Metal casting ultrasonic finishing batch production method and equipment

A batch processing method and technology of metal castings, applied in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the difficulty of processing special-shaped surface parts and the inner surface of the cavity, and difficult large-scale Promotion, quality instability and other issues, to achieve the effect of increasing the range of categories, reducing labor costs, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method of ultrasonic light-batch processing of metal castings, Figure 1 to Figure 14 shown, including the following steps,

[0073] In the feeding step, a plurality of metal castings are dropped into the finishing chamber 24 of the container; a plurality of metal castings are freely placed in the finishing chamber 24, and there is no need to fix the metal castings; therefore, the present invention can process arbitrary shapes and sizes metal castings, as long as it can be put into the finishing chamber 24. Of course, as long as a finishing chamber 24 with a larger volume is used, various large-volume metal castings can also be processed.

[0074] Abrasive feeding step: put magnetically conductive abrasives into the finishing chamber 24; put the abrasives into the finishing chamber 24 through the feeding pipe, at least make the abrasives cover each metal casting, and implement automatic feeding of abrasives.

[0075] In order to increase the effect of ultrasonic fin...

Embodiment 2

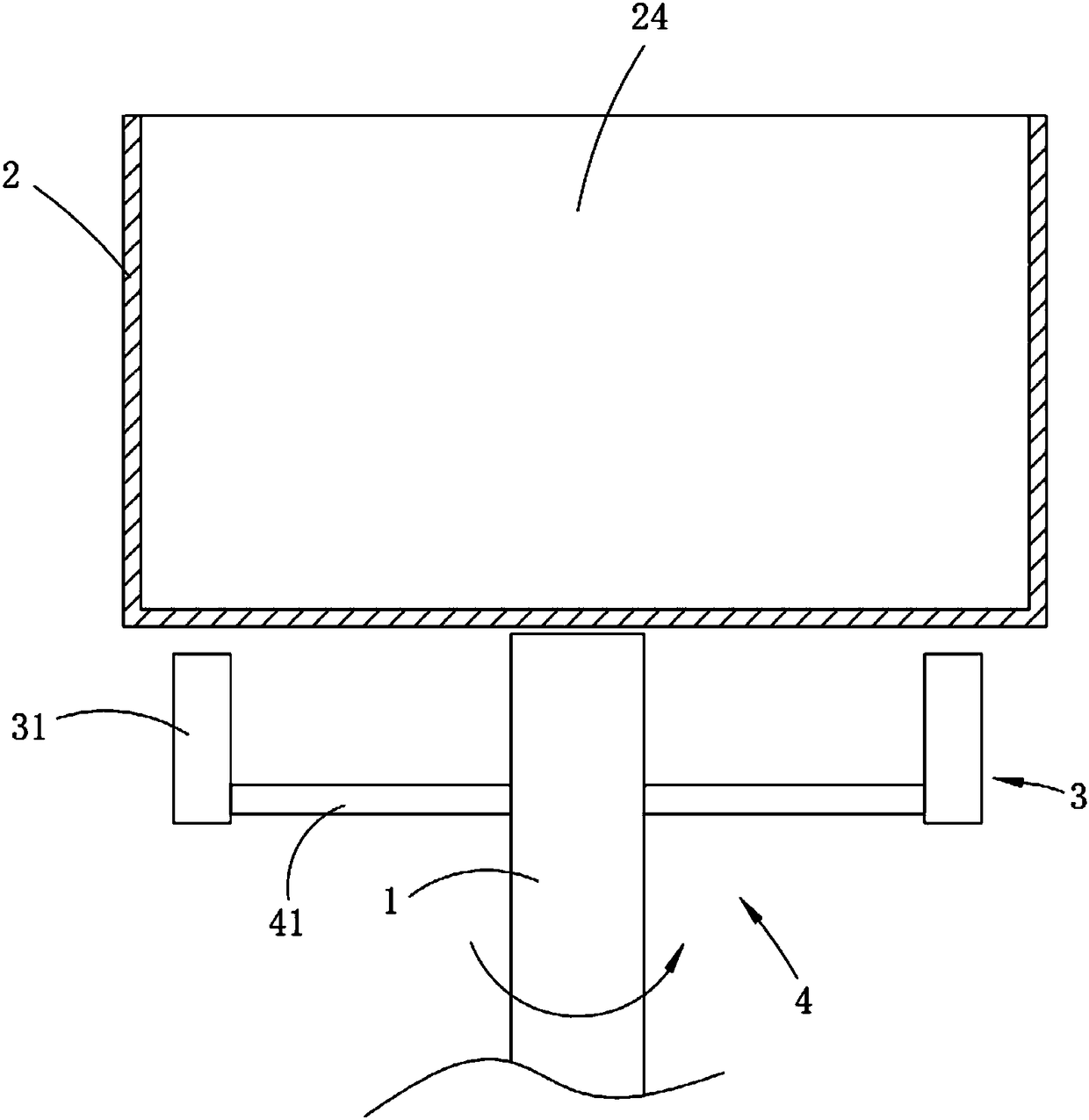

[0089] A kind of ultrasonic light-batch processing equipment for metal castings, see Figure 1-2 , including an ultrasonic tool head 1, a magnetic field generating device 3, a rotating drive device and a housing body 2, the housing body 2 is provided with a finishing chamber 24, the rotating driving device is connected to the ultrasonic tool head 1 by transmission, and the ultrasonic tool head 1 is rotatably mounted on Below the housing body 2. Of course, the ultrasonic tool head 1 can also be rotatably installed inside or above the accommodating body 2 .

