Substrate forming device for producing reconstituted tobaccos through dry paper-making method

A molding device and a technology for reconstituted tobacco leaves are applied in the field of substrate forming devices for producing reconstituted tobacco leaves by a dry papermaking method, which can solve the problems of quantitative vertical and horizontal deviation, affecting the quality of the substrate, and the inability of fibers to fall evenly, and achieves improved accuracy, accuracy, and efficiency. Good to break up fibers and reduce the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

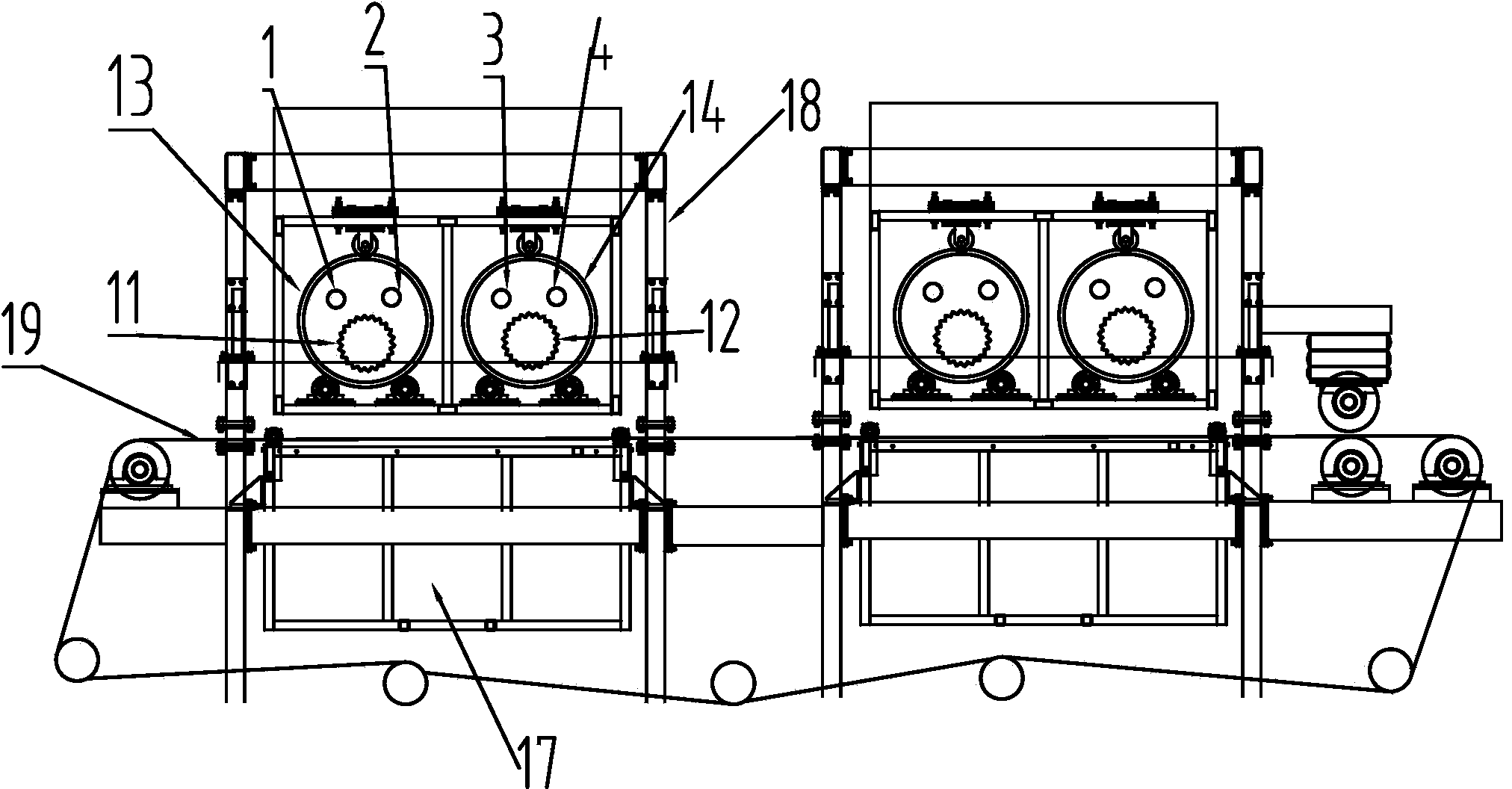

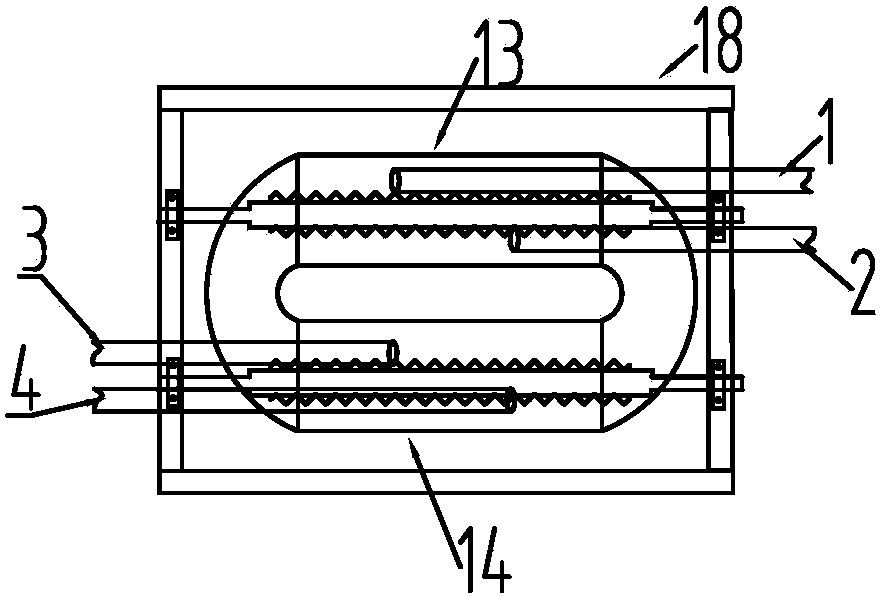

[0031] Such as figure 1 Shown, two groups of molding heads are installed under the frame 18, and every group of molding heads is provided with two groups of sieve cylinders. First screen drum 13 and second screen drum 14 are respectively provided with a first breaking roll 11 and a second breaking roll 12, and first screen drum 13 is provided with a first fiber delivery pipeline 1 and a second fiber delivery pipeline 2 , the second screen drum 14 is provided with a third fiber delivery pipeline 3 and a fourth fiber delivery pipeline 4 .

