A mechanical elevator damping device

A shock absorbing device and mechanical technology, applied in elevators, transportation and packaging, etc., can solve the problems of easy to feel strong vibration, short service life, good shock absorption effect, etc., to improve safety and stability performance, Long service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

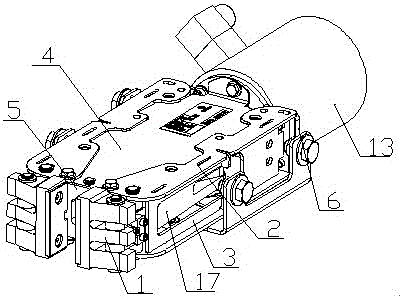

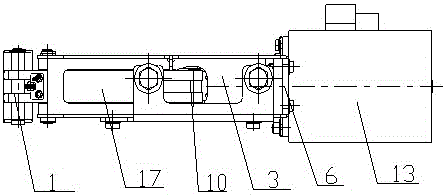

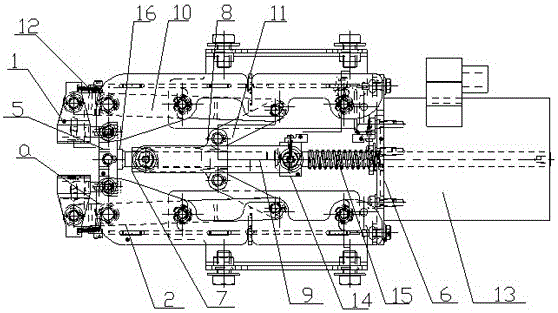

[0018] Such as Figure 1 to Figure 3 As shown, the present invention discloses a mechanical elevator damping device, comprising a frame horizontally installed at the bottom of the elevator car, a crank connecting rod mechanism built in the frame, and a pair of clamping jaws 1 supported at the ends of the frame, one The pair of clamping jaws 1 are driven by a crank connecting rod mechanism to clamp the elevator guide rail, and then lock the bottom of the car on the elevator guide rail.

[0019] The frame is a horizontally arranged rectangular parallelepiped frame. The rectangular parallelepiped frame includes a pair of side frames, a pair of connecting plates A5 and B6 at both ends of the long axis of the side frame, and a pair of baffles 4 covering the top and bottom of the side frame. The frame is formed by a pair of parallel outer plates 2 and a side plate 3 vertically connected between the outer plates 2 in a U-shaped connection, with a U-shaped groove on the inner side; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com