Two-way vise

A pliers body and chute technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve the problem that the clamping accuracy is difficult to meet the high symmetry requirements of drilling processing, etc., and achieve a strong general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

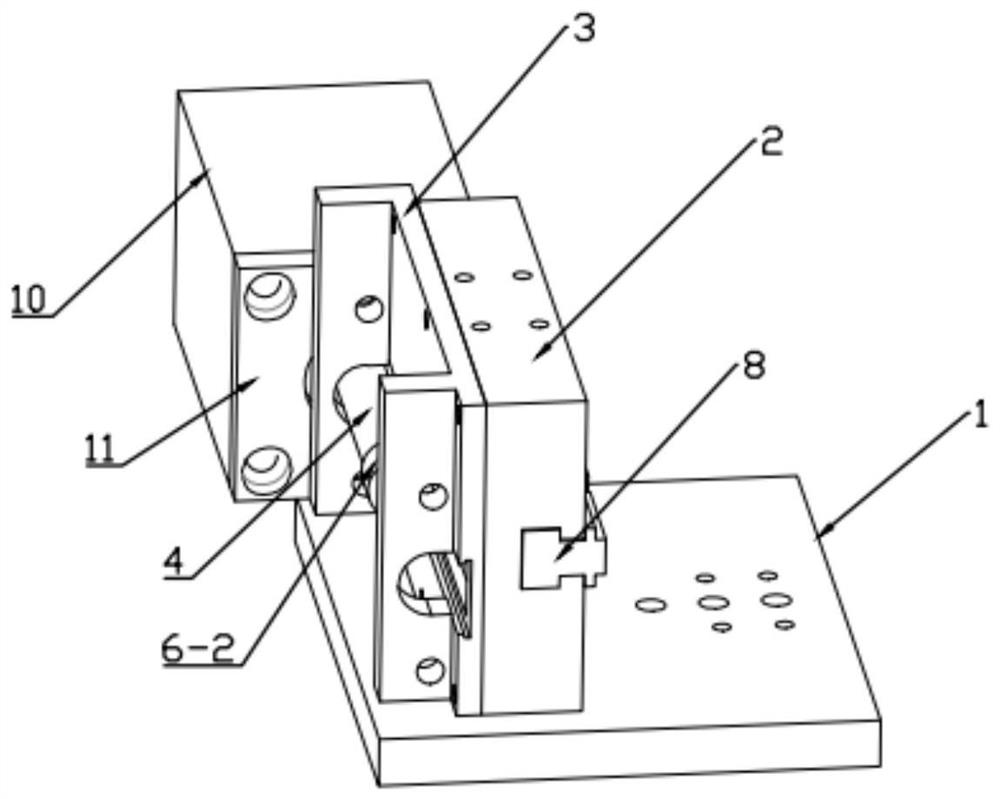

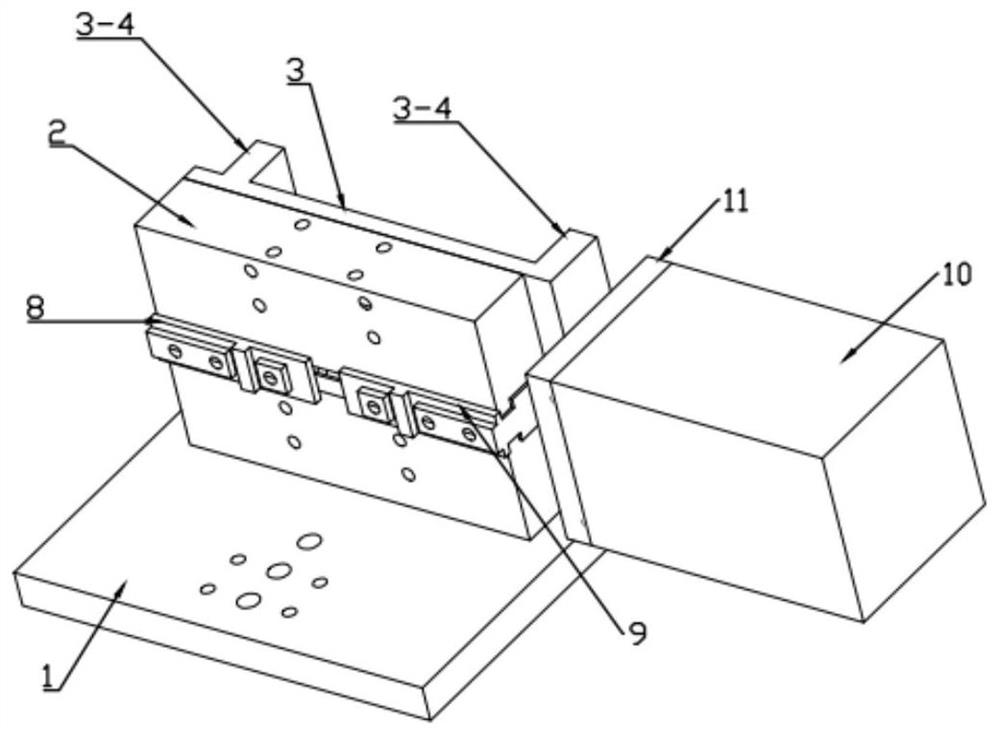

[0032] A two-way vise includes a base plate 1, a clamp body 2, a bracket 3, a spacer 4, a pull rod 5, a slide plate 6, a positioning plate 7, a left slider 8, a right slider 9 and a linear reciprocating mechanism 10.

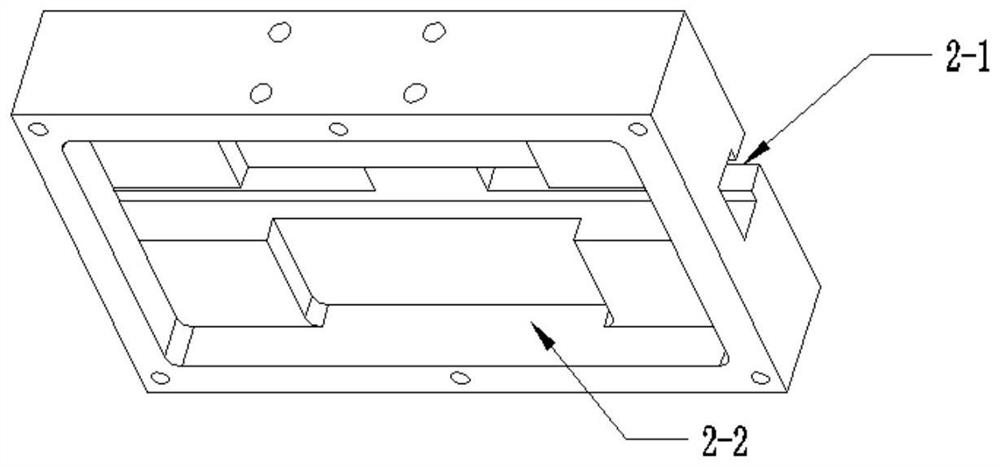

[0033] like image 3 and Figure 4 As shown, the front end surface of the clamp body 2 is provided with a first sliding groove 2-1 transversely, and the rear end surface is provided with an installation groove 2-2, and the first sliding groove 2-1 is communicated with the installation groove 2-2.

[0034] like figure 2 and 5 and Image 6 As shown, the left slider 8 and the right slider 9 are symmetrical, the front end surfaces of the left slider 8 and the right slider 9 are provided with jaw mounting parts for installing different jaws, and the rear end surfaces are provided with bumps.

[0035] like Figure 7 and Figure 8 As shown, the front end surface of the positioning plate 7 is provided with two second sliding grooves 7-1 and 7-2, the second slidin...

Embodiment 2

[0042] like Figure 16 As mentioned, the jaws are installed on the left slider and the right slider according to the positions shown by the arrows. The two-way vise can support and fix different types of workpieces by changing different jaws. like Figure 17 As shown, by changing different jaws, the two-way vise can fix two different workpieces, the earring and the fork respectively. When using the two-way vise of the present invention to process different workpieces, it is only necessary to replace the matching jaws. Therefore, the two-way vise of the present invention is extremely versatile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com