A Keratotomy Knife Using Guided Wave Transmission to Realize Longitudinal Bending Two-dimensional Ultrasonic Vibration

A two-dimensional ultrasonic vibration and cutting knife technology, used in medical science, surgery, laser surgery, etc., can solve the problems of insecurity, uneven incision, instability, etc., and achieve precise drilling depth, smooth incision, and controlled drilling. The effect of depth of cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

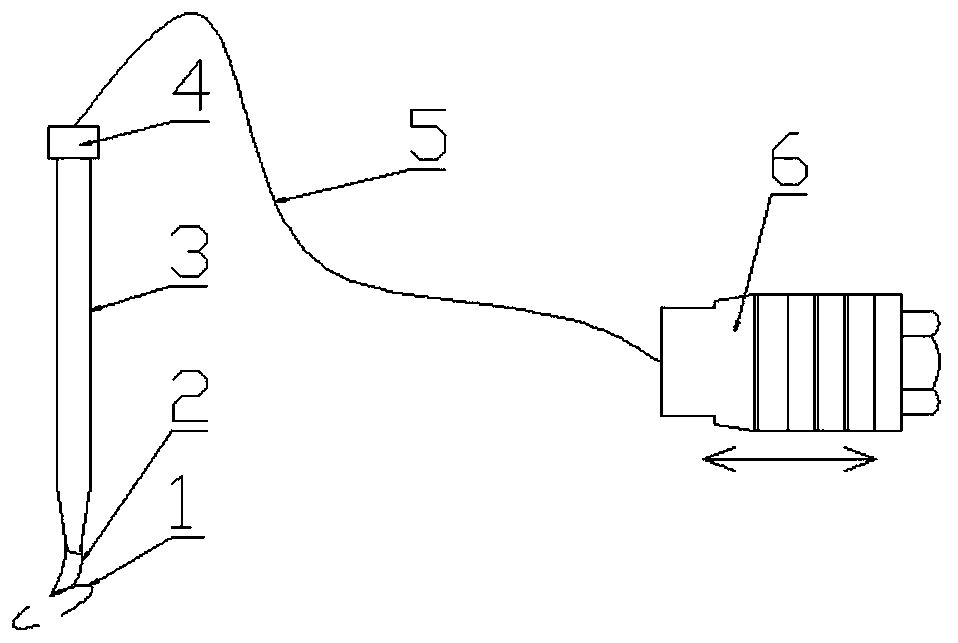

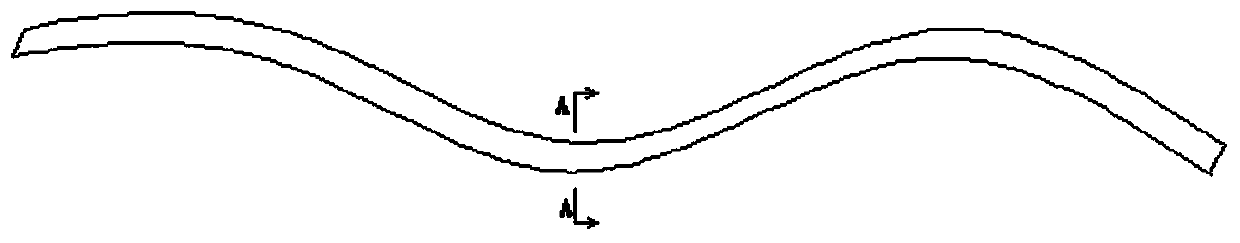

[0012] Such as figure 1 As shown, the embodiment of the present invention is provided with a transducer 6, a waveguide 5, a waveguide welding tool head 4, a knife handle 3 and a curved blade 2; the output end surface of the knife handle 3 is provided with a blade groove, so The curved blade 2 is welded and bonded in the blade groove of the handle 3, so that the curved blade 2 is connected to the handle 3; both inside and outside of the curved blade 2 have cutting edges, and the waveguide 5 is respectively connected to the energy-transforming The waveguide wire welding tool head 4 is welded and bonded, and the waveguide wire welding tool head 4 is screwed onto the handle so that the longitudinal ultrasonic vibration energy of the transducer 6 is transmitted to the curved blade 2 through the waveguide wire 5 . exist figure 1 In , the arrow indicates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com