Patents

Literature

36results about How to "Waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

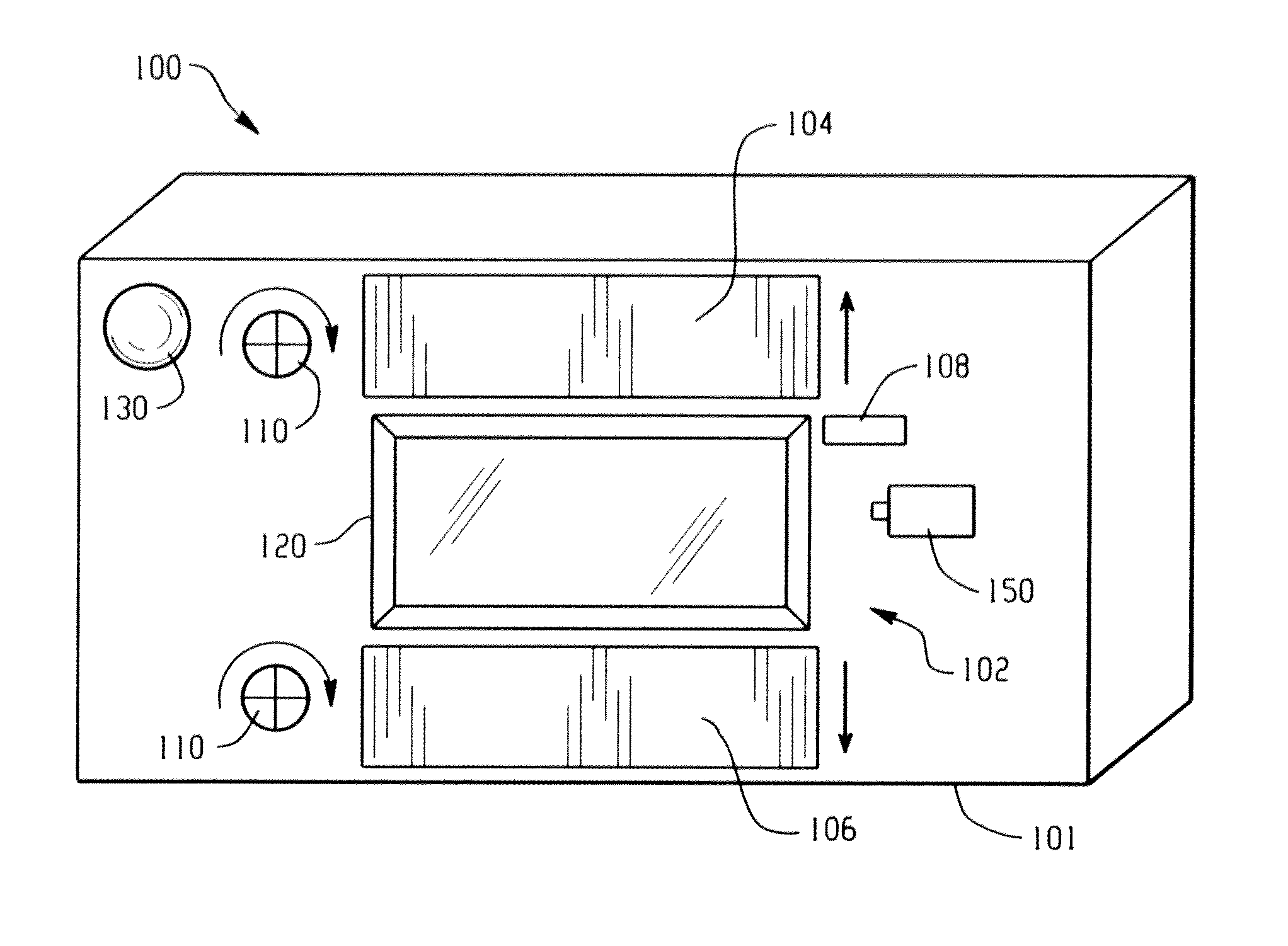

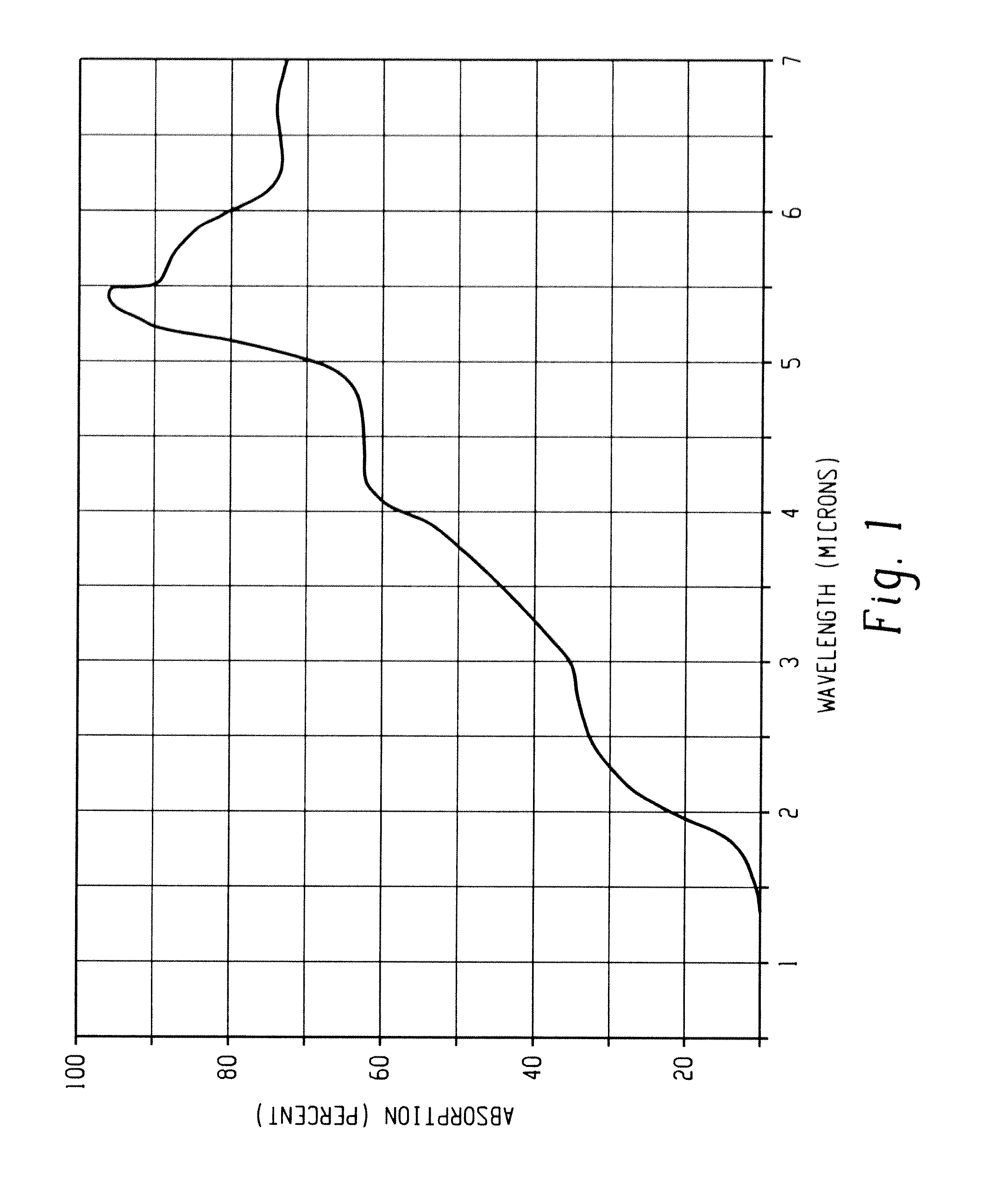

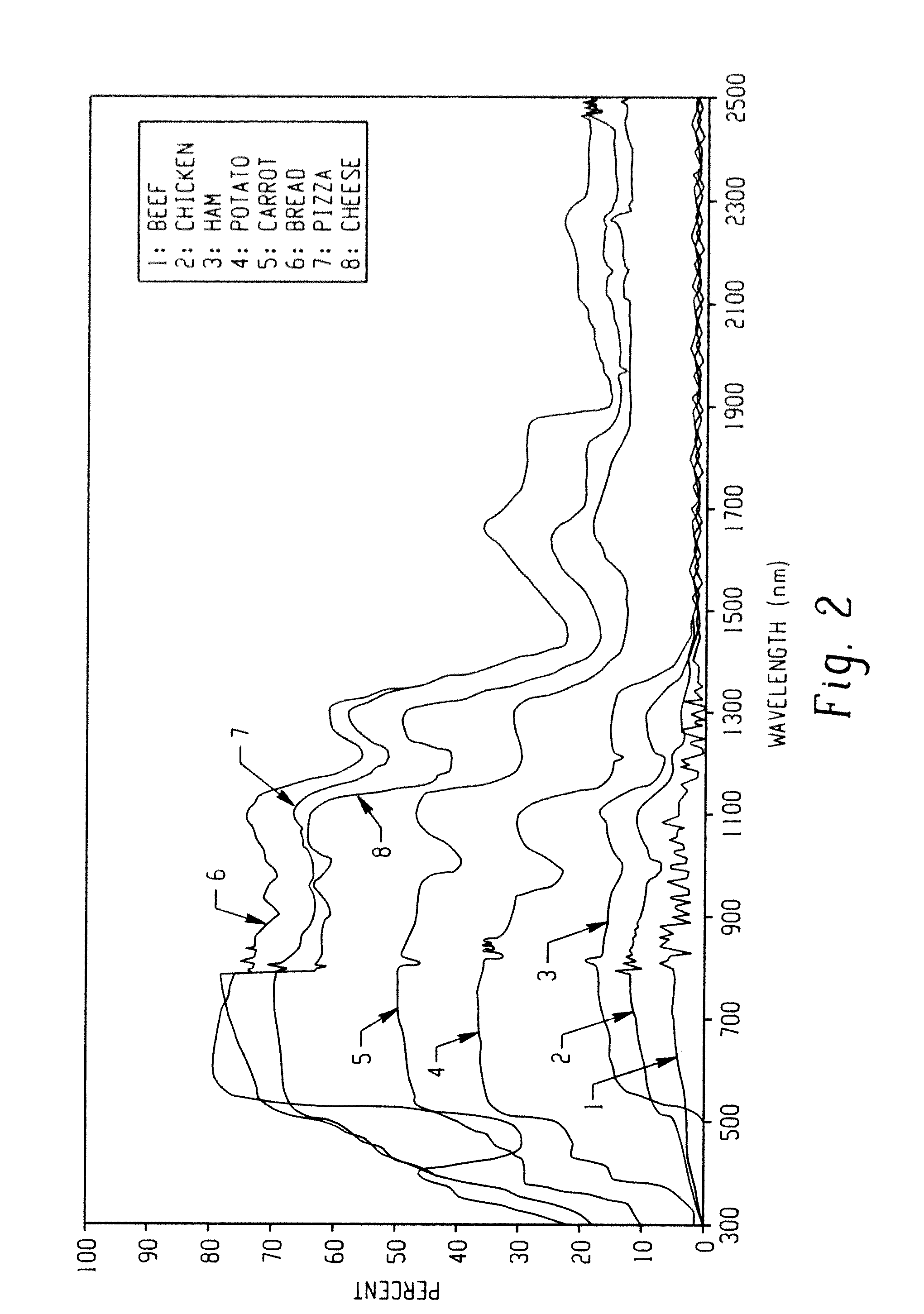

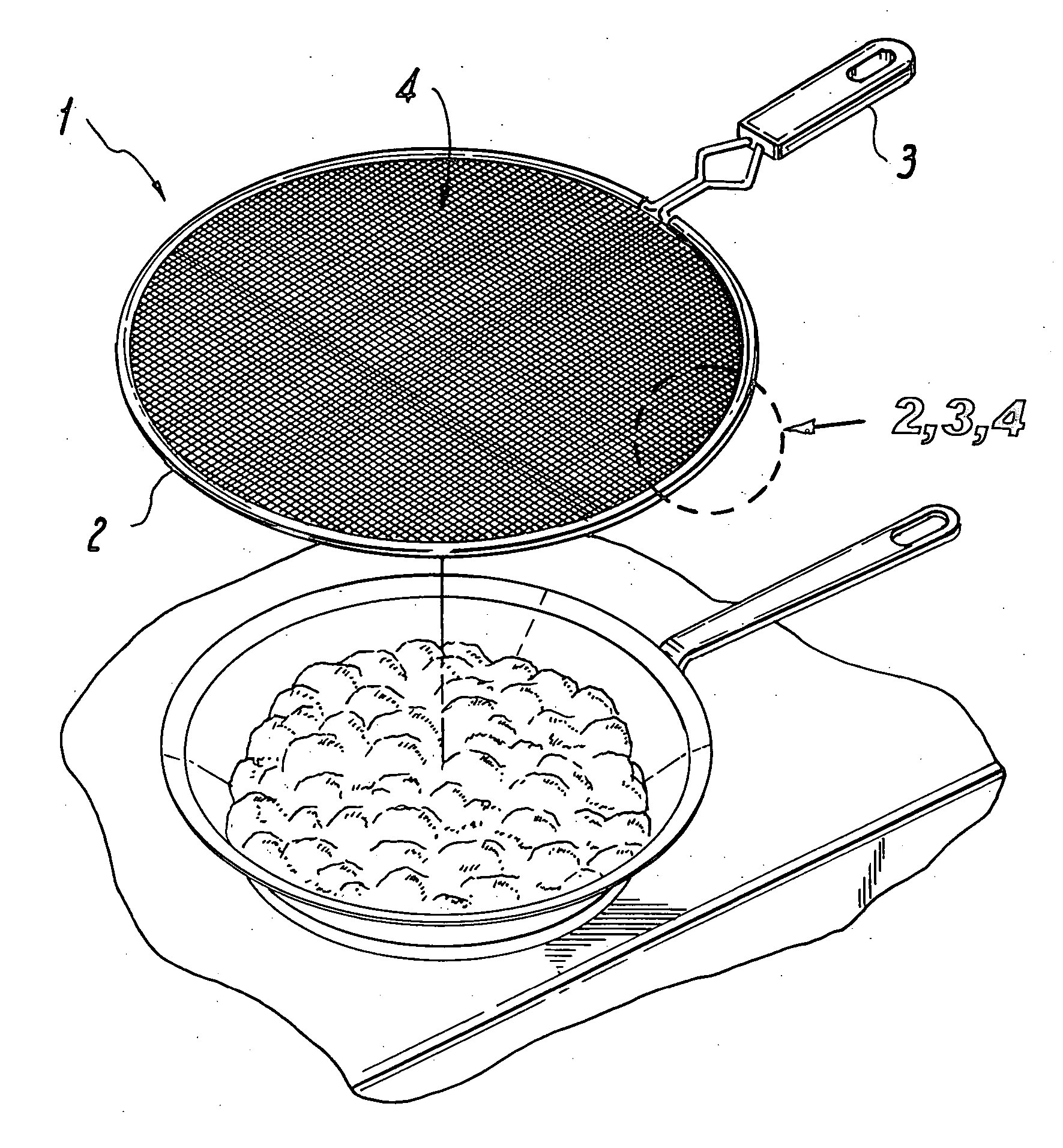

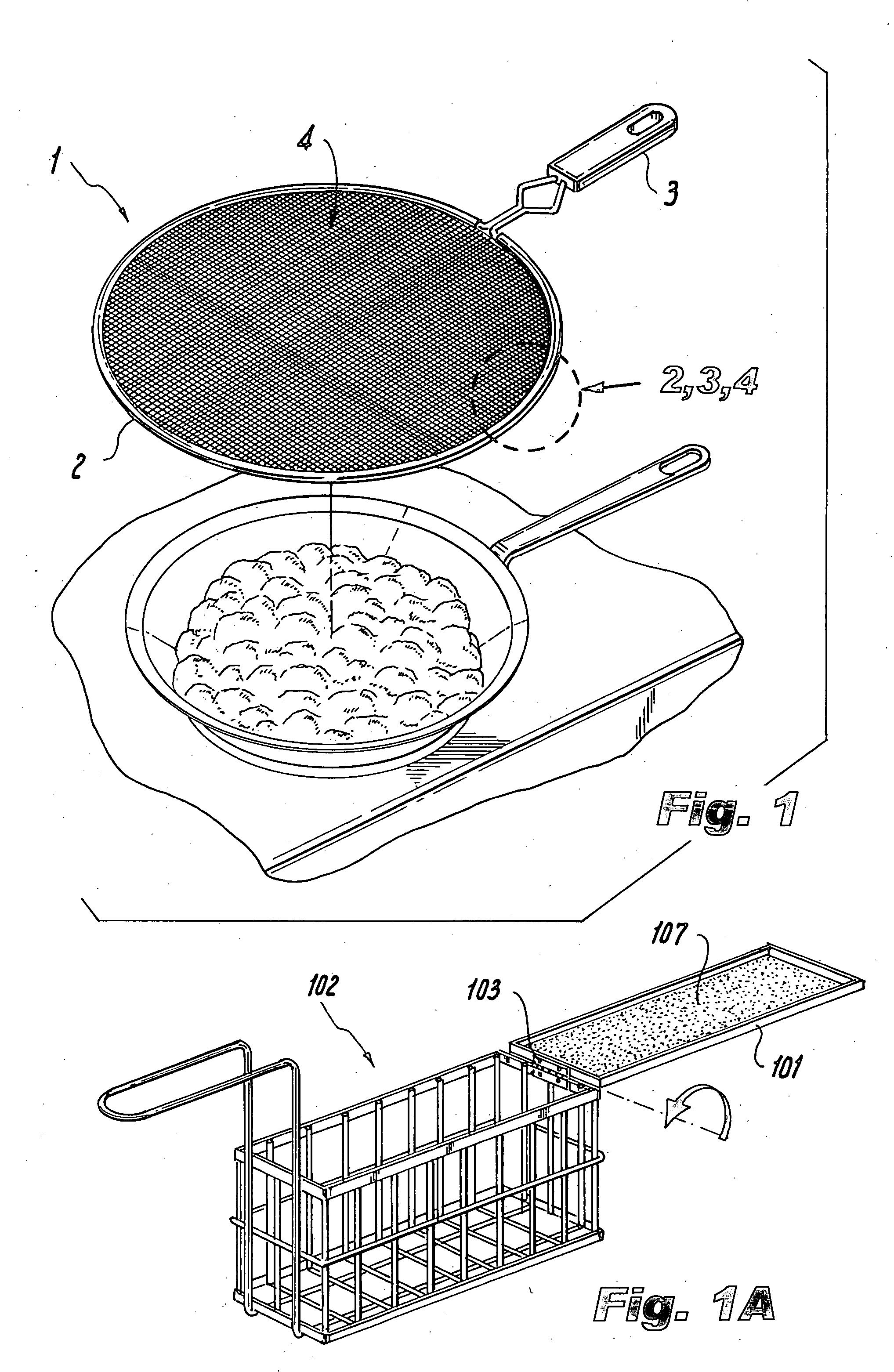

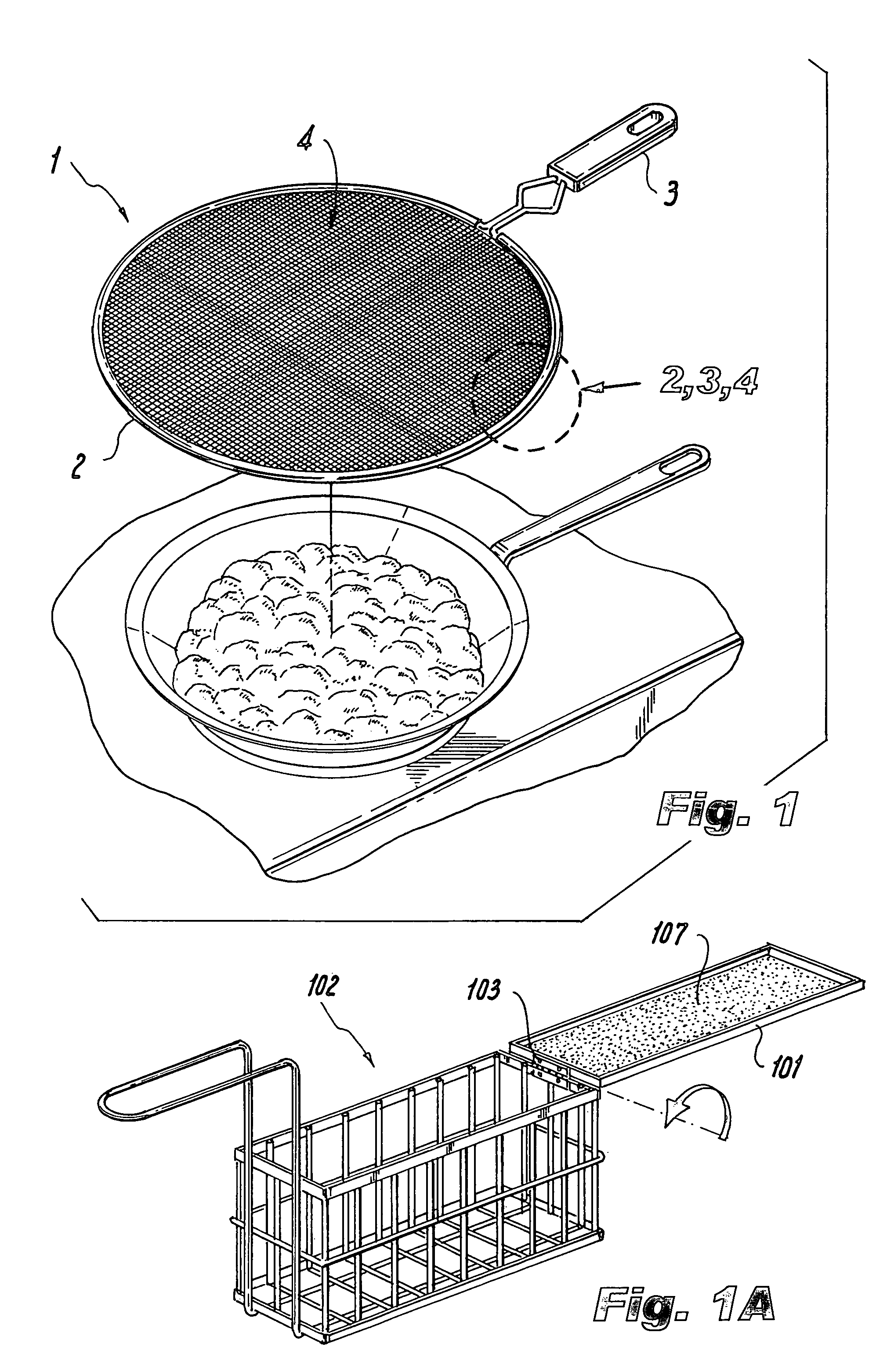

Method and system for digital narrowband, wavelength specific cooking, curing, food preparation, and processing

ActiveUS20110002677A1Input energy efficientFunction increaseDomestic stoves or rangesDrying solid materials with heatEngineeringLength wave

A system for direct injection of selected thermal-infrared (IR) wavelength radiation or energy into food items for a wide range of processing purposes is provided. These purposes may include heating, raising or maintaining the temperature of the food articles. The system is especially applicable to operations that require or benefit from the ability to irradiate at specifically selected wavelengths or to pulse or inject the radiation. The system is particularly advantageous when functioning at higher speeds and in a non-contact environment with the target.

