Damping structure of drilling machine supporting seat

A support seat and drilling machine technology, which is applied to metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of low work efficiency, vibration of the drill bit, vibration of the support seat, etc. The effect of good shock absorption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

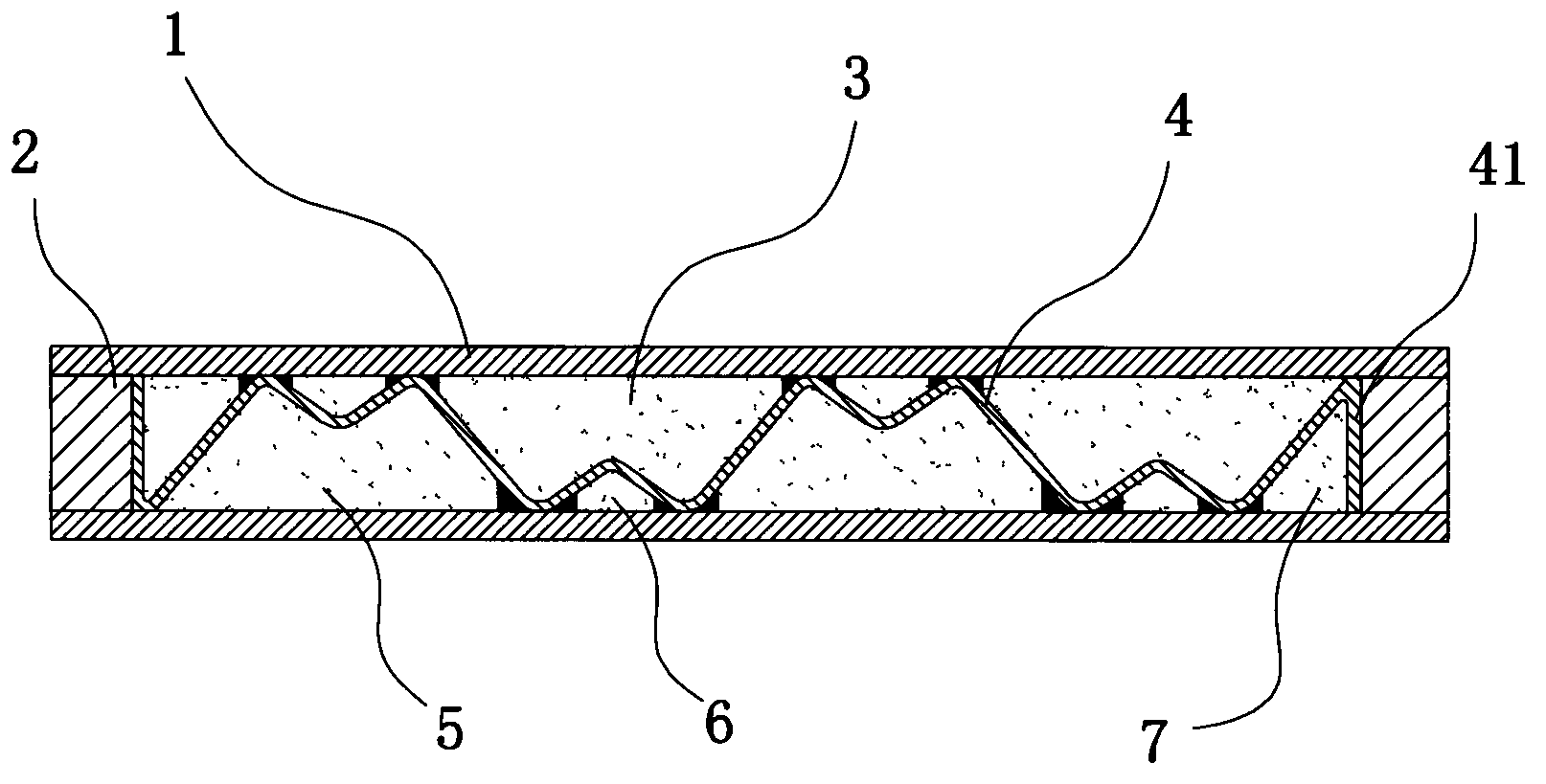

[0010] See figure 1 , the present invention includes a support seat, the support seat includes a wall plate 1 of double-layer structure, the two ends of the wall plate 1 are fixedly connected to the baffle plate 2; The strips 4 are not completely welded, and the damping ribs 4 and the wall plate 1 can slide each other; the cross section of the damping ribs 4 is a curved structure, and the first filling cavity 5 and the second filling cavity are formed between the damping ribs 4 and the wall plate 1. Cavity 6; the two ends of the shock absorbing rib 4 respectively have a vertical plate 41, and the vertical plate 41 is fixedly connected with the baffle plate 2; the two ends of the shock absorbing rib 4 form a third filling cavity 7 between the vertical plate 41 and the wall plate 1 ; The first filling chamber 5, the second filling chamber 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com