Curved plate tool and curved plate drilling equipment and drilling method thereof

A technology for drilling equipment and curved panels, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring/drilling, etc., and can solve the problem that processing equipment and fixtures are prone to mutual interference, and position accuracy and dimensional accuracy are not guaranteed. , Unable to adapt to problems such as arc-shaped surfaces, etc., to achieve the effect of improving positioning accuracy and work efficiency, convenient operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

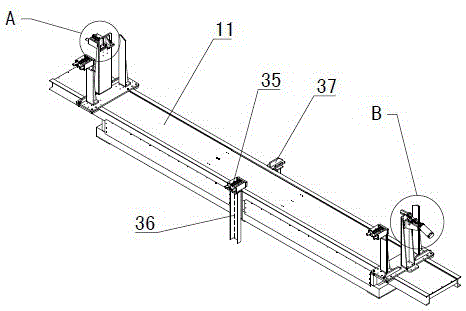

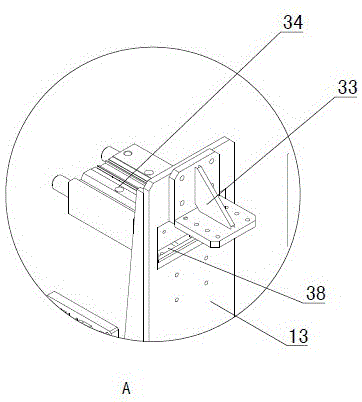

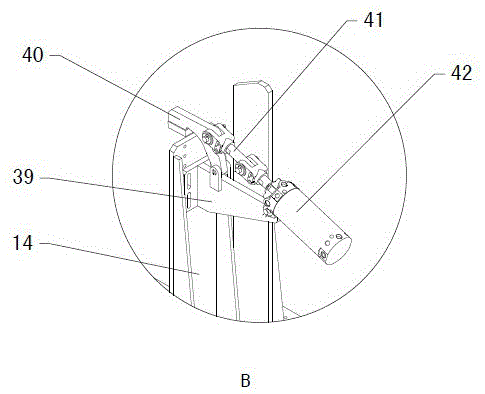

[0043] refer to figure 1 , the curved panel tooling includes a reverse fixed workbench 11, a reverse longitudinal positioning mechanism and a reverse lateral positioning mechanism, and the reverse longitudinal positioning mechanism includes a first bracket 13 and a second bracket 14 fixed on the reverse fixed workbench 11 at intervals, fixed on the The workpiece 10 to be processed on the fixed table 11 on the reverse side is an arc-shaped plate with both ends bent upward. The workpiece 10 to be processed is located between the first bracket 13 and the second bracket 14, and the upper end of the first bracket 13 is provided with the workpiece to be pressed and held. The reverse pressing mechanism at one end of 10, the upper end of the second bracket 14 is provided with a clamping fixture whose height is adjustable and clamps the other end of the workpiece 10 to be processed; The workpieces 10 with different bending heights, and the lower ends of the first bracket 13 and the sec...

Embodiment 2

[0048] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the curved panel tooling also includes a front fixed workbench 12 (the reverse fixed workbench 11 is not drawn in the figure), and the front fixed workbench 12 is arranged on the back fixed workbench 11. On one side, the front fixed workbench 12 and the reverse fixed workbench 11 are slidably arranged independently of each other, and the workpiece 10 to be processed fixed on the front fixed workbench 12 is an arc-shaped plate with both ends bent downwards. The shape of the workpiece 10 selects whether the workpiece 10 to be processed is fixed on the front fixed workbench 12 or the reverse fixed workbench 11. For example, the smoother surface can be used as the upper surface to be fixed on the corresponding curved panel tooling.

[0049] refer to Figure 5 and 6 , two fixed blocks 16 are fixed on the front fixed worktable 12 at intervals, the workpiece 10 to be processed fixed on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com