Annular load box for self-balance method

A load box and self-balancing technology, which is used in construction, infrastructure testing, infrastructure engineering, etc., can solve the problems of unstable grouting effect, small effective area of oil cylinder, and large grouting space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

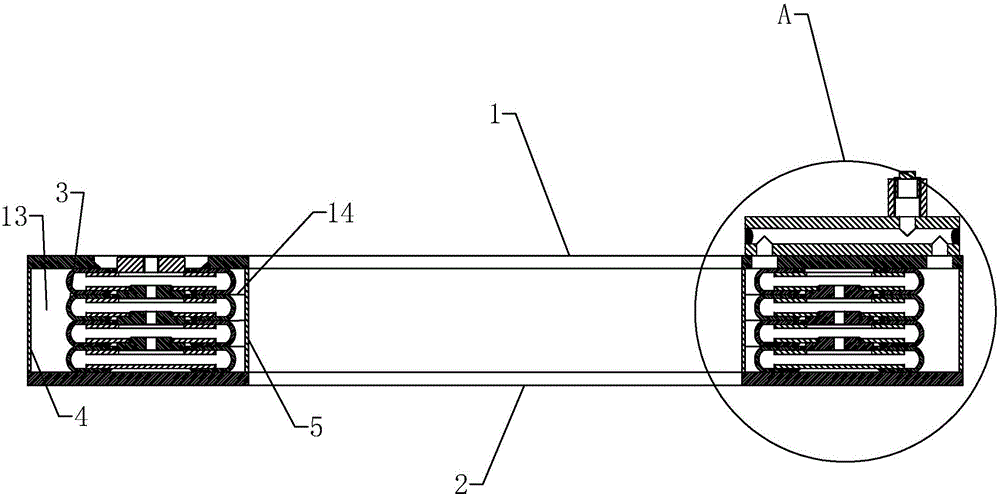

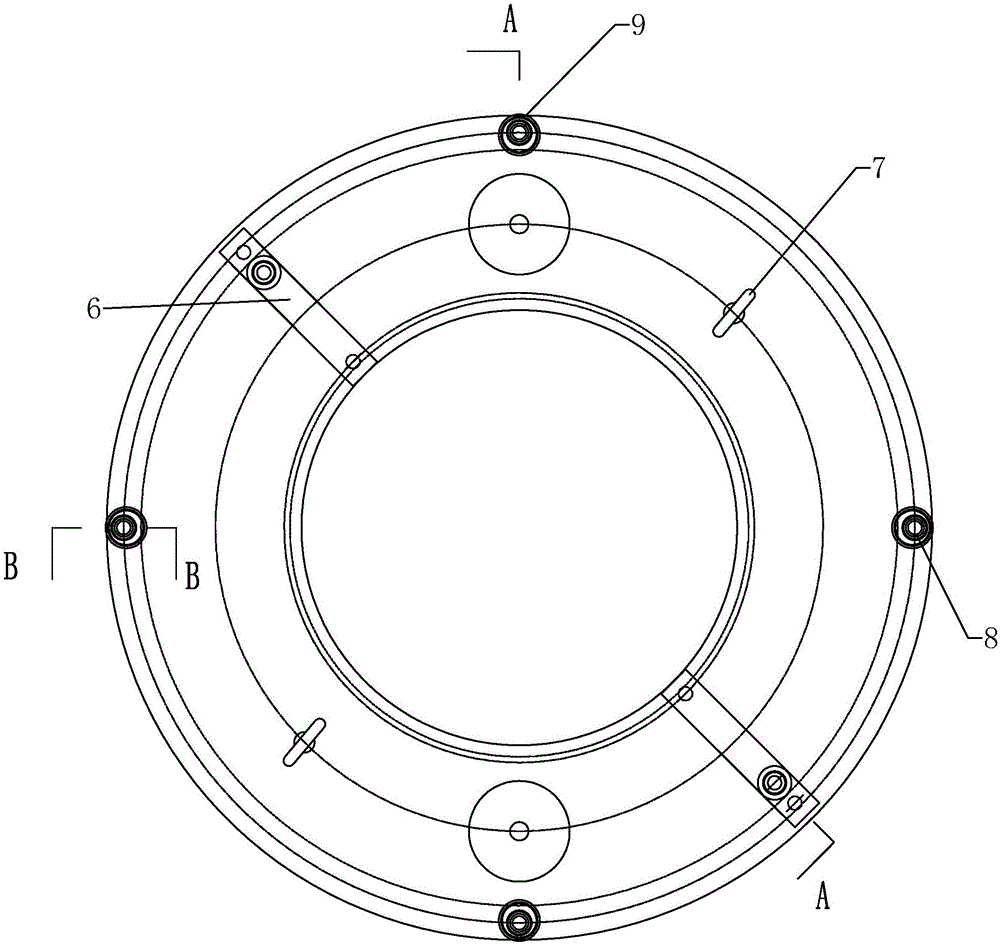

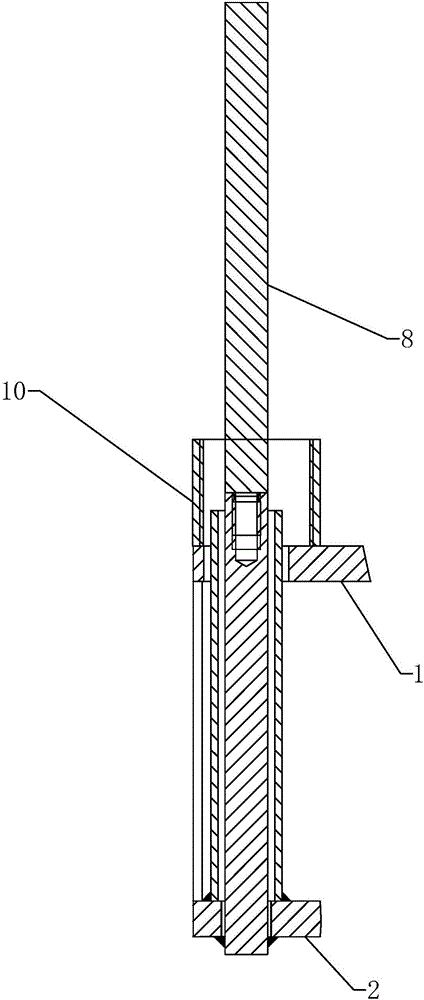

[0024] pass Figure 1 to Figure 4 The self-balancing method of the present invention is further described with an annular load box.

[0025] An annular load box for self-balancing method, comprising an upper annular steel plate 1 , a lower annular steel plate 2 , an outer annular baffle 4 , an inner annular baffle 5 and a pressure device 3 . The upper annular steel plate 1 and the lower annular steel plate 2 are set opposite to each other up and down, and a central hole is opened at the central position for the grouting pipe 11 to pass through. The outer annular baffle plate 4 is connected to the outer edge position of the upper annular steel plate 1 and the lower annular steel plate 2, and the inner annular baffle plate 5 is connected to the inner edge position of the upper annular steel plate 1 and the lower annular steel plate 2, that is, the central hole position, It should be noted here that the upper end of the outer annular baffle 4, the upper end of the inner annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com