Owner:PRESSCO IP LLC

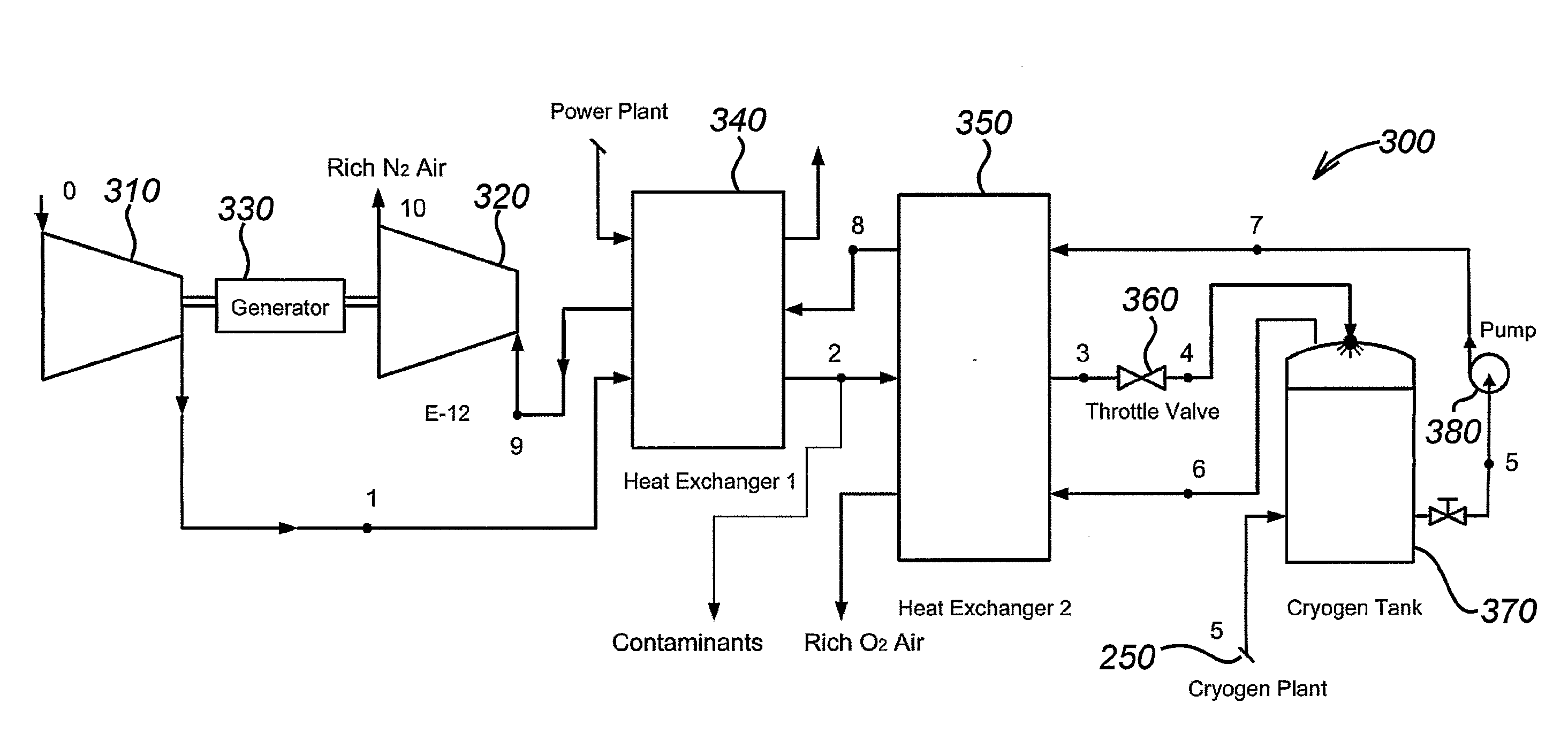

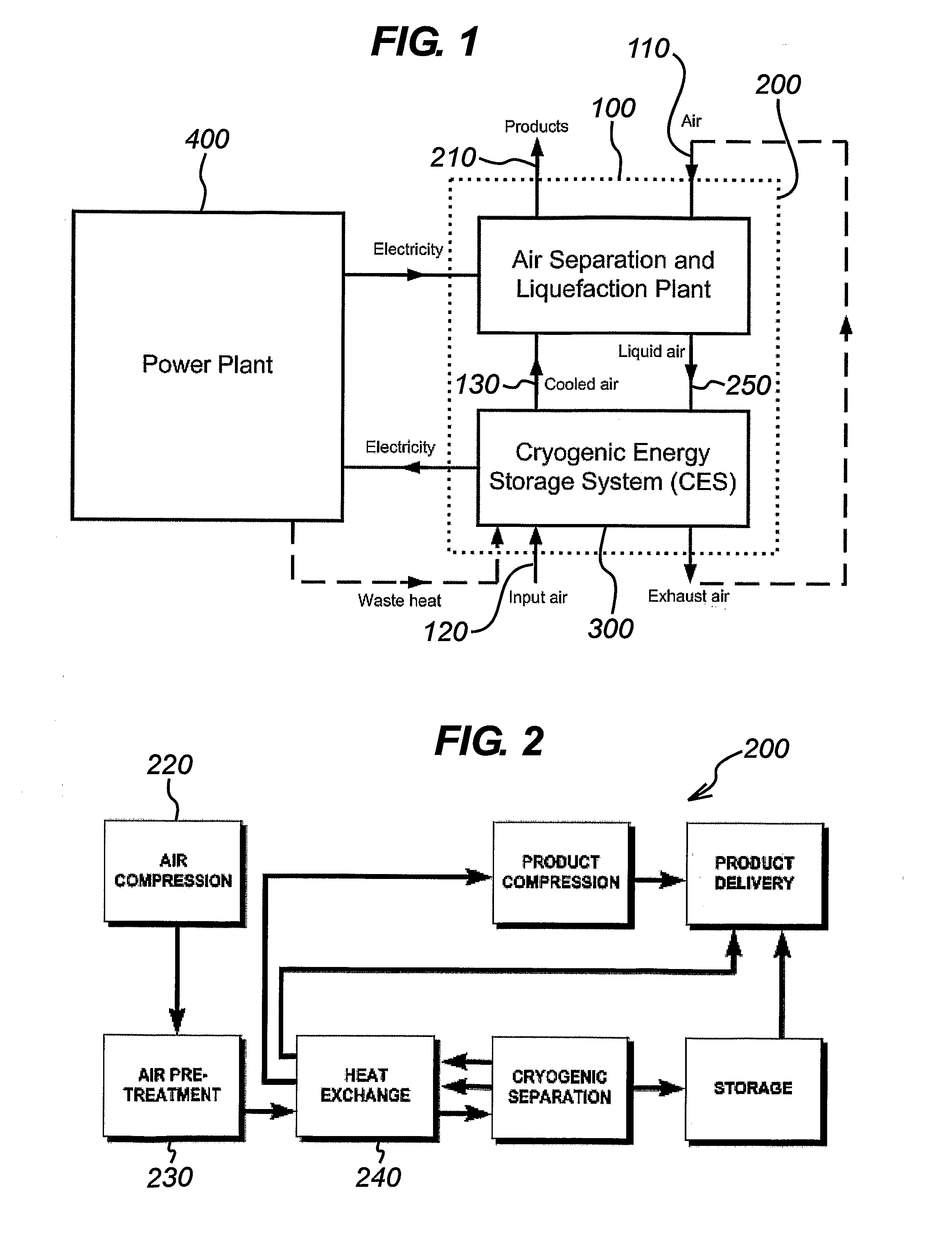

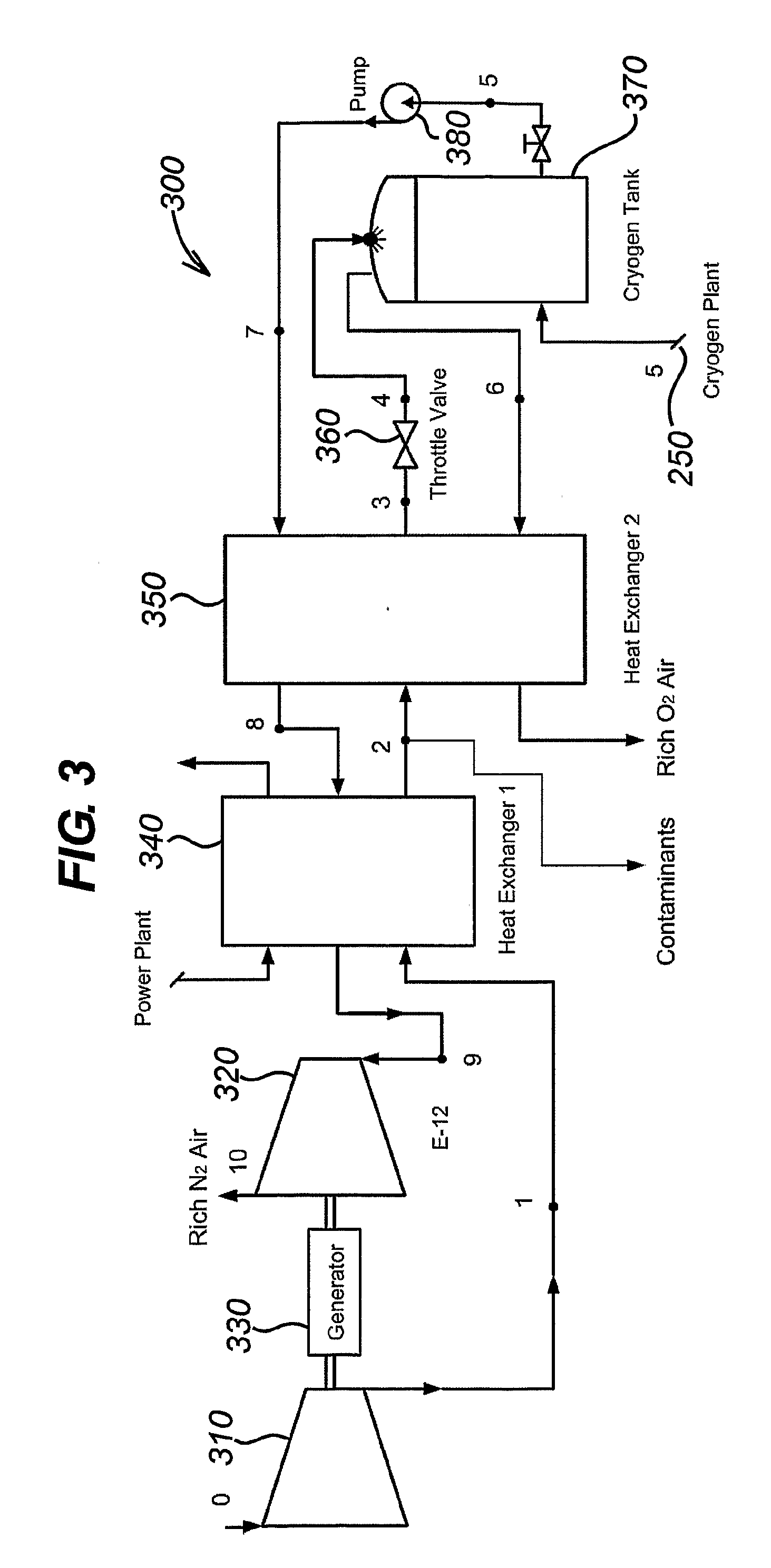

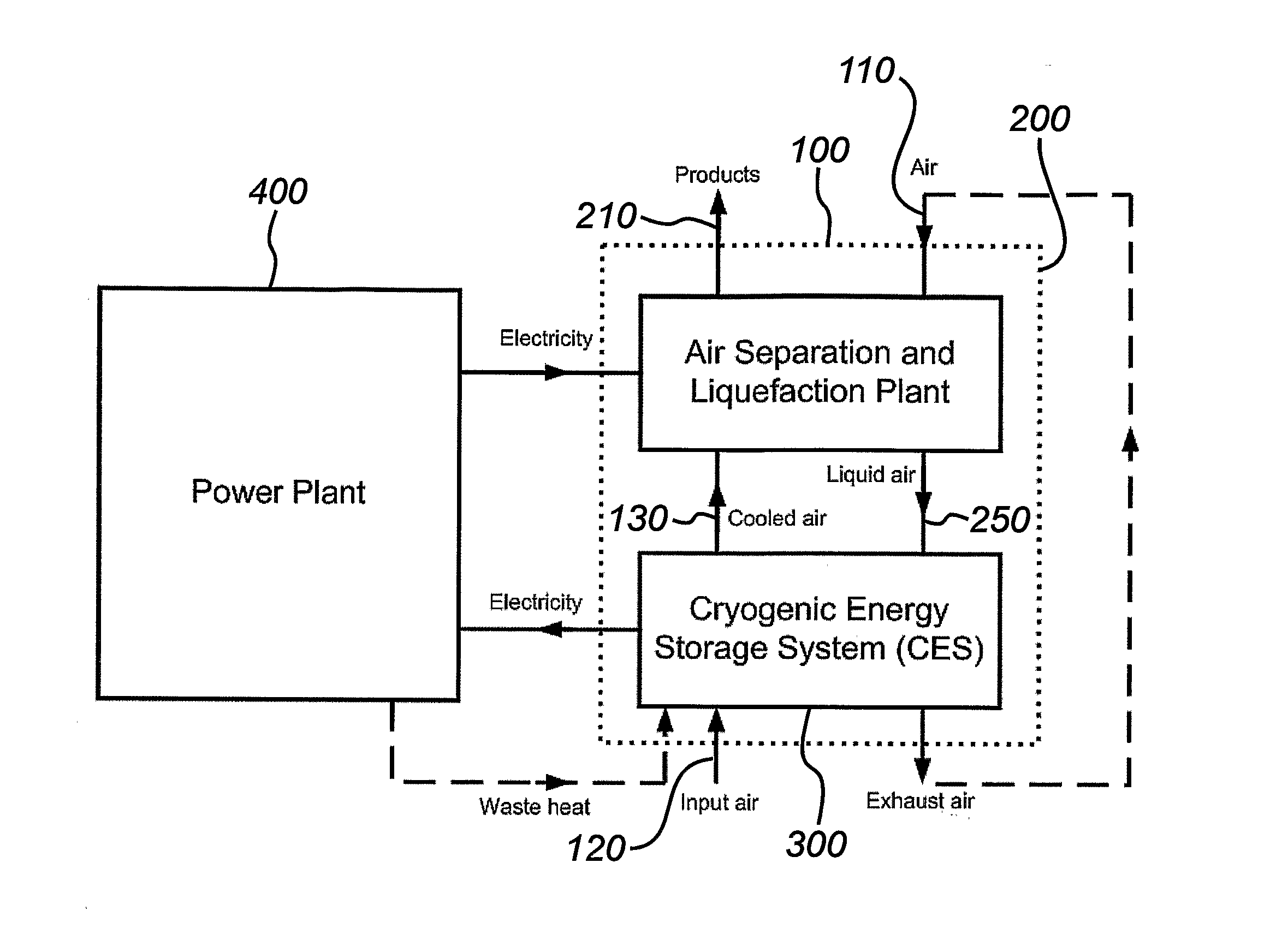

Energy storage and generation

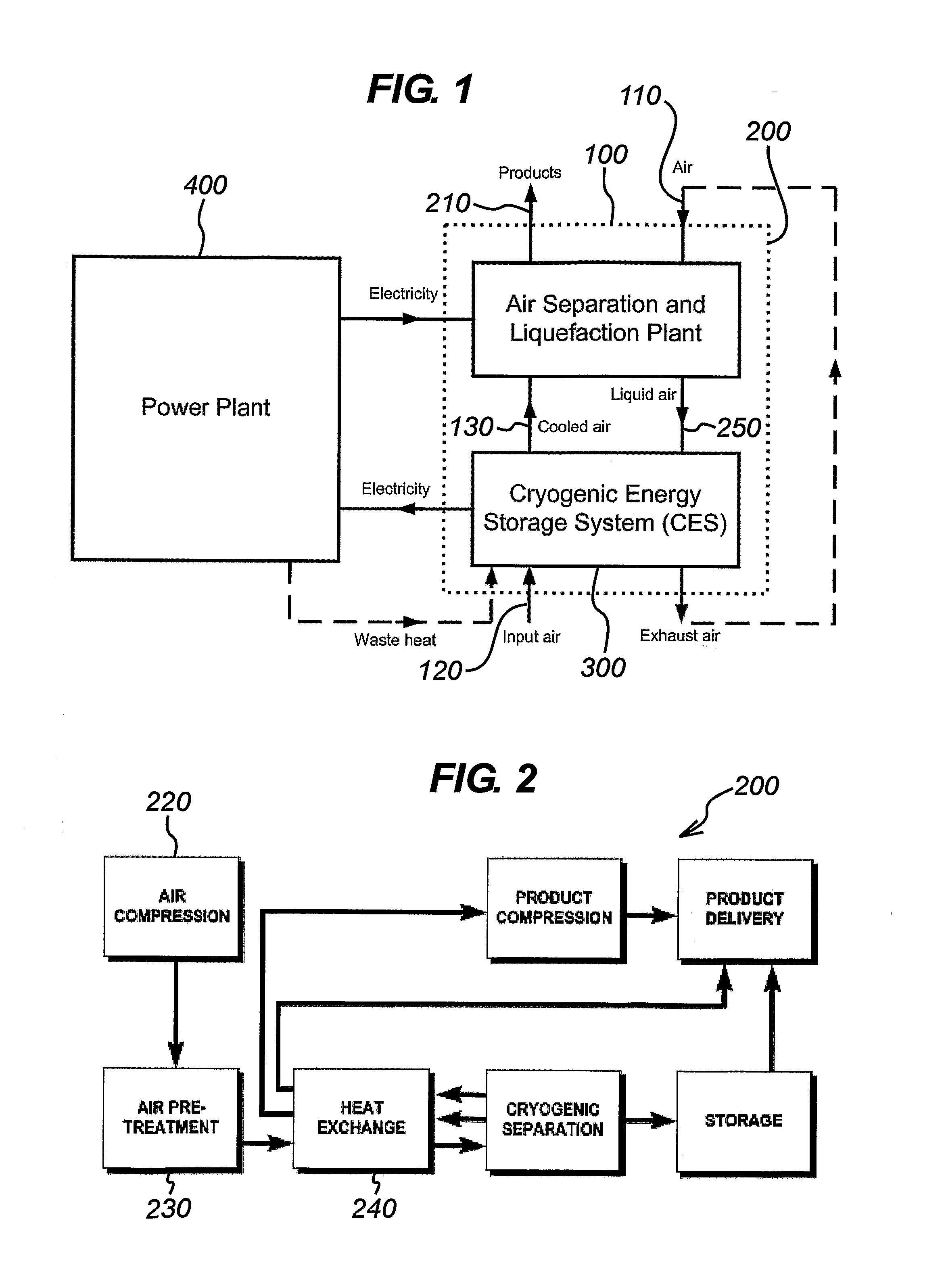

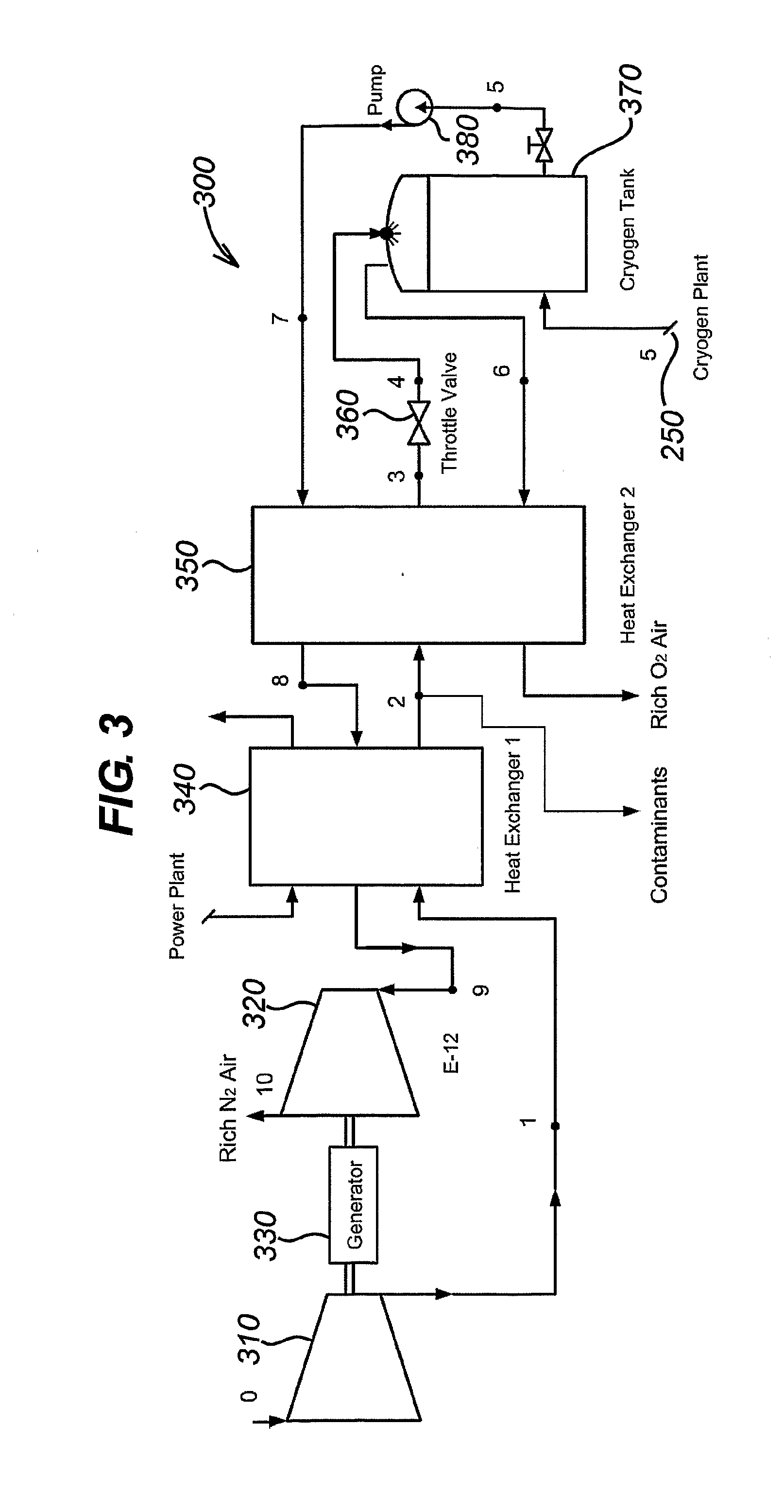

InactiveUS20090282840A1Maximize useMinimize changesSolidificationLiquefactionPropellerProcess engineering

The present invention concerns systems for storing energy and using the stored energy to generate electrical energy or drive a propeller (505). In particular, the present invention provides a method of storing energy comprising: providing a gaseous input, producing a cryogen from the gaseous input; storing the cryogen; expanding the cryogen; using the expanded cryogen to drive a turbine (320) and recovering cold energy from the expansion of the cryogen. The present invention also provides a cryogenic energy storage system comprising: a source of cryogen; a cryogen storage facility (370); means for expanding the cryogen; a turbine (320) capable of being driven by the expanding cryogen; and means (340, 350) for recovering cold energy released during expansion of the cryogen.

Owner:HIGHVIEW ENTERPRISES LTD

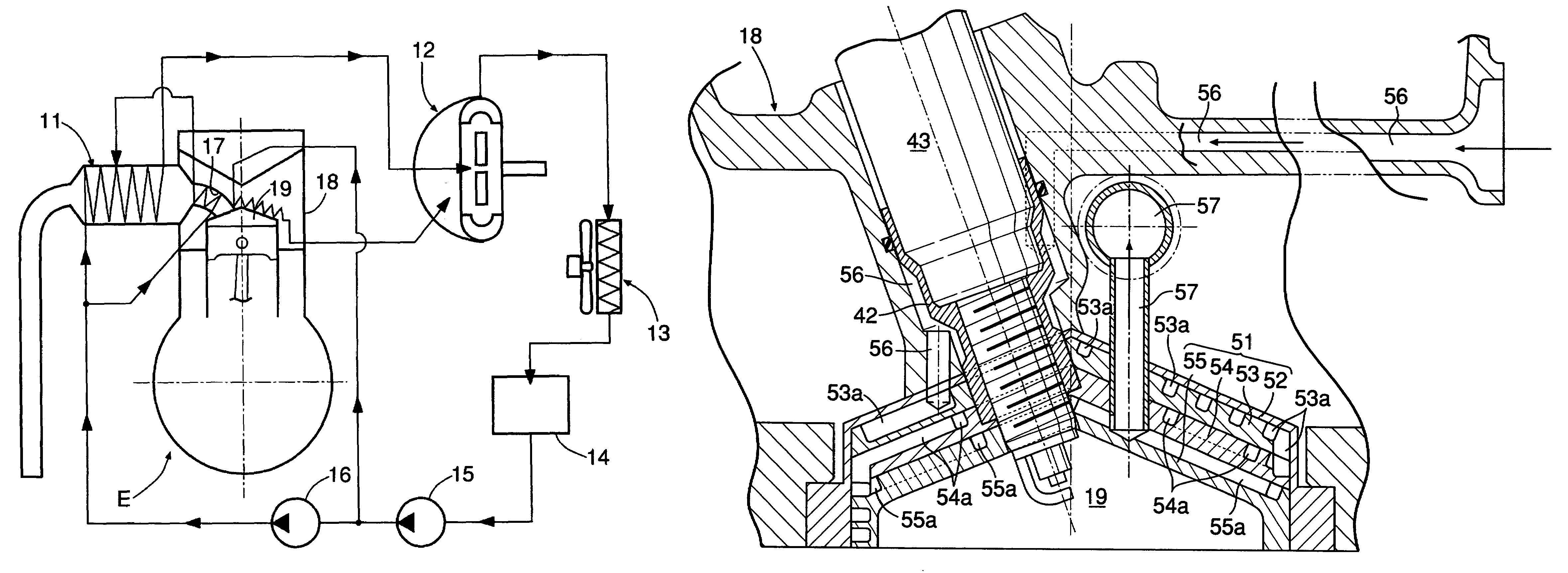

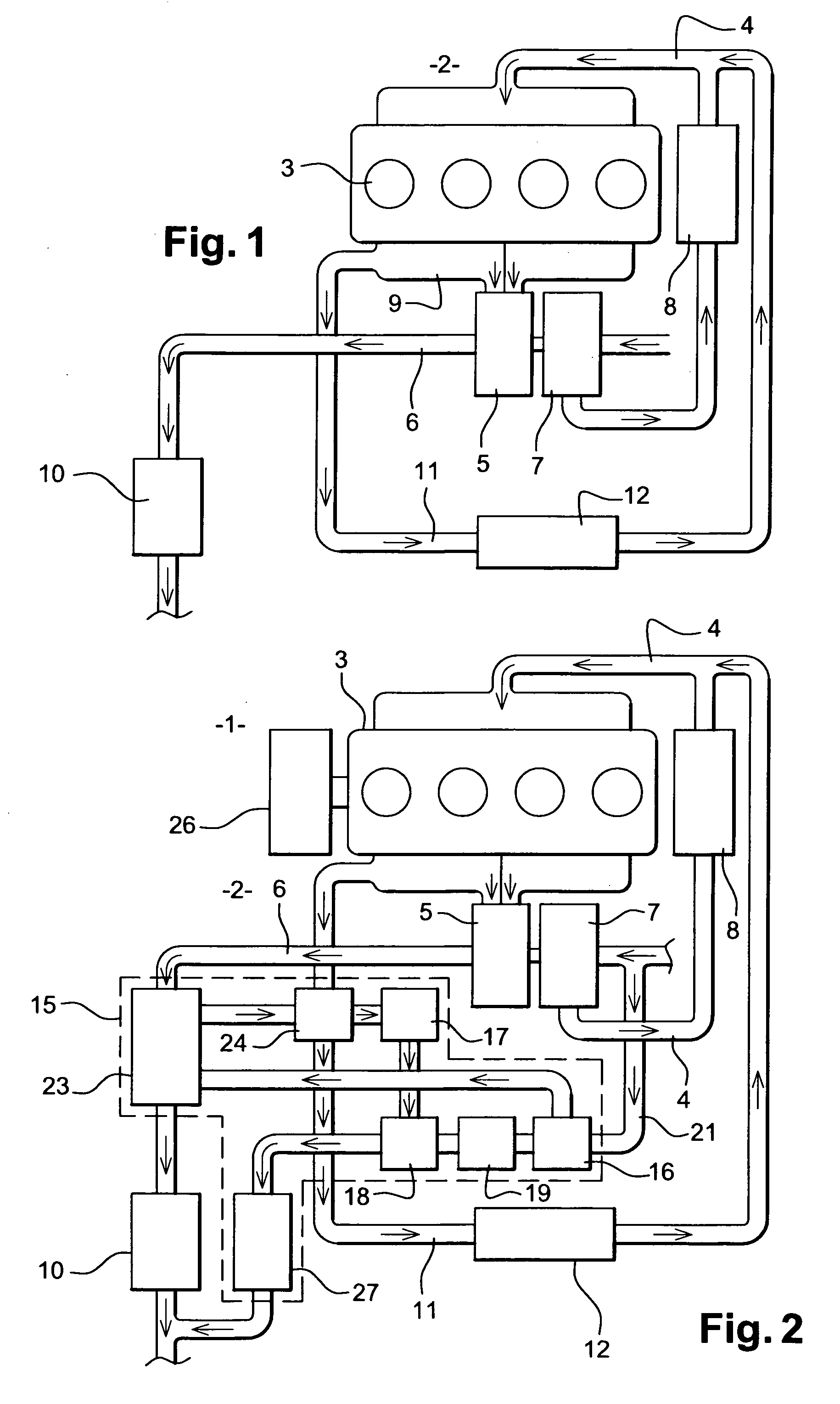

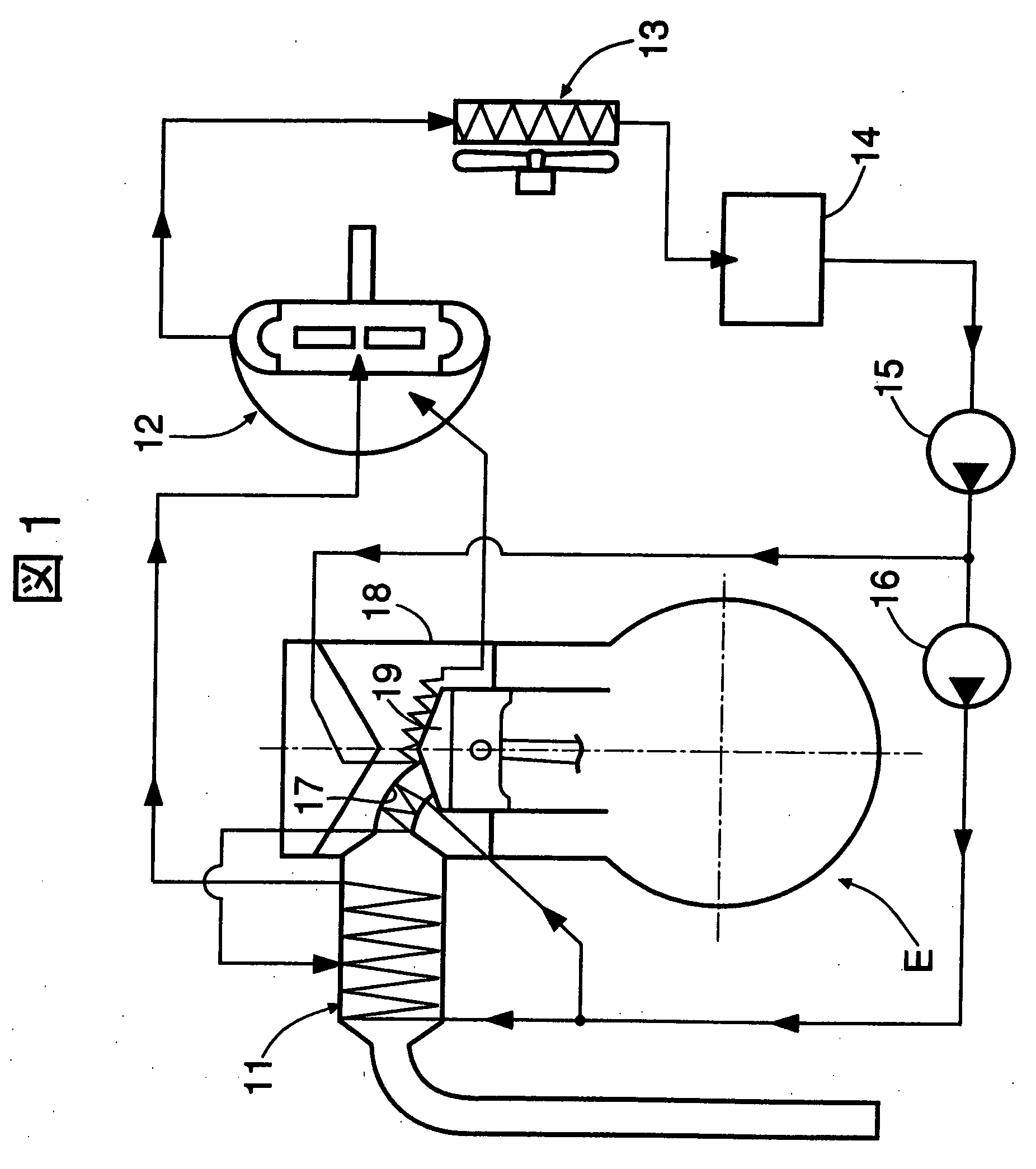

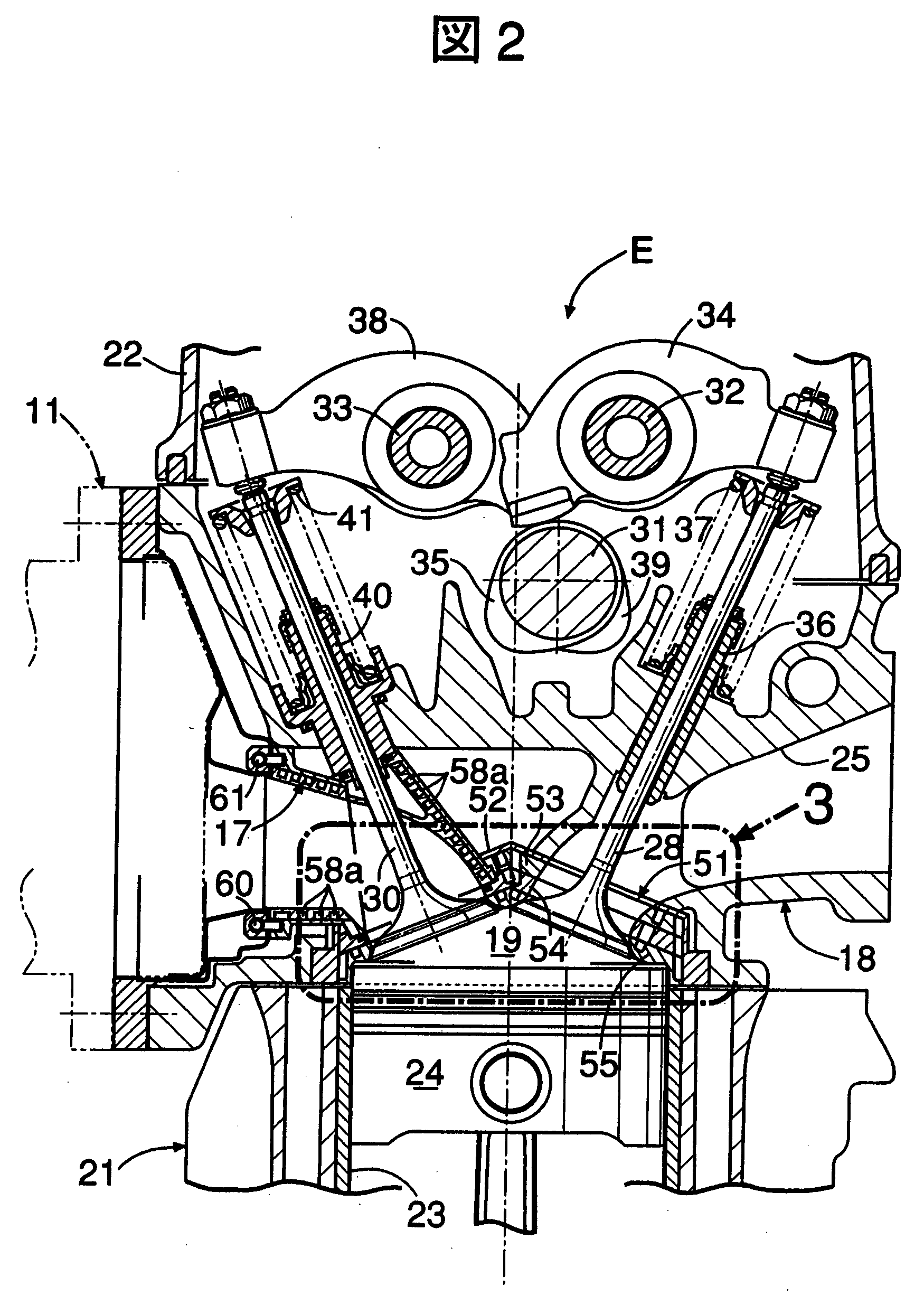

Internal combustion engine

InactiveUS7191740B2Good effectIncrease temperatureLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

A cooling block forming a top wall of a combustion chamber of an internal combustion engine is formed by layering, from the outside to the inside, a casing, an upper layer block, a middle layer block, and a lower layer block. Labyrinth-shaped cooling water passages are formed on upper side faces of the three layers of blocks, and cooling water supplied from a cooling water supply passage flows from the cooling water passage on the side far from the combustion chamber to the cooling water passage on the side close to the combustion chamber, and is discharged from a cooling water discharge passage. Since the cooling water flows in a direction opposite to the direction of emission of heat of combustion from the combustion chamber, it is possible to ensure that there is sufficient difference in temperature between a cylinder head and the cooling water throughout the cooling water passages.

