Perforating apparatus and method for slab workpiece

A technology for plate-shaped workpieces and hole positions, which is applied to feeding devices, boring/drilling, automatic control devices, etc., can solve the problems of hindering the installation and removal of the fixture plate 14, and the time-consuming and laborious replacement of the fixture plate 114. It is easy and The effect of quick job changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

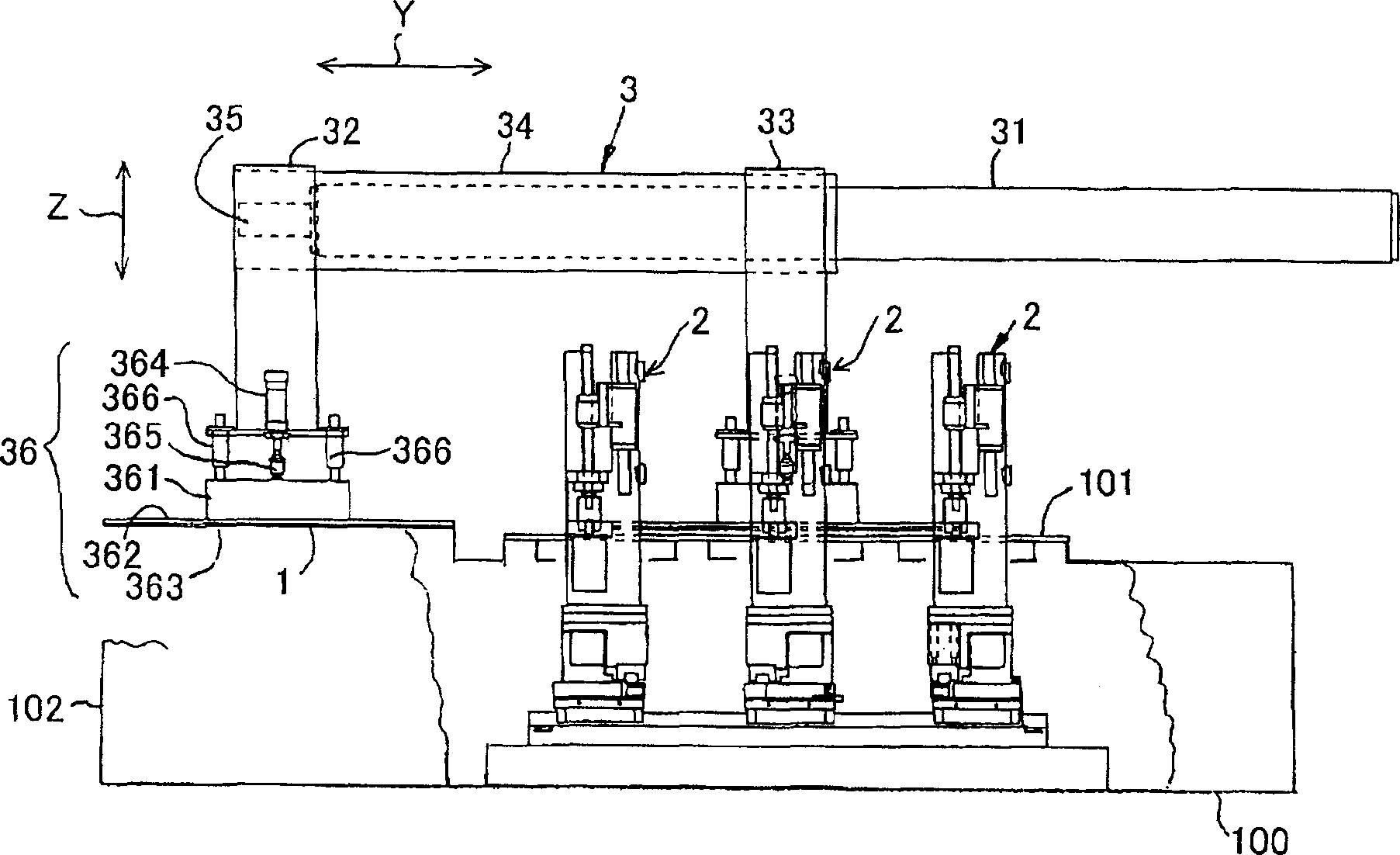

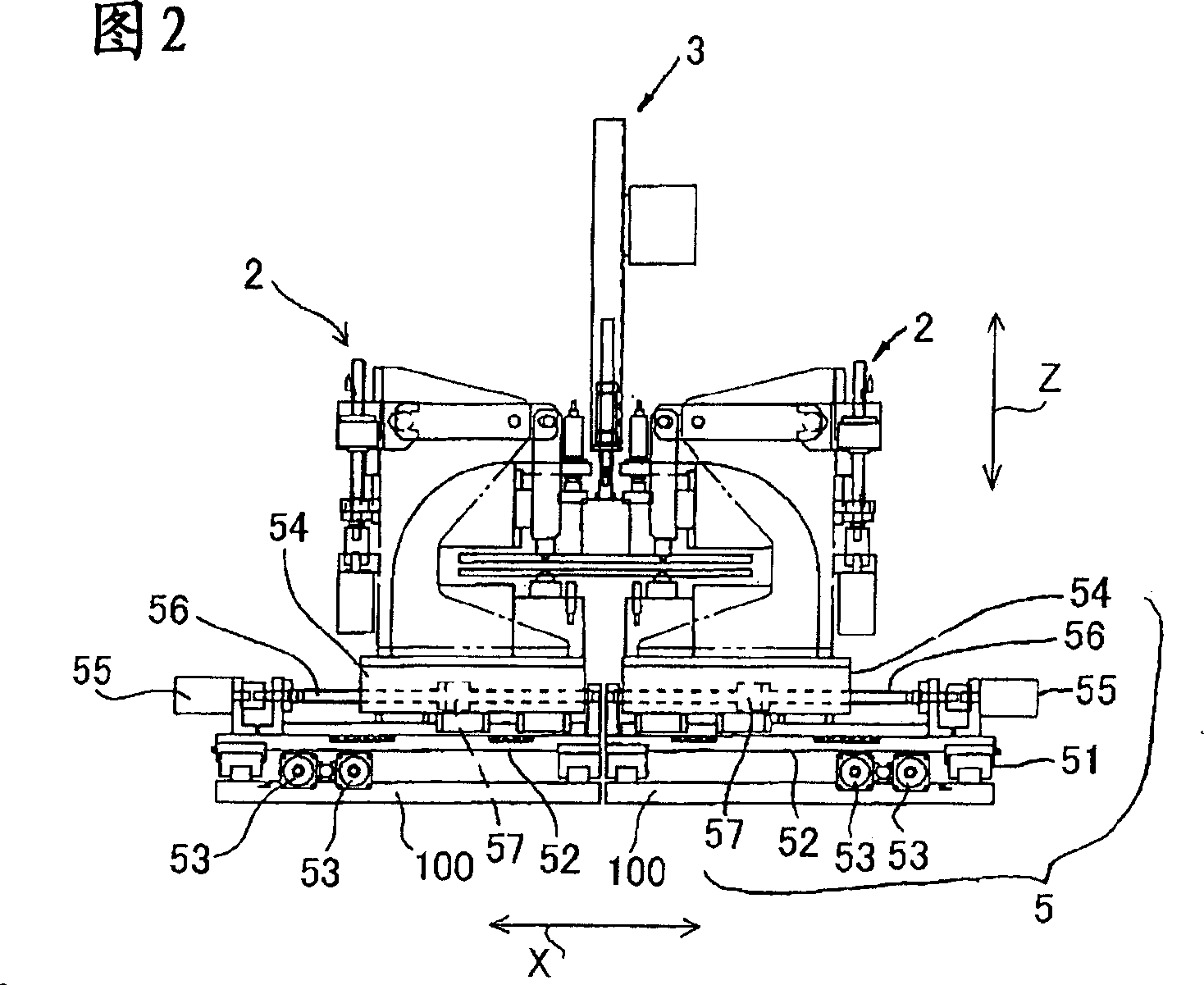

