Depth-controllable rock sample drilling device and utilization method

A technology for rock test pieces and drilling devices, which is applied in the direction of working accessories, stone processing tools, stone processing equipment, etc., can solve problems such as drill sticking, surface damage of holes and test pieces, and deviations in test results, so as to improve work efficiency. Efficiency, reliable measurement, and the effect of overcoming stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

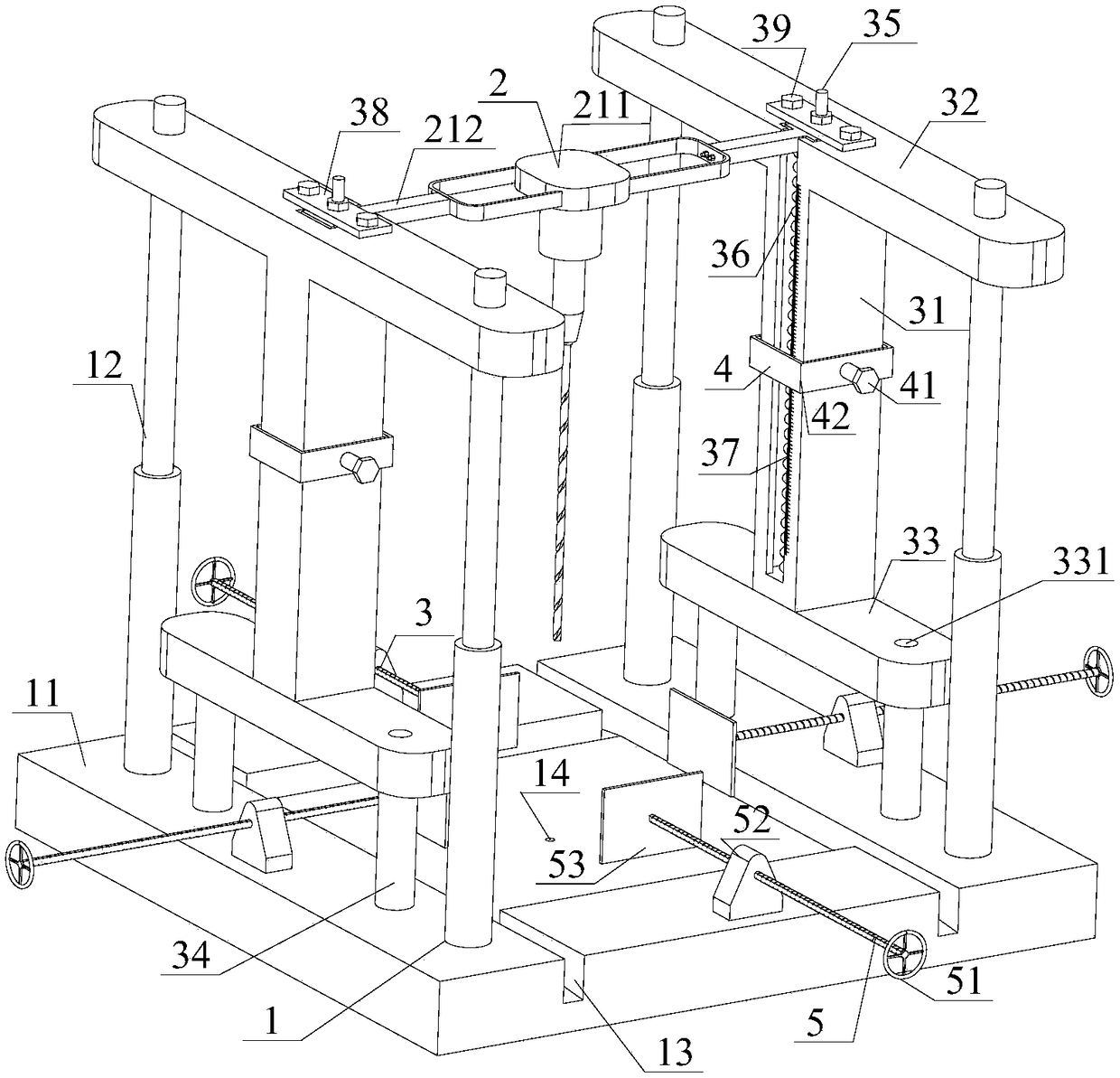

[0028] Such as Figure 1 to Figure 5 As shown, this embodiment is a specific description of the structure of the depth-controllable rock specimen drilling device.

