Automatic bundling device for celery

A technology of bundling device and transmission device, which is applied in packaging, packaging food, transportation and packaging, etc., which can solve the problems of consuming labor time for workers, increasing operating costs of catering enterprises, and boring work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

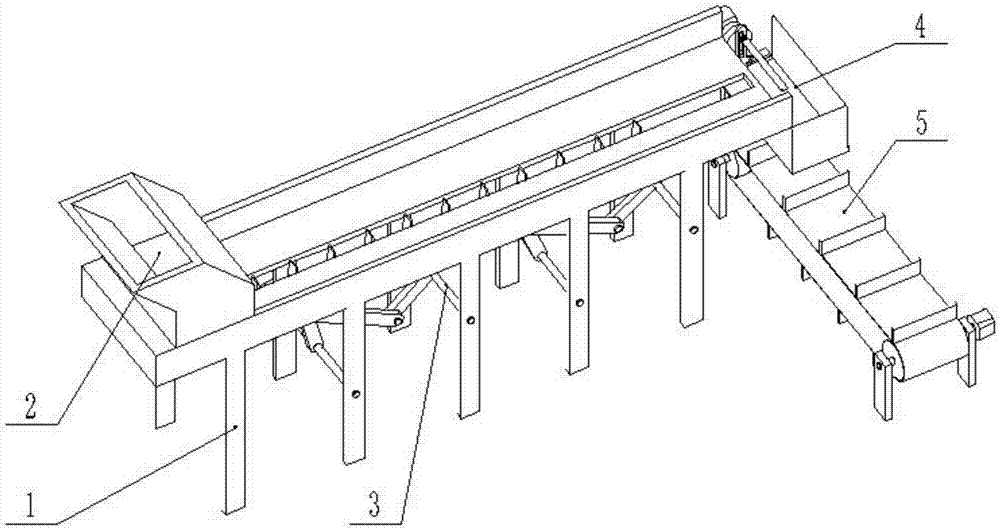

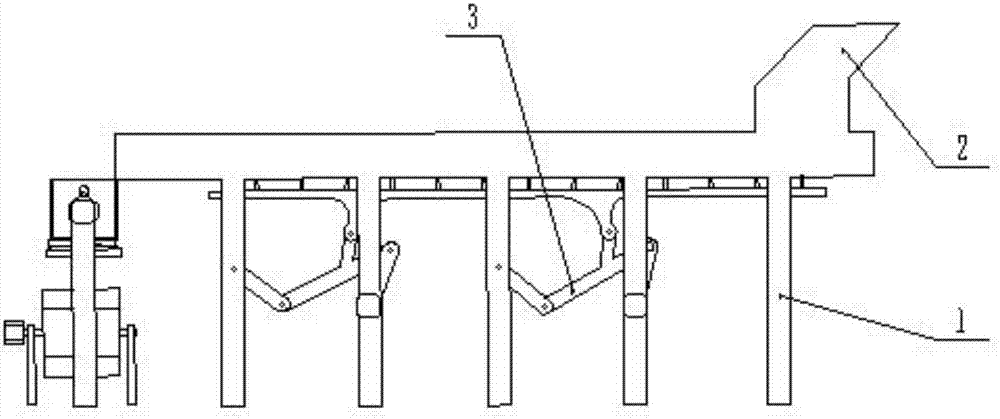

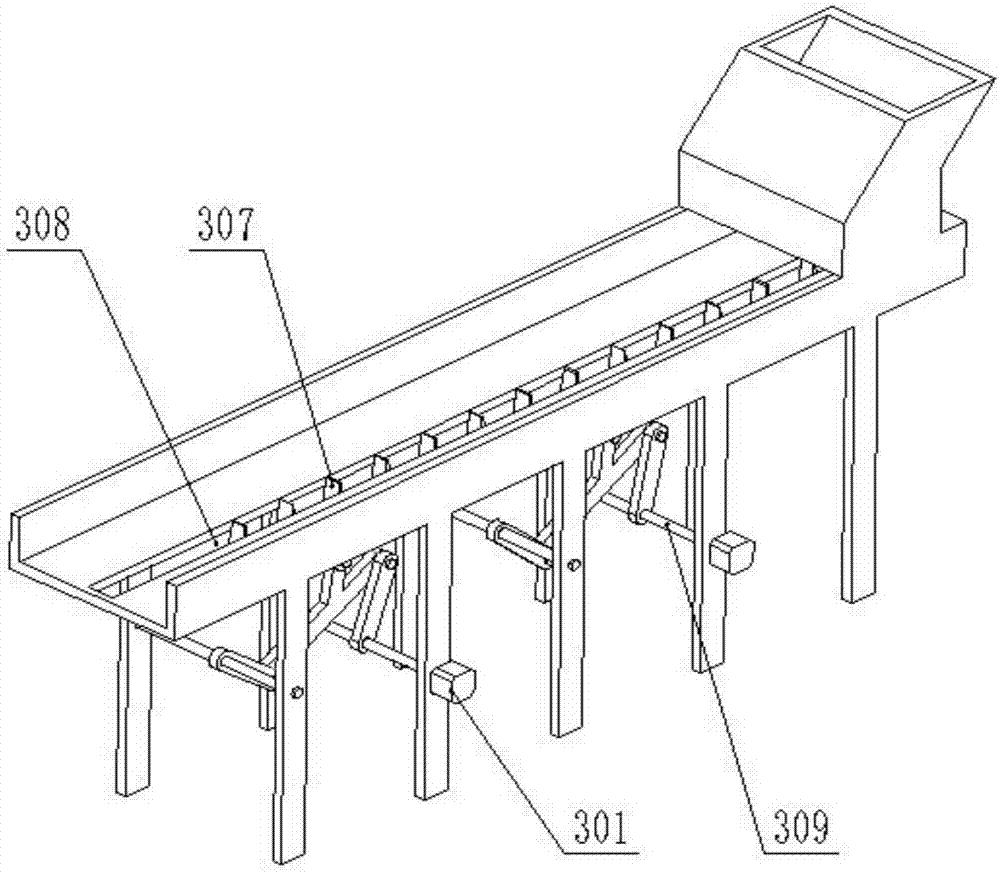

[0018] Combine below Figure 1-7 The structure of a kind of celery automatic bundling device of the invention is described in detail. A celery automatic bundling device is composed of a chassis 1, a feeding port 2, a batch transmission device 3, a bundling device 4 and a transport device 5, the feeding port 2 is arranged on one side of the chassis 1, The batch transmission device 3 is on the upper part of the chassis 1, one side of which communicates with the feed port 2, and the other side is fixedly connected to the bundling device 4, and a transportation device 5 is arranged below the bundling device 4 and is fixedly connected to the transportation bracket 501 on.

[0019] Furthermore, the batch transmission device 3 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com