Owner:HONDA MOTOR CO LTD

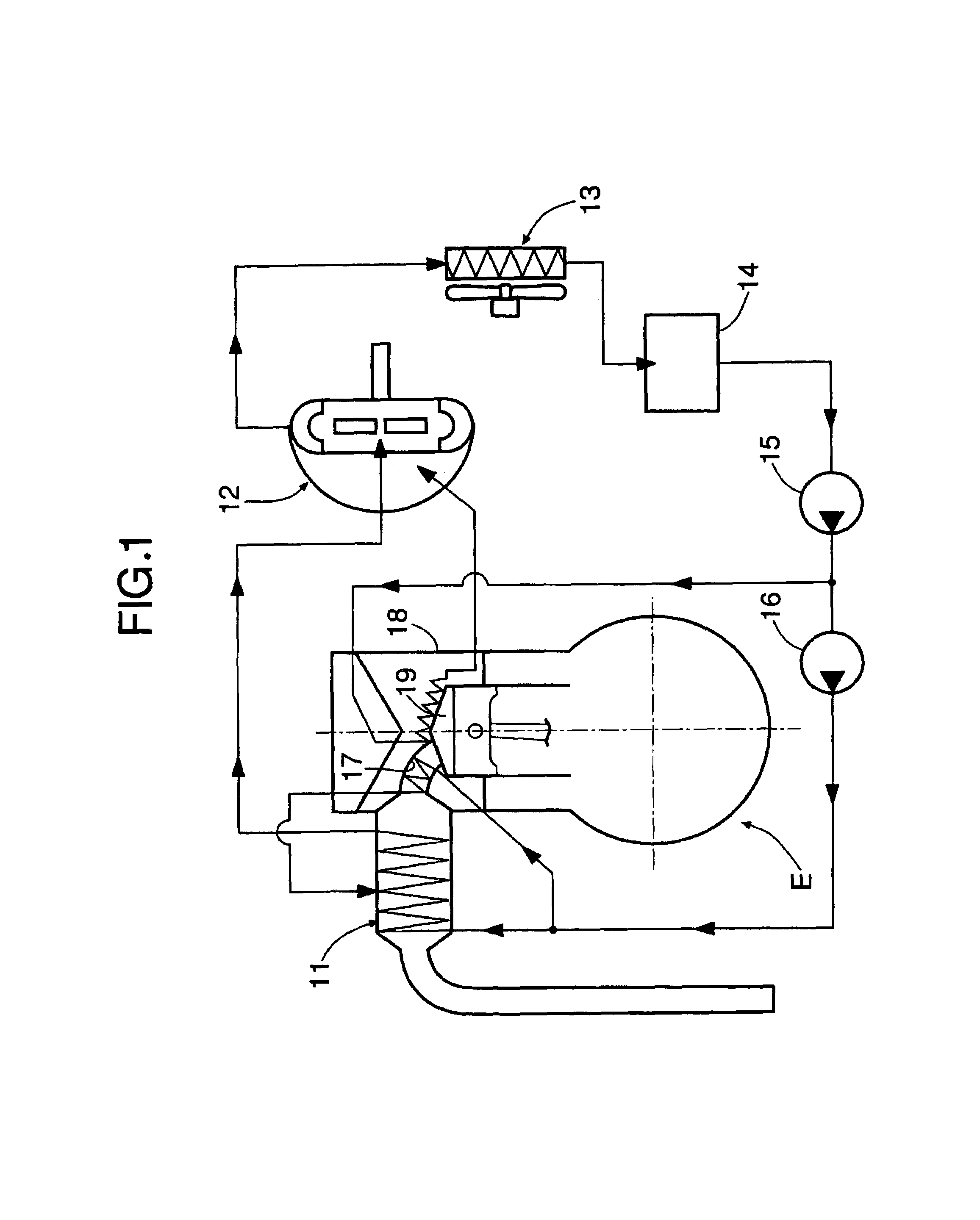

Internal combustion engine

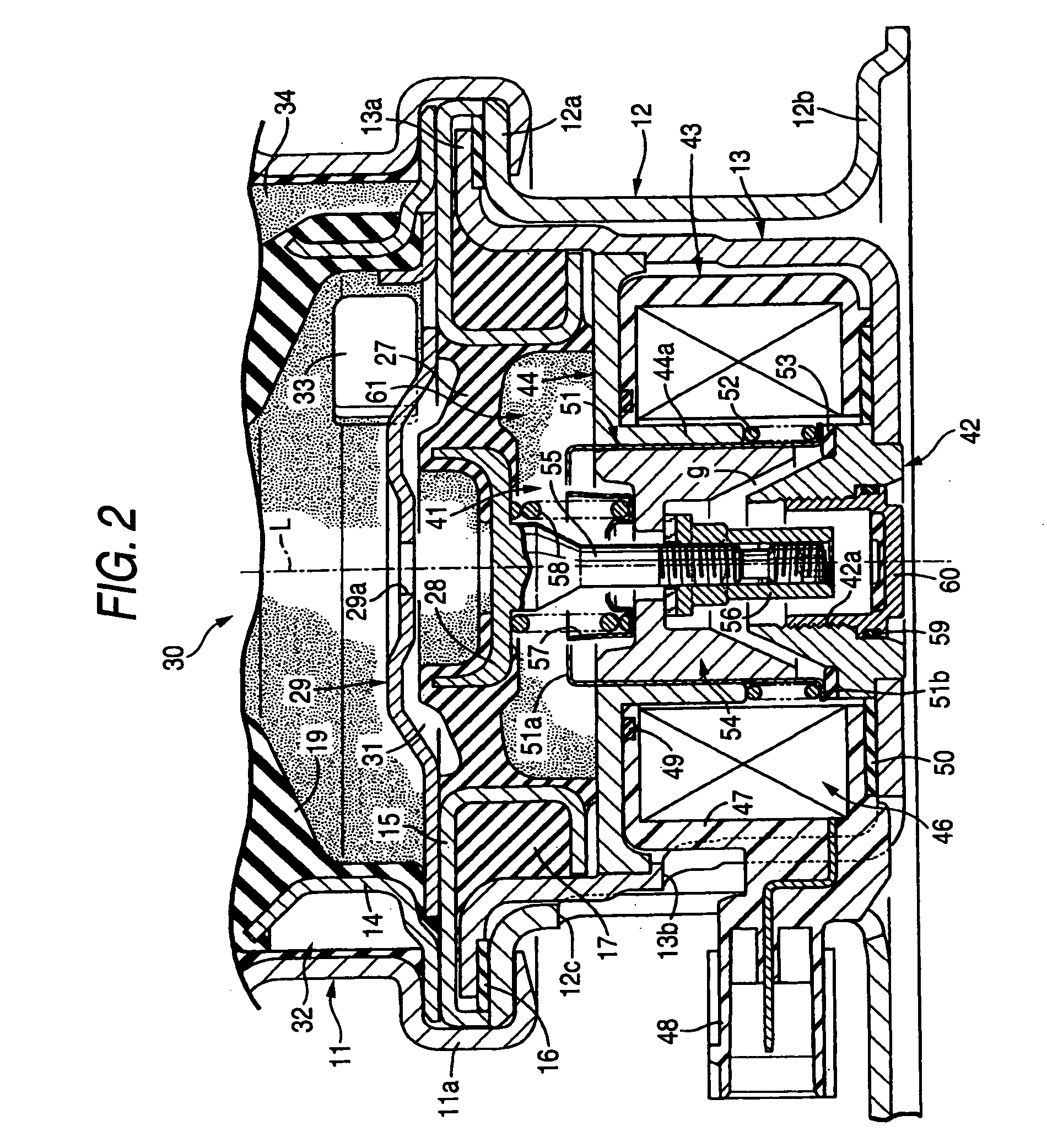

InactiveUS7069884B2Improve cooling effectWaste heat recoveryLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided in which an exhaust port communicating with a combustion chamber formed in a cylinder head is formed from independent exhaust ports, which are positioned on the upstream side, and a grouped exhaust port, in which the plurality of independent exhaust ports are combined. Water supplied from a supply pump passes through a water passage of the grouped exhaust port and a water passage of the independent exhaust ports while cooling the exhaust port, and a valve seat and valve guide on the periphery of the exhaust port, which have high temperatures, thus heating the water itself and thereby recovering waste heat of the internal combustion engine. The heated water carries out heat exchange with exhaust gas in an evaporator provided in an exhaust passage and turns into high temperature, high pressure steam, which drives an expander of a Rankine cycle system. It is thereby possible to maximize the recovery of heat transferred from the exhaust port to the cylinder head of the internal combustion engine.

Owner:HONDA MOTOR CO LTD

Power assembly, especially for an automotive vehicle

ActiveUS20110239643A1Conveniently achievedPower capacityNon-fuel substance addition to fuelInternal combustion piston enginesBrayton cycleAxial compressor

A power assembly includes an internal combustion engine including an air intake line and an exhaust gas line having at least one heat exchanger. The power assembly further includes a Brayton cycle system capable of providing additional power to the main internal combustion engine and that includes a gas compressor, a fuel burning heater and a turbine linked to the compressor so that air is drawn into the compressor where it is pressurized, the pressurized air is further heated by flowing through at least one heat exchanger where it exchanges heat with exhaust gases from the main internal combustion engine, the heated and pressurized air is further heated by the fuel burning heater and is thereafter expanded through the turbine where a first fraction of the work extracted by the turbine is used to drive the compressor and a second fraction of the work extracted by the turbine is used to bring additional energy.

