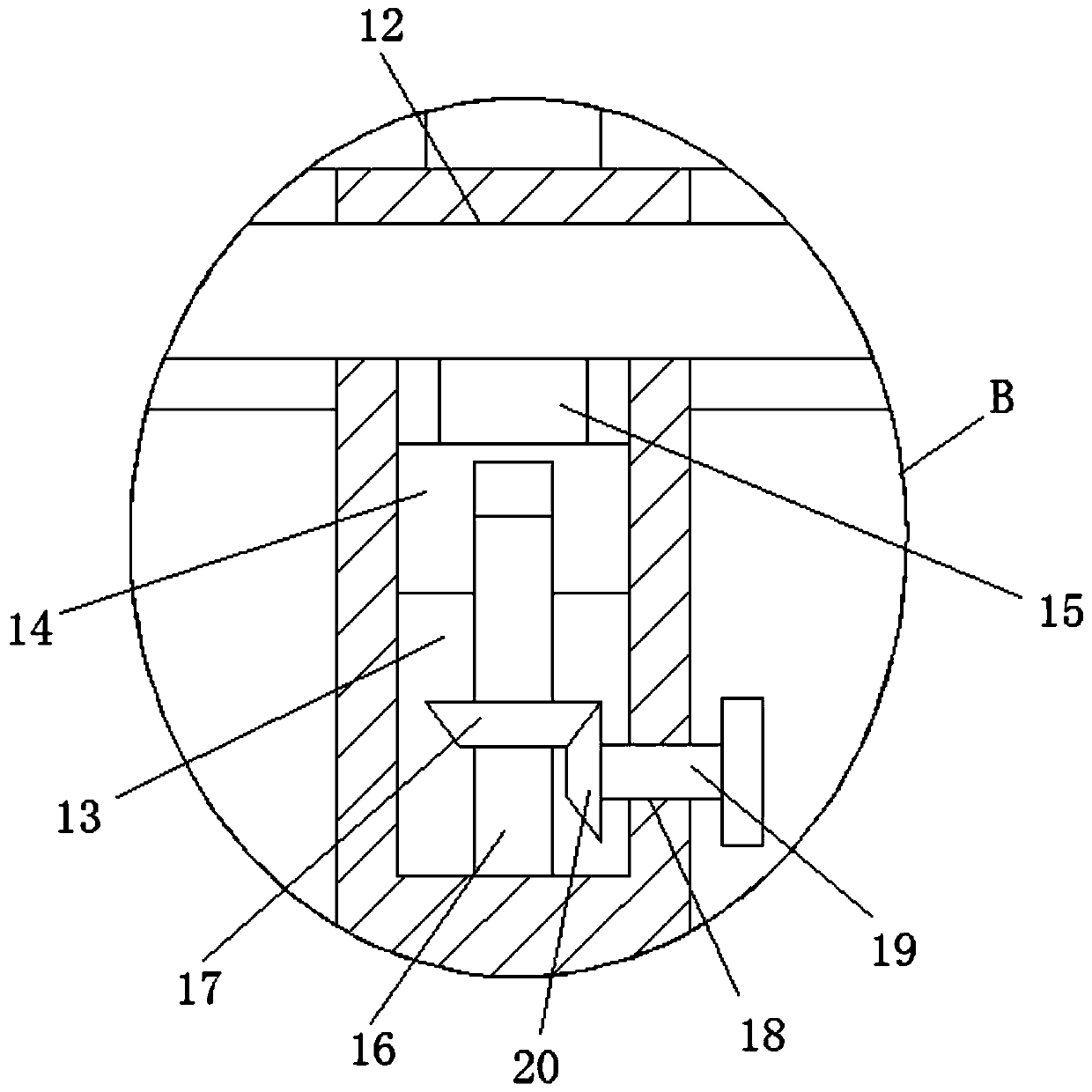

[0034] see Figure 1-Figure 8 , the present invention provides a technical solution:

[0035] A tunnel drilling device capable of controlling the drilling depth, comprising: a first plate 1 and a second plate 2 located on one side of the first plate 1, and one side of the first plate 1 is fixedly installed with three detection rods distributed in a triangular shape 6. The side of the second plate 2 far away from the first plate 1 is fixedly installed with three fixed rods 4 distributed in a triangle. The first plate 1 is provided with three first fixing holes 3, and the three first fixing holes 3 are connected with three The fixed rods 4 are set in one-to-one correspondence, the top and bottom of the second plate 2 are welded with side plates 7, the sides of the two side plates 7 close to each other are provided with chute 9, and the sides of the two chute 9 away from each other The same first baffle plate 8 is slidably installed on the inner wall, and three third fixing hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com