Electrorheological assisted ultrasonic tracking deburring device

A deburring, electrorheological technology, applied in manufacturing tools, machine tools suitable for grinding workpiece edges, grinding slides, etc., can solve problems such as difficult to meet high-precision machining requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

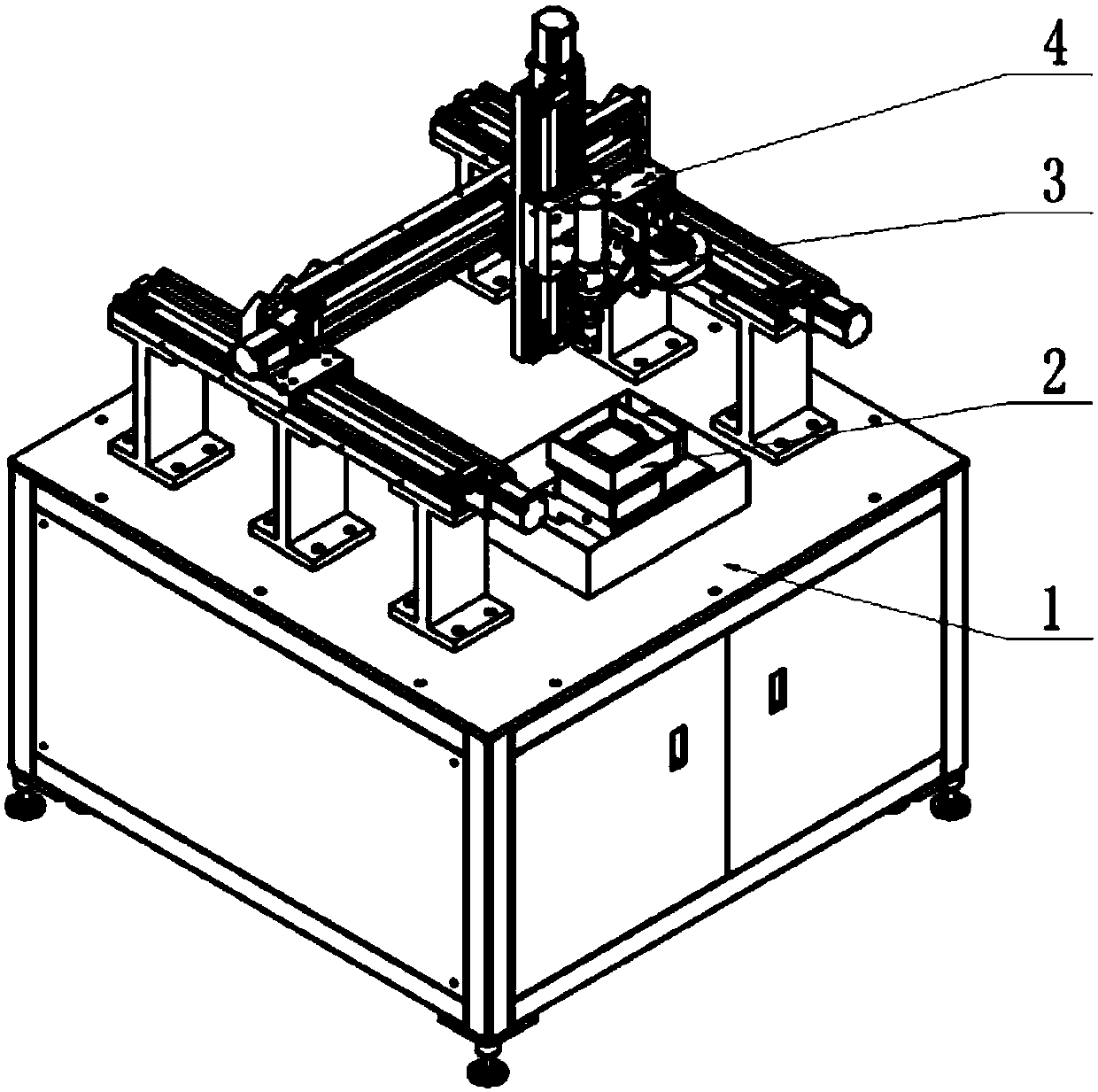

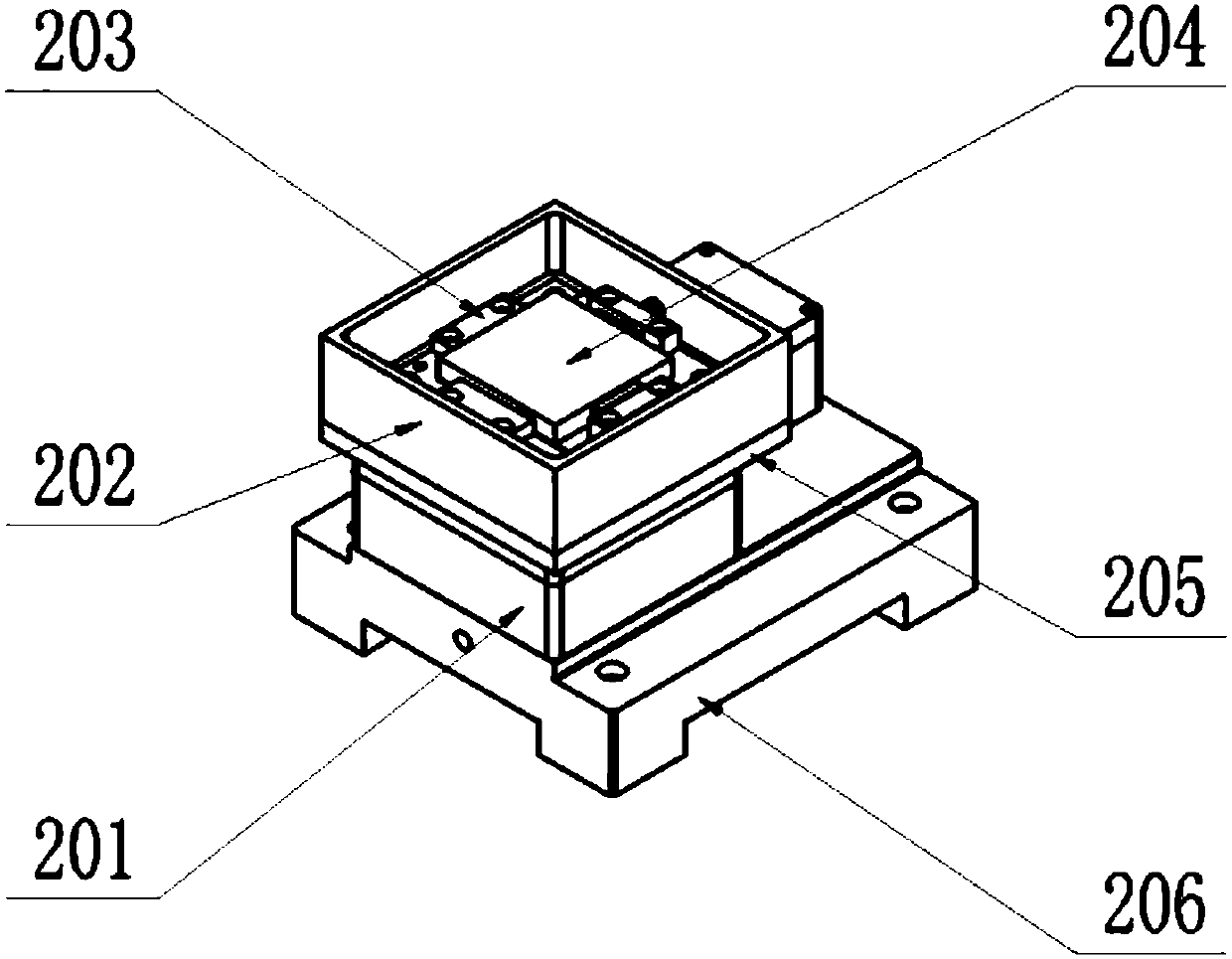

[0018] Such as Figure 1 to Figure 6 As shown, it includes an equipment base 1, a rotary fixture table 2, a tool head 3, and a servo motion mechanism 4. The rotary fixture table 2 is installed on the table top of the equipment support seat 103 of the equipment base 1 for fixed installation. test piece 204, and realize the rotary positioning of the test piece 204 around the Z axis; the servo motion mechanism 4 is installed on the table top of the equipment support seat 103 of the equipment base 1, and is used to drag the tool head 3 along X, Y, Z moves in three directions; the tool head 3 is installed on the slider of the Z-axis module 409 of the servo motion mechanism 4 to realize the tracking and deburring functions of the test piece 204 .