Owner:VOLVO LASTVAGNAR AB

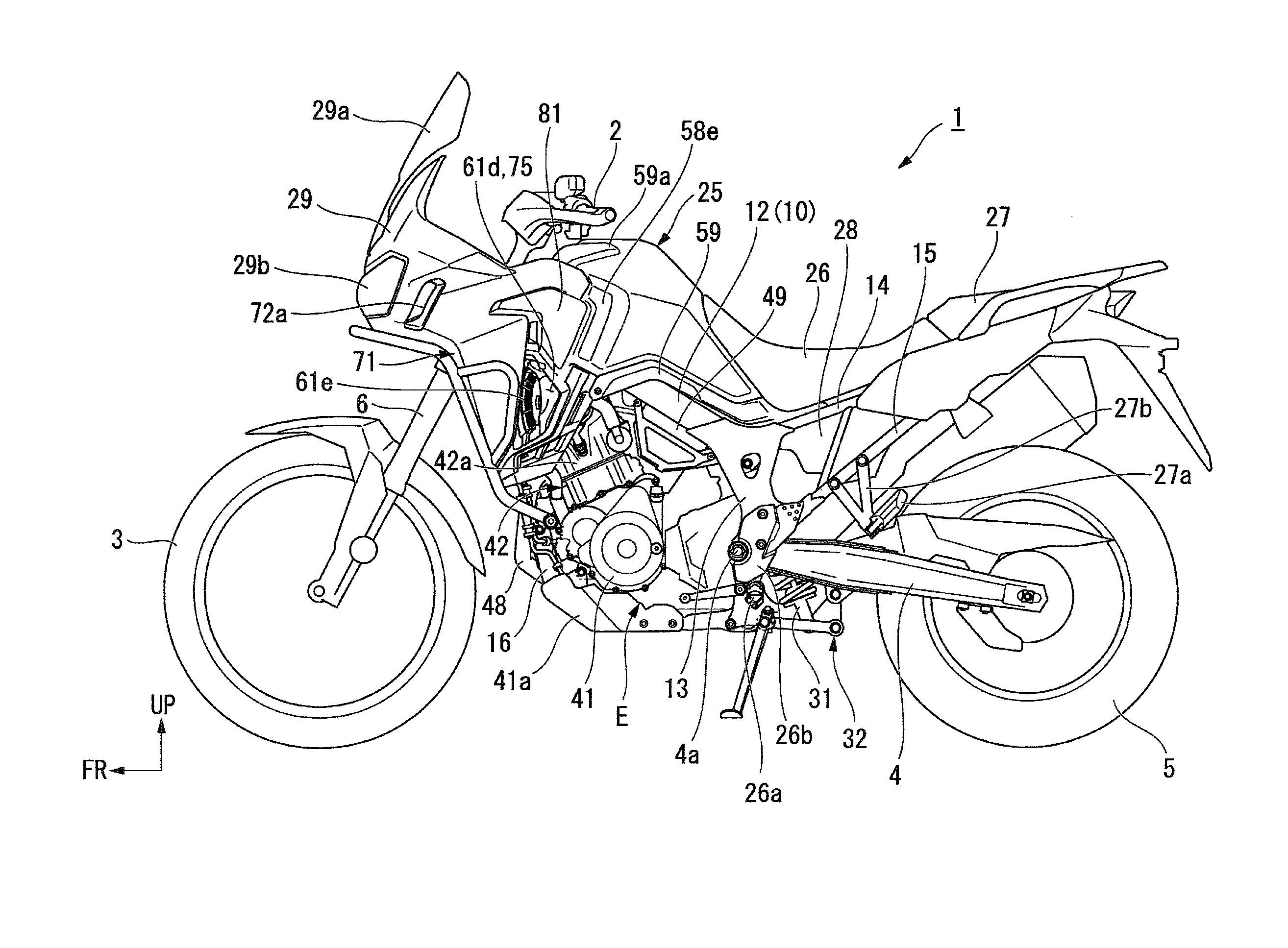

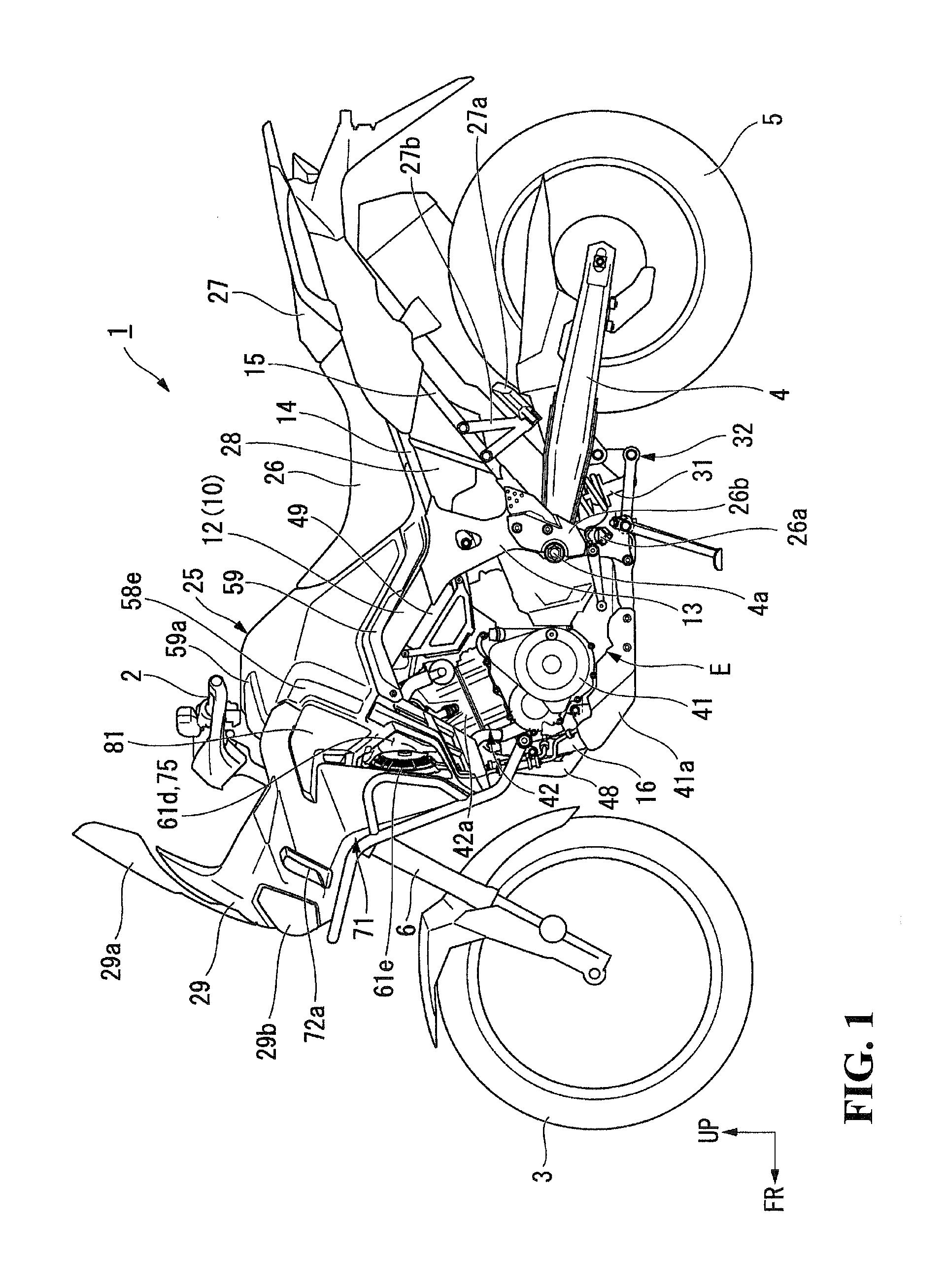

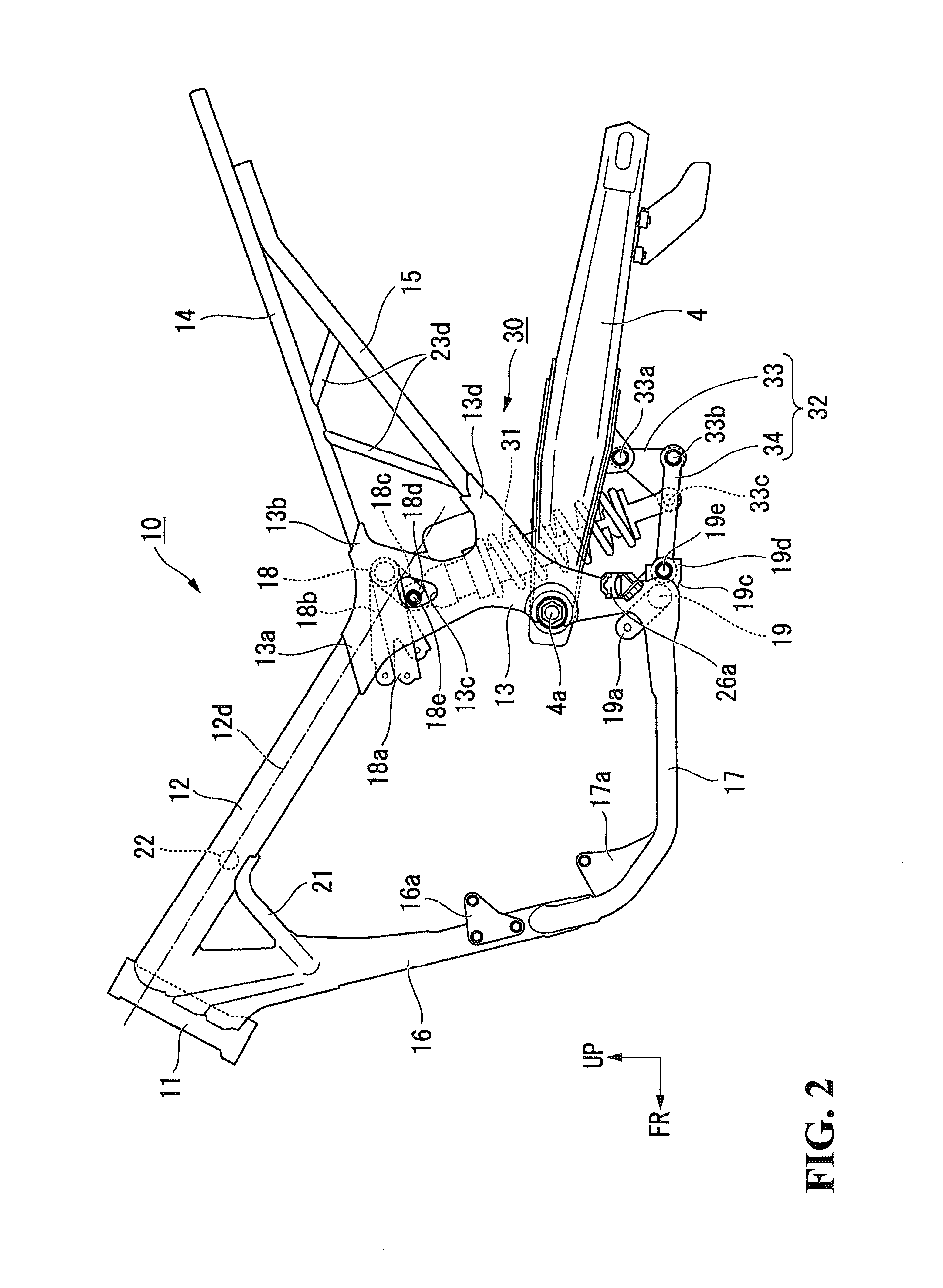

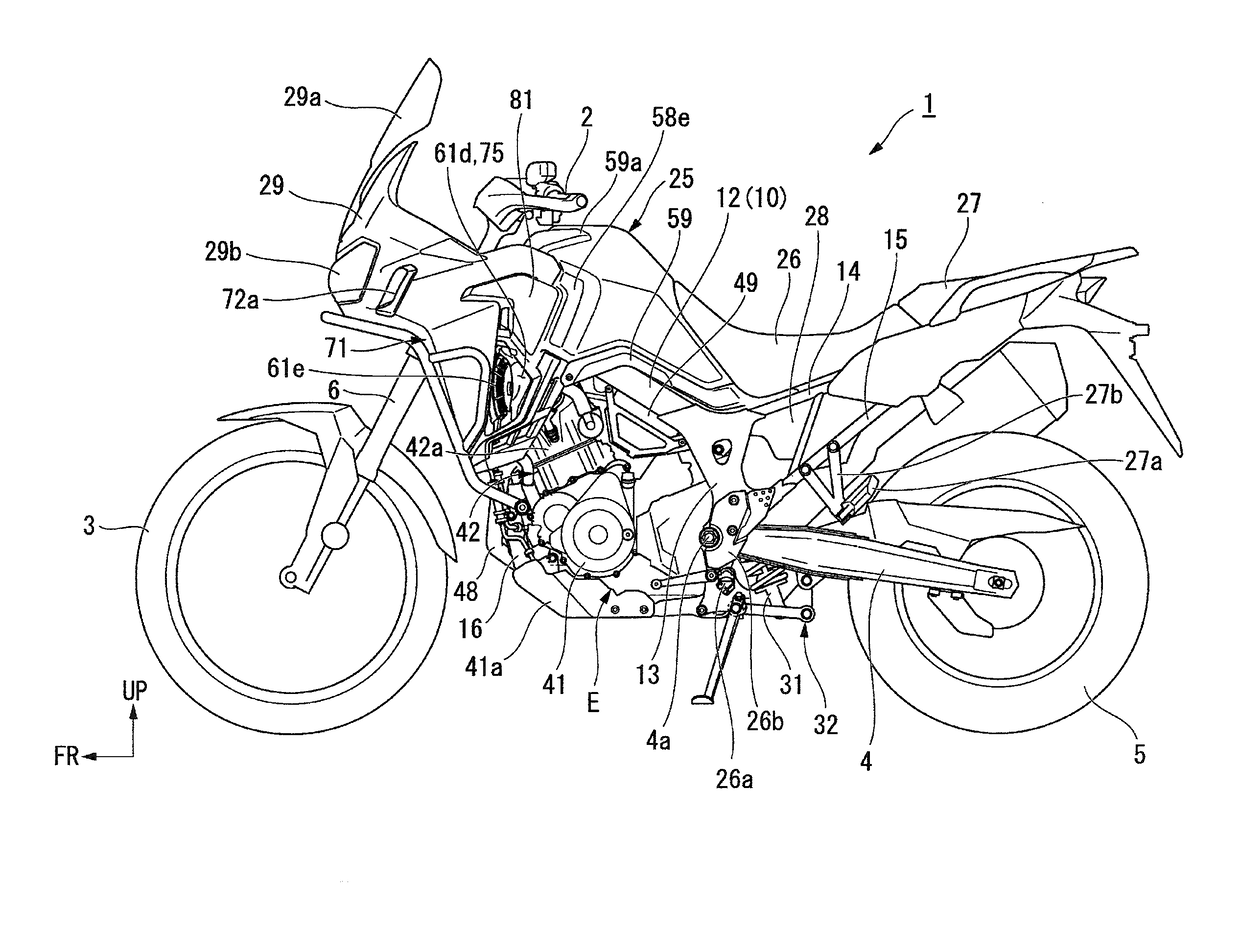

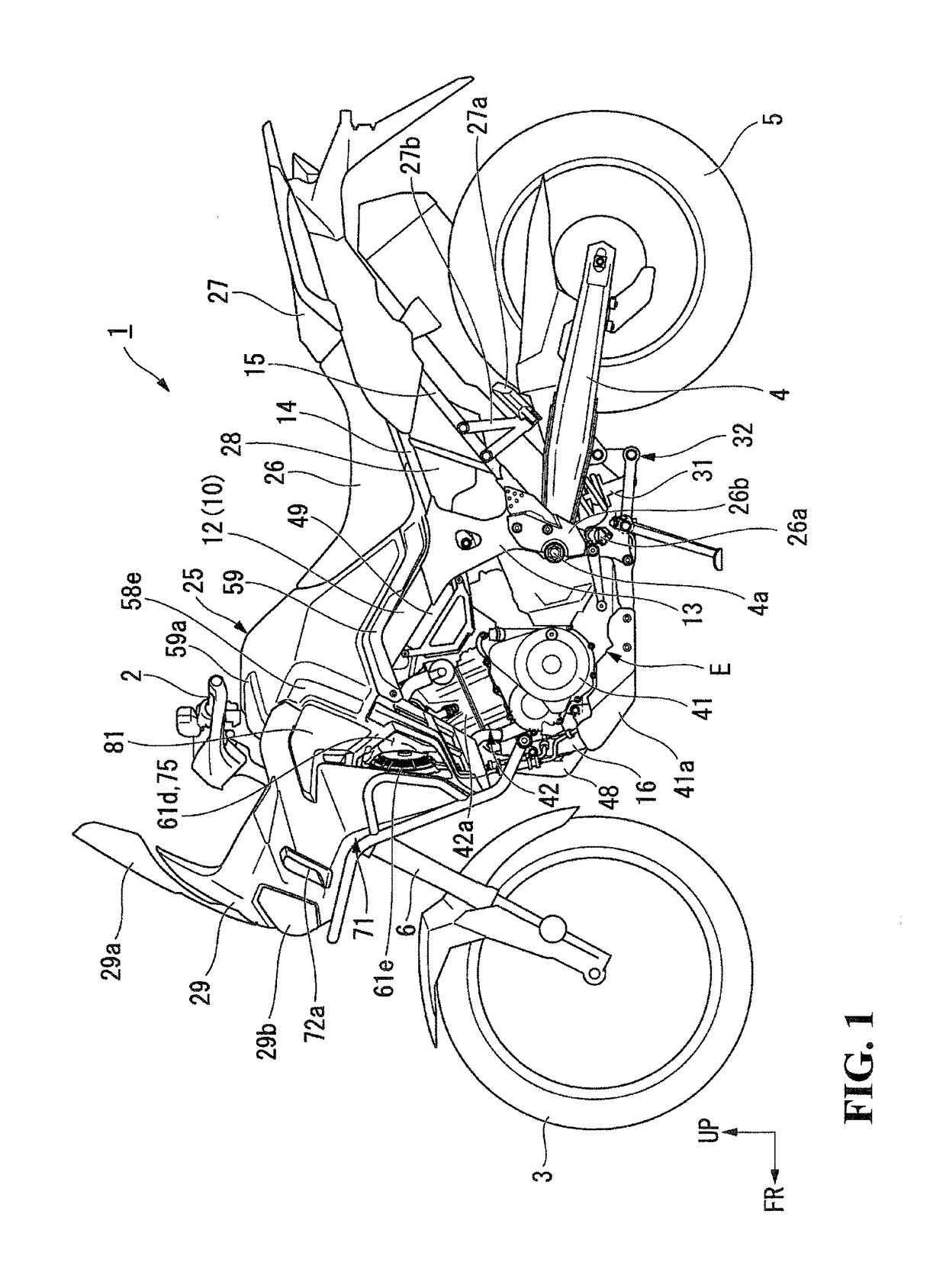

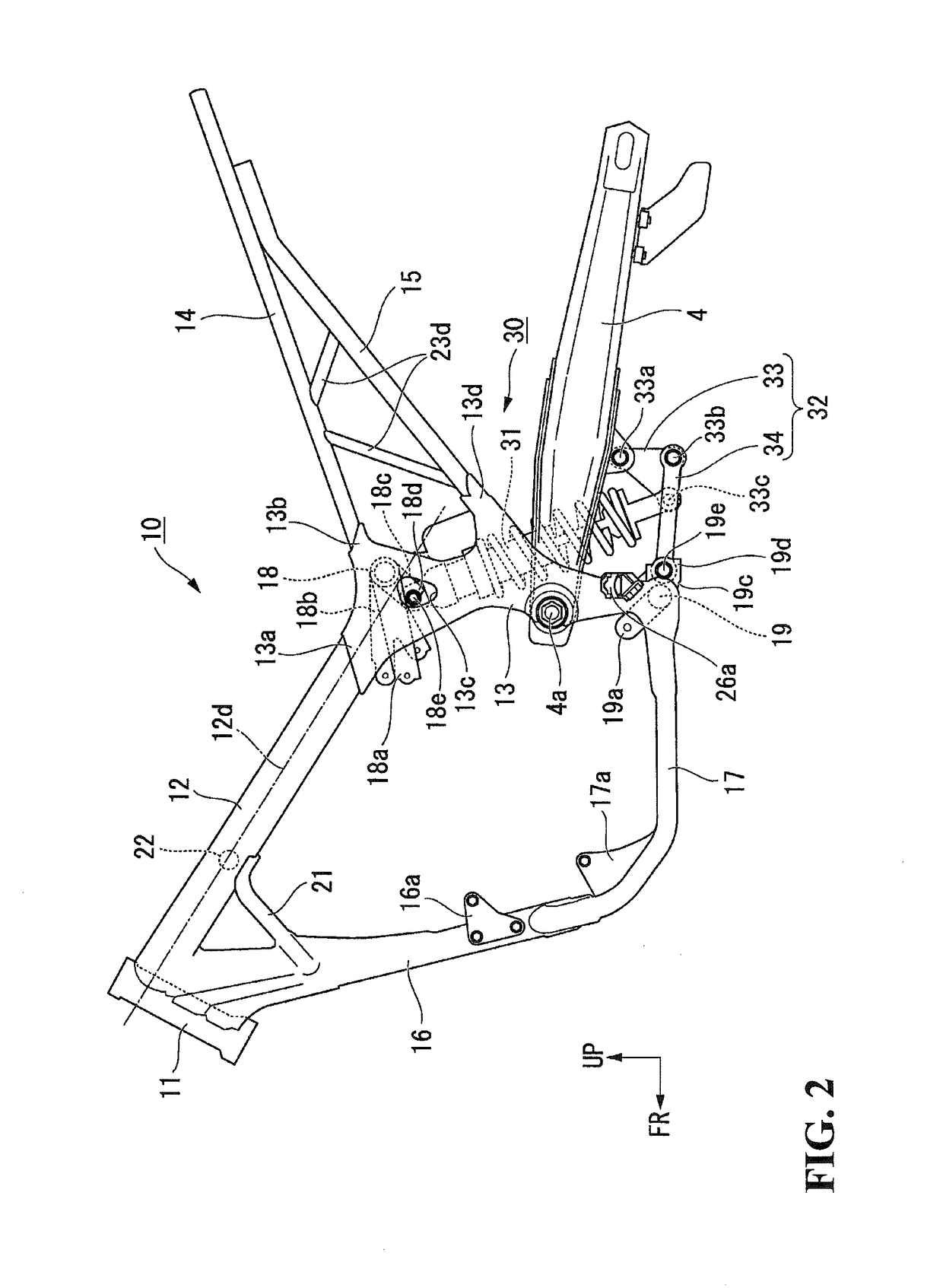

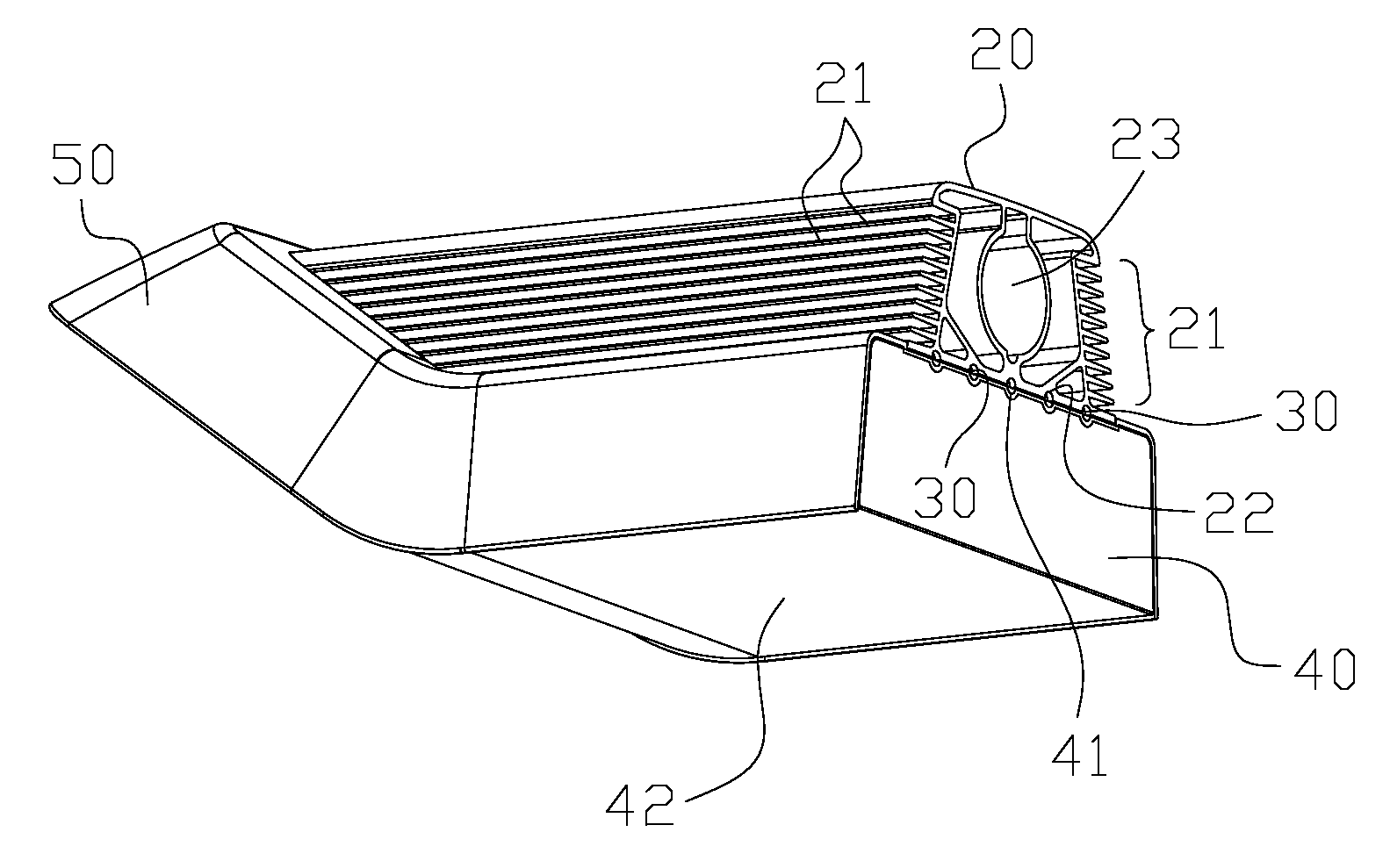

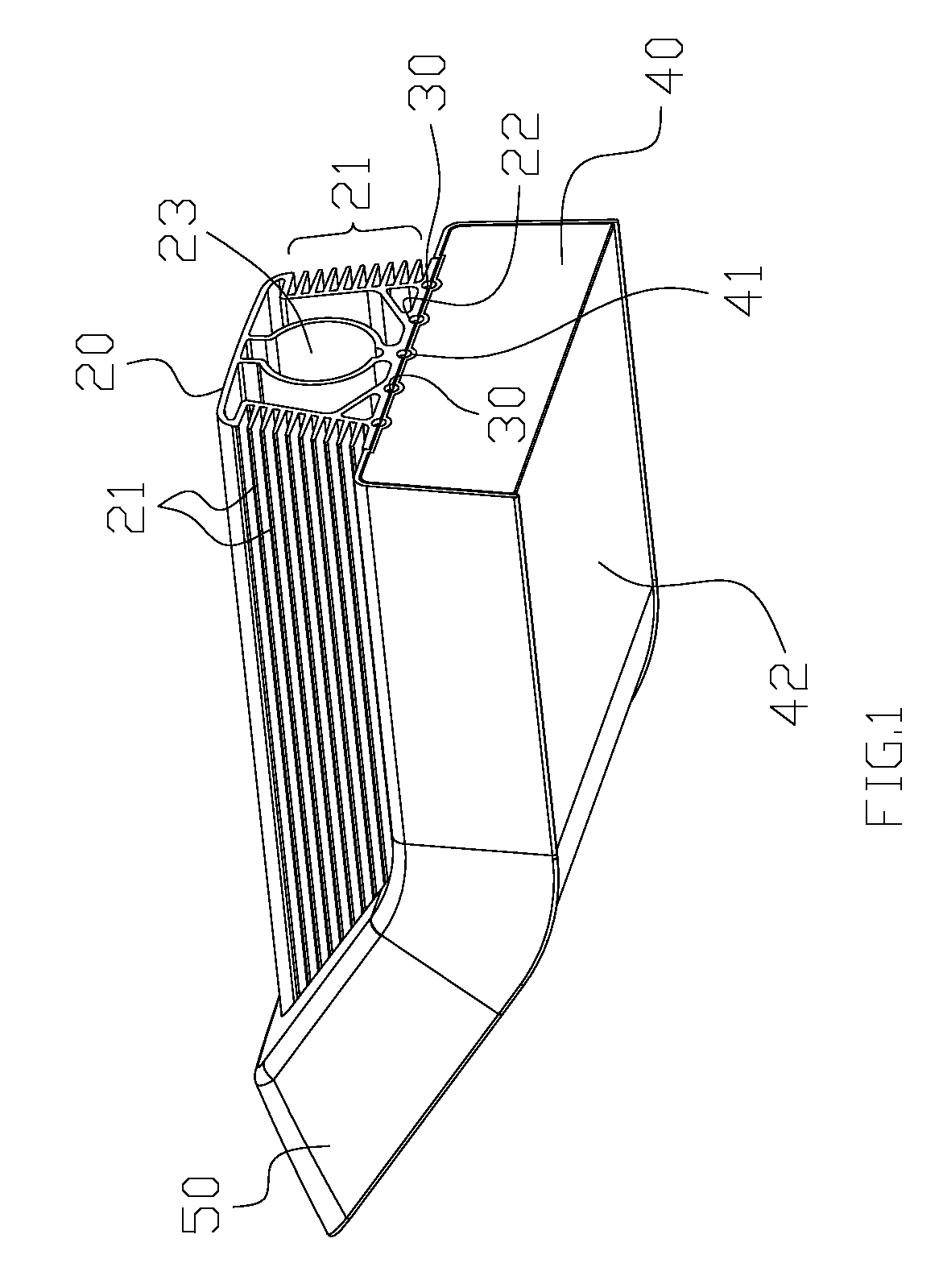

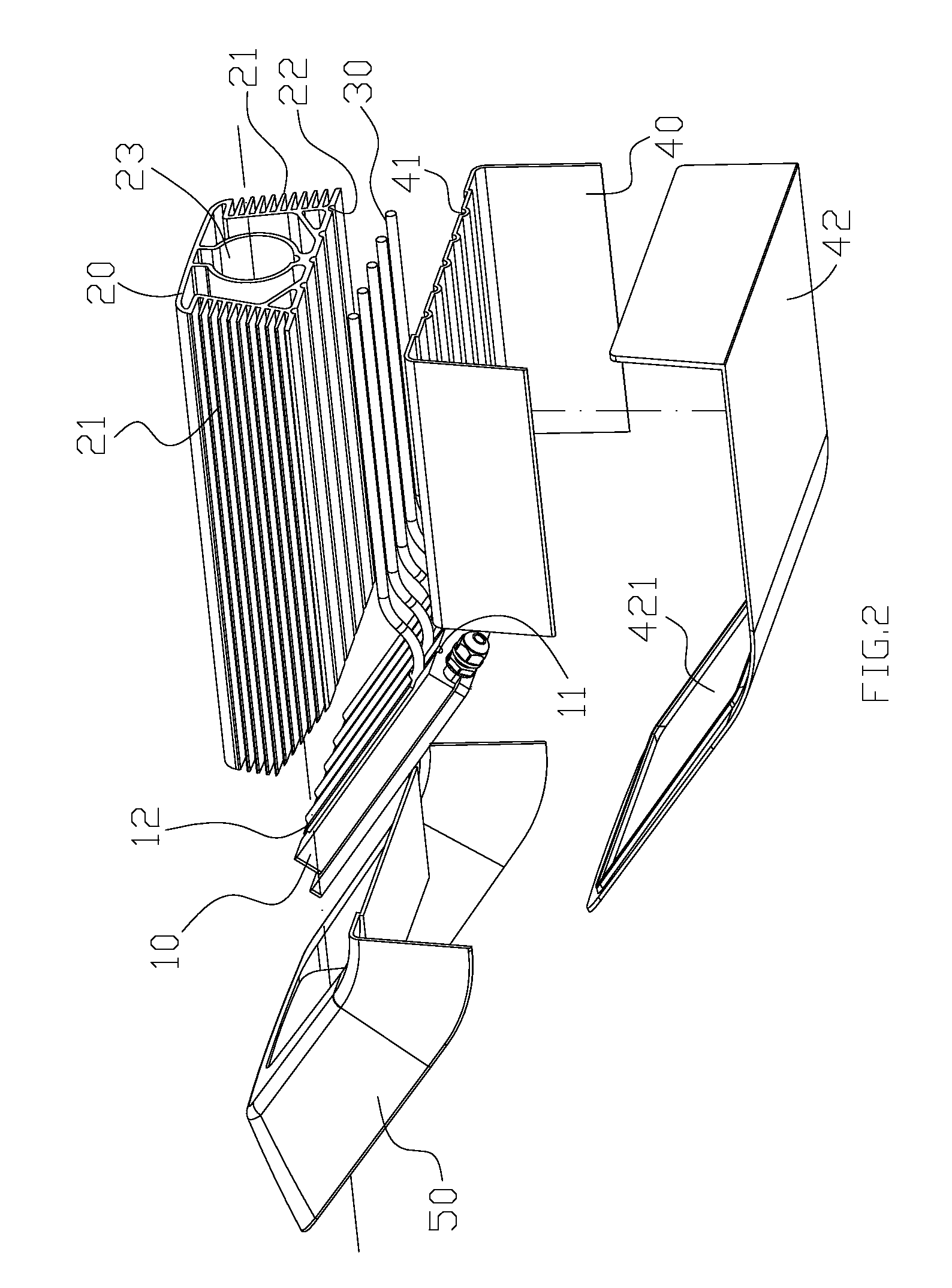

Saddle-ride type vehicle

ActiveUS20160244116A1Avoid wasting heatWaste heatWeather guardsMotorcyclesCylinder headAutomotive engineering

A saddle-ride type vehicle in which an engine is supported on a body frame and radiators are disposed forward of the engine is provided, wherein waste heat of the radiators is prevented from reaching the engine. The saddle-ride type vehicle includes a radiator shroud 71 that covers a range from a lateral side of a radiator 61 to a lateral side of a cylinder head 42a of the engine E. The radiator shroud 71 has an exhaust port 75 opening outward in a vehicle width direction. The saddle-ride type vehicle also includes a partition wall 82A between the radiator and the cylinder head 42a. The partition wall 82A separates a rear space 61d of the radiator 61 and the cylinder head 42a from each other and brings the rear space 61d into communication with the exhaust port 75 of the radiator shroud 71.

Owner:HONDA MOTOR CO LTD

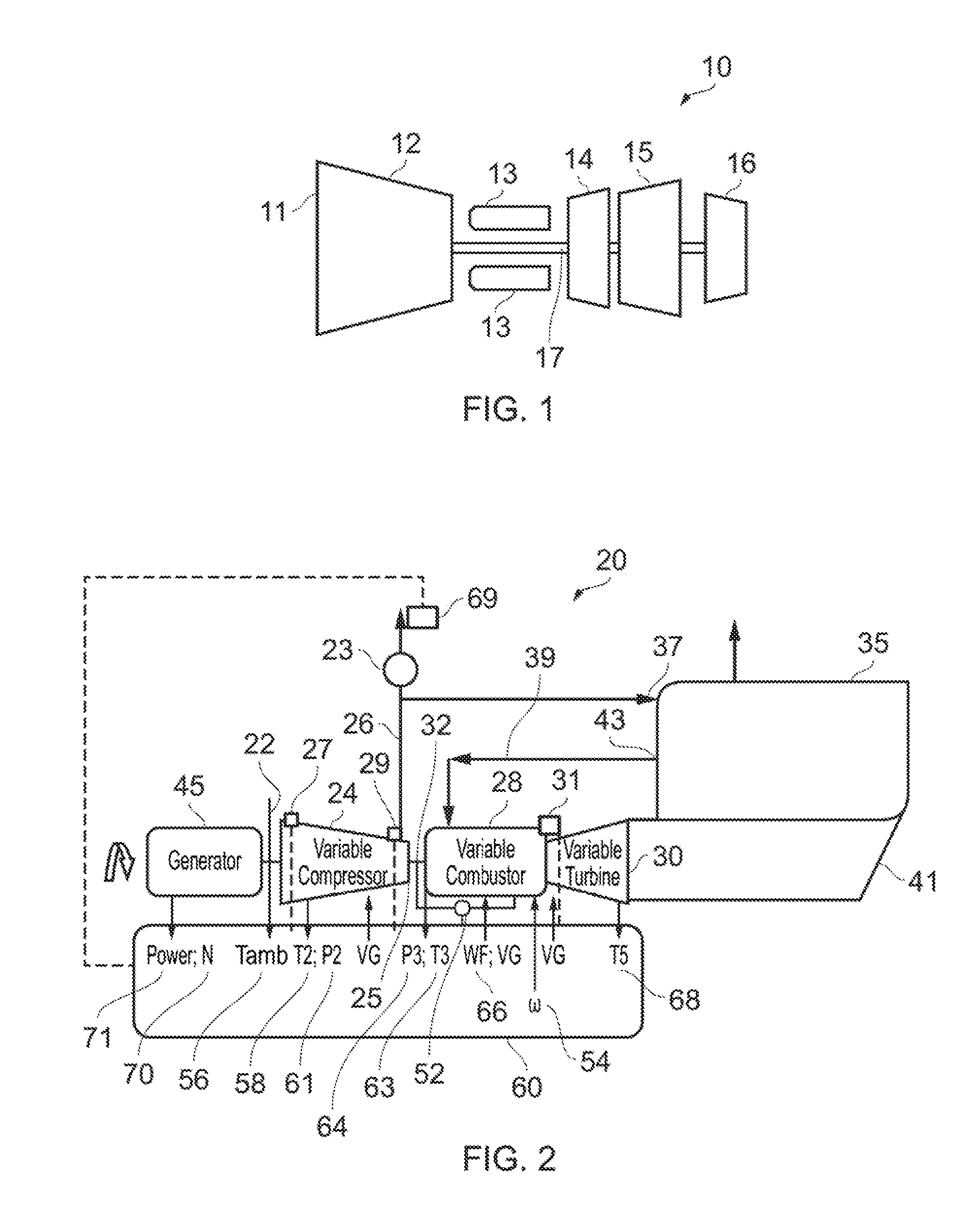

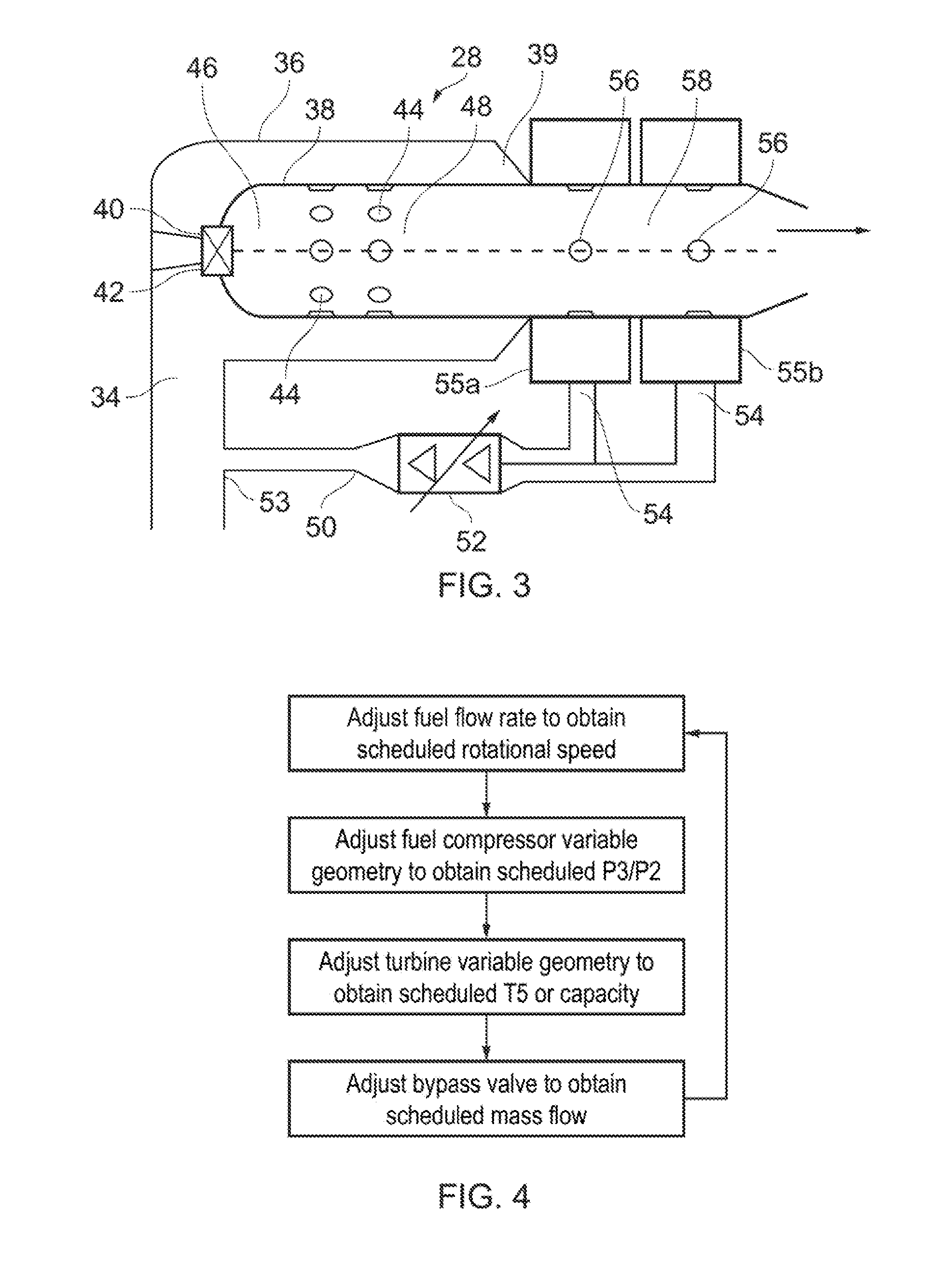

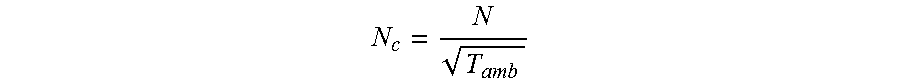

Method of Operation of a Gas Turbine Engine

InactiveUS20160153365A1Increased longevityConstant cycle operationContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustorVariable geometry turbine

A method of operating a gas turbine engine (20) comprising a variable geometry compressor (24), a variable geometry combustor (28), and a variable geometry turbine (30). The method comprises operating the variable geometry combustor (28) such that a corrected flow ωc through a combustion zone (46, 48) of the combustor (28) matches a predetermined value.

Owner:ROLLS ROYCE PLC

Method and apparatus for odor control using panels of activated carbon cloth

ActiveUS20060156926A1Efficiently adsorb any water vaporAvoid dissipationGas treatmentBoiling over preventionActivated carbonChemistry

Owner:ALEMAO THADDEUS

Method of Storing Energy and a Cryogenic Energy Storage System

The present invention concerns systems for storing energy and using the stored energy to generate electrical energy or drive a propeller (505). In particular, the present invention provides a method of storing energy comprising: providing a gaseous input, producing a cryogen from the gaseous input; storing the cryogen; expanding the cryogen; using the expanded cryogen to drive a turbine (320) and recovering cold energy from the expansion of the cryogen. The present invention also provides a cryogenic energy storage system comprising: a source of cryogen; a cryogen storage facility (370); means for expanding the cryogen; a turbine (320) capable of being driven by the expanding cryogen; and means (340, 350) for recovering cold energy released during expansion of the cryogen.

Owner:HIGHVIEW ENTERPRISES LTD

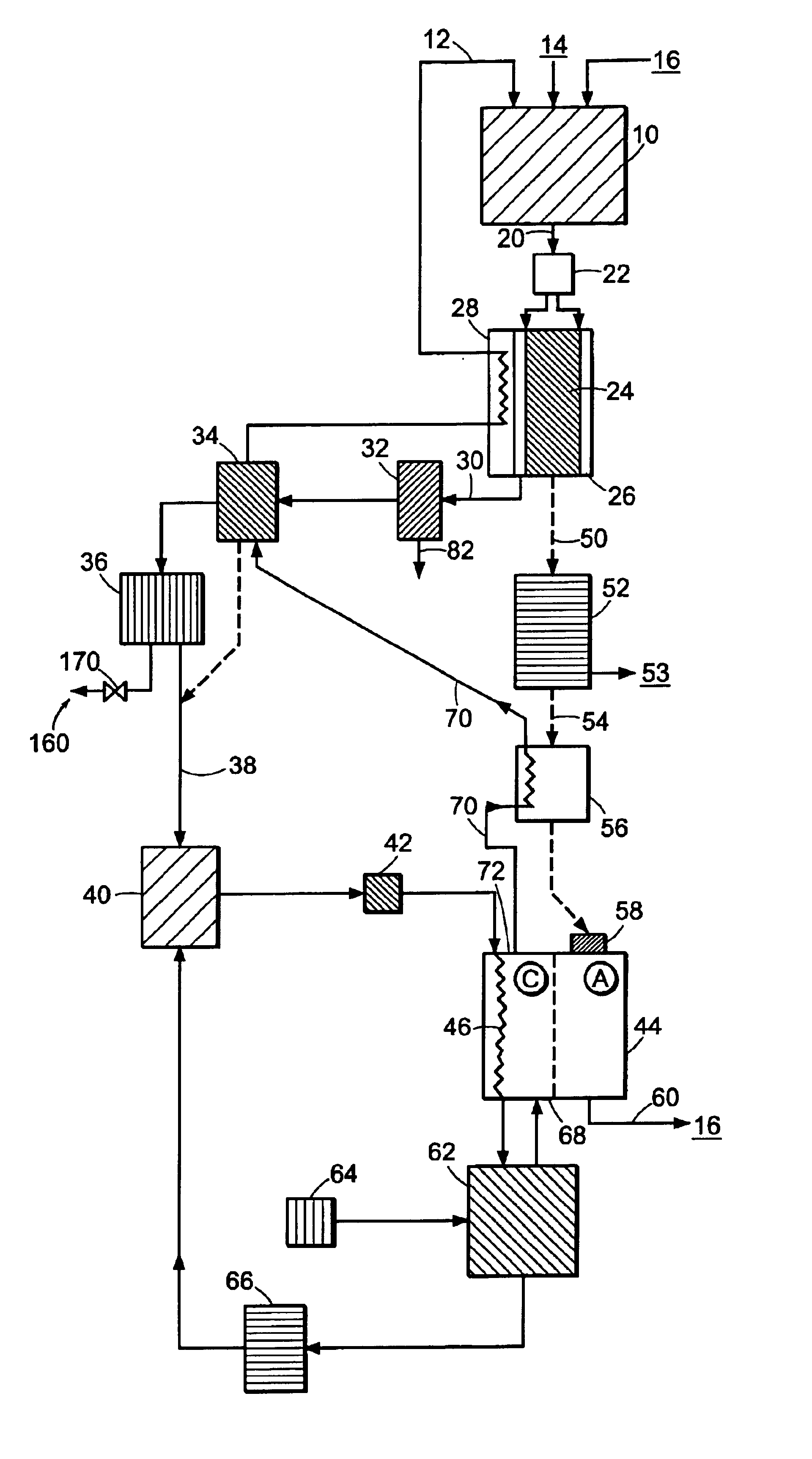

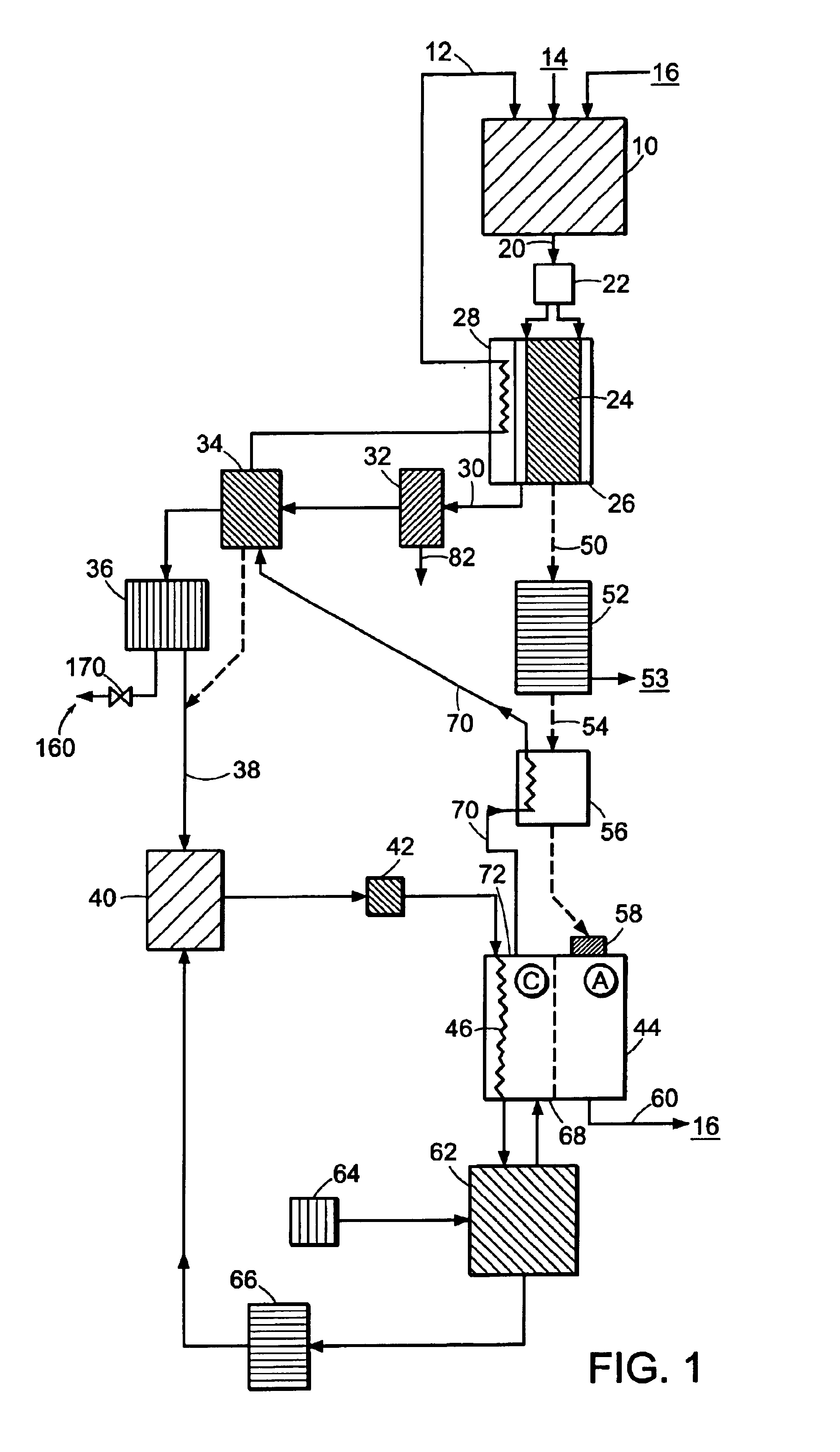

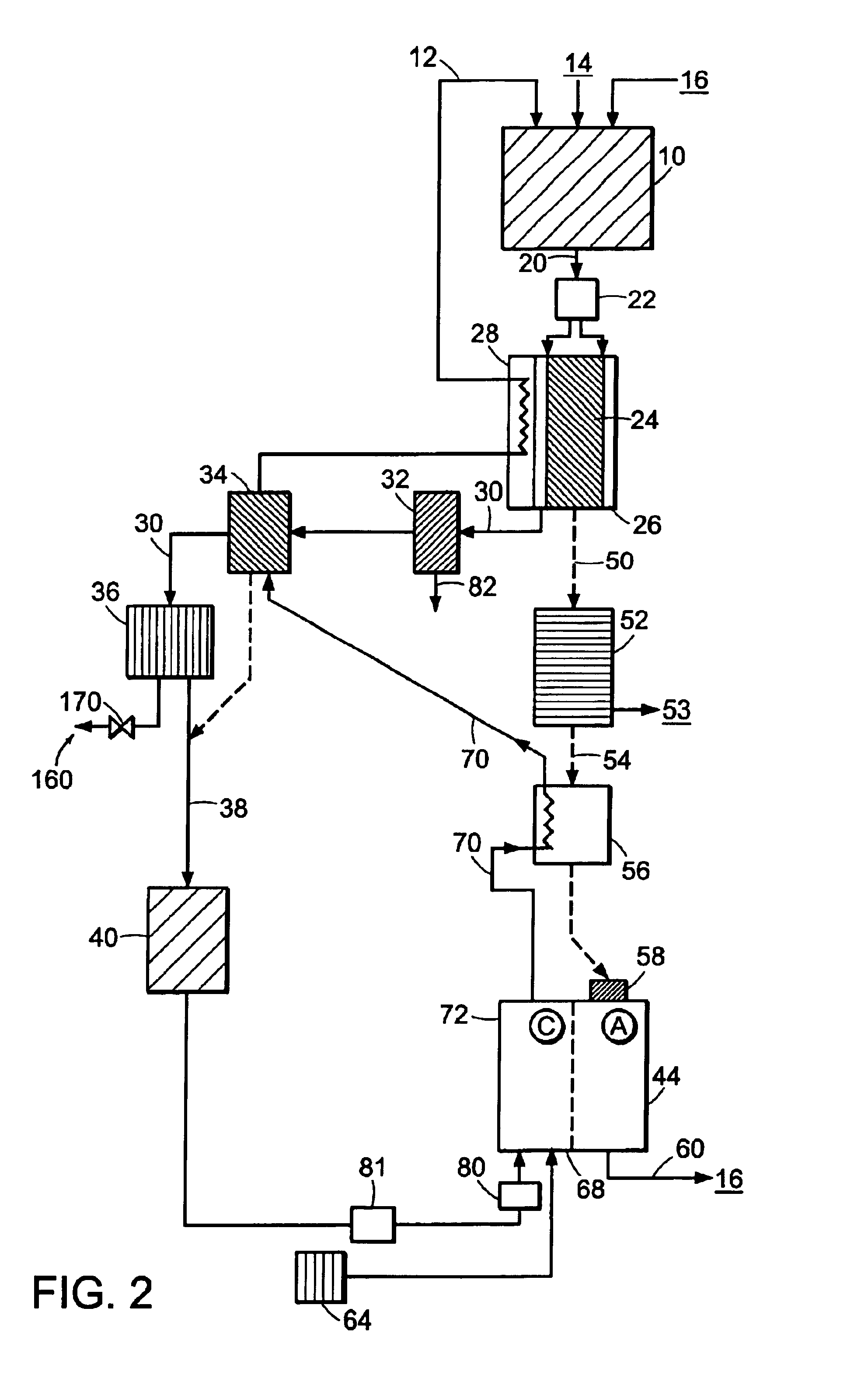

High-efficiency fuel cell power system with power generating expander

InactiveUS6916564B2Improve efficiencyImprove system efficiencyElectricity cogenerationRegenerative fuel cellsElectric power systemHydrogen fuel cell

A hydrogen fuel cell power system having improved efficiency comprises a fuel cell, a source of hydrogen gas, a compressor for creating a pressurized air stream, and a liquid supply which is heated by waste heat form the power system and evaporates into the pressurized air stream to produce a pressurized air and steam mixture. The pressurized air / steam mixture, which is preferably used as the oxidant in the fuel cell, is combusted with fuel in a burner to produce a high-temperature steam-laden exhaust stream. The high-temperature steam-laden exhaust stream drives an expander to produce a power output, and a power take-off from the expander uses the expander power to, for instance, drive an electrical generator, or drive other system components. The evaporation of liquid can take place external to the fuel cell, or can take place directly within the fuel cell, preferably using a cooling liquid that is directly injected into the fuel cell. The fuel cell power system advantageously uses the low-temperature waste heat of the fuel cell to evaporate liquid into the pressurized air, resulting in a steam / air mixture having a relatively large expansion potential.The systems and related methods of the invention are applicable to a wide range of fuel cell power systems, including a “pure” or “non-hybrid” fuel cell power system, powered by hydrogen from either an external source, such as a hydrogen storage tank, or from “direct” reforming of a fuel at the anode. The invention is also applicable to integrated or “hybridized” fuel cell power systems which contain a local fuel reformer. In these systems, the fuel cell is powered by hydrogen-containing reformate generated by the reformer.