[0032] Among them, attached figure 2 and 5 As shown, the length of the first fiber delivery pipeline 1 and the fourth fiber delivery pipeline 4 is 50 cm, and the length of the second fiber delivery pipeline 2 and the third fiber delivery pipeline 3 is 30 cm.

[0033] A front annular channel 15 and a rear annular channel 16 are respectively provided between the first screen drum 13 and the second screen drum 14 .

[0034] Open the forming...

Embodiment 2

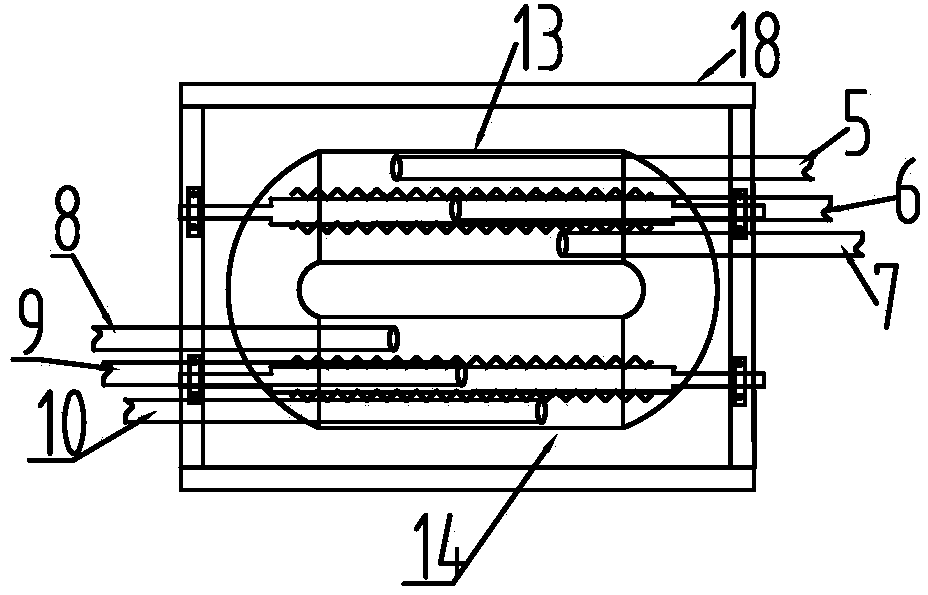

[0038] Such as image 3 Shown, similar to embodiment 1. The difference is that three fiber pipes are set in each screen drum, the length of fiber pipes 7 and 8 is 35CM, the length of fiber pipes 6 and 9 is 45CM, and the length of fiber pipes 5 and 10 is 55CM.

Embodiment 3

[0040] Such as Figure 4 Shown, similar to embodiment 1. The difference is that three fiber delivery pipes are set in each screen drum, the length of fiber delivery pipes 7 and 8 is 30CM, the length of fiber delivery pipes 6 and 9 is 40CM, and the length of fiber delivery pipes 5 and 10 is 50CM. Production of substrates for dry-laid papermaking reconstituted tobacco leaves, the quantitative detection of the substrates, once every half hour within 8 hours, the quantitative range is 20-22g / m 2 , the fluctuation range is ≤±5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com