A method and device for electrolytic-magnetic grinding composite smoothing hard materials

A magnetic grinding and hard material technology, which is applied in the field of precision machining of hard material parts, can solve the problems of low processing efficiency of magnetic grinding process, many elements of electrolytic processing control, and large loss of magnetic grinding particles, so as to improve the grinding processing efficiency and the effect of workpiece surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

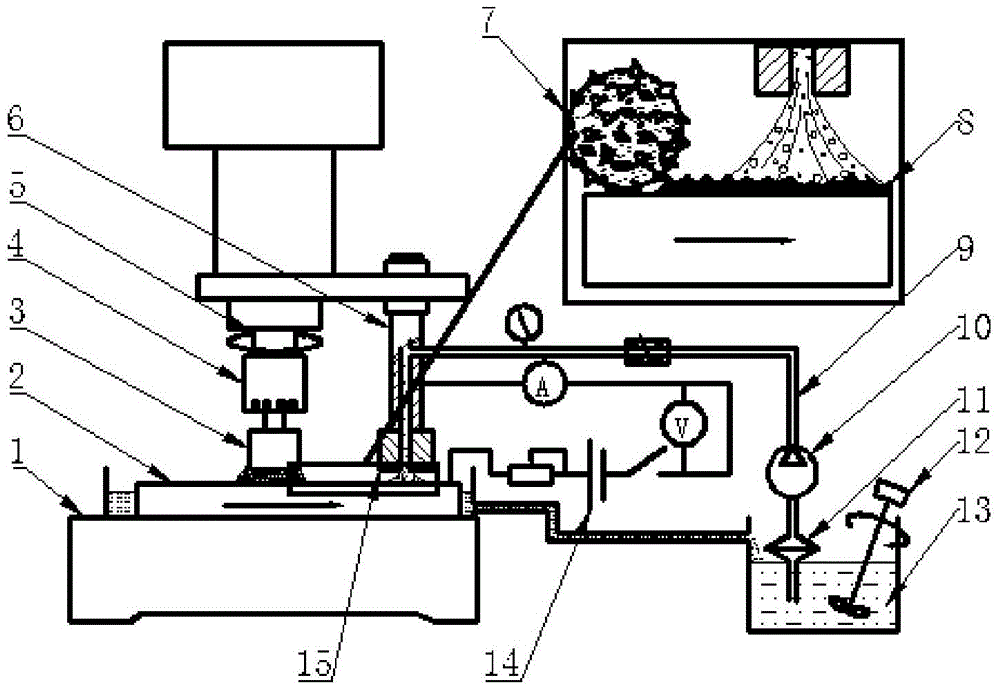

[0023] Such as figure 1 Shown, a kind of method and its device of electrolytic-magnetic grinding compound finishing hard material, carry out the compound grinding of nickel base superalloy, its solution is as follows:

[0024] ①Clamping: clamp the workpiece 2 on the workbench 1, connect the magnetic pole 3 to the machine tool spindle 5, adjust the gap between the magnetic pole 3 and the workpiece 2 to 1.5mm, and the distance between the electrode and the workpiece to 1mm;

[0025] ②Parameter setting: the DC power supply voltage is 14V, the electrolyte is sodium nitrate solution with a concentration of 20%, and the horizontal speed of workbench 1 is 120mm / min;

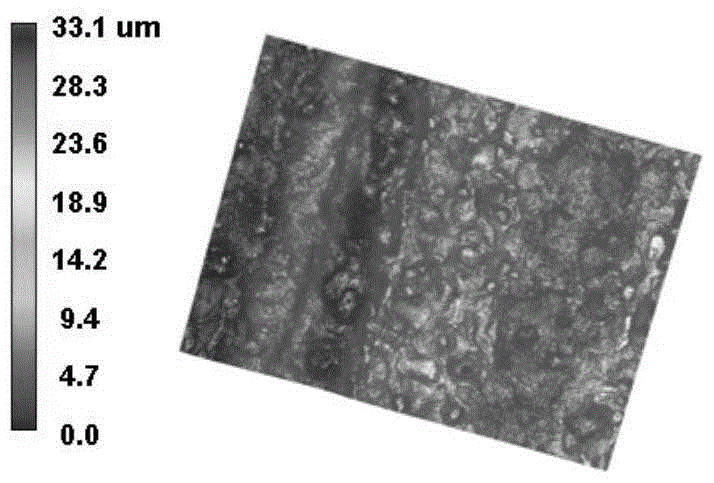

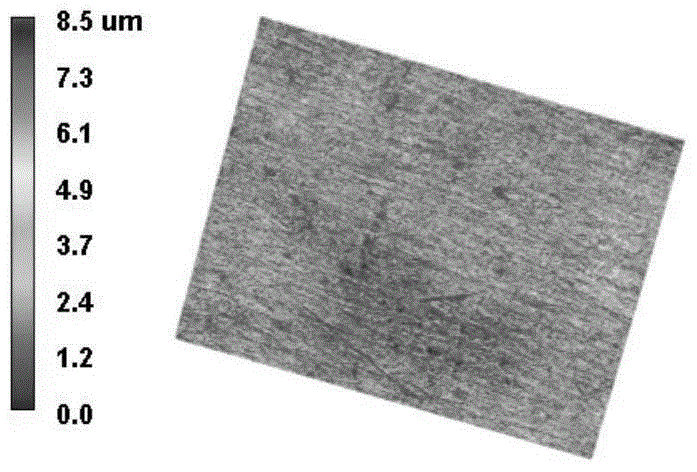

[0026] ③ Fine grinding: After mixing the sintered magnetic abrasive with an average particle size of 350 μm and the oil-based abrasive at a volume ratio of 1:2, evenly fill it in the processing gap between the magnetic pole 3 and the workpiece 2, and turn on the DC power supply 14, creep The pump 10 and the machine too...

Embodiment 2

[0031] Such as figure 1 Shown, a kind of method and its device of electrolysis-magnetic grinding compound finishing hard material, carry out titanium alloy compound grinding, its solution is as follows:

[0032] ①Clamping: clamp the workpiece 2 on the workbench 1, connect the magnetic pole 3 to the spindle 5 of the machine tool, adjust the gap between the magnetic pole 3 and the workpiece 2 to be about 1.5mm, and the distance between the electrode and the workpiece to be 1mm;

[0033] ②Parameter setting: the DC power supply voltage is 12V, the electrolyte is sodium nitrate solution with a concentration of 16%; the horizontal speed of workbench 1 is 120mm / min;

[0034] ③ Fine grinding: After mixing the sintered magnetic abrasive with an average particle size of 250 μm and the oil-based abrasive at a volume ratio of 1:2, evenly fill it in the processing gap between the magnetic pole 3 and the workpiece 2, turn on the DC power supply 14, creep The pump 10 and the machine tool 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com