Owner:NUVERA FUEL CELLS

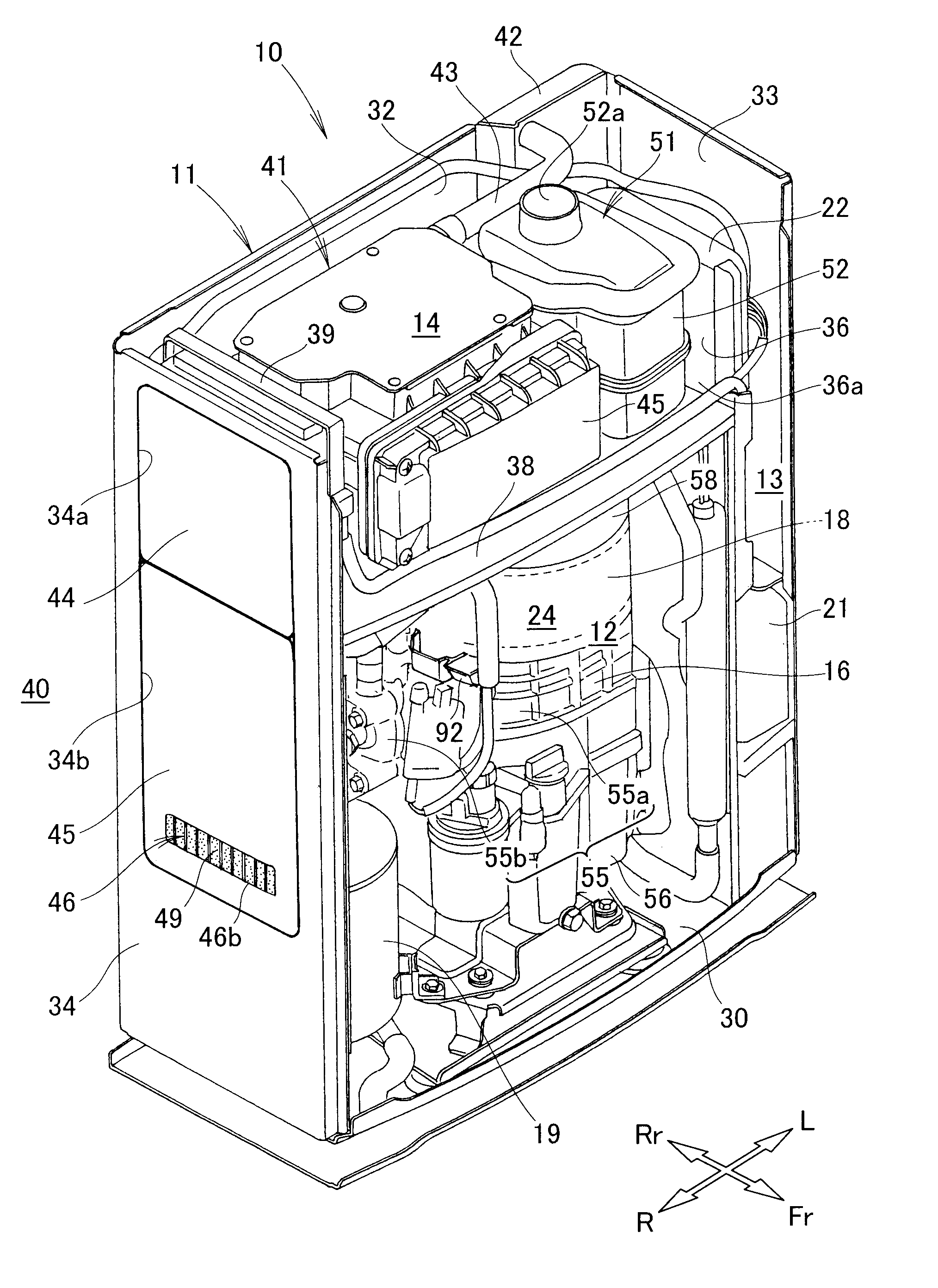

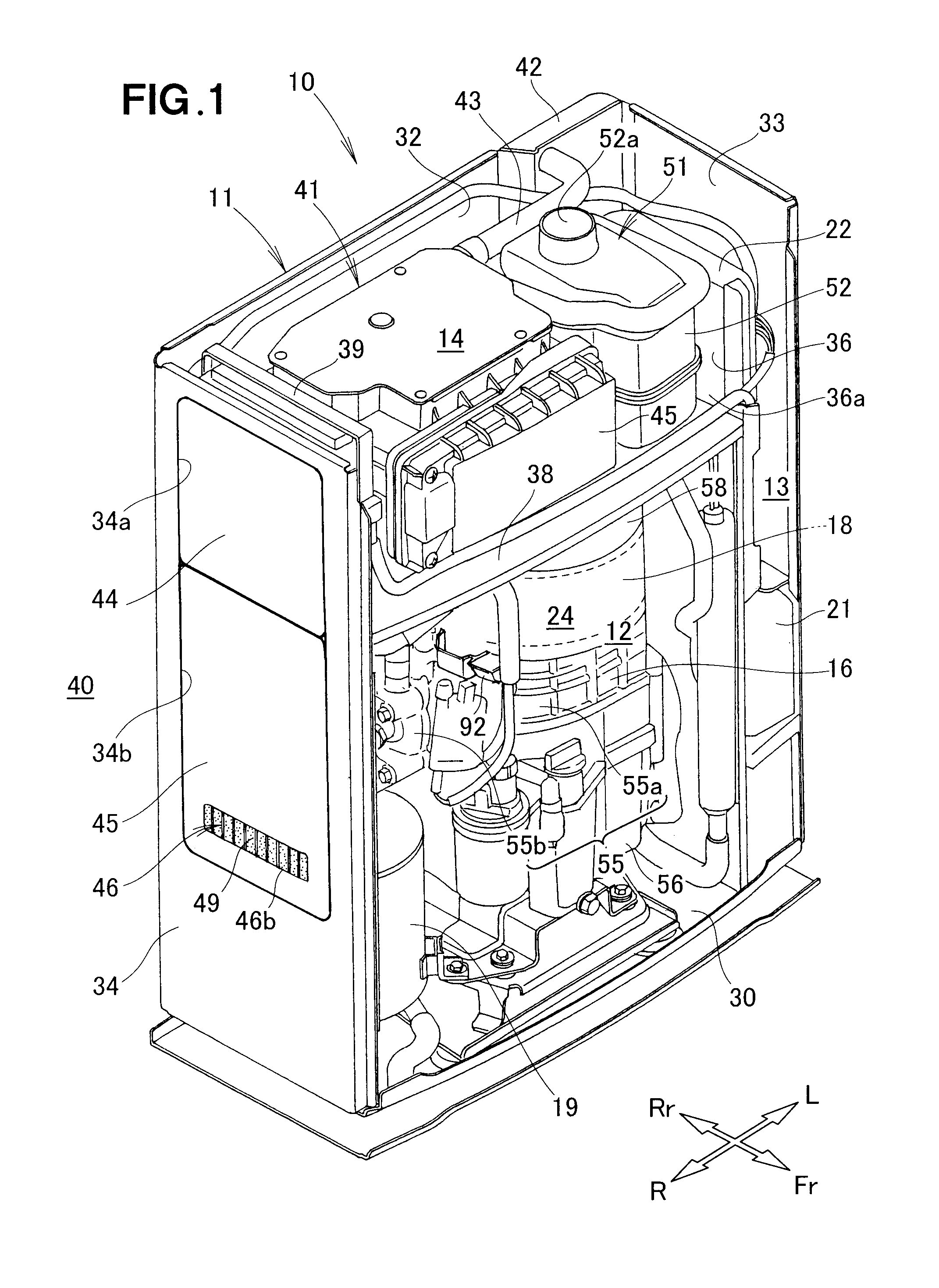

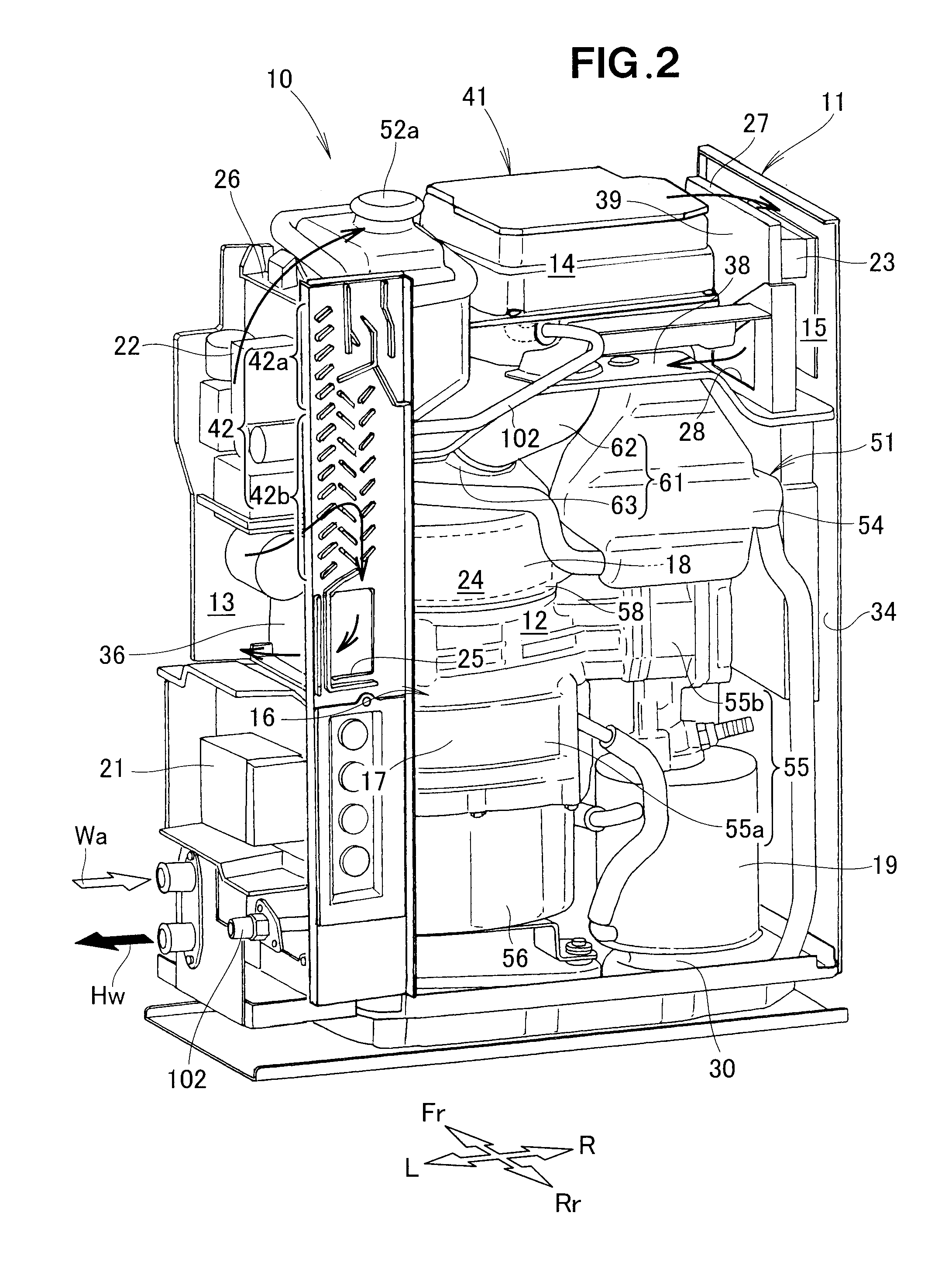

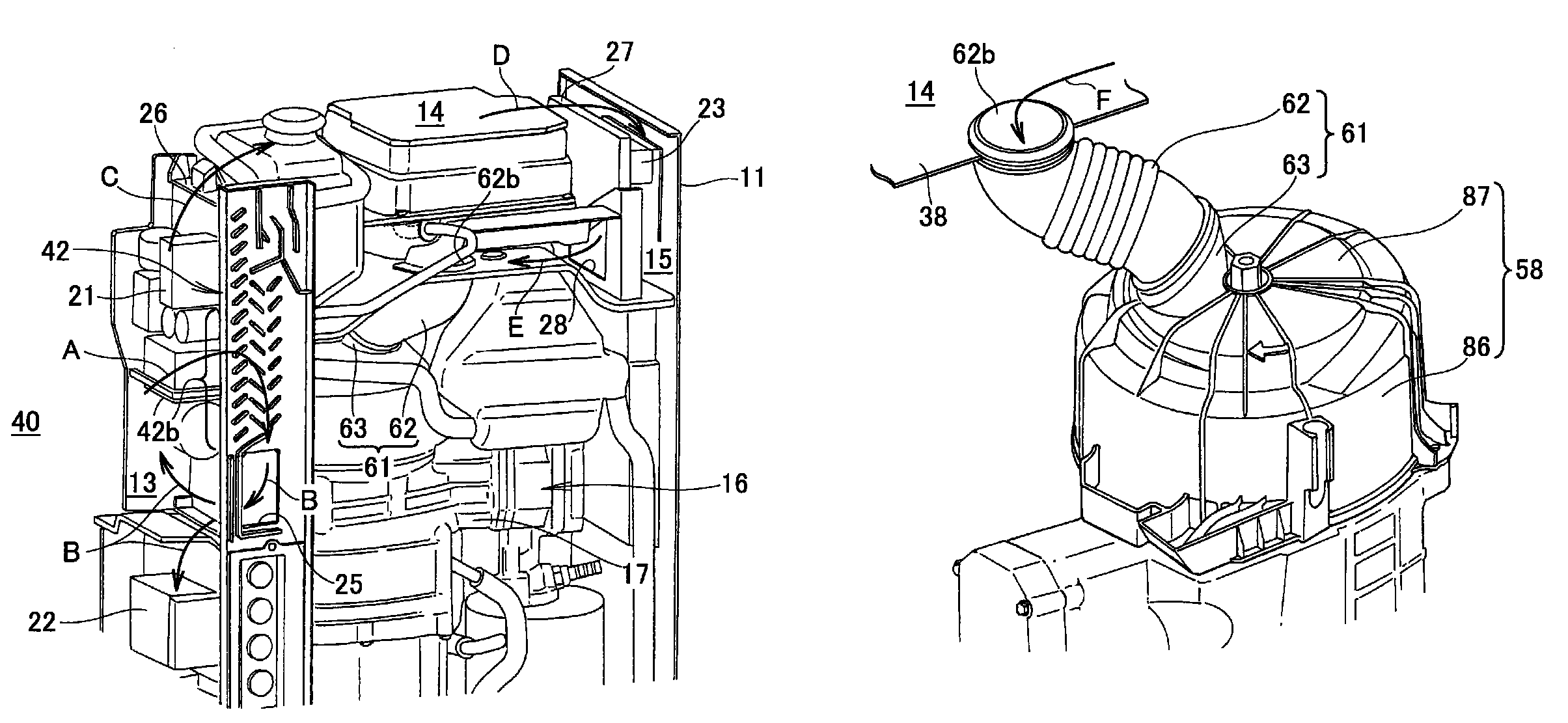

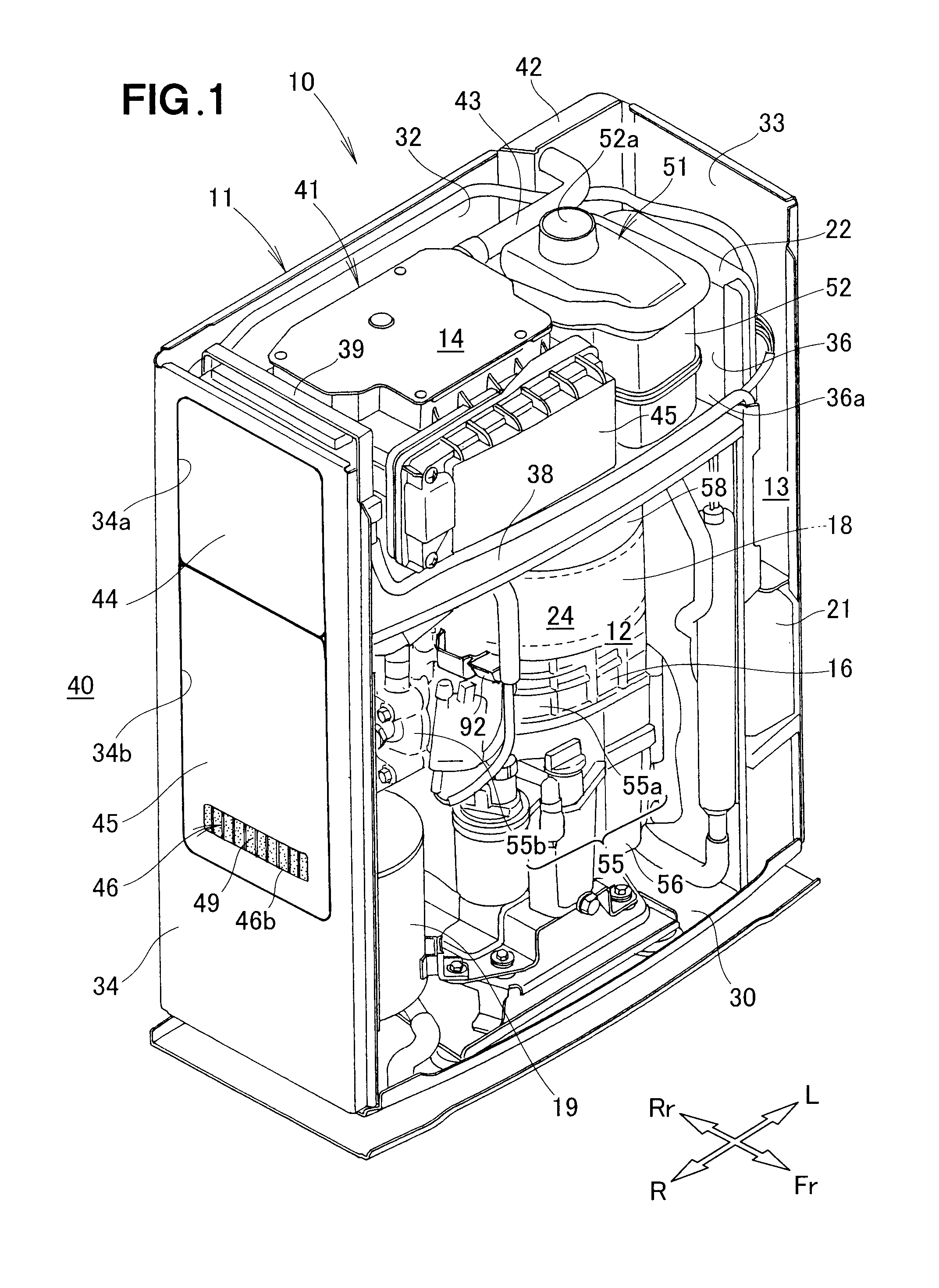

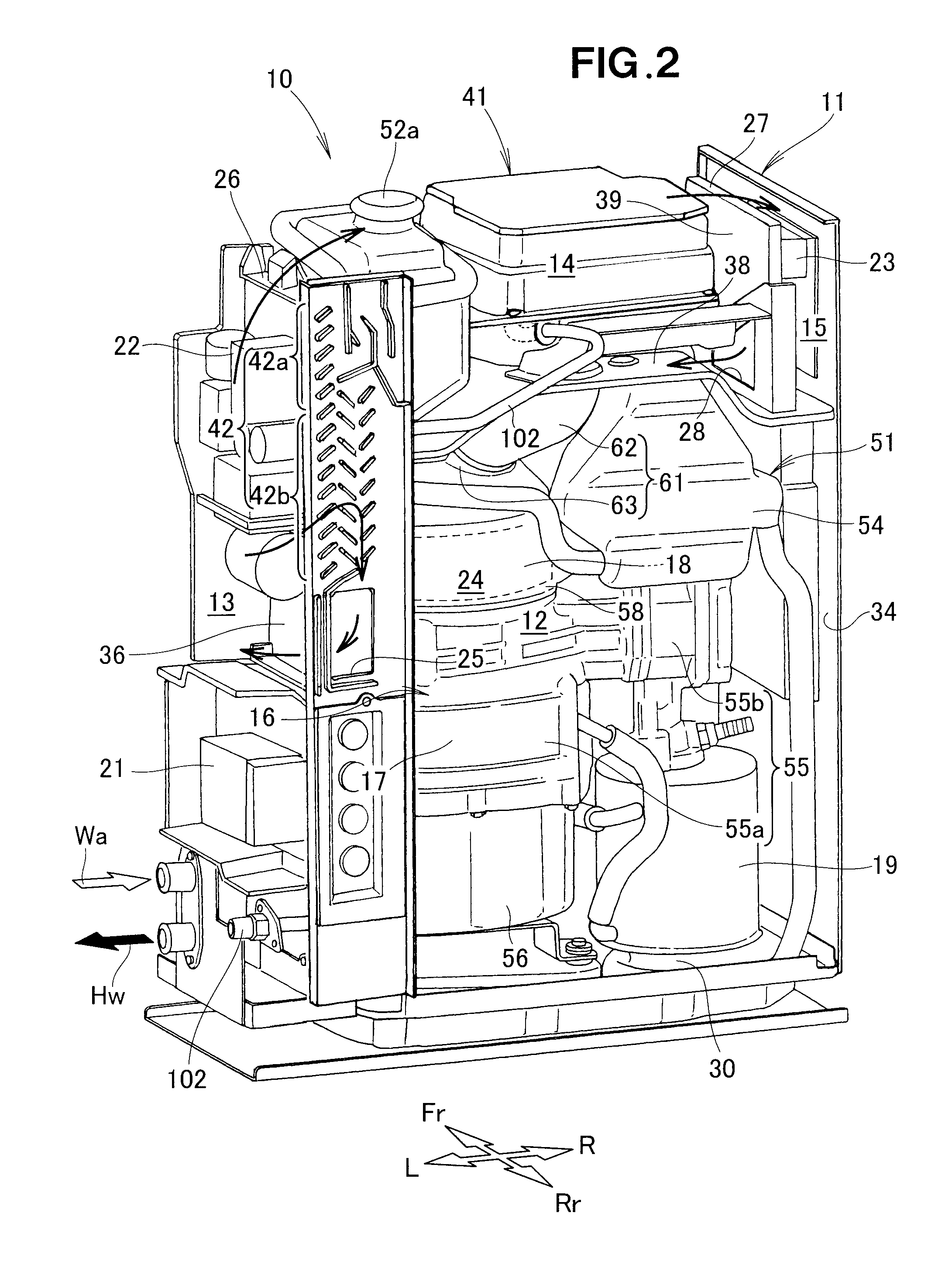

Cogeneration apparatus

ActiveUS20120187679A1Easy to adjustMinimized pressure lossAir-treating devicesInternal combustion piston enginesCogenerationElectrical equipment

A cogeneration apparatus having a ventilation-introducing channel communicating an electrical-equipment compartment with a ventilation fan is disclosed. Driving the ventilation fan causes air to be led from an exterior of a cogeneration case through the electrical-equipment compartment to the interior of the ventilation-introducing channel. The air led to the interior of the ventilation-introducing channel is led to an electrical generator. The air led to the electrical generator is exhausted through a power-generation compartment to the exterior of the cogeneration case.

