Punching device and punching method for foundation horizontal bar planting

A drilling device and basic technology, applied in drilling/drilling equipment, measuring/indicating equipment, portable drilling rigs, etc., can solve the problems of difficulty in precise control of manual drilling depth, inability to guarantee construction quality, and increased safety risks, etc. Achieve the effect of improving operation efficiency, ensuring construction quality and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

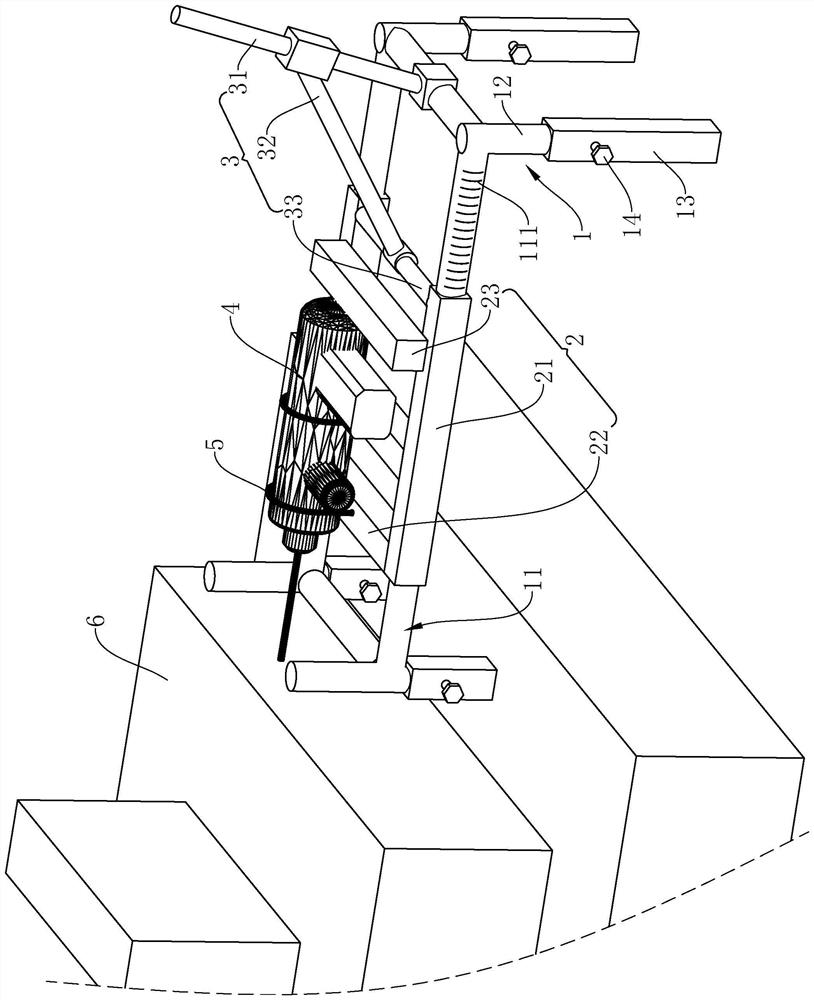

[0040] refer to figure 1 , The punching device used for the foundation horizontal planting bar includes an adjustable base bracket 1, a sliding frame 2 and a stroke control mechanism 3. The adjustable base support 1 is placed on the ground or the surface of the foundation 6 of the structure, and the height of the adjustable base support 1 itself can be adjusted. The sliding frame 2 is installed on the adjustable base support 1 and is slidingly matched with the adjustable base support 1 . The hand-held electric drill 4 is located on the top of the sliding frame 2 and is detachably connected with the sliding frame 2. The stroke control mechanism 3 is connected with the adjustable base support 1 and the sliding frame 2 at the same time, and the stroke control mechanism 3 is used to control the moving distance and speed of the sliding frame 2 .

[0041] The adjustable base bracket 1 is used as the installation carrier of the sliding frame 2, the hand-held electric drill 4 and th...

Embodiment 2

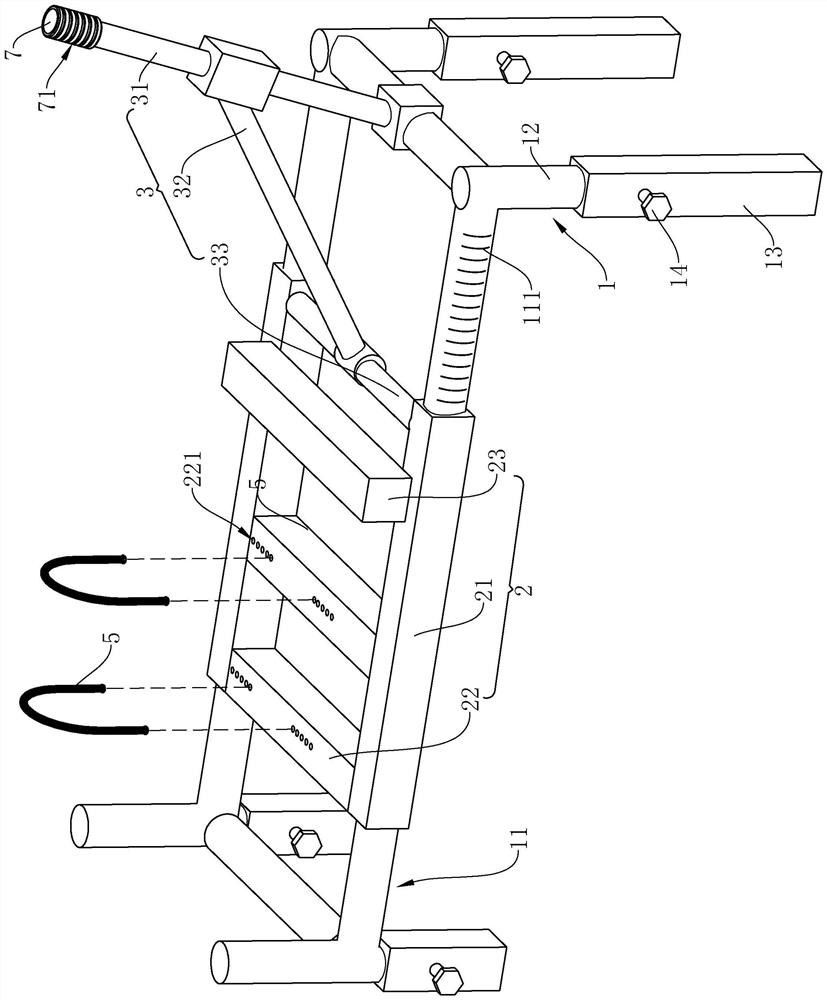

[0050] refer to figure 2 The difference between Embodiment 2 and Embodiment 1 is that the connecting beam 22 is uniformly provided with a plurality of mounting holes 221 along its own extending direction, and any mounting hole 221 is used for inserting U-shaped forks 5 of different specifications. Because in actual construction, the specification of steel bar is different, and the depth and aperture that need punching are different, therefore need to adopt the hand-held electric drill 4 of different specification, just need to support the U-shaped fork 5 of different size, by opening multiple A mounting hole 221 can facilitate the matching of the connecting beam 22 with U-shaped forks 5 of different sizes, thereby realizing the fixed installation of the hand-held electric drill 4 of different specifications.

[0051] refer to figure 2 The end of the active push rod 31 away from the rectangular frame 11 is fixedly sleeved with an anti-slip handle 7, and the outer peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com