Punching device automatically controlled by PLC

A technology of punching device and mounting plate, applied in positioning devices, manufacturing tools, boring/drilling and other directions, can solve the problem of difficulty in controlling the stability of punching quality, poor depth accuracy of punching, and low efficiency of manual punching and other problems, to achieve the effect of stable punching quality, increased quality and high punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

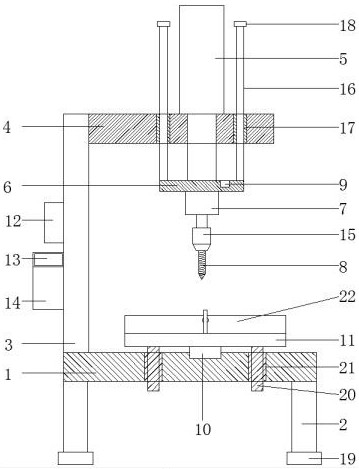

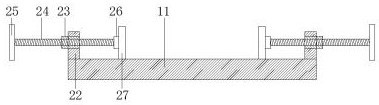

[0026] Example 1 see Figure 1-2 , according to a PLC automatic control punching device according to an embodiment of the present invention, comprising a workbench 1, support columns 2 are fixed under the four corners of the workbench 1, and a support plate 3 is fixedly arranged on one side of the workbench 1 , the inner wall of the upper end of the support plate 3 is fixed with a top plate 4, the top plate 4 is fixed with a hydraulic cylinder 5, the piston rod of the hydraulic cylinder 5 runs through the top plate 4 and the lower end is fixed with a mounting plate 6, and a motor 7 is fixed under the mounting plate 6, A drill bit 8 is fixed under the rotating shaft of the motor 7, an infrared distance measuring sensor 9 is fixedly embedded on the mounting plate 6, a limit device is provided on the mounting plate 6, a pressure sensor 10 is fixedly embedded on the workbench 1, and a pressure sensor 10 is fixedly embedded on the mounting plate 6. A bearing plate 11 is fixedly pro...

Embodiment 2

[0028] Embodiment 2 is on the basis of embodiment 1 such as figure 1 As shown, for the motor 7, the lower end of the rotating shaft of the motor 7 is fixedly equipped with a drill chuck 15, and a drill bit 8 is installed under the drill chuck 15, and the drill chuck 15 can facilitate the dismounting and installation of the drill bit 8.

Embodiment 3

[0029] Embodiment 3 is shown in Figure 1 on the basis of Embodiment 1. For the limiting device, the limiting device includes a first sliding rod 16 and a first sliding cylinder 17, and all four corners of the mounting plate 6 are fixedly installed. There are first sliding rods 16, and the top plate 4 is fixedly embedded with four first sliding cylinders 17 that match the first sliding rods 16. The first sliding cylinders 17 are respectively slidably sleeved on the corresponding first sliding rods. 16, the outer wall can make use of the limiting effect of the first sliding rod 16 and the first sliding cylinder 17 to make the mounting plate 6 move straight up and down, thereby further increasing the quality of drilling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com