Owner:HONDA MOTOR CO LTD

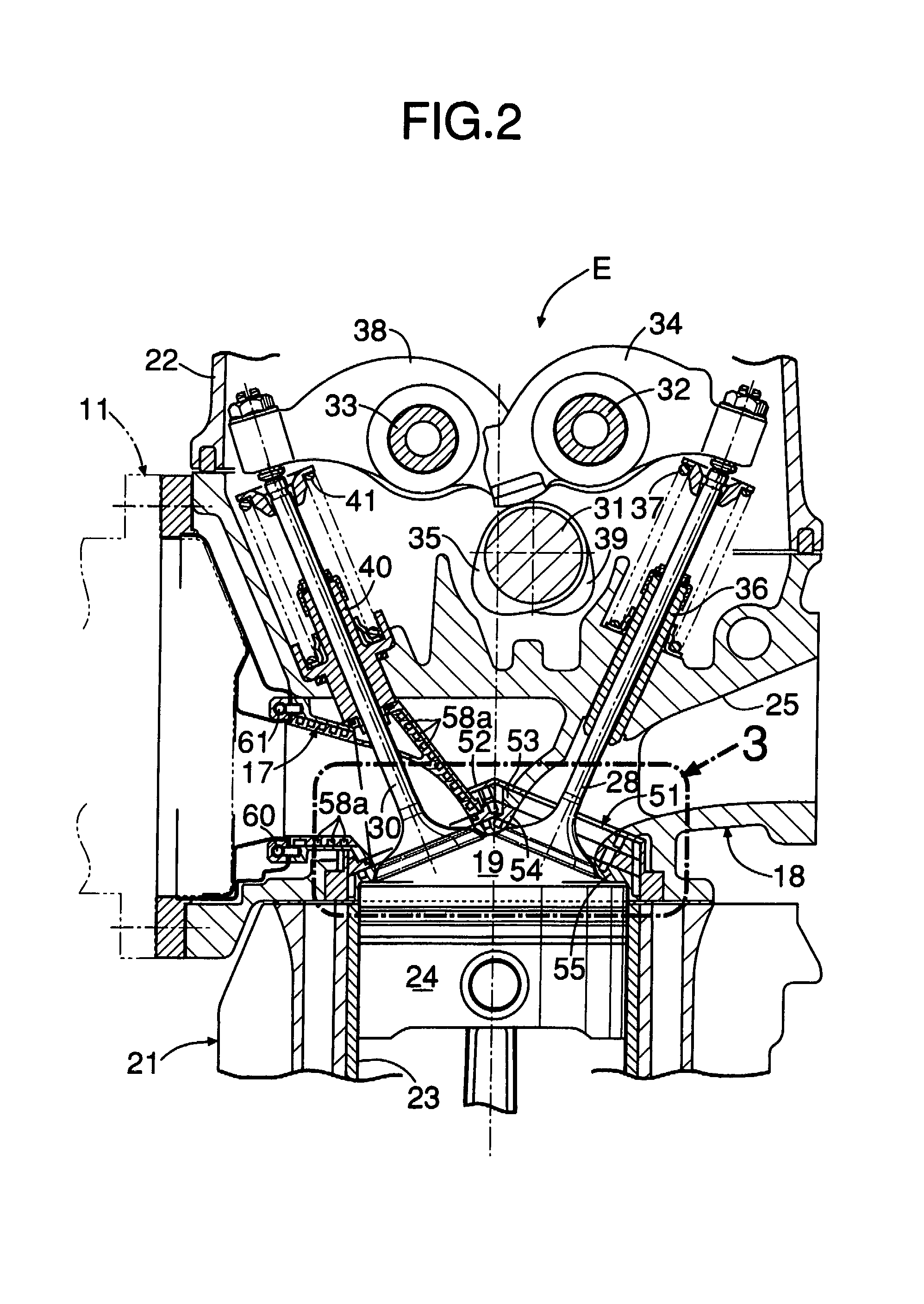

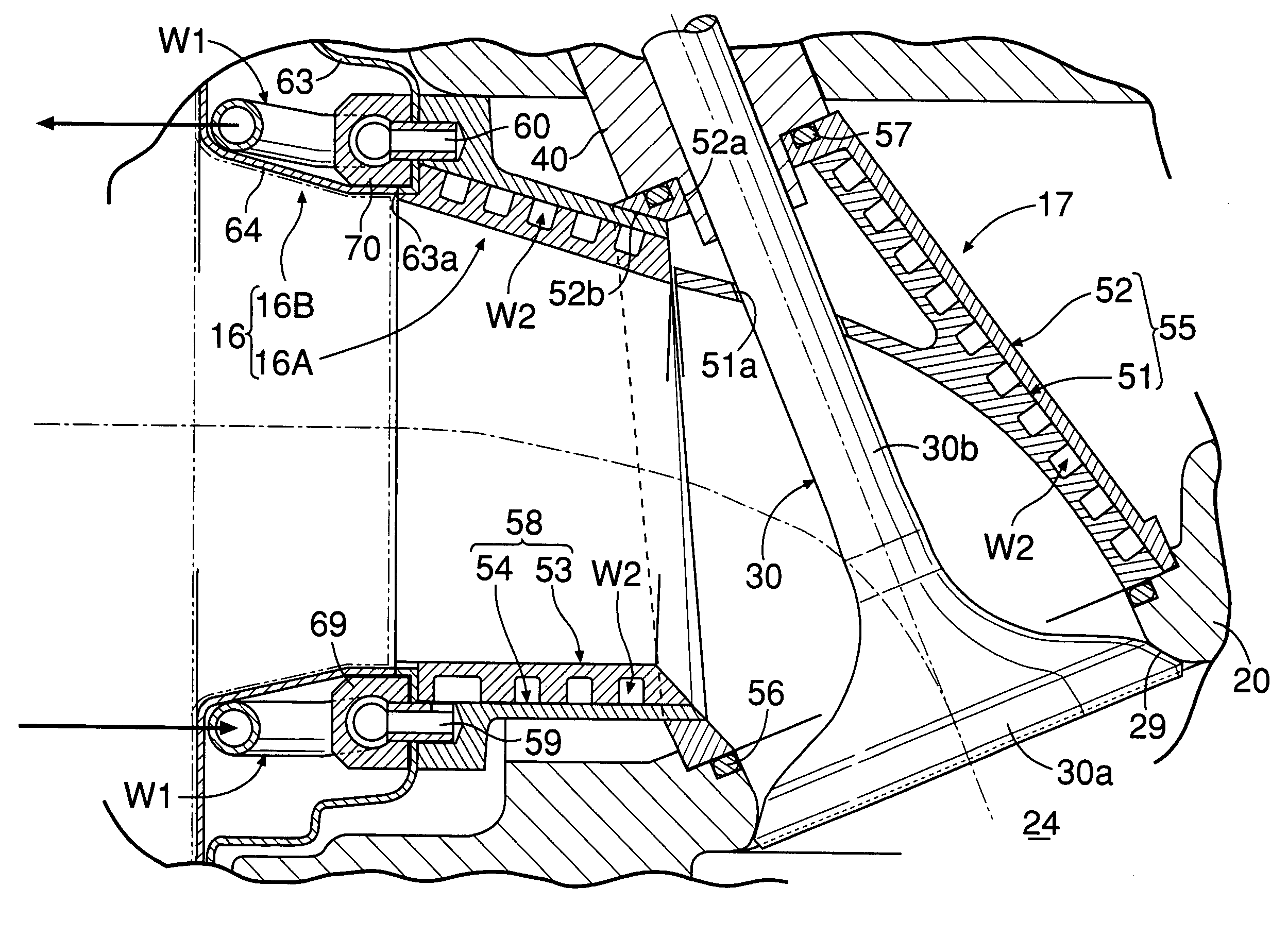

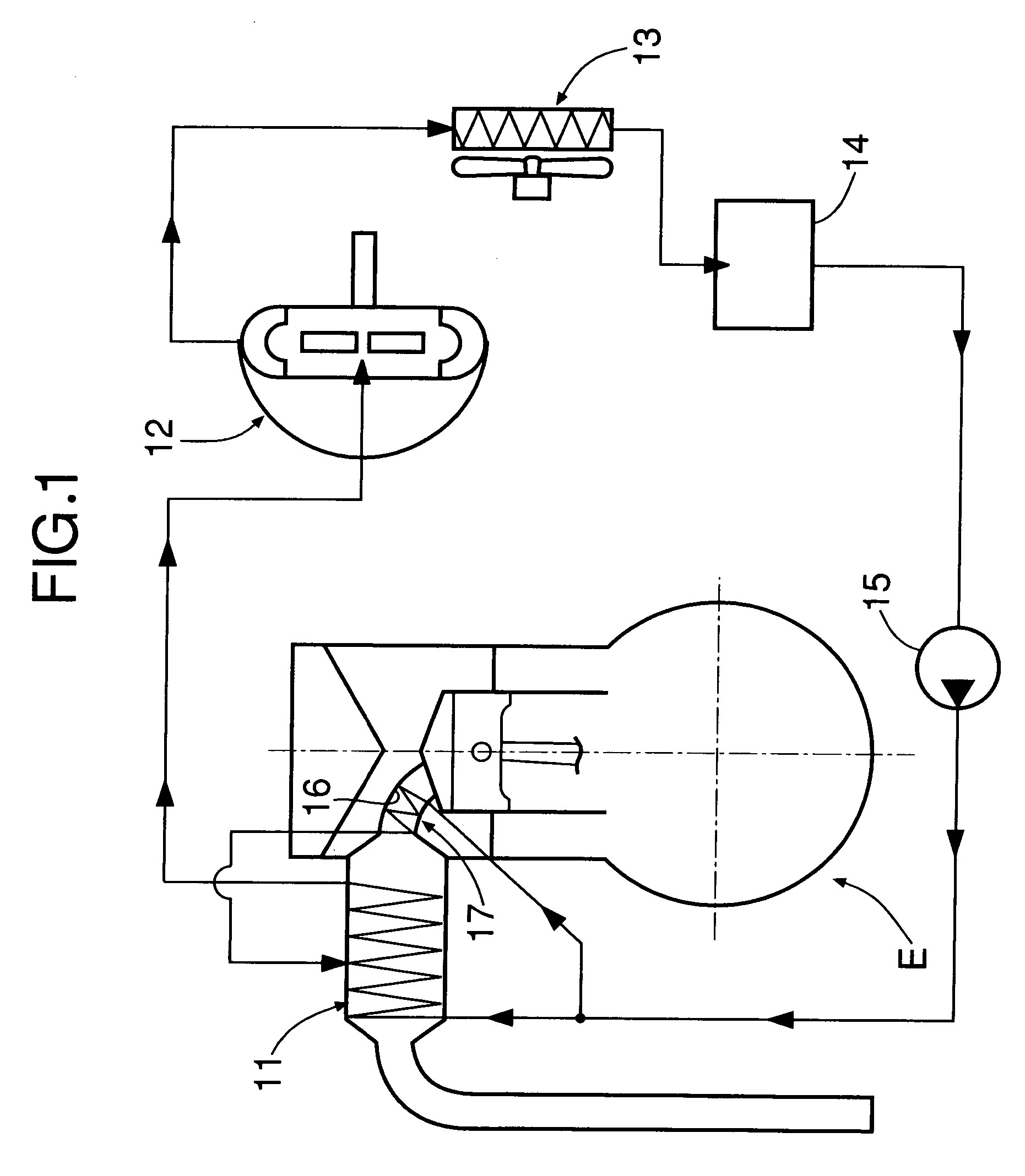

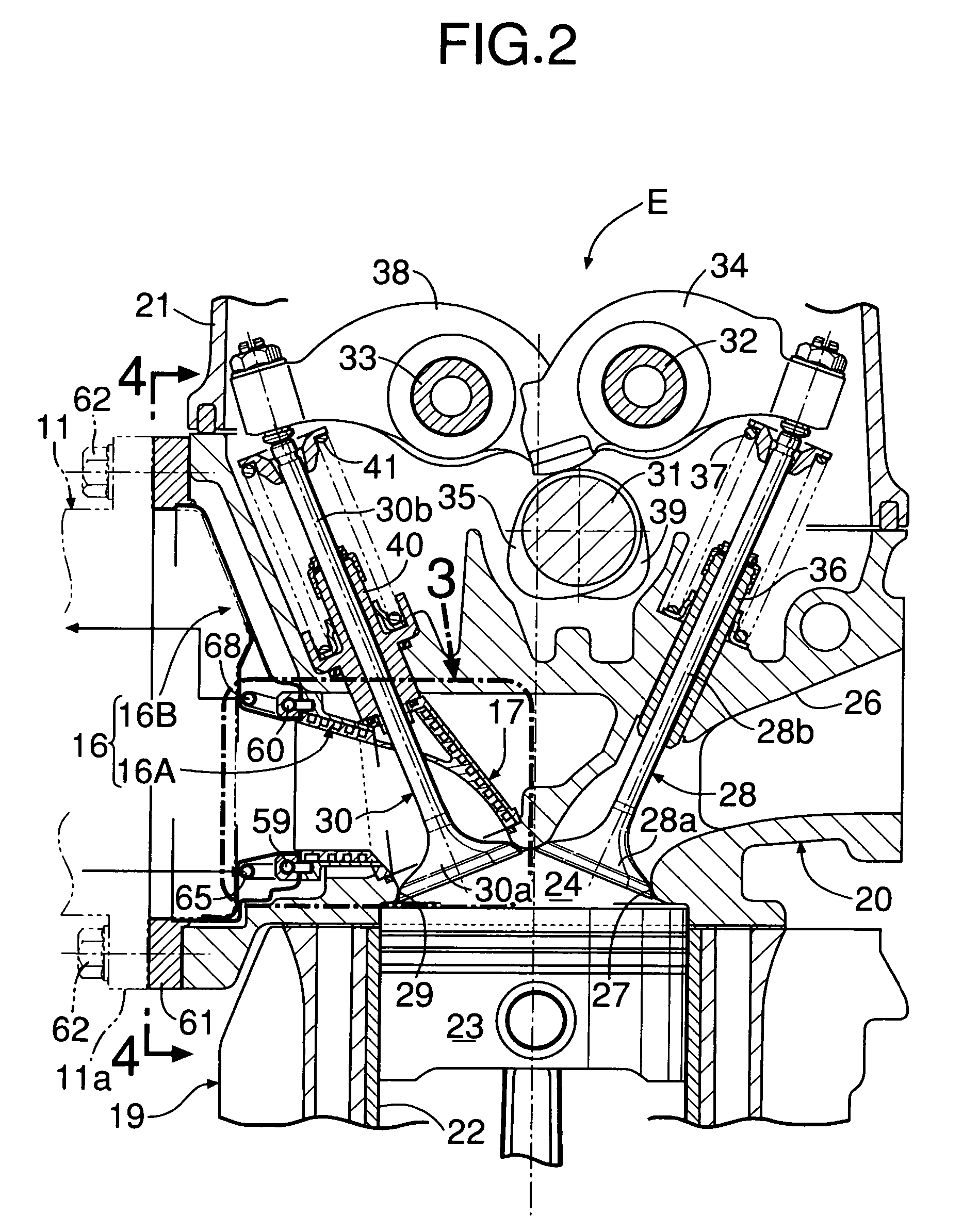

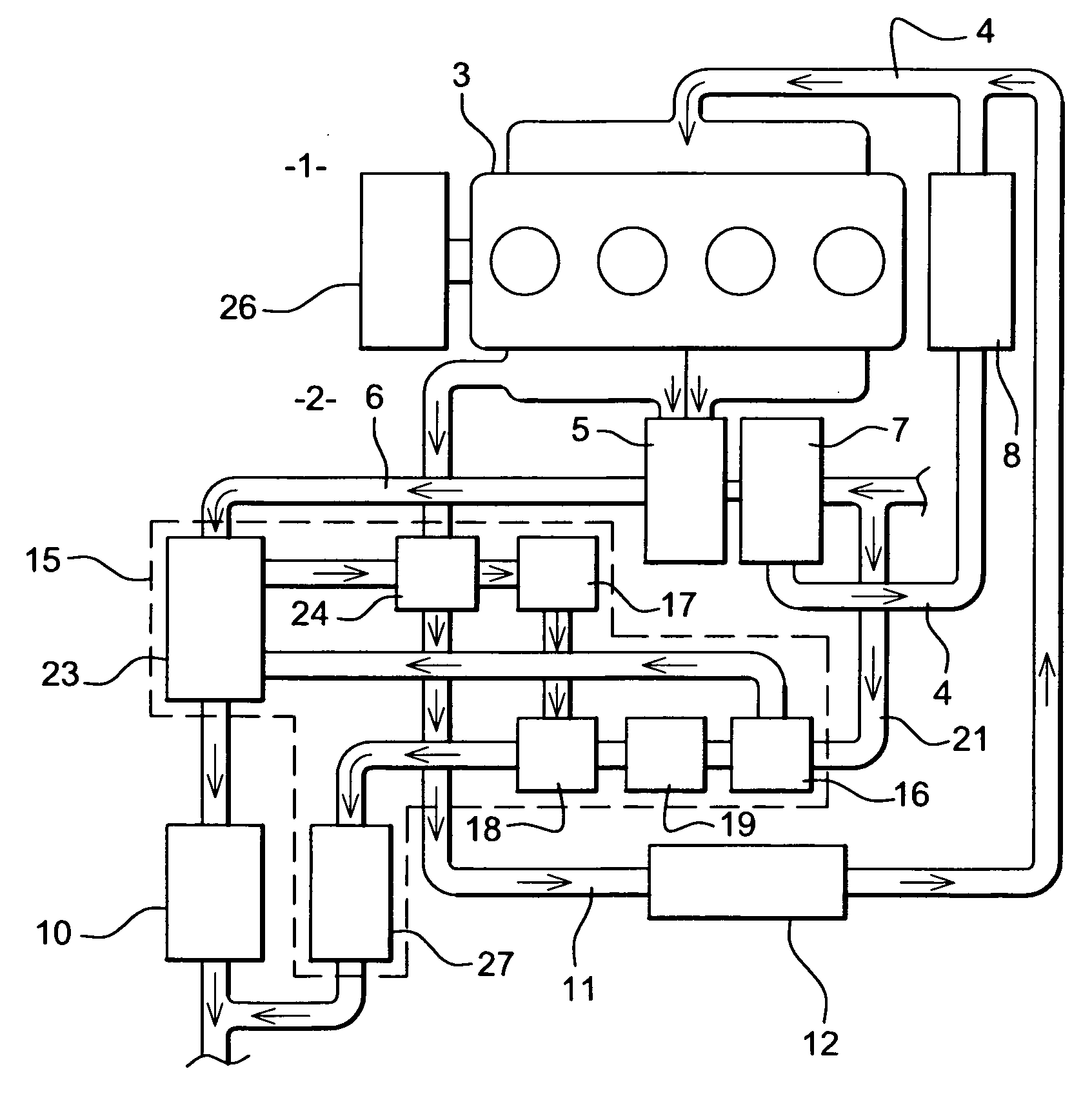

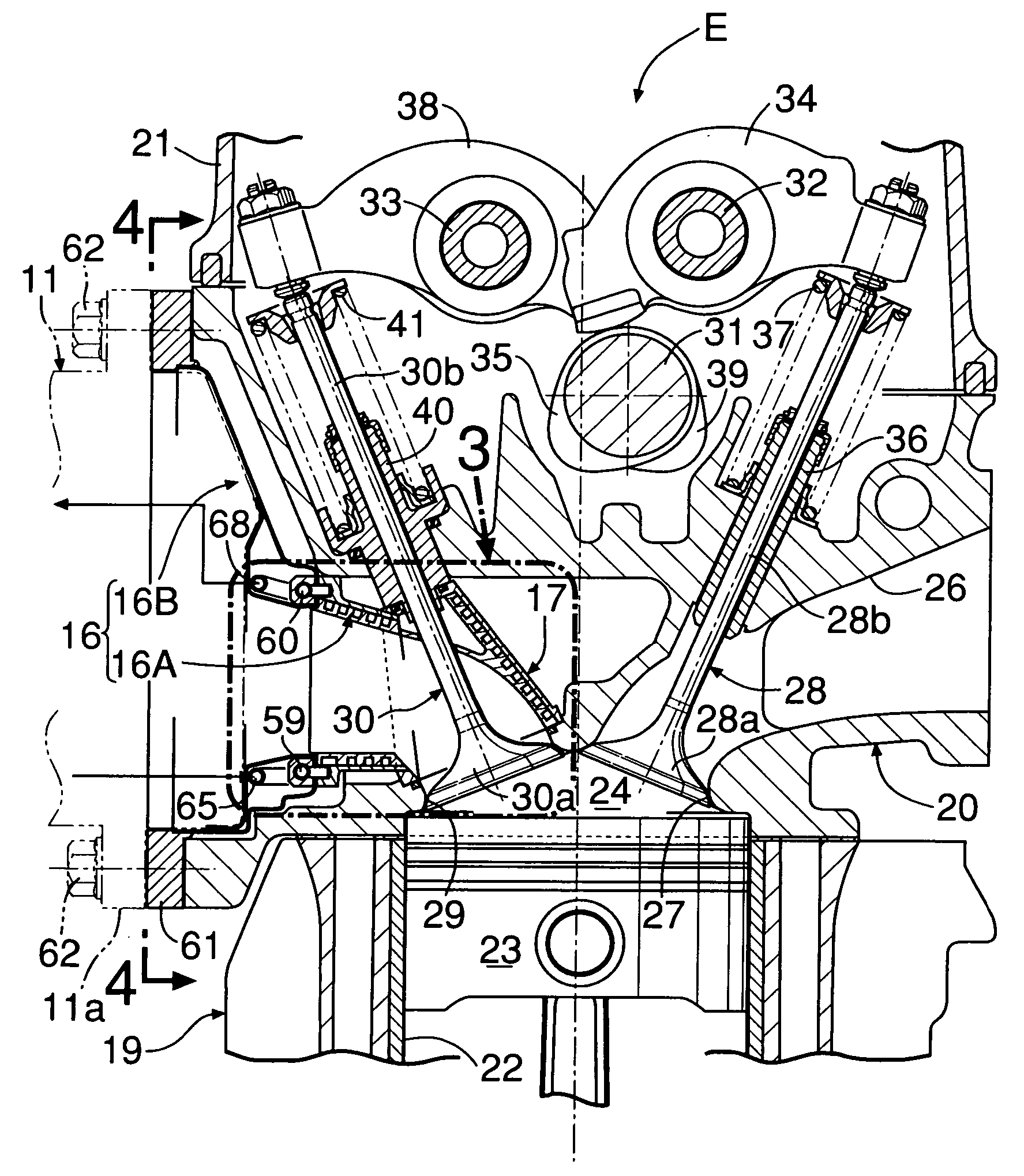

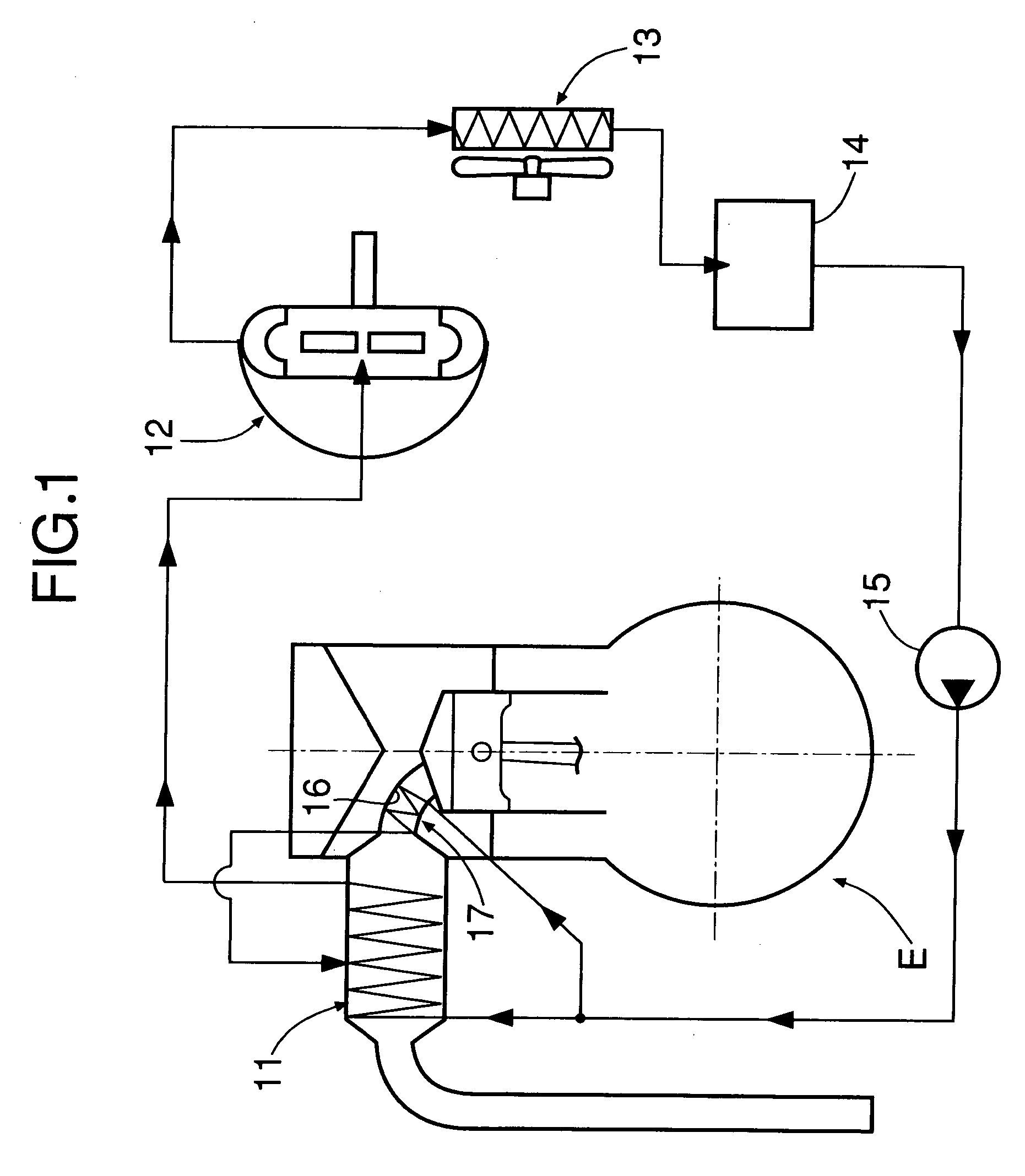

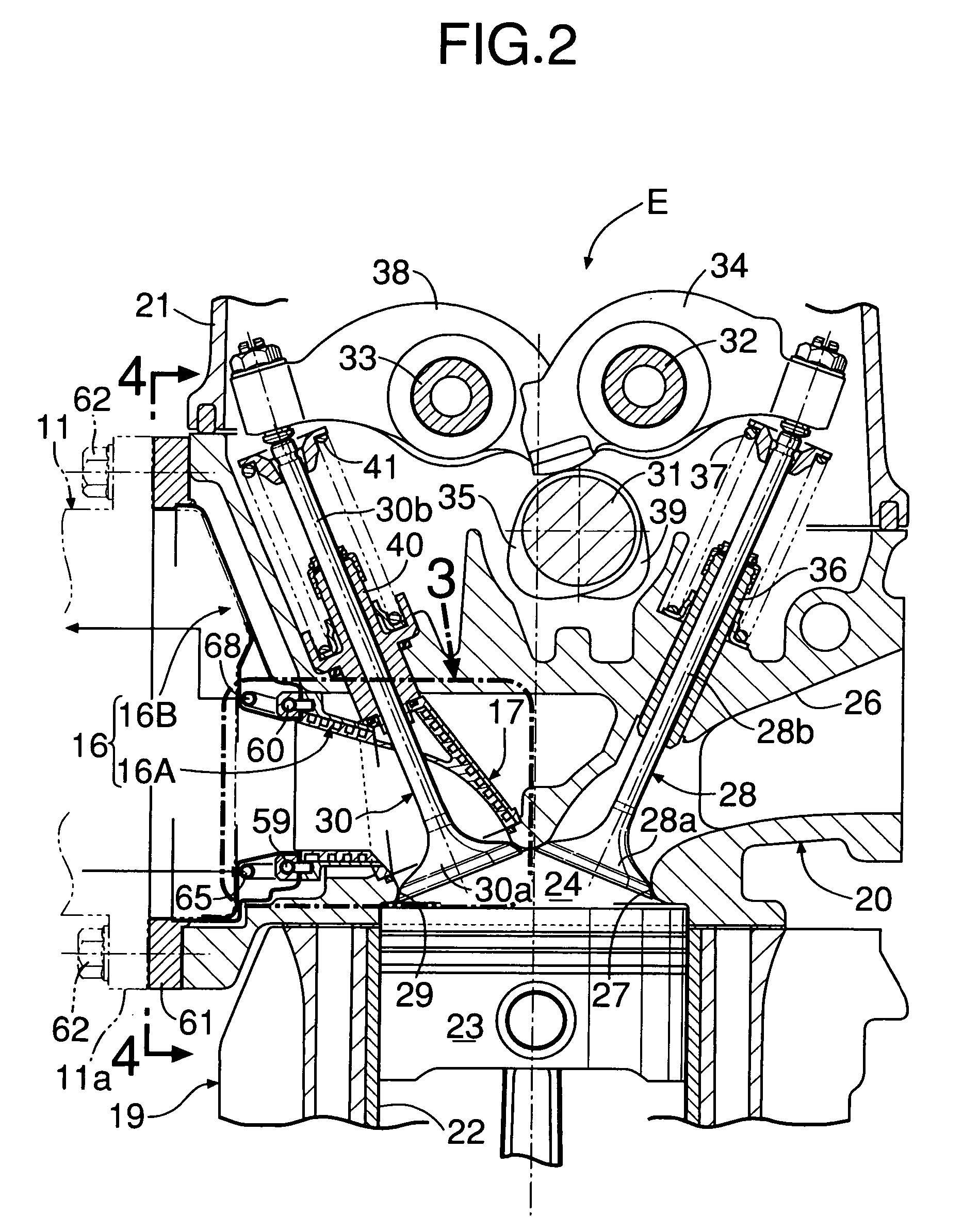

Internal combustion engine

InactiveUS20050076863A1Improve cooling effectWaste heat recoveryLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided in which an exhaust port (16) communicating with a combustion chamber (24) formed in a cylinder head (20) is formed from independent exhaust ports (16A), which are positioned on the upstream side, and a grouped exhaust port (16B), in which the plurality of independent exhaust ports (16A) are combined. Water supplied from a supply pump passes through a water passage (W1) of the grouped exhaust port (16B) and a water passage (W2) of the independent exhaust ports (16A) while cooling the exhaust port (16), and a valve seat (29) and valve guide (40) on the periphery of the exhaust port (16), which have high temperatures, thus heating the water itself and thereby recovering waste heat of the internal combustion engine. The heated water carries out heat exchange with exhaust gas in an evaporator provided in an exhaust passage and turns into high temperature, high pressure steam, which drives an expander of a Rankine cycle system. It is thereby possible to maximize the recovery of heat transferred from the exhaust port (16) to the cylinder head (20) of the internal combustion engine.

Owner:HONDA MOTOR CO LTD

Method and apparatus for odor control using panels of activated carbon cloth

ActiveUS8192537B2Efficiently adsorb any water vaporAvoid dissipationGas treatmentBoiling over preventionActivated carbonChemistry

Owner:ALEMAO THADDEUS

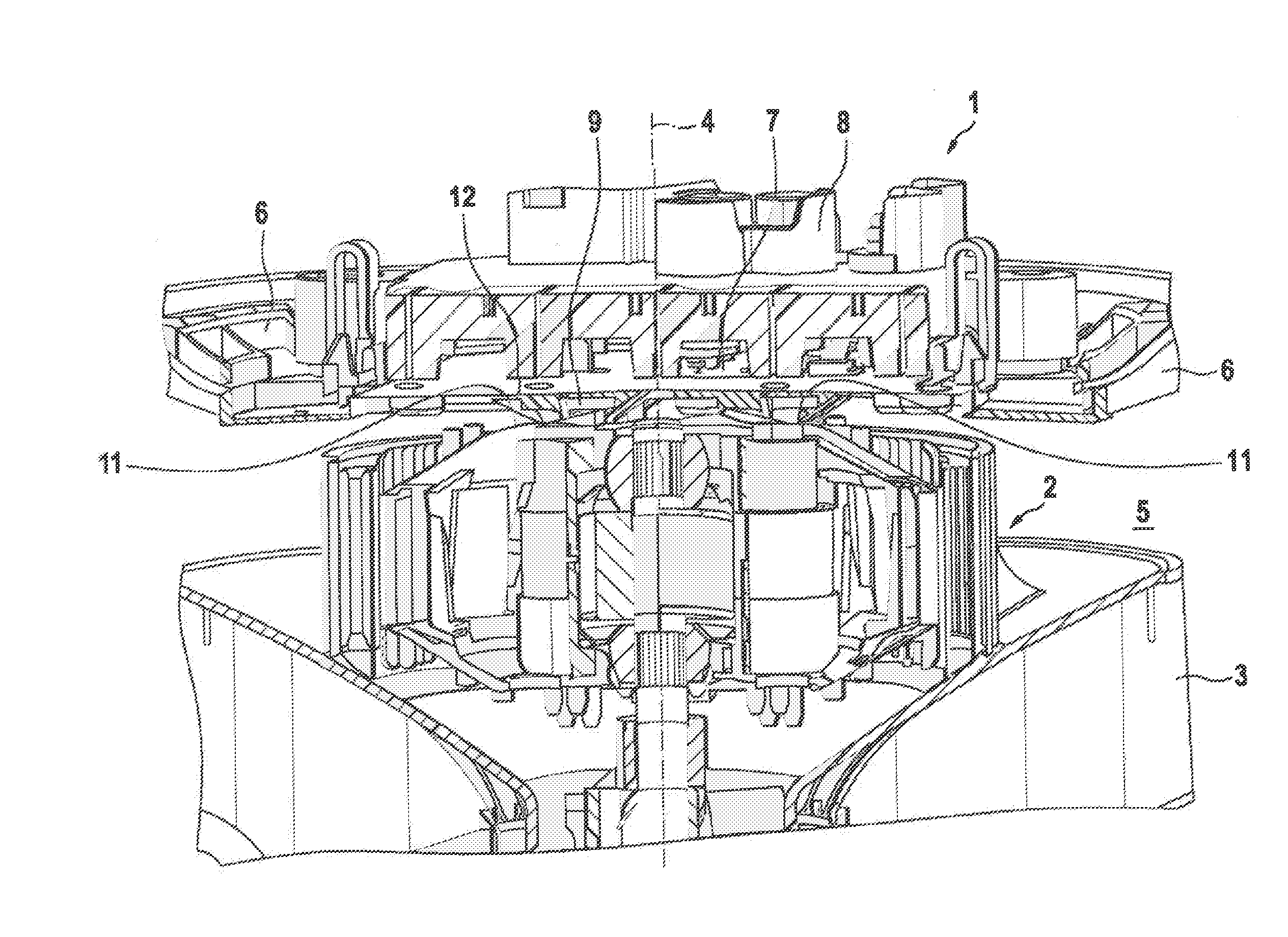

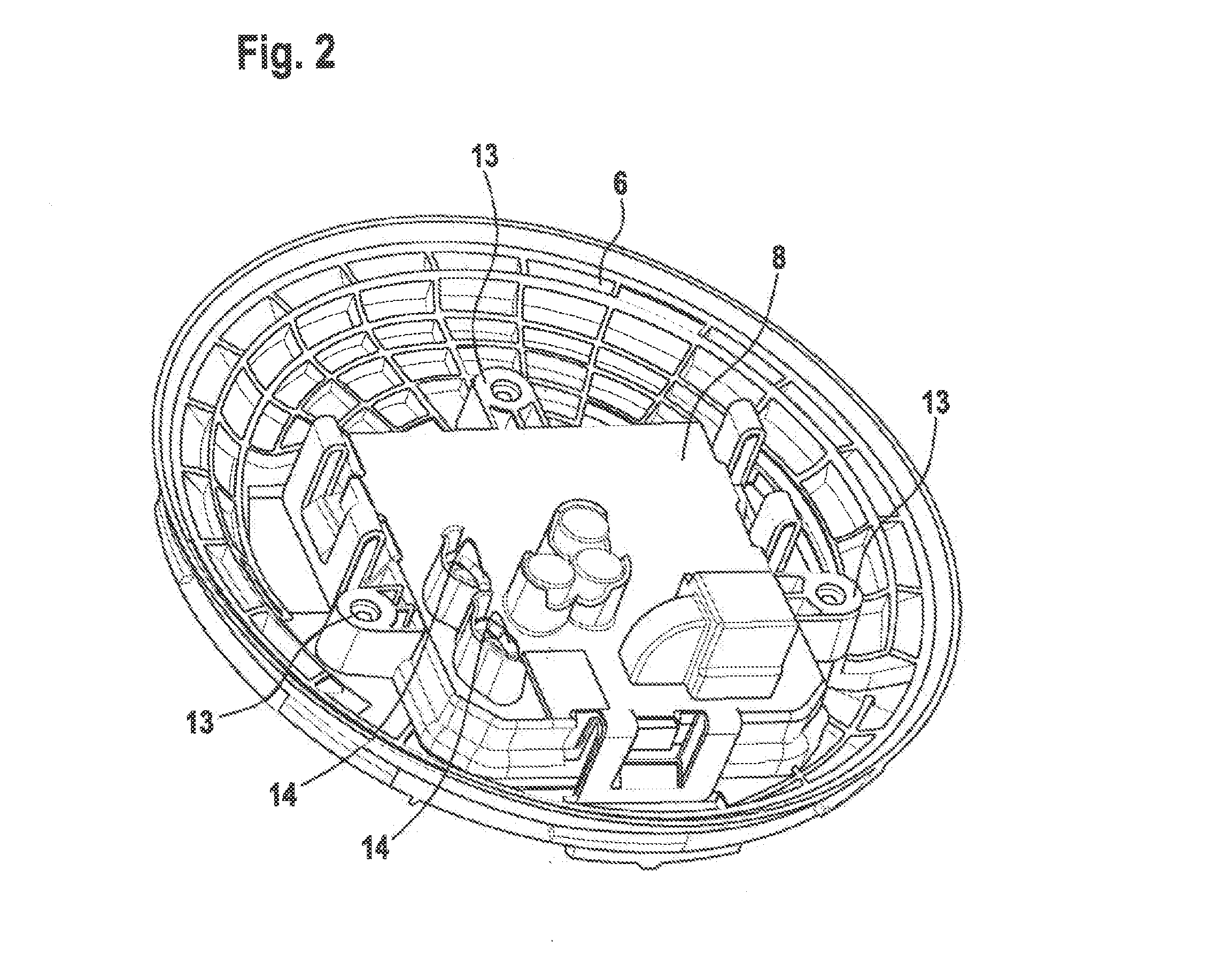

Fan unit

ActiveUS20130084197A1Simple cost-effective manufactureReliable coolingAssociation with control/drive circuitsPositive displacement pump componentsImpellerPower flow

A fan unit (1), in particular for an air conditioning system of a motor vehicle, comprising an electric motor (2) for driving a fan wheel (3), an electronic device (7) which generates waste heat and provides electrical current to the electric motor (2) and a fan housing (6), wherein the fan wheel (3) is disposed together with said electric motor (2) in an air guiding region (5) delimited by the fan housing (6). Provision is thereby made for the electronic device (7) to be fastened to the side of the fan housing (6) which faces away from the air guiding region (5) in a heat transferring manner so that a heat transfer connection is formed between said electronic device (7) and said air guiding region (5).

Owner:ROBERT BOSCH GMBH

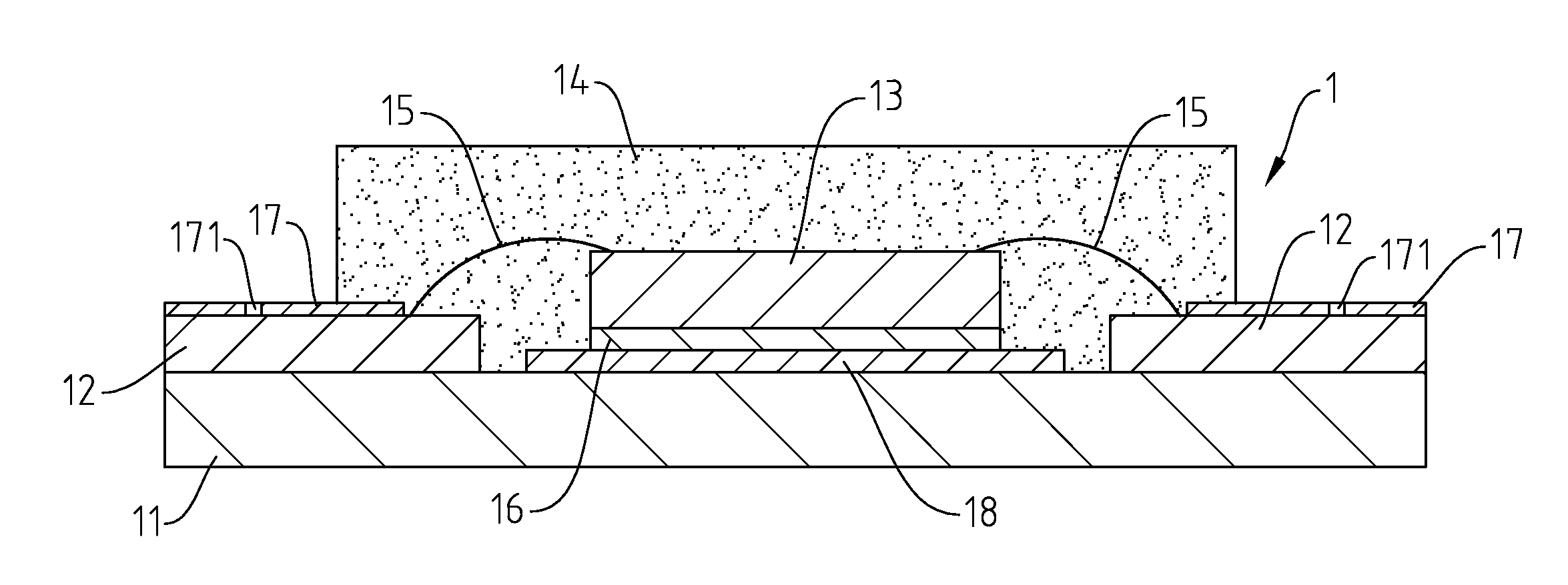

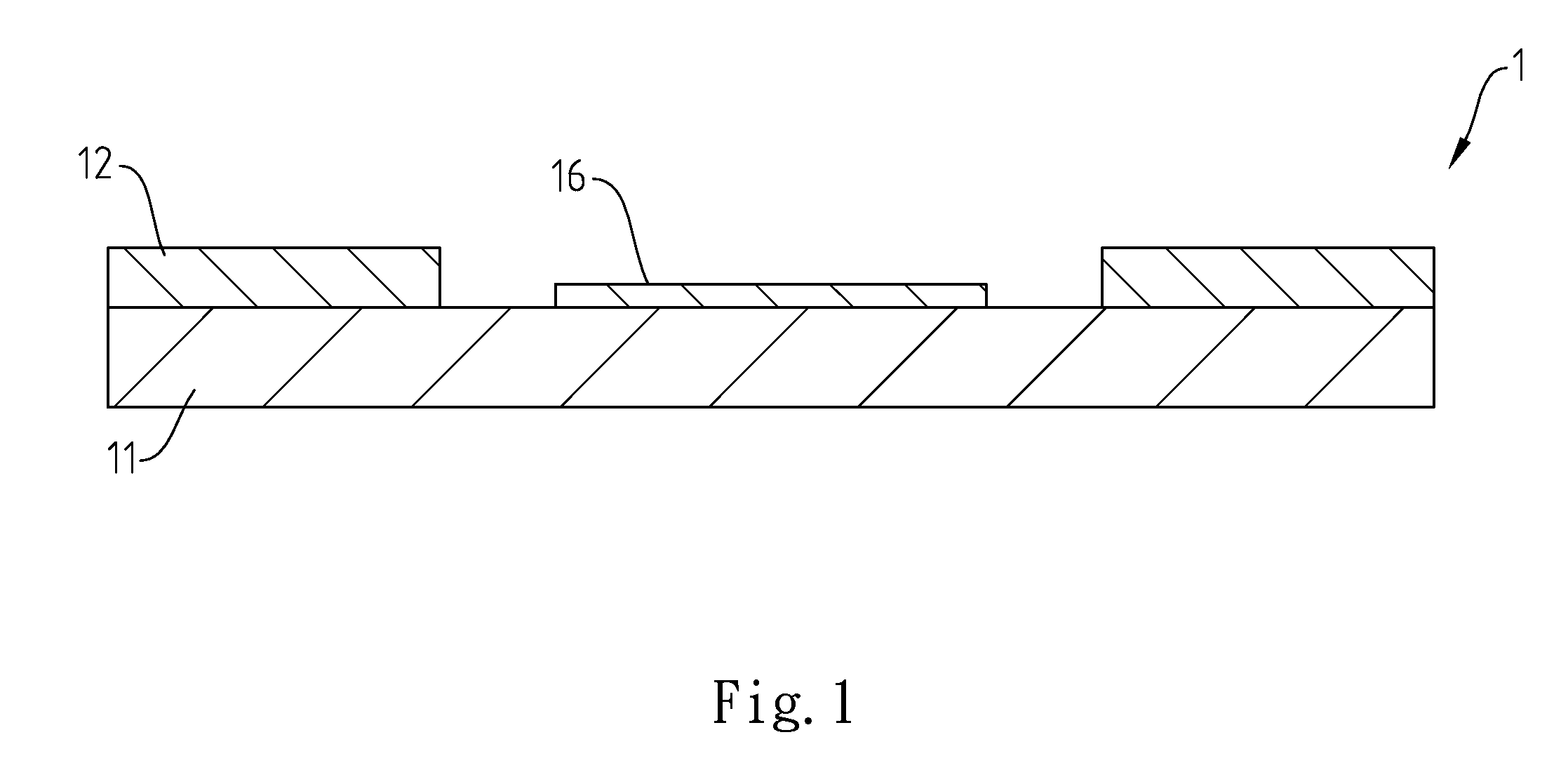

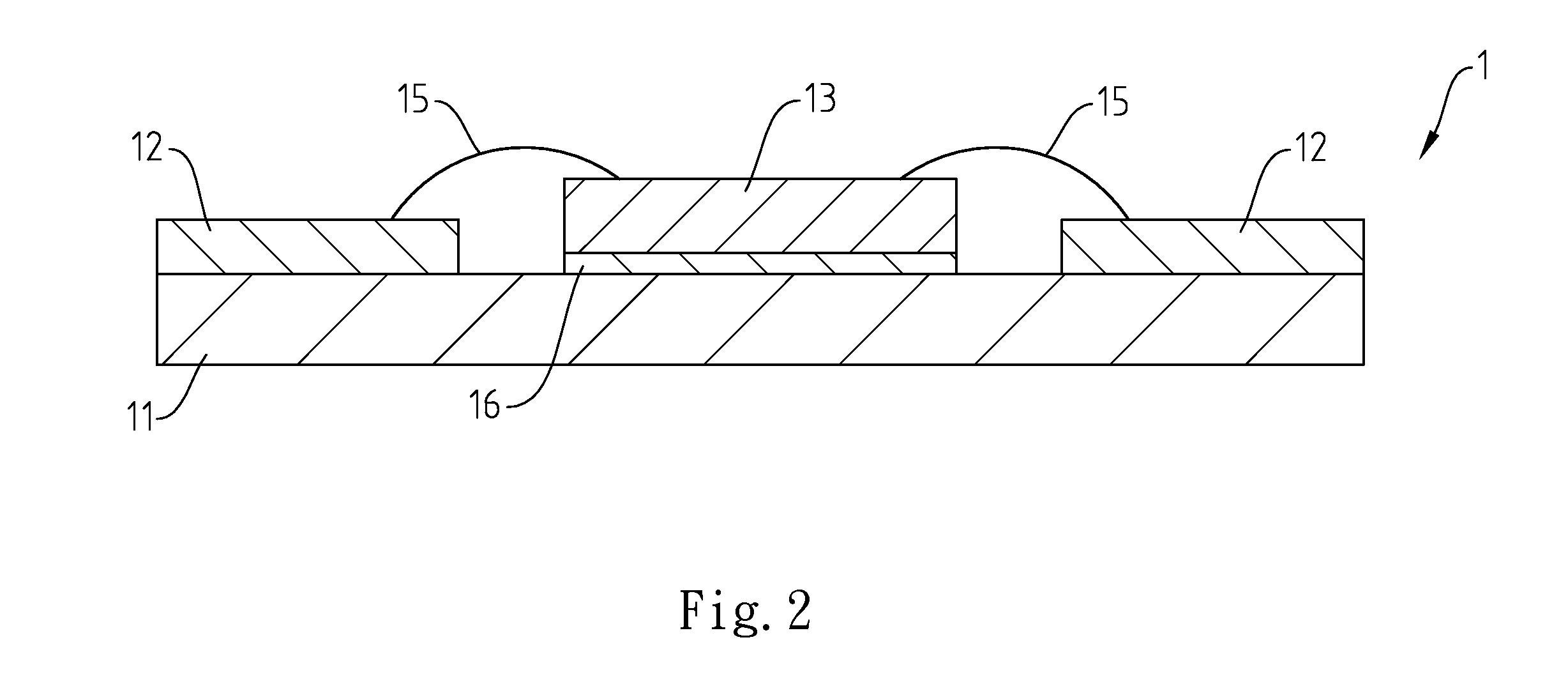

High-power LED package

InactiveUS20110233583A1High performanceLow power consumptionSolid-state devicesSemiconductor devicesElectrical and Electronics engineeringWaste heat

