Bell valve self-lifting system and working method thereof

An automatic lifting and bell valve technology, which is applied in the direction of fluid pressure actuated system components, valve operation/release devices, lifting valves, etc., can solve the problems of bell valve leakage, bell opening and closing degree cannot be accurately controlled, etc. Achieve the effect of preventing smoke and dust from entering and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

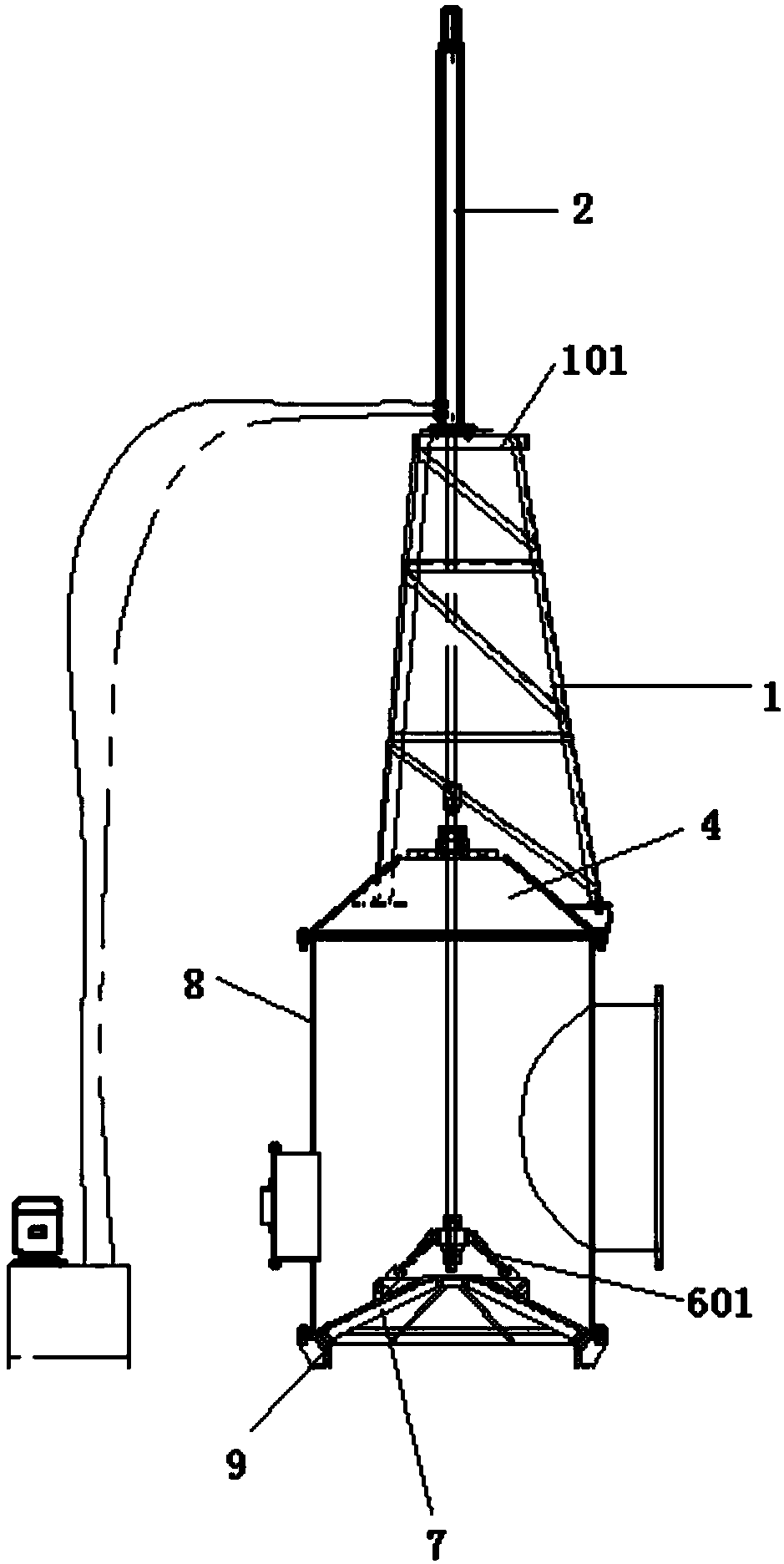

