Oil temperature control method and device

An oil and temperature setting technology, applied in fluid pressure actuating devices, lubricating parts, fluid pressure actuating system components, etc., can solve the problems of low oil temperature adjustment efficiency and high failure rate of cleaning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

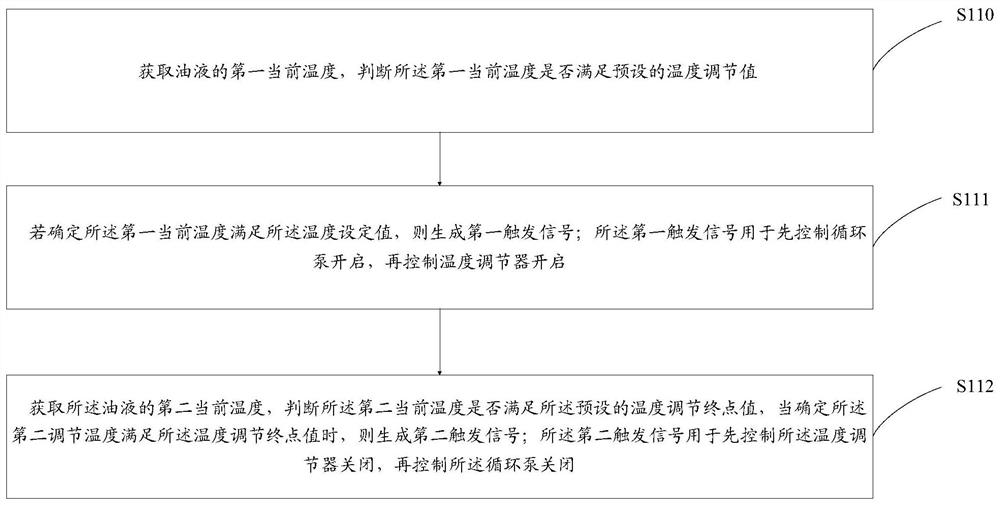

[0047] This embodiment provides an oil temperature control method, such as figure 1 As shown, the methods include:

[0048] S110, acquiring a first current temperature of the oil, and judging whether the first current temperature satisfies a preset temperature setting value;

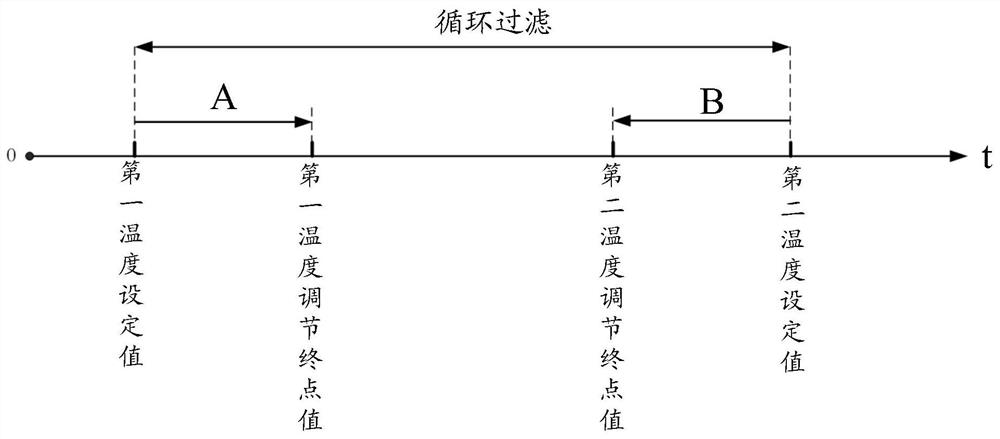

[0049] When the hydraulic system is running, the first current temperature of the oil is obtained by using the temperature monitoring device, and it is judged whether the first current temperature satisfies a preset temperature setting value. Here, when the oil temperature is too high or too low, it will cause the failure of the hydraulic equipment, so see figure 2, the temperature adjustment interval in this embodiment includes two: low temperature adjustment interval A and high temperature adjustment interval B; then the temperature setting value includes: the first temperature setting value and the second temperature setting value, the first temperature setting value The second temperature setting ...

Embodiment 2

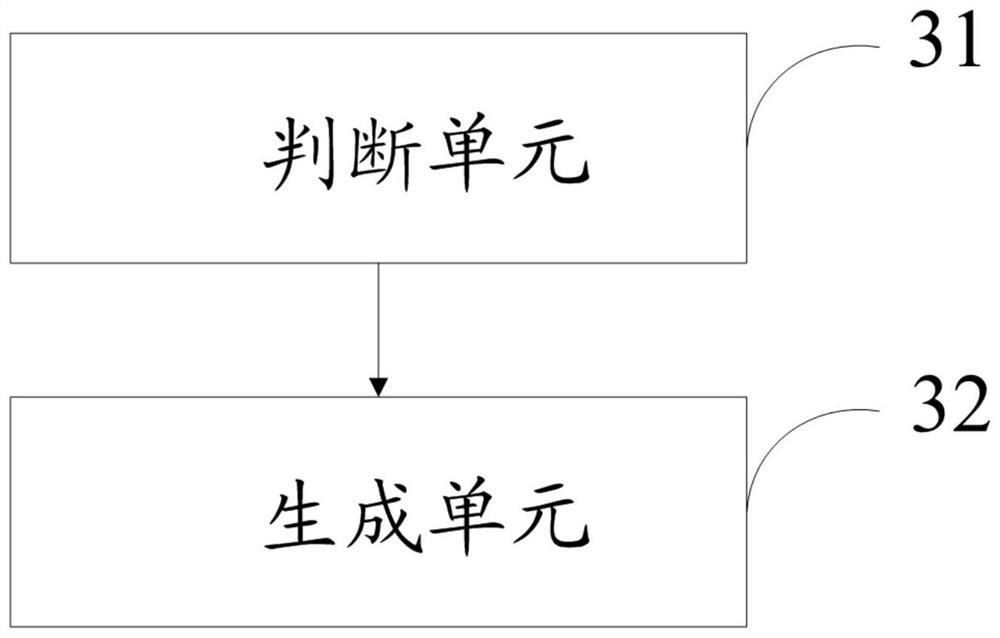

[0082] This implementation provides an oil temperature control device, such as image 3 As shown, the device includes: a judging unit 31 and a generating unit 32; wherein,

[0083] The judging unit 31 is configured to acquire a first current temperature of the oil, and judge whether the first current temperature satisfies a preset temperature setting value; acquire a second current temperature of the oil, and judge the second current temperature Whether the preset temperature adjustment end point value is met;

[0084] A generating unit 32, configured to generate a first trigger signal if it is determined that the first current temperature satisfies the temperature setting value; the first trigger signal is used to first control the circulation pump to be turned on, and then control the temperature regulator to be turned on; When it is determined that the second adjustment temperature satisfies the temperature adjustment end value, a second trigger signal is generated; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com