Method for improving surface performance of single-phase high-entropy alloy

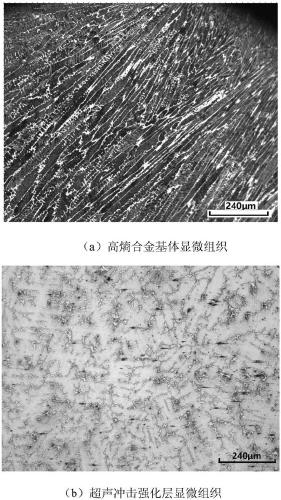

A high-entropy alloy and surface performance technology, applied in the field of surface engineering, can solve problems such as reducing surface roughness and refinement, and achieve the effects of saving process time and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

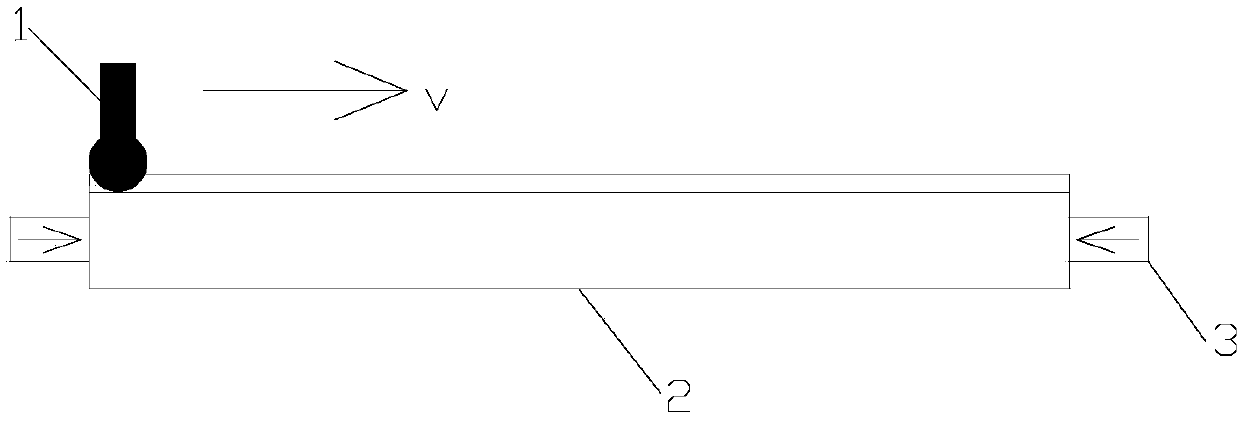

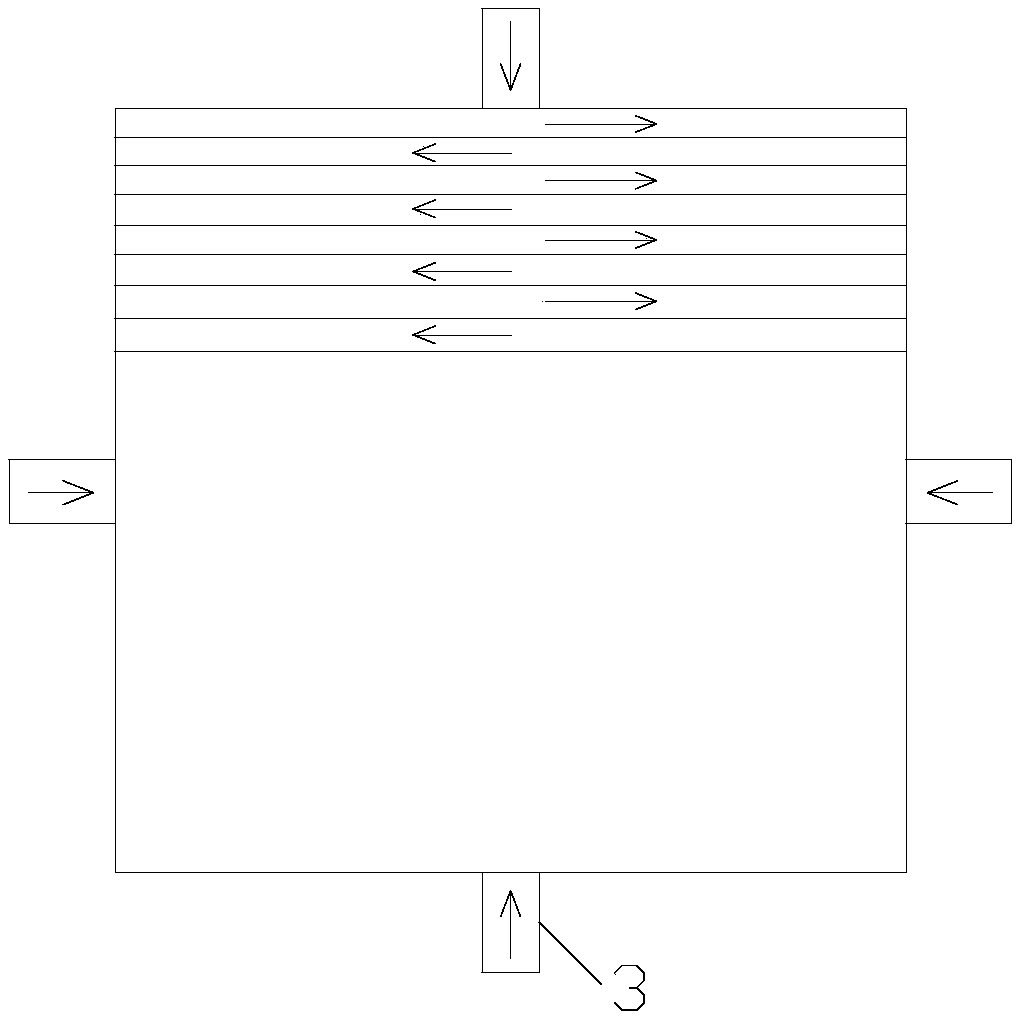

[0041] A method for improving the surface performance of a single-phase high-entropy alloy, the specific process steps are as follows:

[0042] (1) Taking the as-cast CrCoFeMnNi (x=0) high-entropy alloy with a single-phase face-centered cubic lattice structure as the object;

[0043] (2) processing the surface of the cast high-entropy alloy sample in step (1) into a plane;

[0044] (3) Then use sandpaper to carry out rust removal treatment on the surface of the sample, and then wipe the surface to be treated with acetone to remove oil stains;

[0045] (4) Fix the flat sample under the ultrasonic shock working head;

[0046] (5) Use a spherical ultrasonic impact working head with a radius of 5mm to process the surface of the flat sample. Specific parameters: step distance: 0.05mm, cutting speed: 300mm / min, working air pressure: 0.2MPa, amplitude: 12μm, frequency: 30KHz, current: 1.18A, resonance voltage: 13.26V, static pressure 0.3MPa.

[0047] (6) Ultrasonic impact treatmen...

Embodiment 2

[0054] A method for improving the surface performance of a single-phase high-entropy alloy, the specific process steps are as follows:

[0055] (1) As-cast Al with a single-phase face-centered cubic lattice structure 0.5 CrCoFeMnNi (x=0.5) high-entropy alloy is the object;