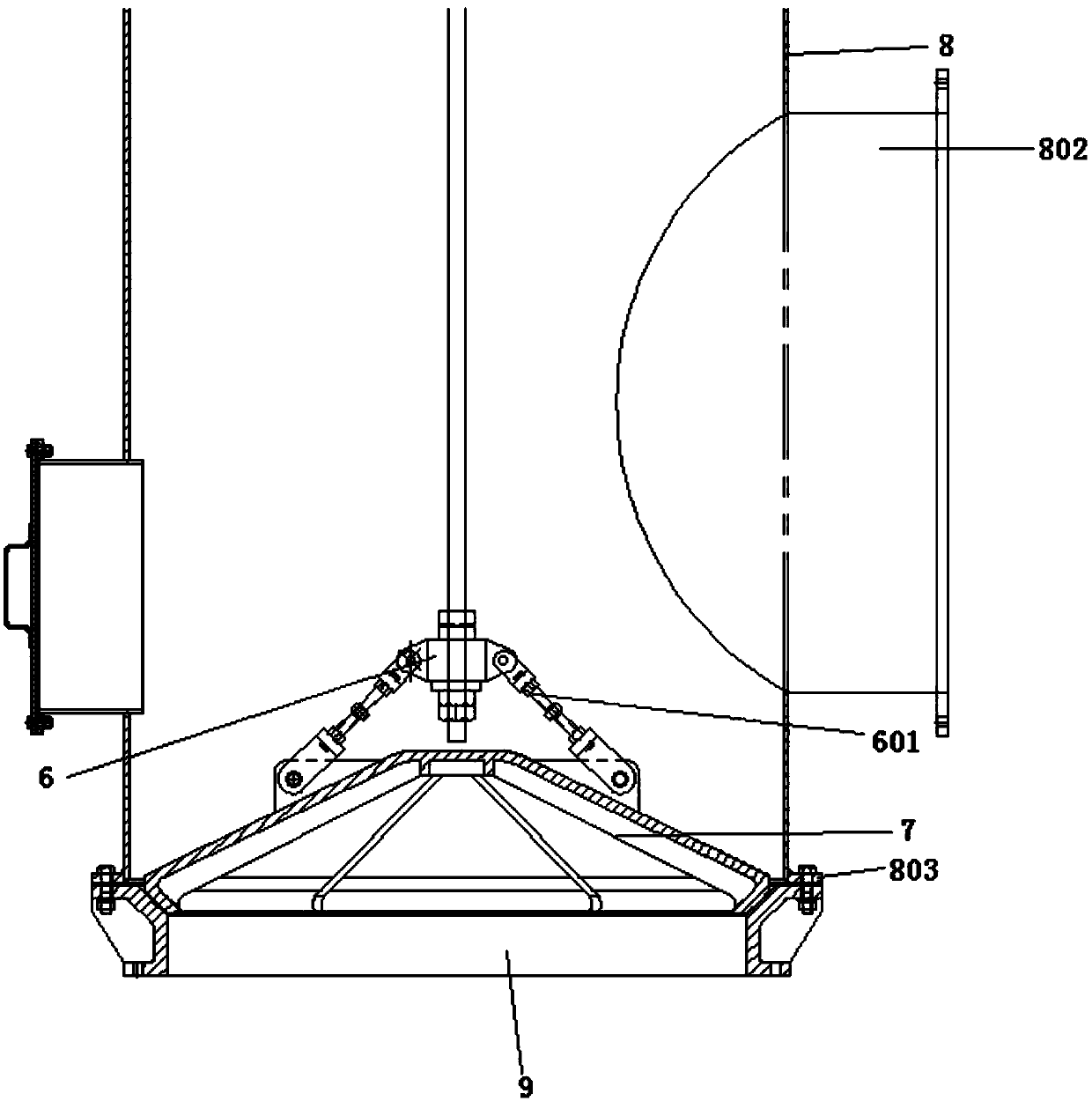

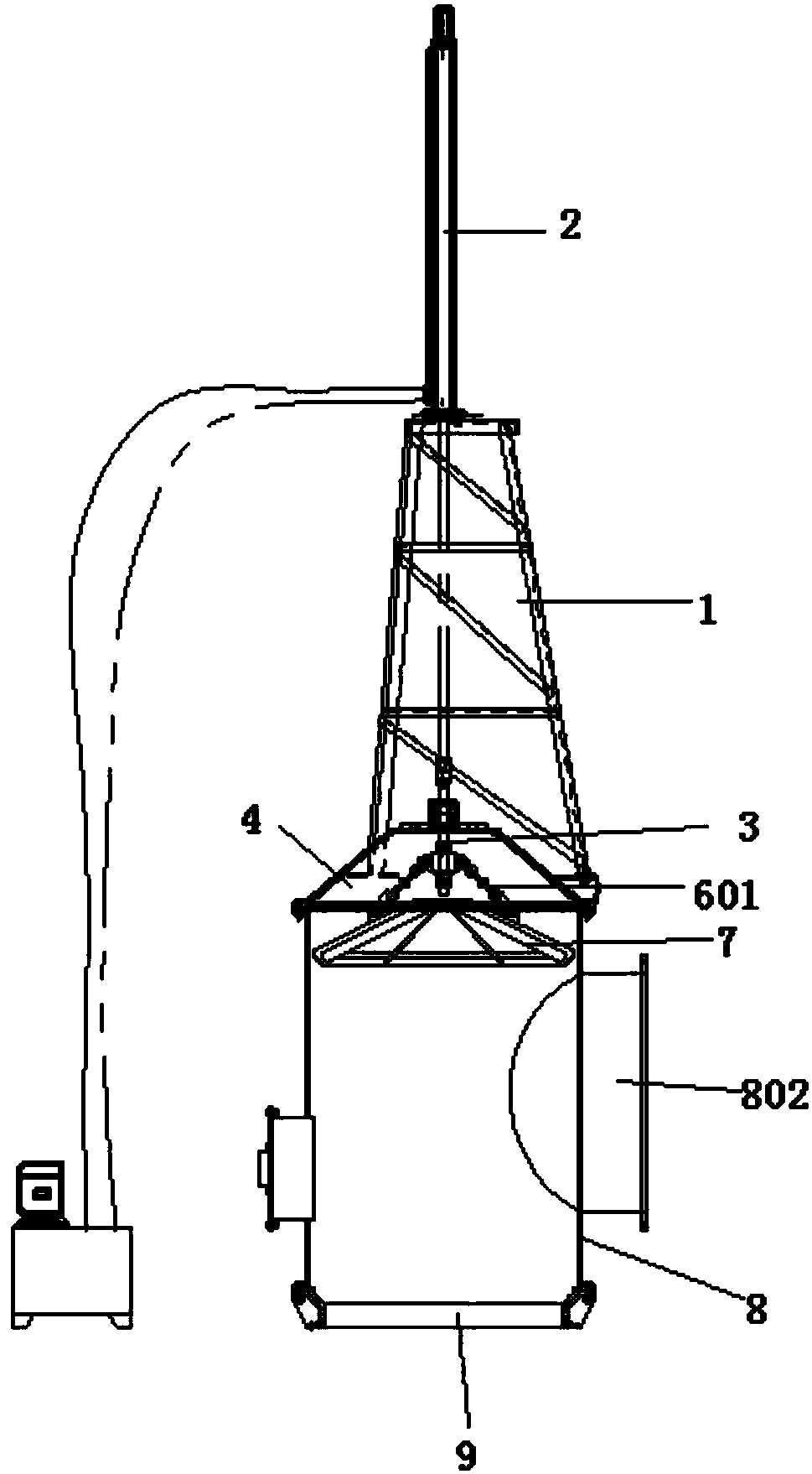

[0029] A bell valve automatic lifting system, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a triangular support 1, a triangular support plate 101 is fixed on the top of the triangular support 1, a through hole is provided at the center of the surface of the triangular support plate 101, a hydraulic cylinder 2 is fixed on the surface of the triangular support plate 101, and the hydraulic cylinder 2 is connected to the high-pressure cylinder The intelligent controller, the high-pressure cylinder intelligent controller is connected to the PLC control system, the power output end of the hydraulic cylinder 2 passes through the through hole on the surface of the triangular support plate 101, and is connected and fixed with vertically distributed suspenders 3, the bottom end of the triangular support 1, etc. A number of first fixed blocks 102 are evenly distributed at an angle, and the bottom end of the first fixed block 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com