A high-power LED package includes a thermal conductive substrate, a circuit layer formed on the top wall of the thermal conductive substrate, a LED chip mounted on the top wall of the thermal conductive substrate, lead wires electrically connected between the LED chip and the circuit layer, and a packaging layer covering the LED chip, the lead wires and the connection areas between the lead wires and the circuit layer outside the bottom wall of the thermal conductive substrate for enabling waste heat to be directly transferred from the LED chip to the thermal conductive substrate and then rapidly dissipated into the outside open air by the thermal conductive substrate during operation of the LED chip.

Owner:H&T ELECTRONICS

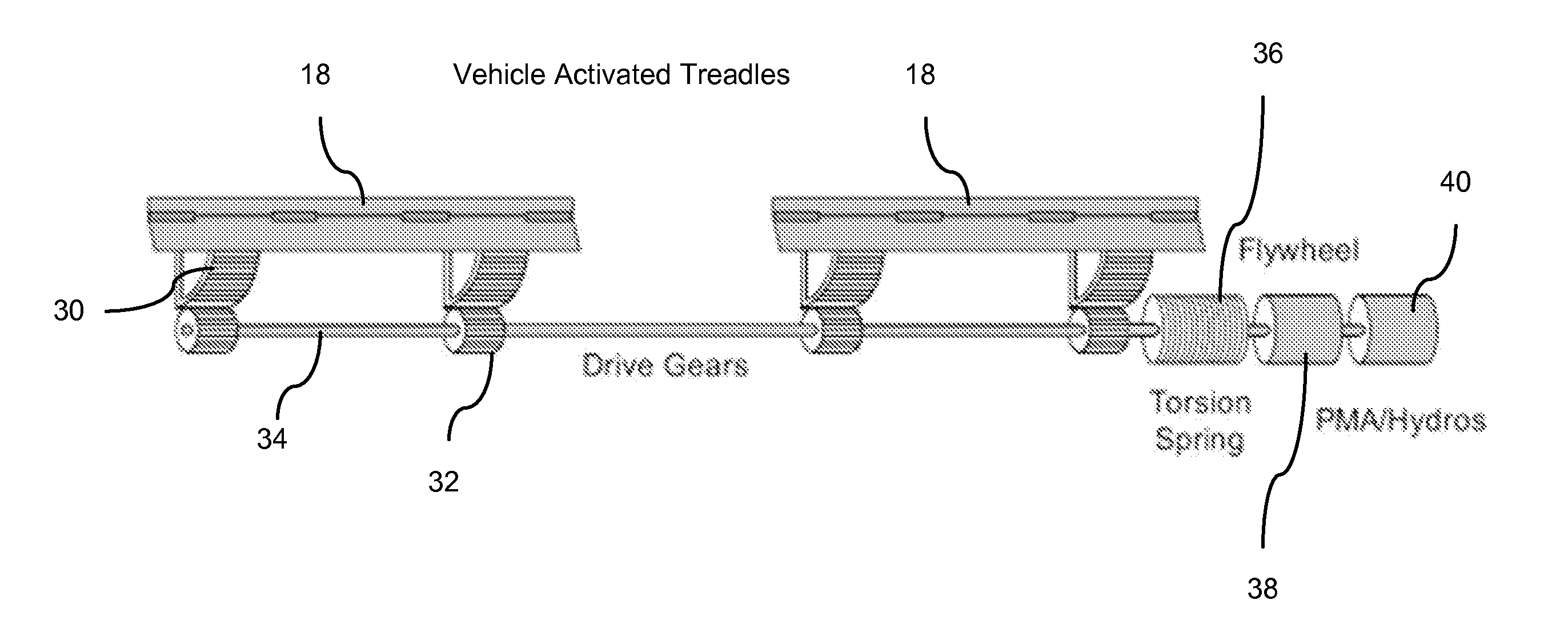

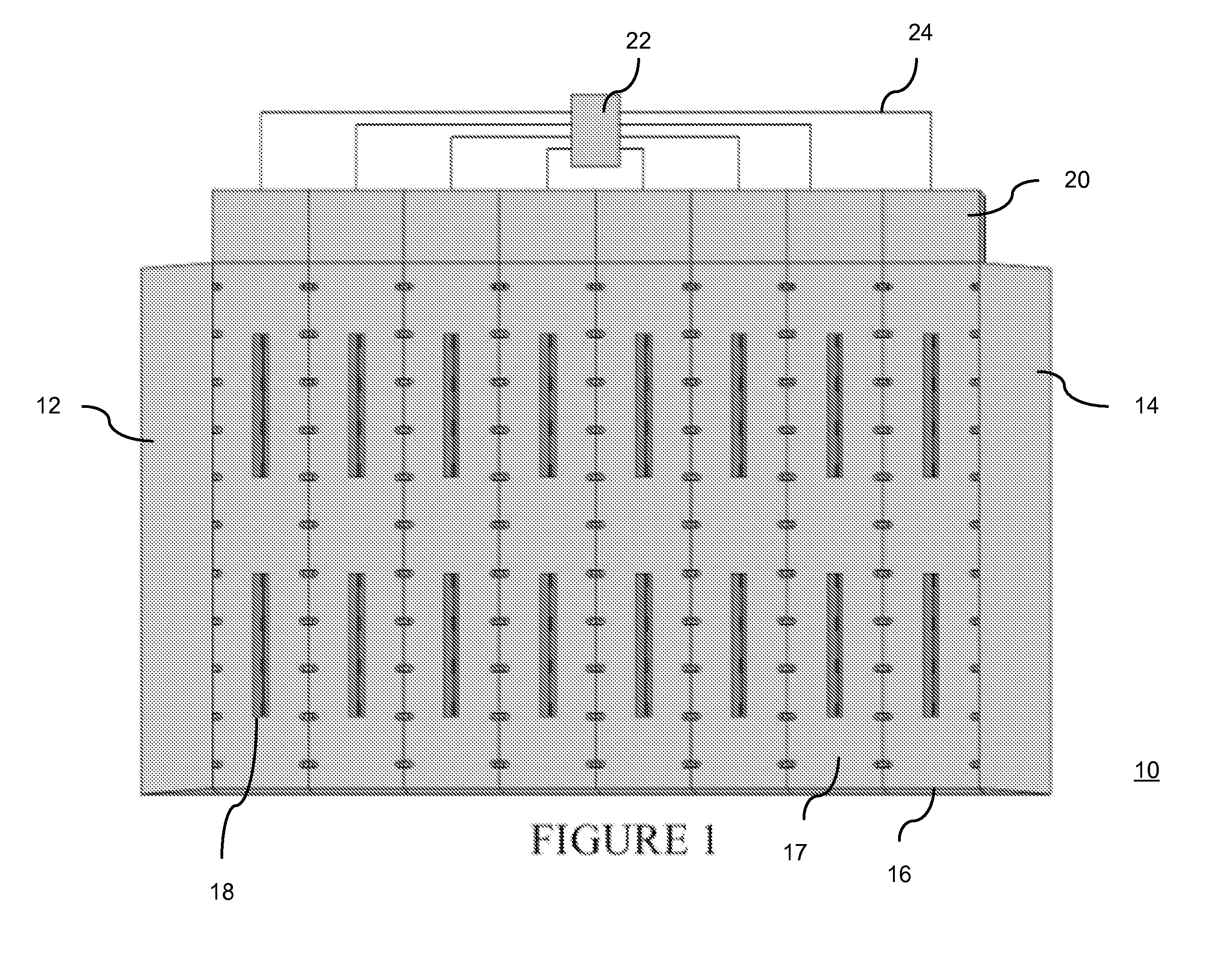

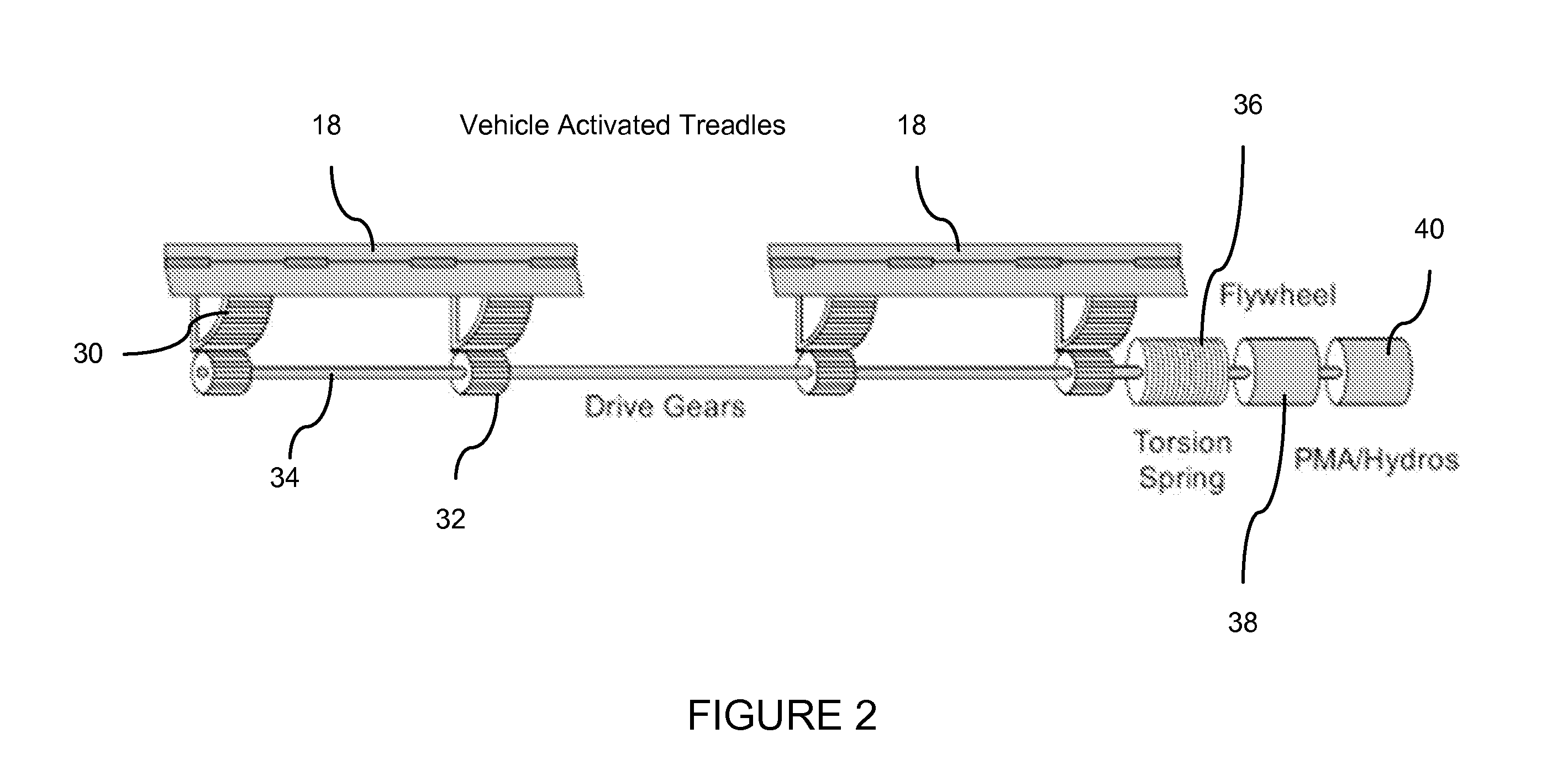

Low profile, surface-mounted power generation system

InactiveUS20110084500A1Easy to installShort payback periodIn situ pavingsMachines/enginesEnergy harvesterSurface mounting

A low-profile, surface mount vehicle energy harvester including a low-profile, surface mount subunit having an upper surface forming a roadway surface; a vehicle activated treadle on the subunit, the vehicle activated treadle moveable between a first position in which an upper surface of the treadle is at an angle with respect to the upper surface of the roadway surface and a second position in which the upper surface of the treadle is flush with the upper surface of the roadway surface; a generator that generates power in response to movement of the vehicle activated treadle; and an entry ramp at a first end of the harvester roadway surface; and an exit ramp at a second end of the harvester roadway surface.

Owner:SOLARWINDOW TECH

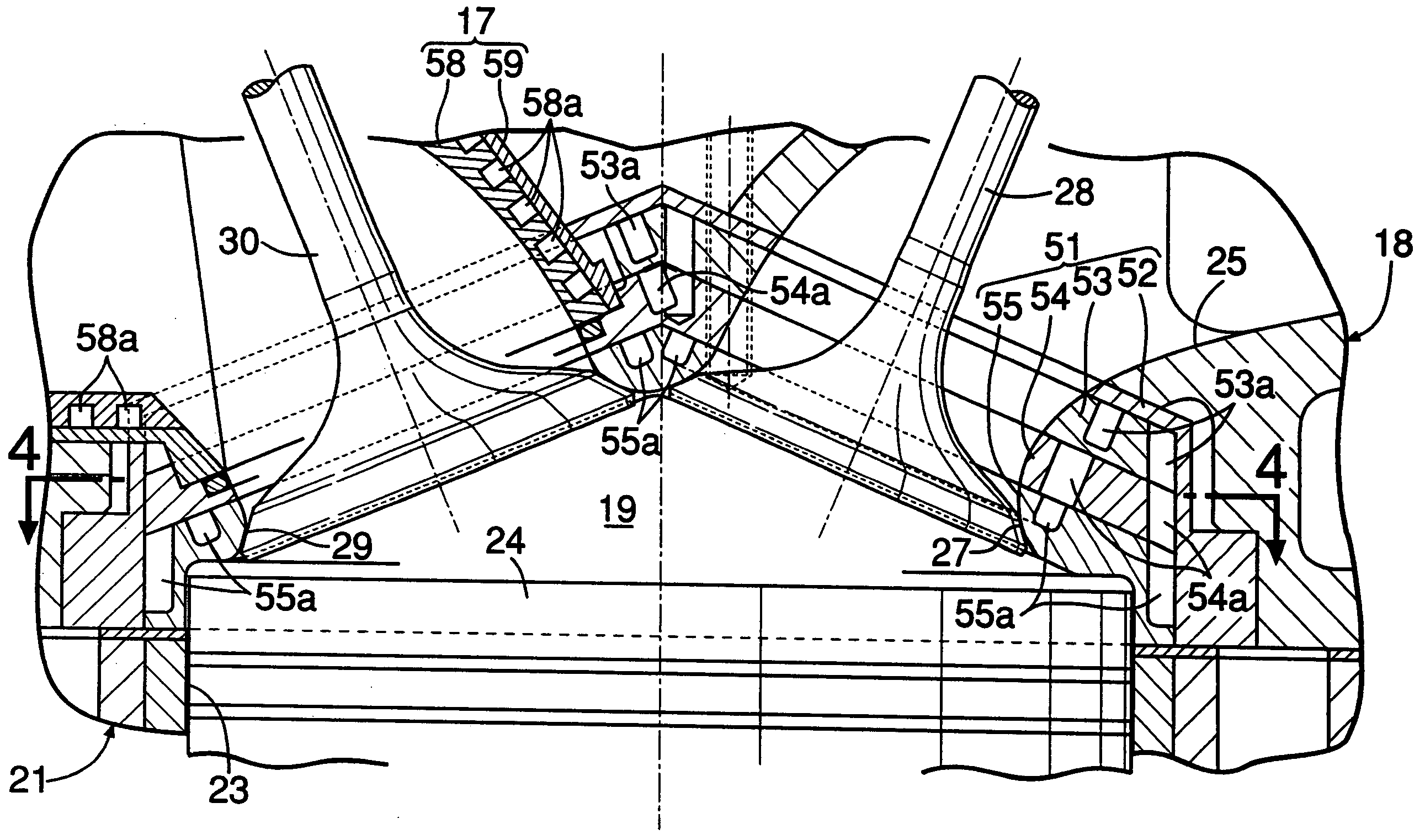

Internal combustion engine

InactiveUS20050051114A1Reduced dimensionEliminateLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

A cooling block (51) forming a top wall of a combustion chamber (19) of an internal combustion engine is formed by layering, from the outside to the inside, a casing (52), an upper layer block (53), a middle layer block (54), and a lower layer block (55). Labyrinth-shaped cooling water passages (53a, 54a, 55a) are formed on upper faces and side faces of the three layers of blocks (53, 54, 55), and cooling water supplied from a cooling water supply passage (56) flows from the cooling water passage (53a) on the side far from the combustion chamber (19) to the cooling water passage (55a) on the side close to the combustion chamber (19), and is discharged from a cooling water discharge passage (57). Since the cooling water flows in a direction opposite to the direction of emission of heat of combustion from the combustion chamber (19), it is possible to ensure that there is sufficient difference in temperature between a cylinder head (18) and the cooling water throughout the cooling water passages (53a, 54a, 55a), thereby improving the effect of the cooling water in cooling the cylinder head (18) and enabling the waste heat of the internal combustion chamber to be recovered effectively.

Owner:HONDA MOTOR CO LTD

Cogeneration apparatus case venting system

ActiveUS8446023B2Waste heatEfficientlyAir-treating devicesInternal combustion piston enginesCogenerationEngineering

A cogeneration apparatus having a ventilation-introducing channel communicating an electrical-equipment compartment with a ventilation fan is disclosed. Driving the ventilation fan causes air to be led from an exterior of a cogeneration case through the electrical-equipment compartment to the interior of the ventilation-introducing channel. The air led to the interior of the ventilation-introducing channel is led to an electrical generator. The air led to the electrical generator is exhausted through a power-generation compartment to the exterior of the cogeneration case.

Owner:HONDA MOTOR CO LTD

Pre-coated sand regeneration system energy recovery method

InactiveCN103286260AWaste heatMake full use of waste heatIncreasing energy efficiencyMould handling/dressing devicesCombustion chamberEnergy recovery

The invention discloses a pre-coated sand regeneration system energy recovery method, which comprises the following steps of: afterheat energy recovery of off gas after fuel is combusted in a roasting furnace, wherein hot off gas generated after fuel is combusted in a combustion chamber of the roasting furnace is subjected to heat exchange at the tail of the roasting furnace through a mounted heat exchange device to generate hot air, then the hot air is delivered to the combustion chamber of the roasting furnace and an air distribution port at the bottom of the roasting furnace respectively so as to supply the hot air to a soaking zone of the roasting furnace; hot gas energy recovery in a boiling cooling bed, wherein a heat exchange device is mounted in an appropriate position of the boiling cooling bed, high-temperature hot gas in the boiling cooling bed is delivered into a cold sand hopper in a mixed sand hopper, and cold sand is pre-heated; energy recovery of regenerated heat pre-coated sand cooled by the boiling cooling bed, wherein the regenerated heat pre-coated sand cooled by the boiling cooling bed is delivered to a sand rolling bucket through a hot sand hopper, and is fully rolled, stirred, and mixed with pre-heated cold sand from the cold sand hopper to achieve heat exchange. The pre-coated sand regeneration system energy recovery method can achieve the comprehensive energy recovery rate of above 70%, and realize a remarkable progress in improving the thermal efficiency and reducing the production cost.