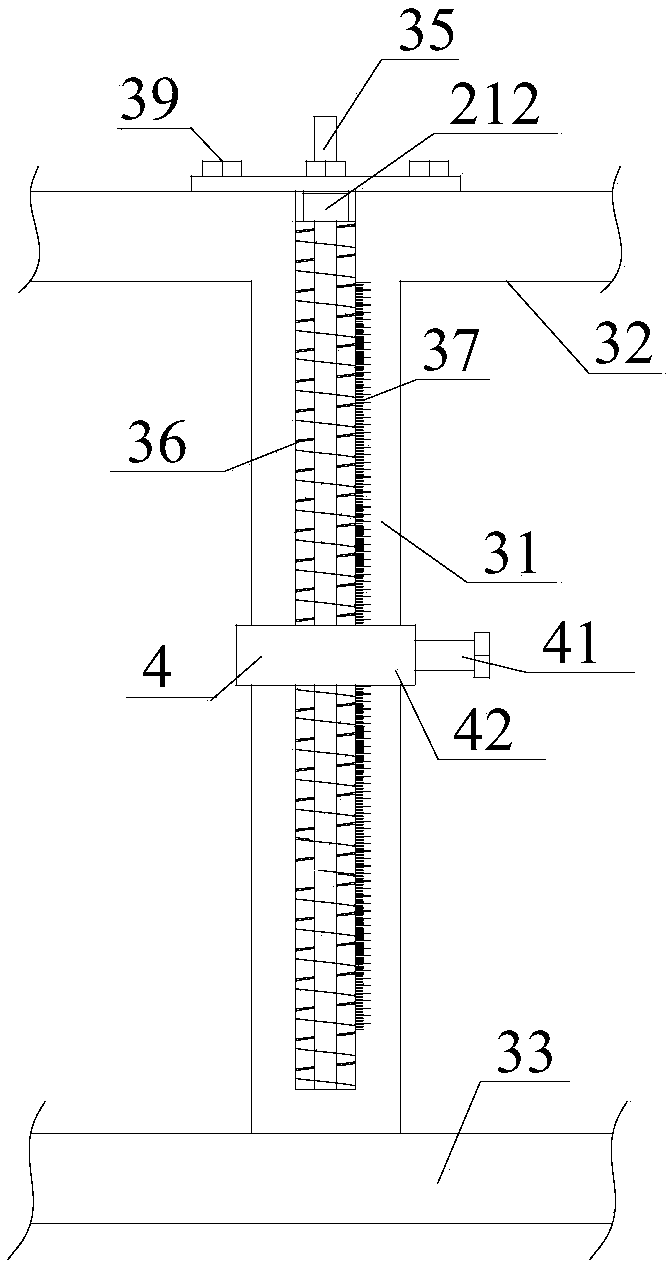

[0029] A depth-controllable drilling device for a rock test piece specifically includes a vertical frame 1 , a drilling mechanism 2 , an I-shaped slideway mechanism 3 , a caliper mechanism 4 and a displacement mechanism 5 . Wherein the I-shaped slideway mechanism 3 is fixed on both sides of the vertical frame 1, the drilling mechanism 2 moves up and down along the slideway 31 of the I-shaped slideway mechanism through the connecting handle 212, and the displacement mechanism 5 is fixed on the bottom of the vertical frame 1 , the caliper mechanism 4 moves along the slideway outside the slideway 31.

