A rubber picking method, a rubber picking processor, a rubber picking needle drill, and a glue collecting system

A processor and rubber picking technology, which is applied in control/adjustment systems, instruments, and measurement using digital measurement technology, etc., can solve the problems of large trauma to rubber trees, reduced rubber discharge, easy bending or breaking of rubber picking needles, etc. The effect of multiple rows of glue, reduced extrusion, and simple and convenient punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

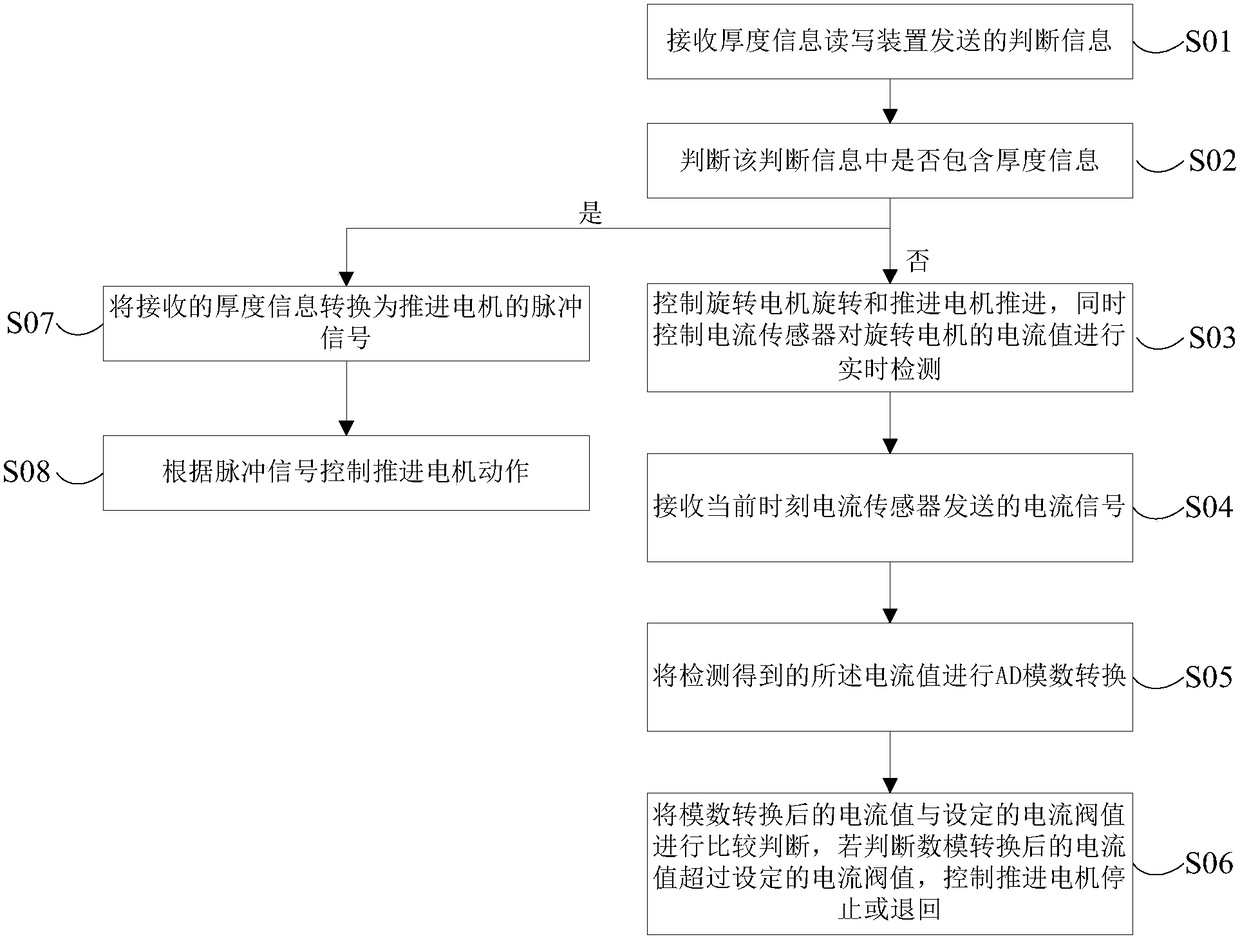

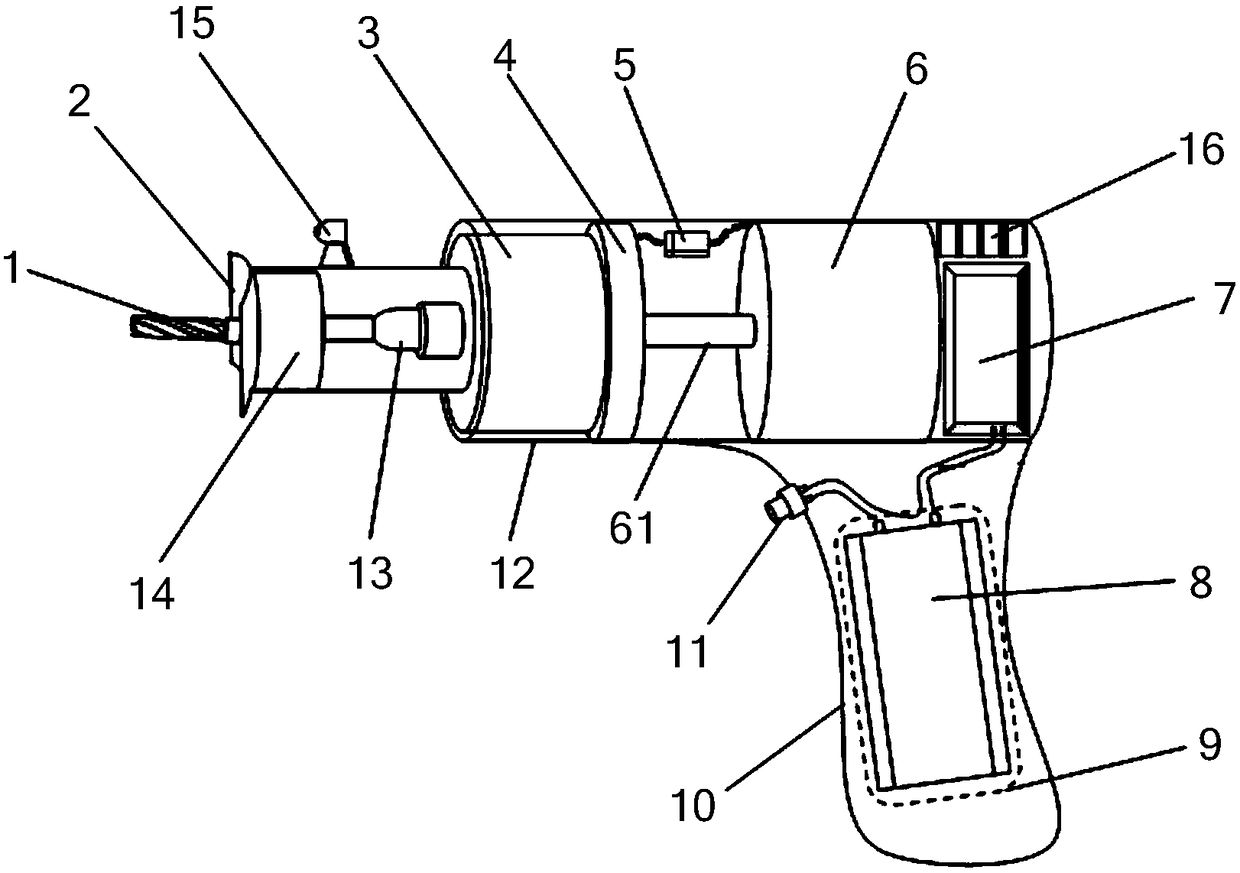

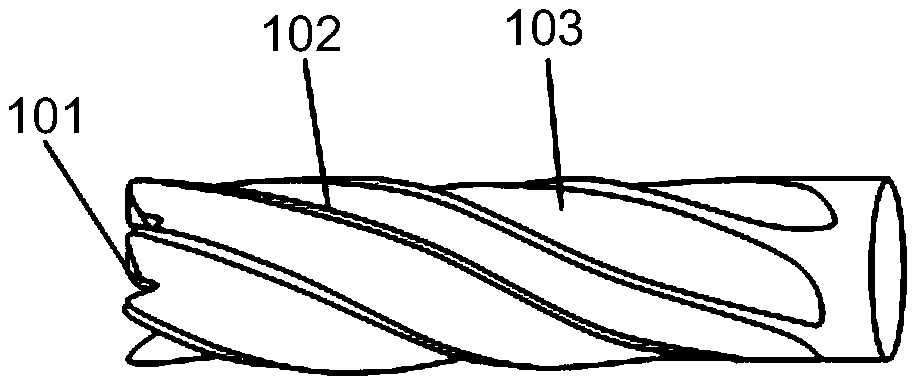

[0060] The core of the present invention is to provide a rubber mining method, which can obtain as much latex as possible while reducing the difficulty of rubber mining technology, reducing labor intensity, and protecting the gum tree cambium from damage.

[0061] The invention also provides a rubber harvesting processor based on the rubber harvesting method, which can control the thickness of the harvested rubber and protect the gum tree cambium from damage.

[0062] The present invention also provides a rubber-harvesting needle drill comprising the rubber-harvesting processor, which can reduce the technical difficulty of rubber harvesting, reduce labor intensity, and protect the gum tree cambium from damage.

[0063] The invention also provides a rubber collection system using the rubber mining method, which protects the gum tree cambium from damage.

[0064] The following will clearly and completely describe the technical solutions in the embodiments of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com