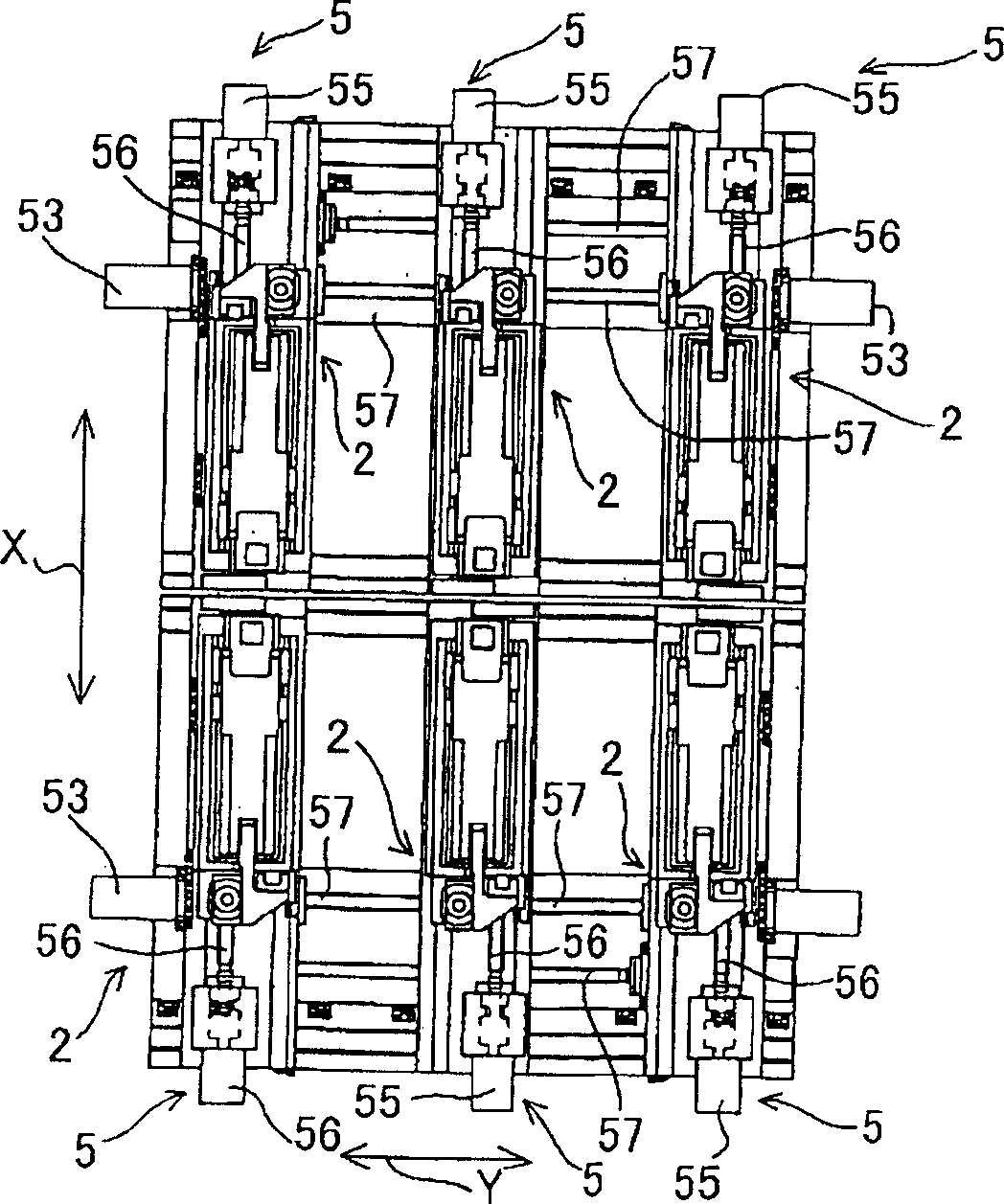

[0027] Below, refer to Figure 1 to Figure 11 , and the structure of the drilling device for a plate-shaped workpiece to which the present invention is applied will be described. First, a general description of the overall structure is given. In this hole-drilling device, there are 6 hole-drilling mechanisms 2 for punching holes in the plate-shaped workpiece 1, and the input mechanism 3 that holds the plate-shaped workpiece and transports the plate-shaped workpiece to the hole-opening mechanism is respectively connected with the plate-shaped workpiece. The hole opening mechanisms are provided as an integral camera mechanism 4 and a moving mechanism 5 capable of moving each hole opening mechanism independently of each other. Also, the hole opening device has processing such as Figure 10 The image processing mechanism 6 of the imaging result of the imaging mechanism 4 shown, the computing mechanism 7 that calculates the processing result of the image processing mechanism, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com