[0056] (2) processing the surface of the cast high-entropy alloy sample in step (1) into a plane;

[0057] (3) Then use sandpaper to carry out rust removal treatment on the surface of the sample, and then wipe the surface to be treated with acetone to remove oil stains;

[0058] (4) Fix the flat sample under the ultrasonic shock working head;

[0059] (5) Use a spherical ultrasonic impact working head with a radius of 5mm to process the surface of the flat sample. Specific parameters: step distance: 0.05mm, cutting speed: 350mm / min, working air pressure: 0.2MPa, amplitude: 14μm, frequency: 30KHz, current: 1.18A, resonance voltage: 13.26V, static pressure 0.3MPa.

[0060] (6) Cast Al 0.5 CrCoFeMnNi hig...

Embodiment 3

[0067] A method for improving the surface performance of a single-phase high-entropy alloy, the specific process steps are as follows:

[0068] (1) As-cast Al with a single-phase face-centered cubic lattice structure 0.5 CrCoFeMnNi (x=0.5) high-entropy alloy is the object;

[0069] (2) processing the surface of the cast high-entropy alloy sample in step (1) into a plane;

[0070] (3) Then use sandpaper to carry out rust removal treatment on the surface of the sample, and then wipe the surface to be treated with acetone to remove oil stains;

[0071] (4) Fix the flat sample under the ultrasonic shock working head;

[0072] (5) Use a spherical ultrasonic impact working head with a radius of 5mm to process the surface of the flat sample. Specific parameters: step distance: 0.05mm, cutting speed: 360mm / min, working air pressure: 0.2MPa, amplitude: 13μm, frequency: 30KHz, current: 1.18A, resonance voltage: 13.26V, static pressure 0.3MPa.

[0073] (6)Al 0.5 CrCoFeMnNi high-entr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com