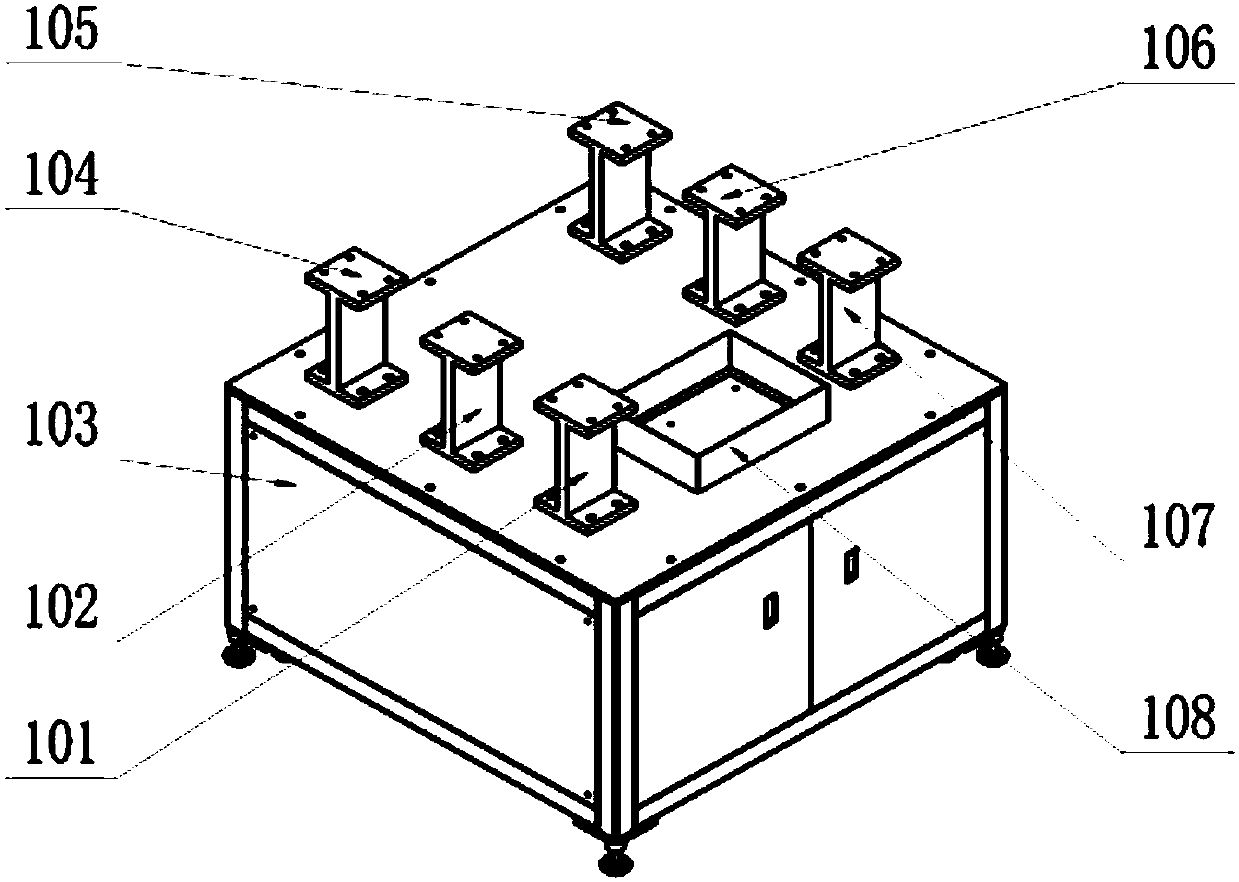

[0019] The structure of the equipment base 1 is: the equipment support base 103 is used as the support of the whole equipment, the module base A101, the module base B102, the module base C104, the module base D105, the module base E106, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com