Device and method for magnetically grinding inner surfaces of large-diameter long and straight pipes

A magnetic grinding and inner surface technology, applied in surface polishing machine tools, grinders, grinding/polishing equipment, etc., can solve the problems of single grinding track and large deformation of the inner groove of pipe fittings, and achieve a high degree of automation and processing. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

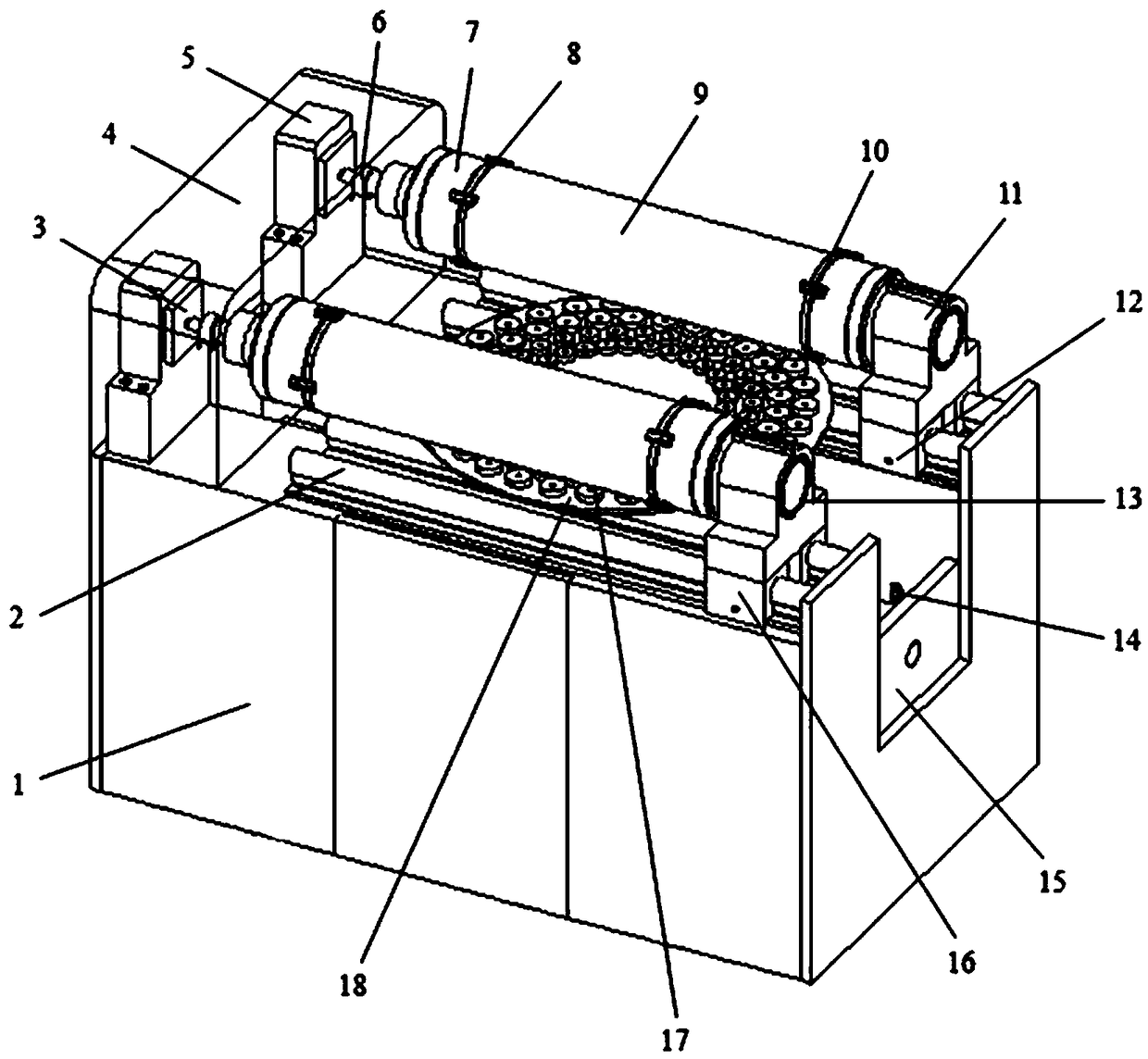

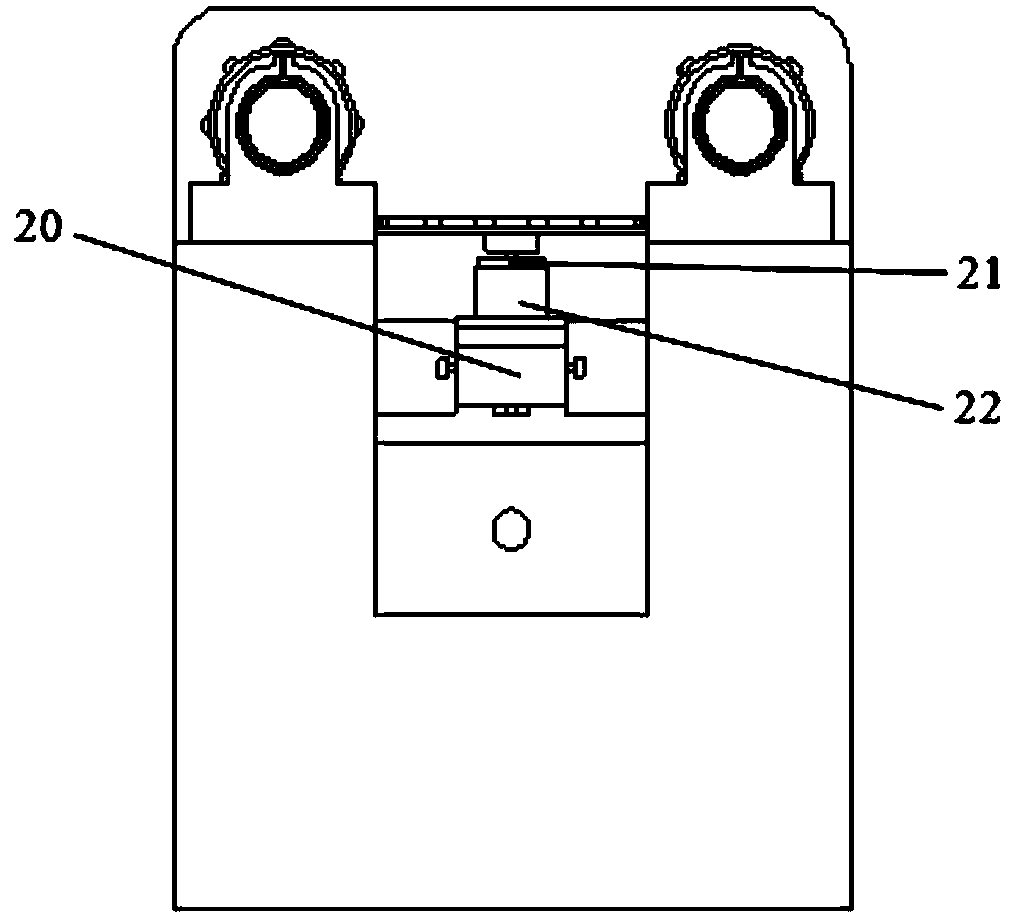

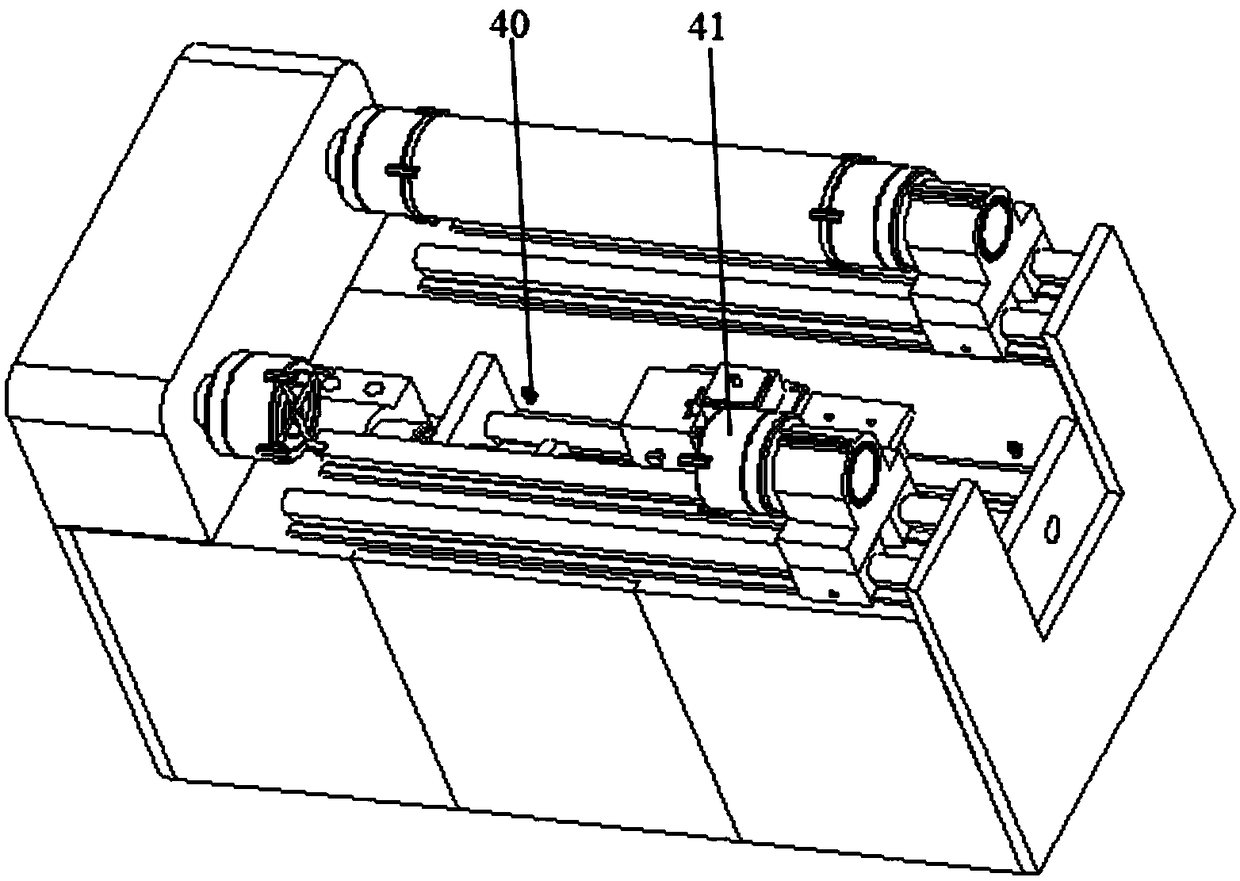

[0034] See figure 1 , figure 2 , image 3 , a large-diameter long straight tube inner surface magnetic grinding device, including a machine base 1, a spindle motor 3, a device housing 4, a spindle motor support seat 5, a coupling 6, a four-jaw chuck 7, a magnetic pole plate 18, and a photoelectric sensor One 14, photoelectric sensor two 40, motor-driven slide rail device 15, lifting device 20. The device housing 4 covers the outside of the main shaft motor 3 and is fixed above the machine base 1; the main shaft motor 3 is fixed above the left side of the machine base 1 through the main shaft motor support seat 5; the main shaft motor 3 is connected to the four-jaw chuck 7 through the coupling 6 Connected; support base slide rail 2 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com