Laser machining center

A laser processing and laser technology, applied in the field of mechanical processing, can solve the problems of high tool consumption, low tool service life, cutting heat effect, etc., and achieve the effect of high work efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

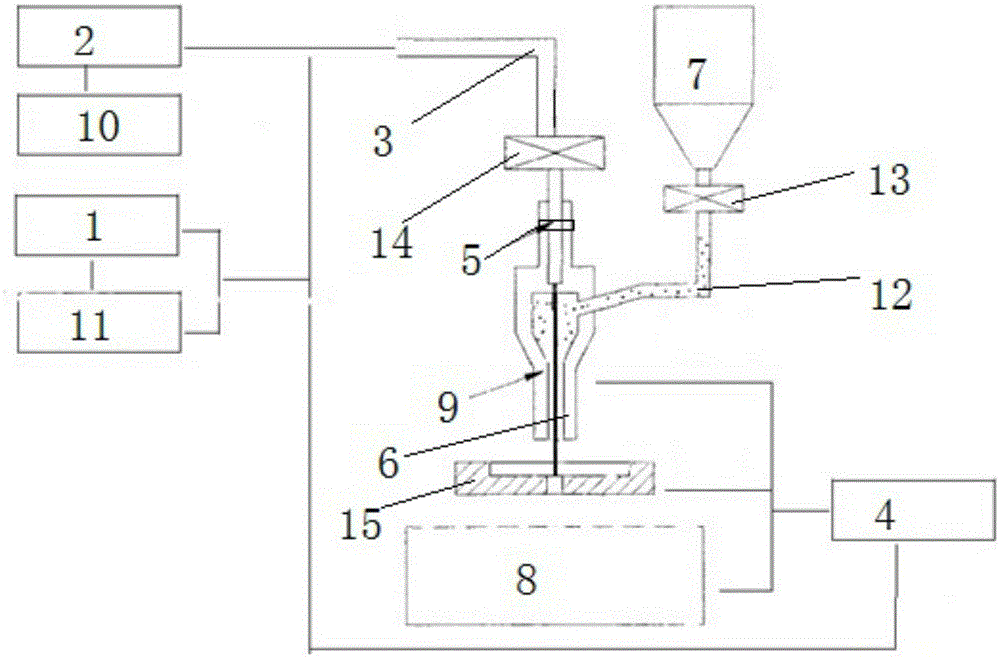

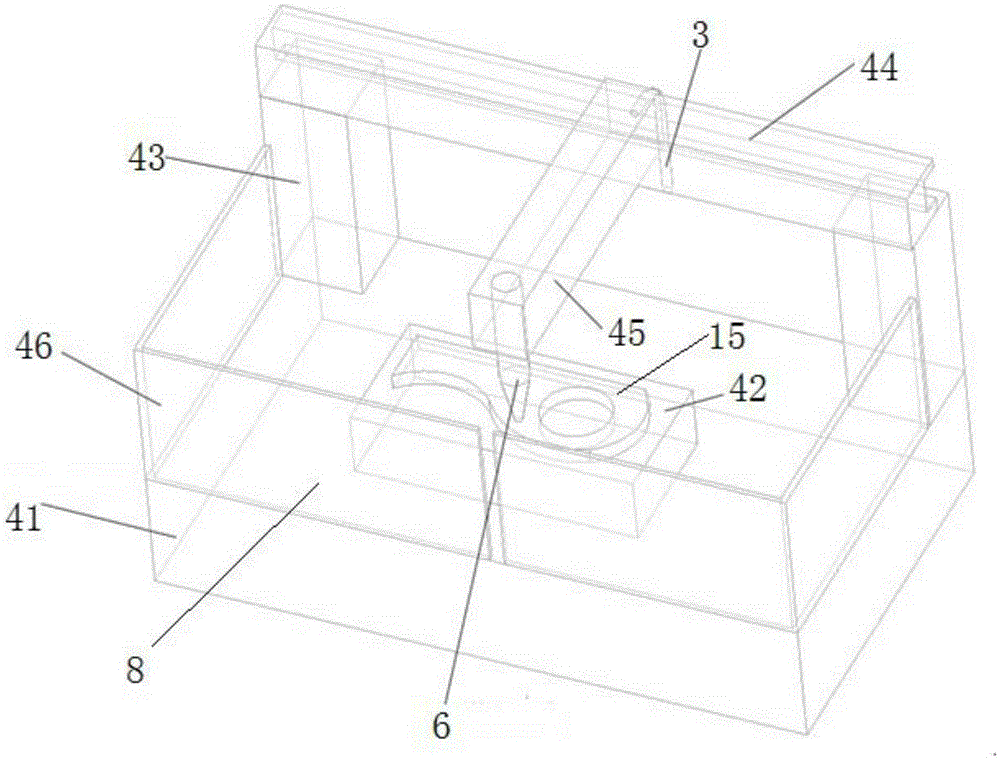

[0027] Embodiment: a laser processing center, including a control system 1, a laser 2, an optical path system 3, a processing machine tool 4, a focusing system 5, a laser cutter head 6, a gas source 7 and a waste receiving device 8, and the laser cutter head is movably installed on On the processing machine tool, the optical path system is connected between the laser and the laser cutter head, the laser cutter head is provided with a protective gas nozzle 9, and the protective gas nozzle is communicated with the gas source, so The condensing system is located between the optical path system and the laser cutter head, the waste material receiving device is located below the laser cutter head, and the laser and the processing machine tool are both communicated with the control system.

[0028] The laser processing center uses high-energy laser beams as processing tools instead of traditional tools, has almost no cutting force, and does not have cooling and lubrication problems. I...

experiment example

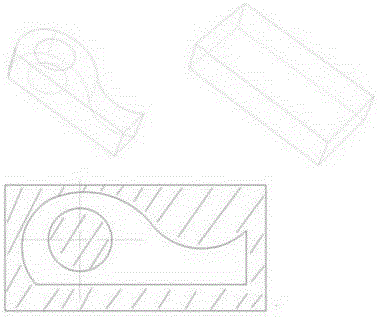

[0041] Experimental example: such as Figure 4 As shown, the blank that needs to be machined is a rectangular piece of raw material. Assuming that the axis of the circular hole is the z-axis direction, for this part, the plane perpendicular to the z-axis direction is obviously the same as any cross-sectional profile within the part range, and the shaded part is the material to be removed for each part. In the case of certain parameters, if the laser beam is moved at a certain scanning speed, and the depth of material removal is h (for example, 0.05mm), then the slicing cad software can be set to slice every h height. Then the control computer scans the blank layer by layer to remove material according to the slice data, and finally obtains the corresponding parts. Of course, this is a special case of equal cross section, and the process for variable cross section is exactly the same, except that the slice thickness at this time will directly affect the final machining accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com