[0090] The magnetic field generating device 3 is arranged under the containing body 2 . Of course, the magnetic field generating device 3 can also be installed inside or above the containing body 2 .

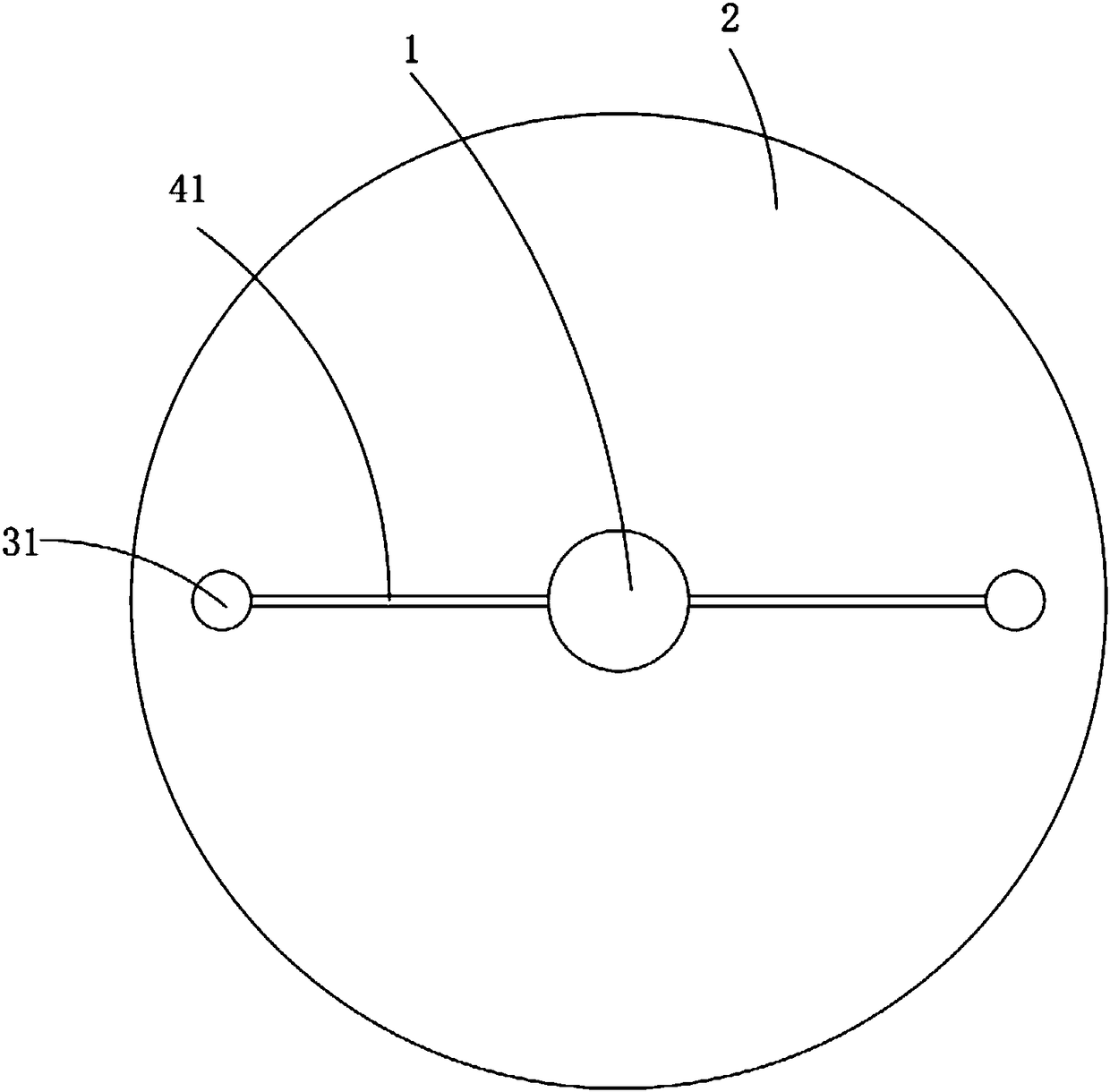

[0091] The ultrasonic tool head 1 is arranged in the middle of the magnetic field generating device 3, and the magnetic field generating device 3 is fixed on the ultrasonic tool head 1 and combined to form a composite finis...

