Power head of timber door drilling device

A technology of drilling device and power head, which is applied to fixed drilling machines and other directions, can solve the problems of high production cost, difficult maintenance, complex structure, etc., and achieve the effects of low manufacturing cost, convenient maintenance and accurate displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

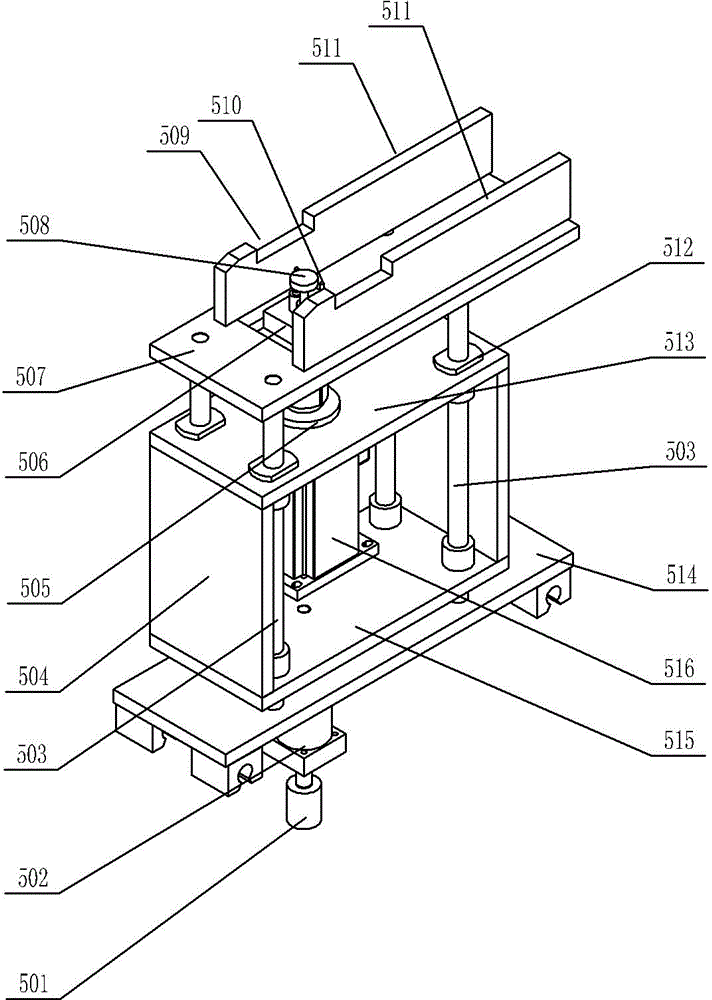

[0009] like figure 1 As shown, including the power head base plate 514, the four corners of the guide rod fixing plate 507 are supported on the power head base plate 514 by the guide rod 503, the cylinder 502 and the slide block are fixed on the lower end surface of the power head base plate 514, and the piston rod end of the cylinder 502 After passing through the bottom plate 514 of the power head, the motor seat is connected to the motor seat. The motor seat is a rectangular frame, including the motor seat top plate 513, the motor seat bottom plate 515 and the motor seat side plate 504. The four corners of the motor seat top plate 513 and the motor seat bottom plate 515 are arranged symmetrically. The linear bearing 512, the guide rod passes through the linear bearing 512 of the motor seat top plate 513 and the motor seat bottom plate 515 successively, the motor 516 is fixed on the lower end surface of the motor seat top plate 513, and the drilling planer connection seat 505 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com