[0030] Wherein, the drilling mechanism 2 specifically includes a drilling machine driving unit 21, a drilling machine 211 and a connecting handle 212, and the drilling mechanism is connected with the I-shaped slideway ...

Embodiment 2

[0036] Such as Figure 6 and Figure 7 As shown, this embodiment is a specific description of the method of using the depth-controllable rock specimen drilling device in embodiment 1.

[0037] The drilling method using a depth-controllable rock test piece drilling device, the specific steps include:

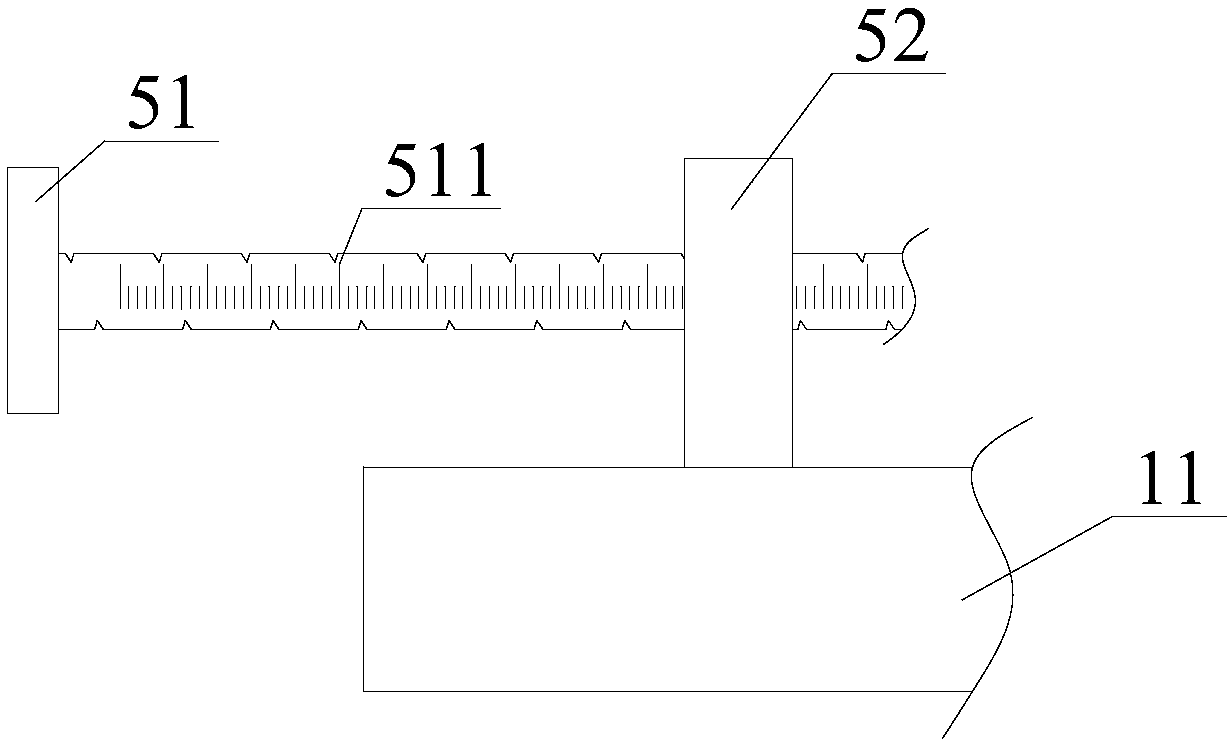

[0038] The first step is to fix the specimen, and select a plane splint or an arc splint according to the shape of the specimen 6: if it is a square specimen, fix the plane splint on the push rod; It is fixed on the push rod 51; after the splint 53 is fixed, the test piece is fixed by the push rod 51 and the splint 53; the square and cylindrical test pieces can be fixed by using the plane splint or the curved splint, which improves the drilling of different test pieces. work efficiency.

[0039] The second step is precise positioning. According to the needs of drilling corresponding positions on the test piece, the drilling depth h is determined, and the push rod 51 on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com