Embodiment 3

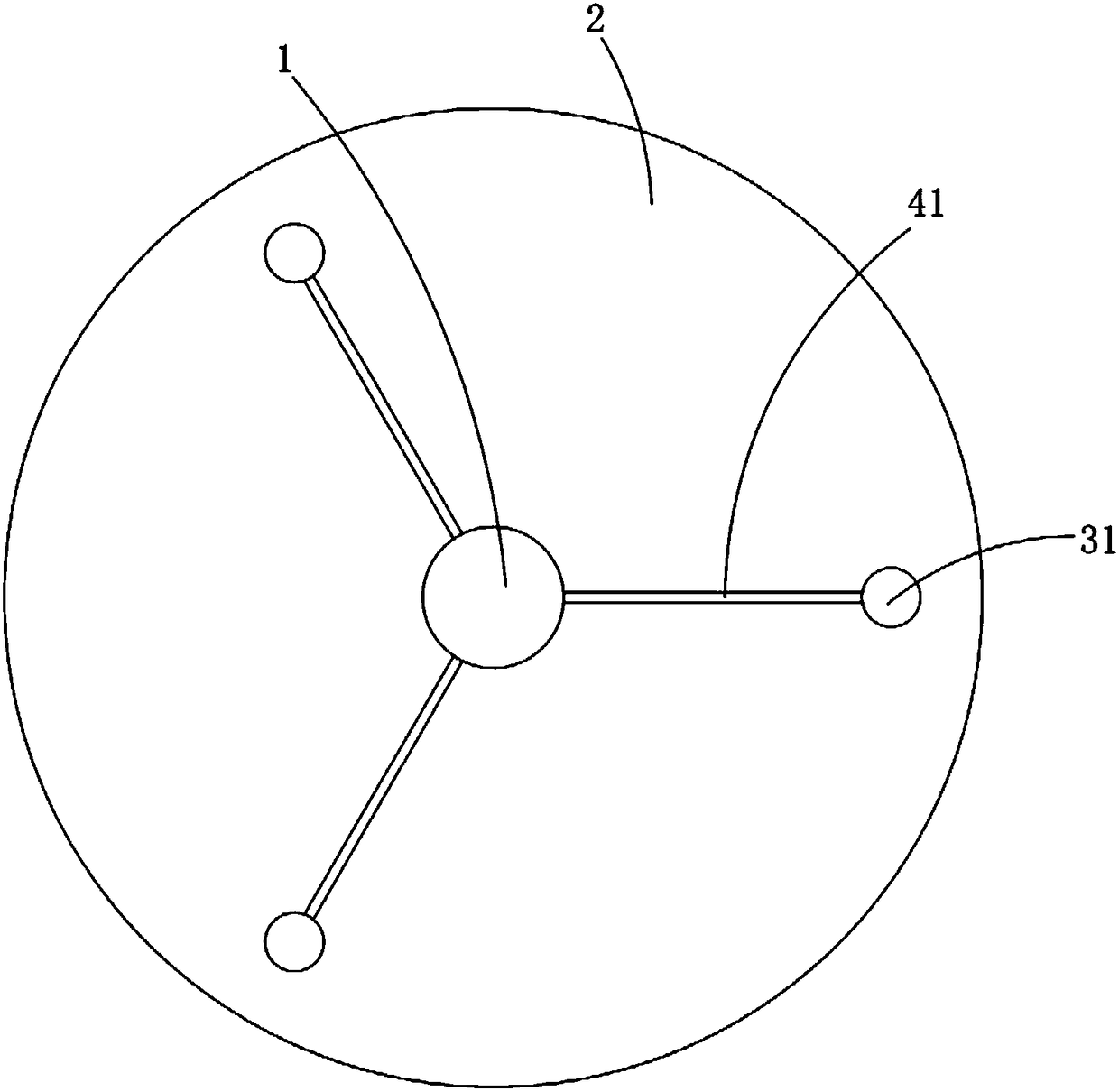

[0102] An ultrasonic light-batch processing equipment for metal castings. The main structure, principle and effect of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that, see image 3 , the magnetic field generating device 3 is provided with three magnets 31, the magnetic pole directions between two adjacent magnets 31 are opposite, the included angle between adjacent magnets 31 is 120 degrees, the magnets 31 are distributed at intervals along the circumferential direction of rotation, and the magnets 31 respectively pass through The connecting rod 41 is connected with the ultrasonic tool head 1 . The rotation driving device drives the ultrasonic tool head 1 to rotate, and the ultrasonic tool head 1 drives the magnetic field generator 3 to rotate, thereby forming a rotating magnetic field. The increase in the number of magnets 31 can make the magnetic force distribution in the magnetic field generating device 3 more dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com