Device and method for finishing suspended abrasive pool through triangular frustum air pressure jet holes

A technology of smooth finishing and triangular platform, which is applied in the direction of grinding workpiece support, metal processing equipment, grinding/polishing equipment, etc., and can solve the problems of environmental pollution and high cost of magnetic fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings;

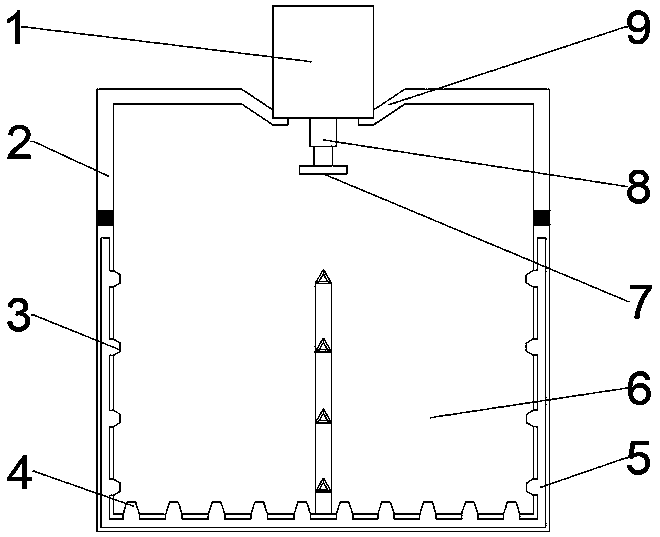

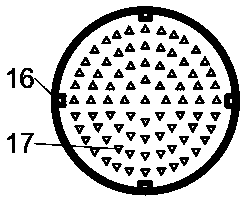

[0014] figure 1 It is a general diagram of the structure of the abrasive pool finishing device. The workpiece rotation system in the figure includes: stepping motor [1], bracket [9], coupling [8], magnetic workpiece fixture [7], wherein the stepping motor [1] is fixed on the bracket [9] through bolt connection , and then firmly combined with the upper frame [2]. In the abrasive pool [6] in the figure: the side triangular platform spray holes [3] and the bottom triangular platform spray holes [4] are equally spaced on the side constant temperature pipeline [5] and the bottom constant temperature pipeline [10], and the constant temperature pipeline is inlaid on the inside of the frame.

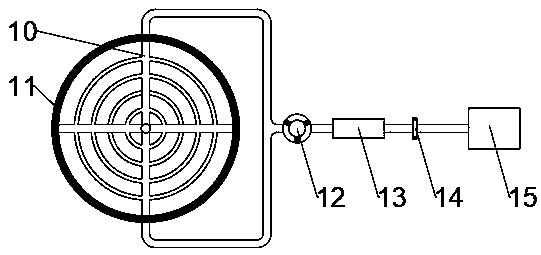

[0015] figure 2 It is the pipeline distribution of the abrasive pool and the structure diagram of the pneumatic power system. The bottom constant temperature pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com