Owner:QINGDAO TIANHENG MACHINERY

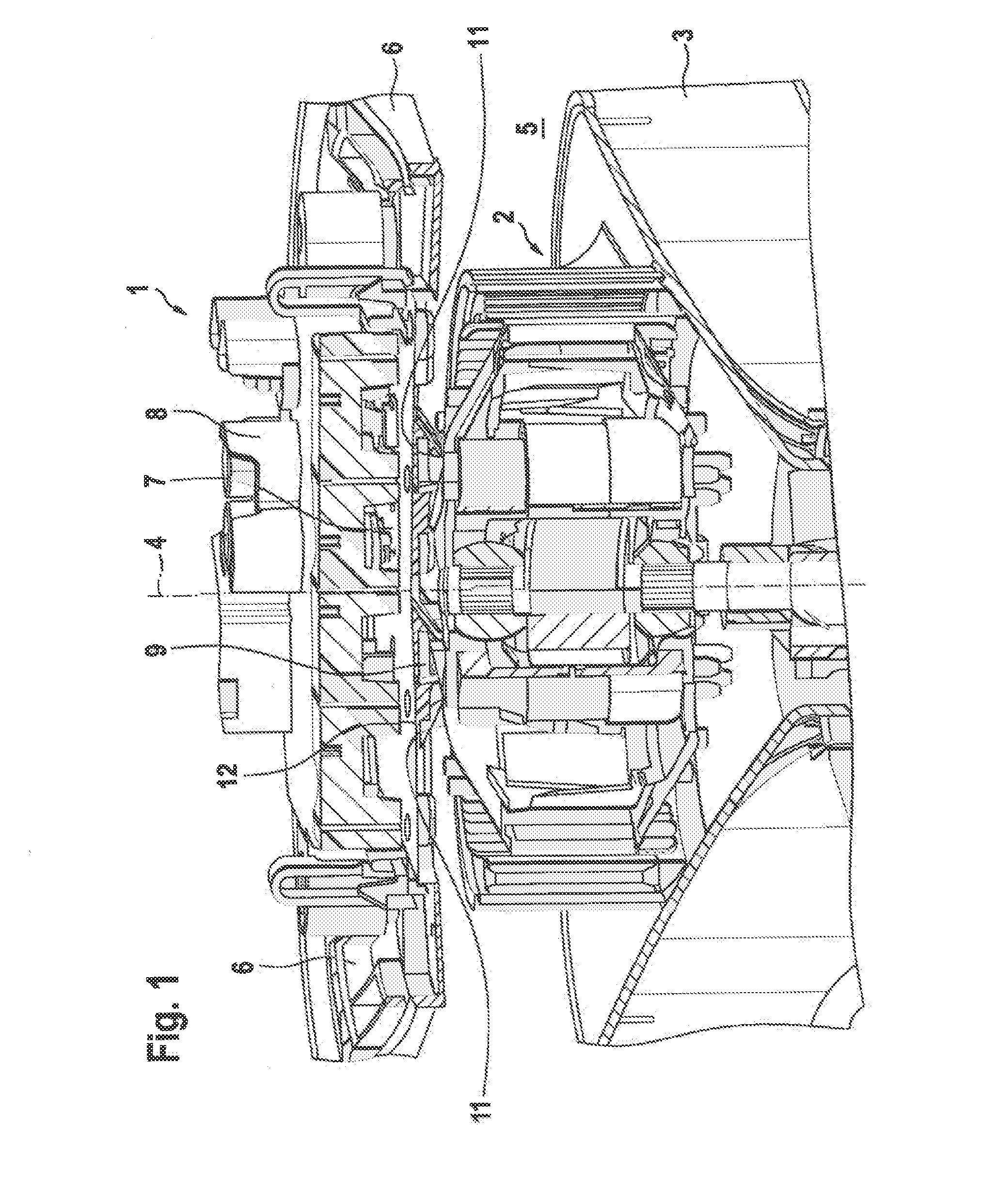

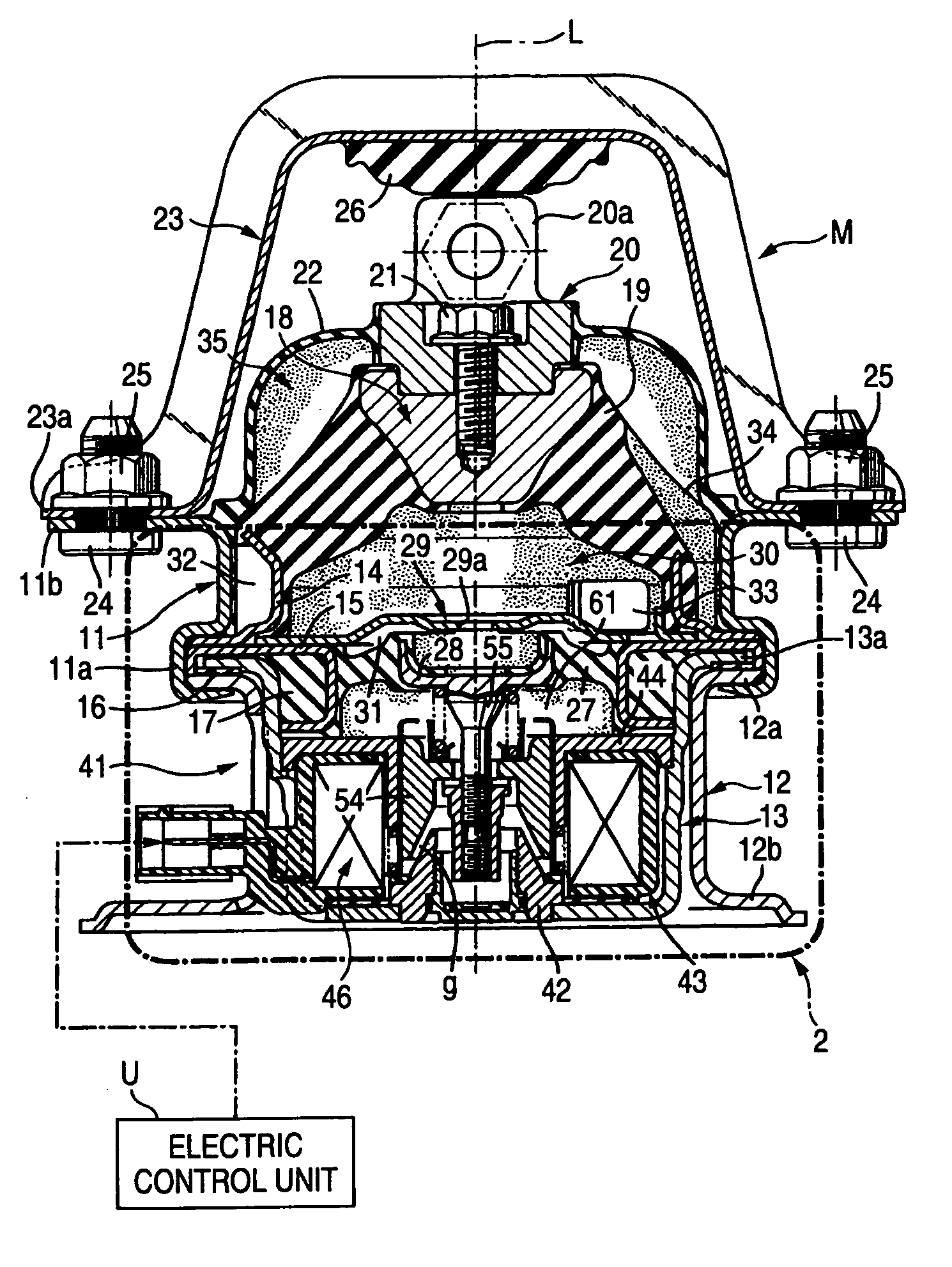

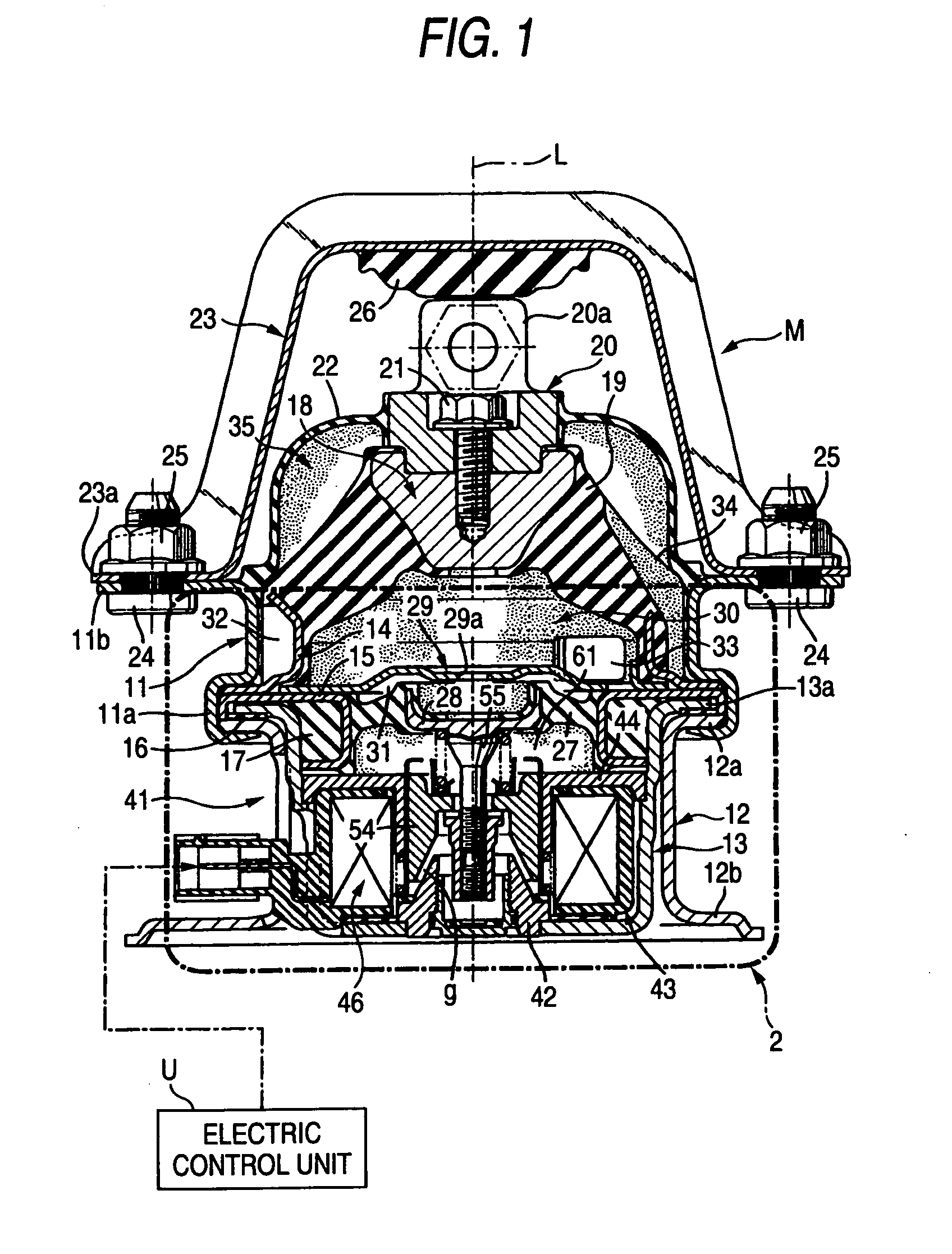

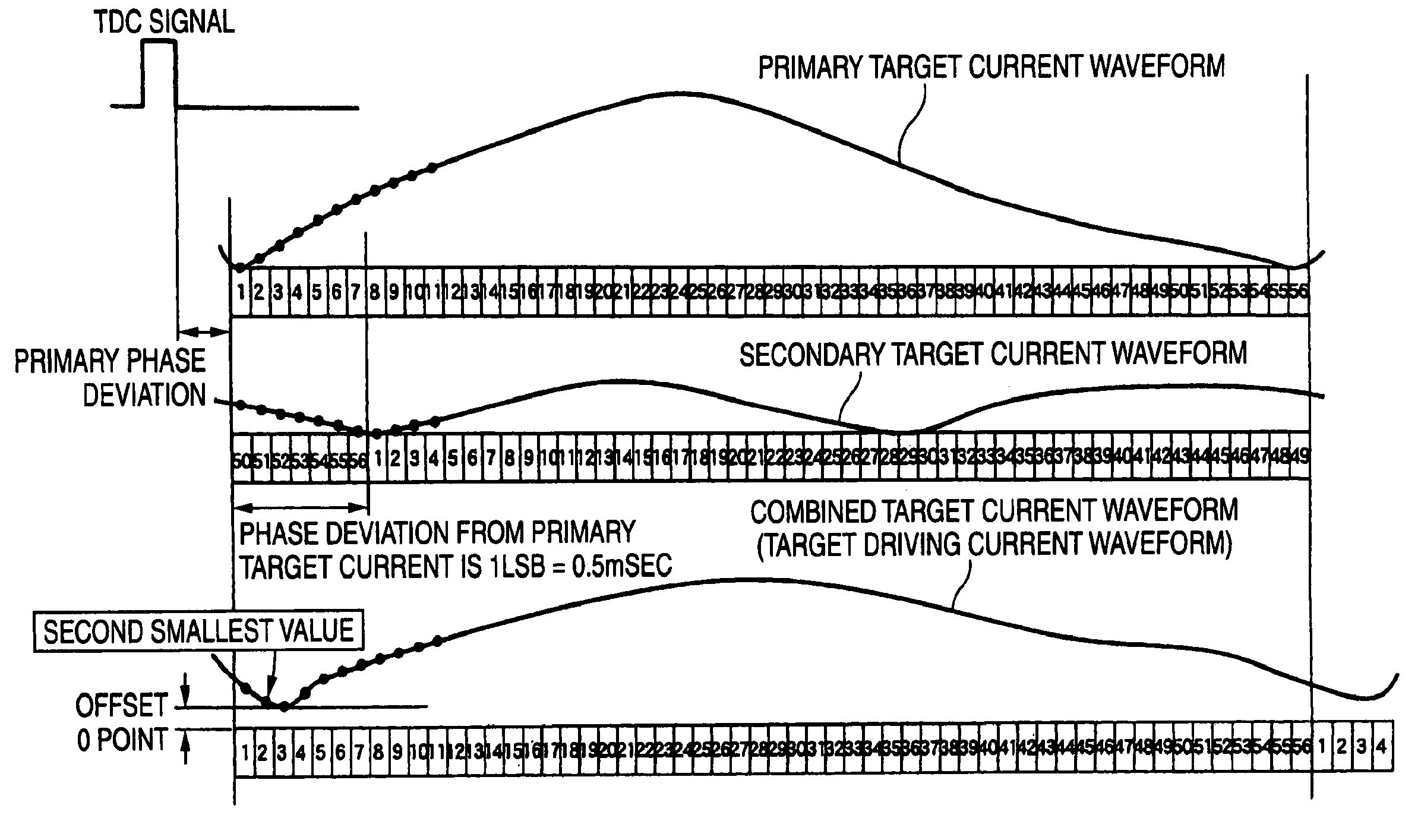

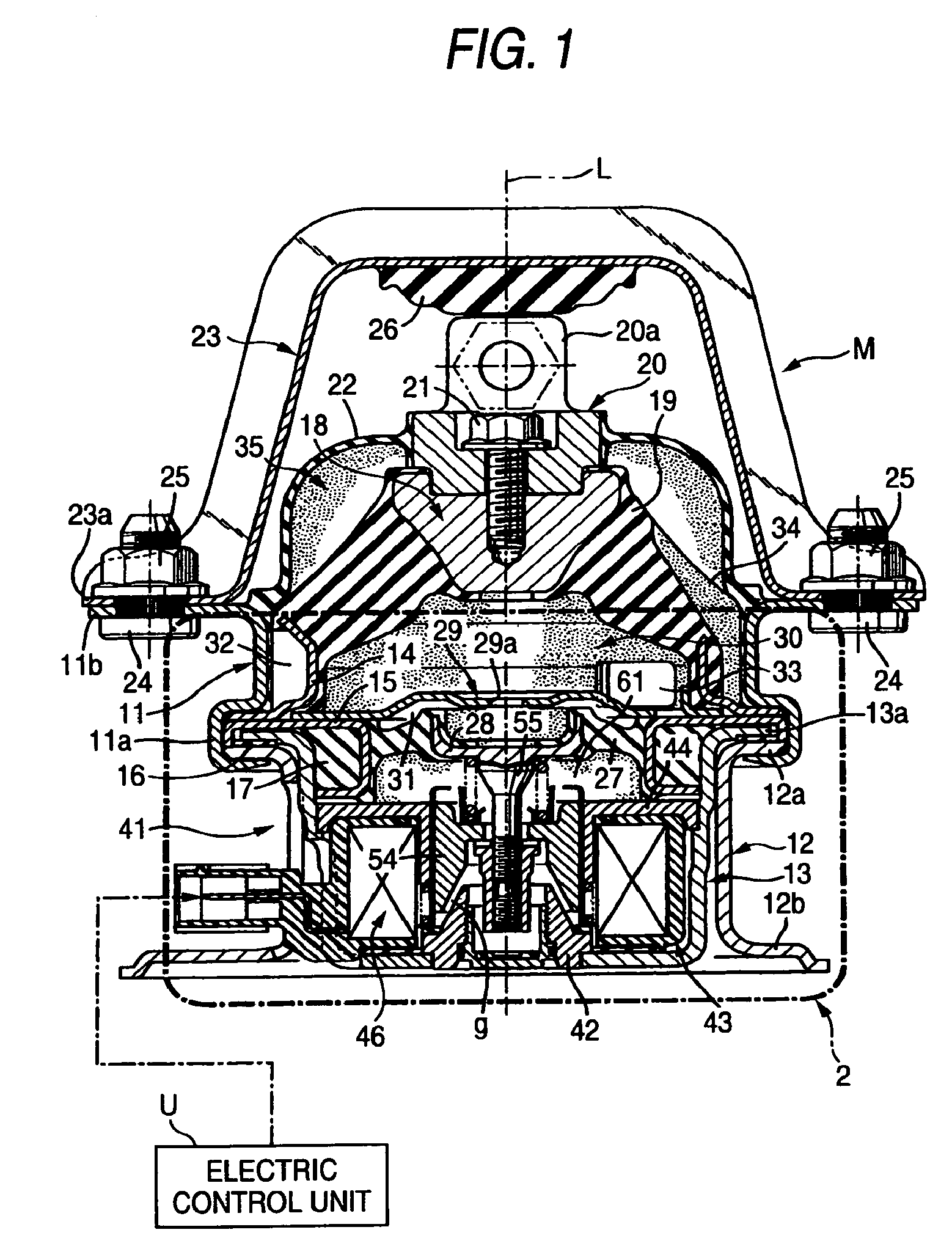

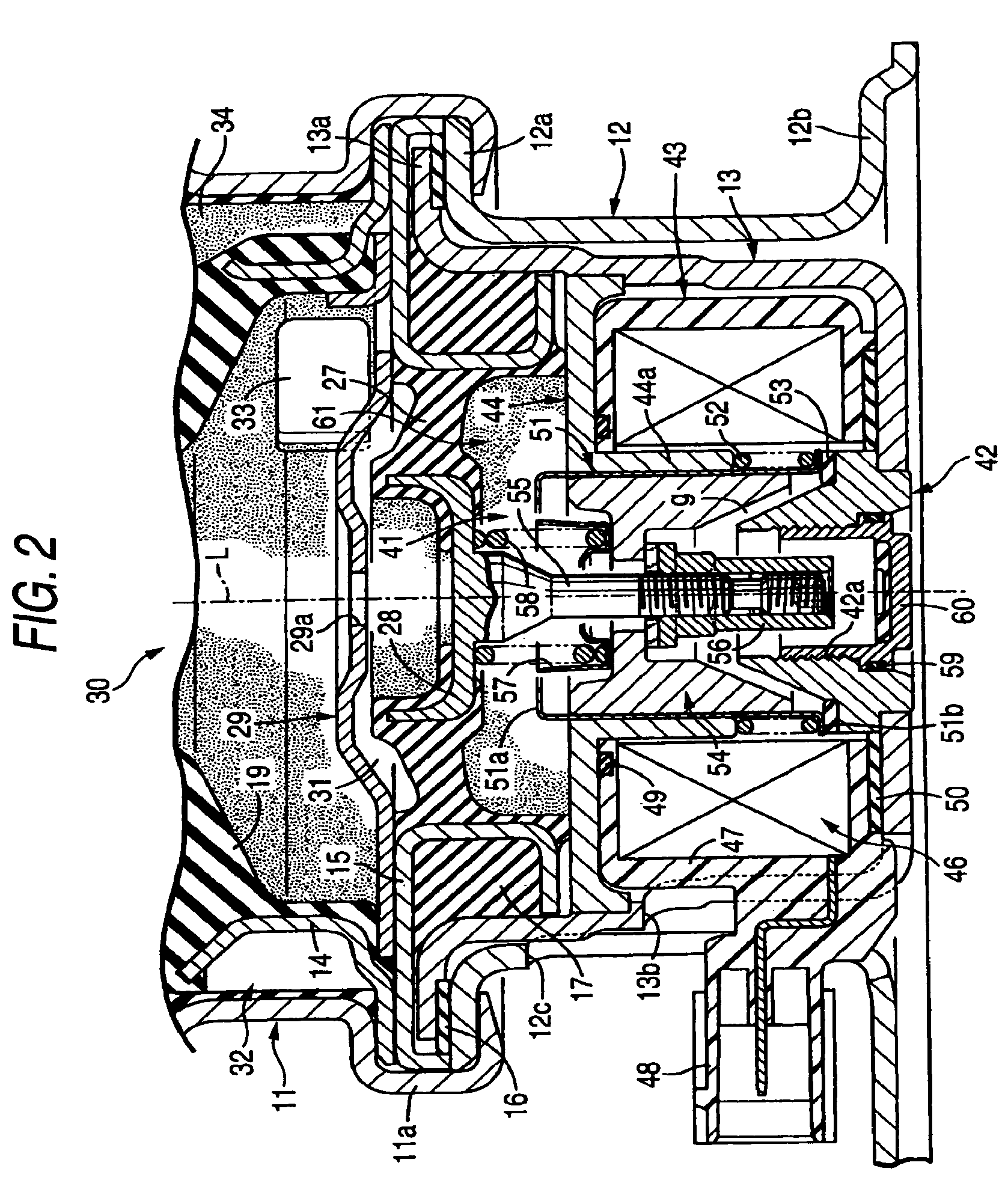

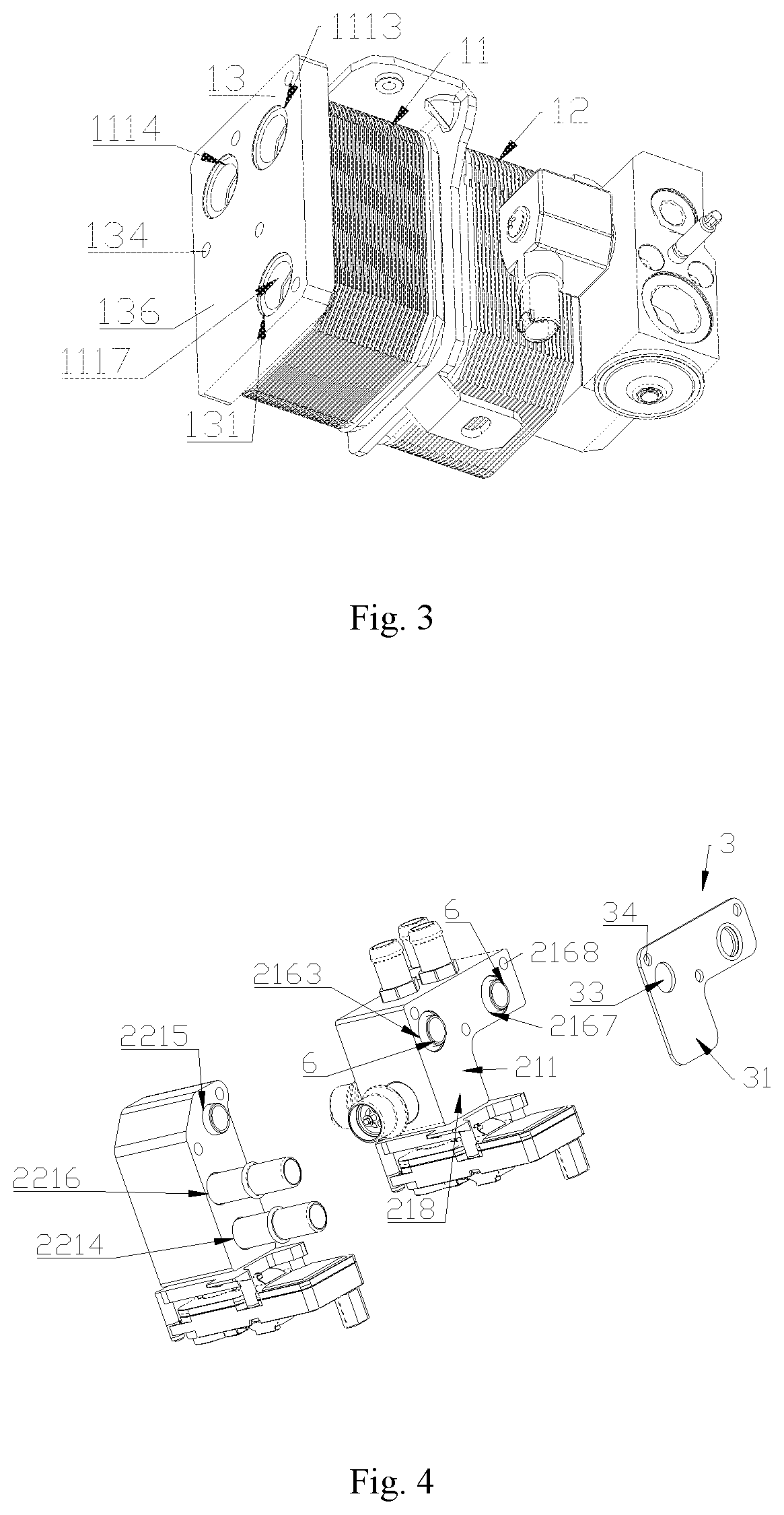

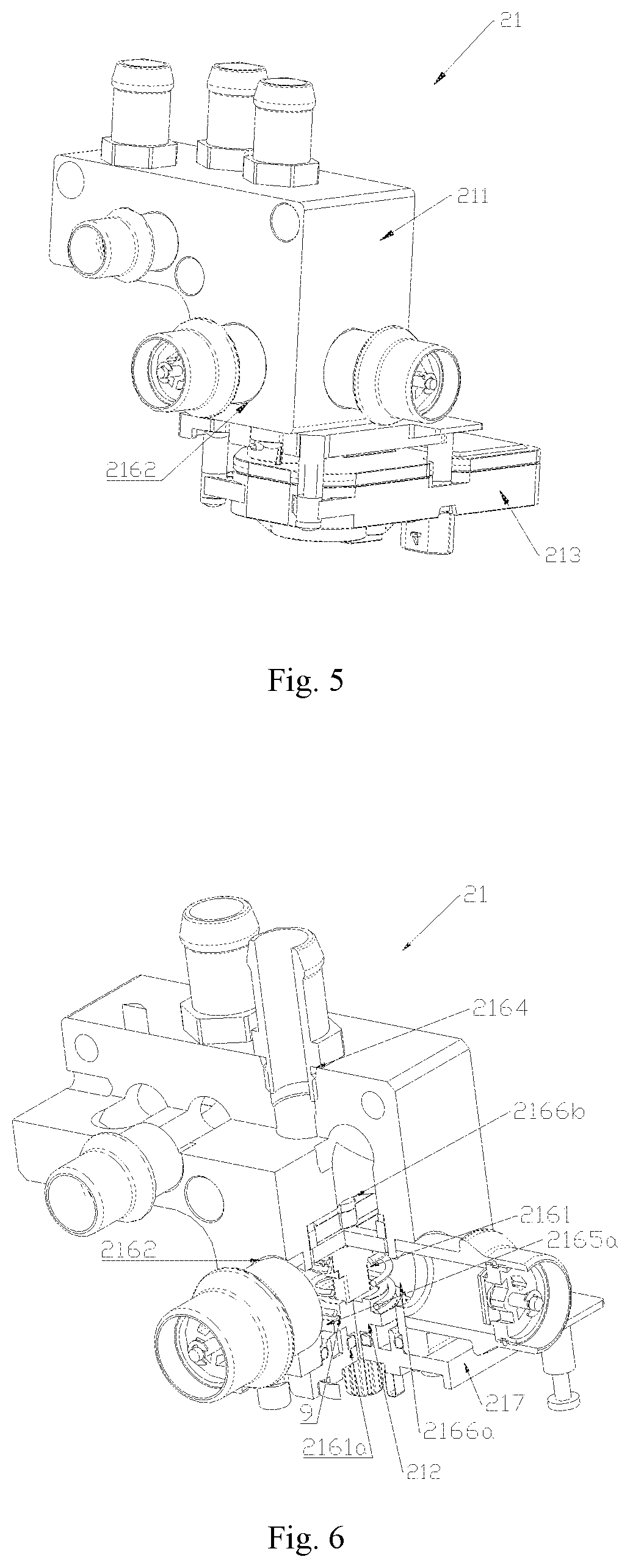

Active vibration isolating support apparatus

When driving an actuator 41 of an active vibration isolating support apparatus M to extend and contract on a predetermined cycle so as to suppress the transmission of vibrations of an engine, since a combined target current ICMDT is calculated by combining a primary target current which cancels a primary vibration of the engine with a secondary target current which cancels a secondary vibration of the engine and furthermore, the actuator 41 is driven with a target driving current ICMD in which a minimum value of the combined target current ICMDT is offset to 0, can the primary vibration and the secondary vibration of the engine be cancelled so as to enhance a vibration isolating function and the inclusion of a direct current component into the target driving current ICMD can be prevented so as to suppress a wasteful heat release of the actuator 41 to a minimum level.

Owner:HONDA MOTOR CO LTD

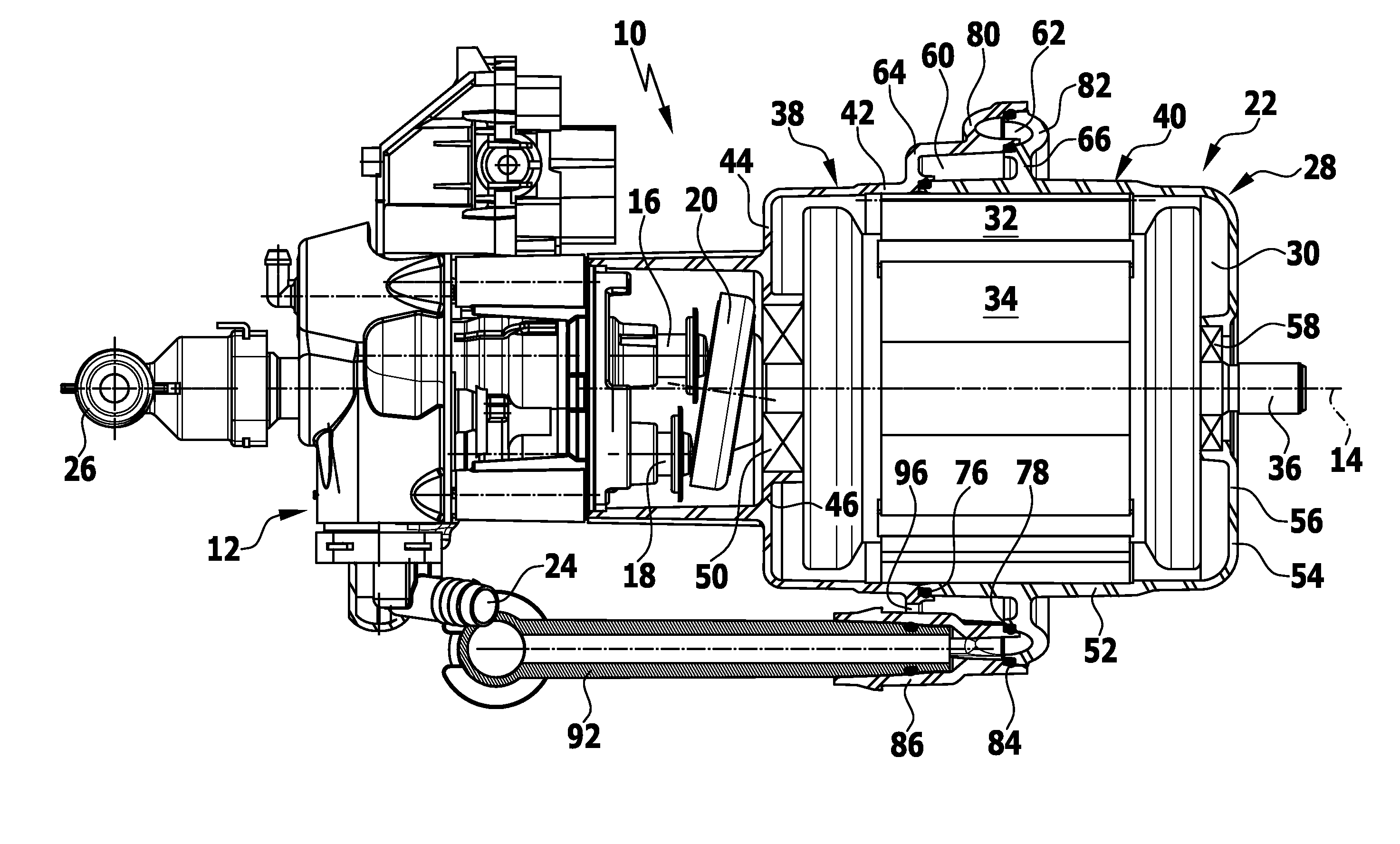

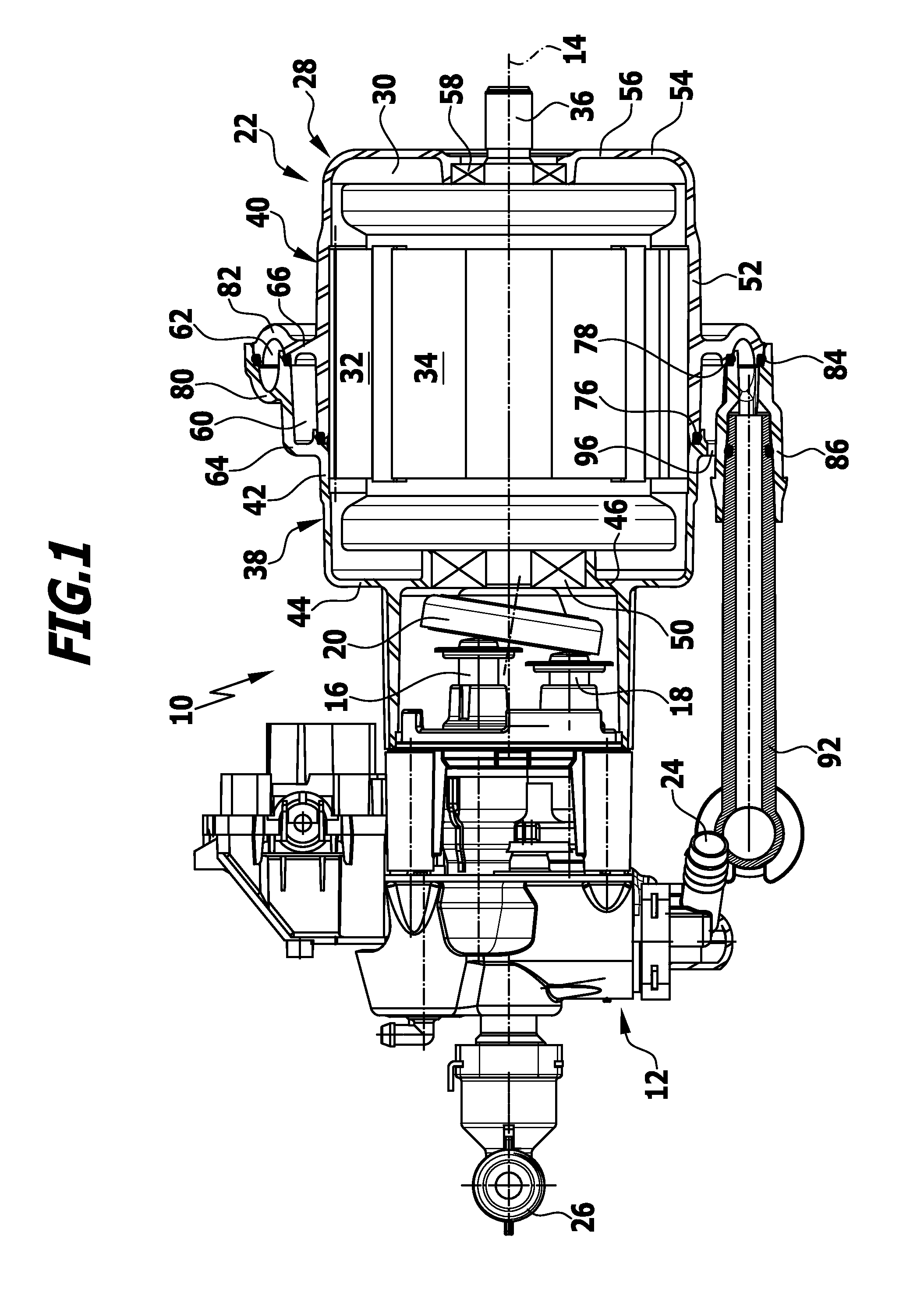

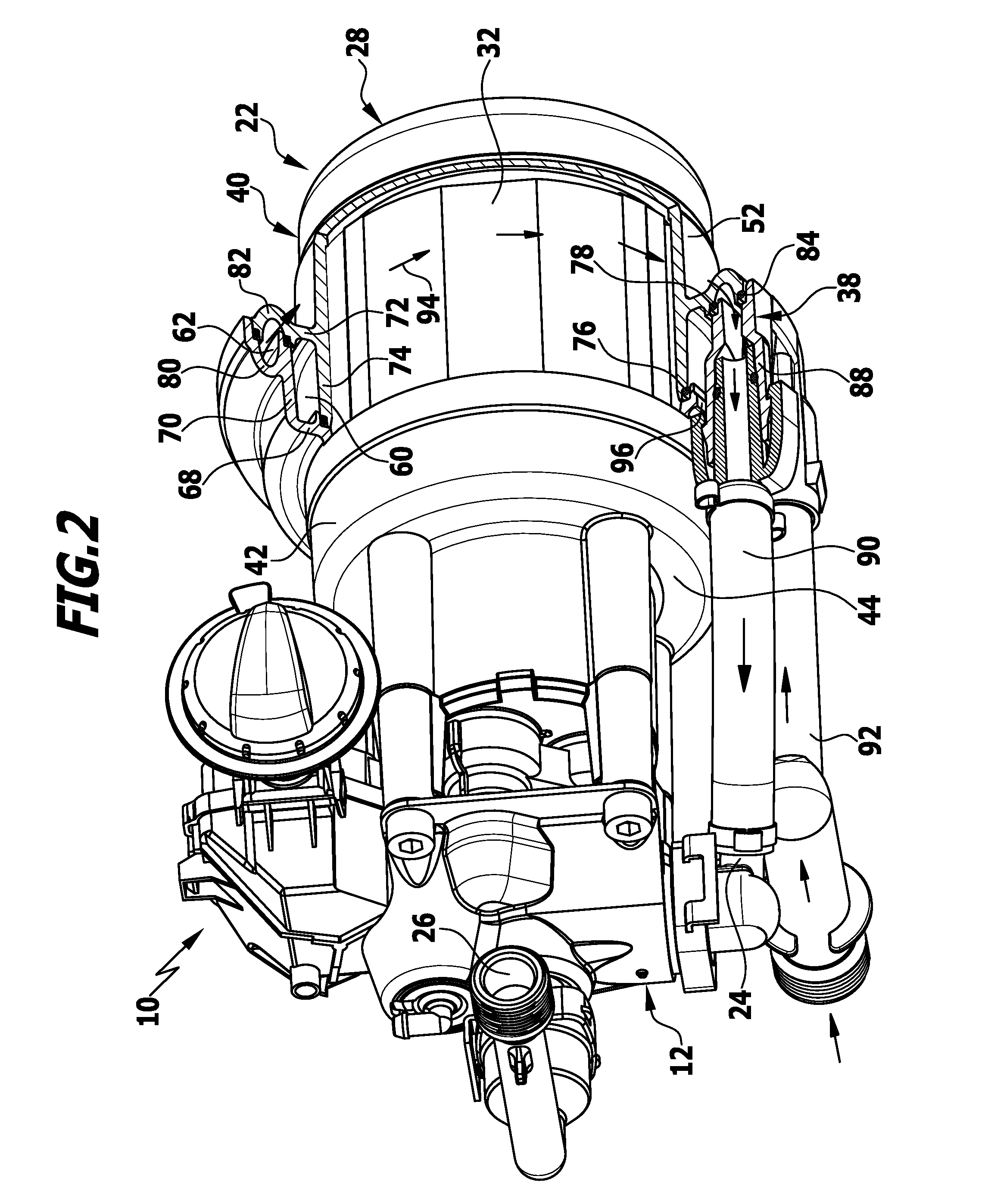

Motor-pump unit

ActiveUS20140154112A1Cost effective productionEasy to assemblePositive displacement pump componentsPiston pumpsEngineeringCooling channel

A motor-pump unit includes an electric motor and a pump. The electric motor has a motor housing, on the outside of which a cooling channel is arranged. The pump has a suction inlet and a pressure outlet. Liquid to be pressurized can be fed by way of the cooling channel to the suction inlet. In order that the motor-pump unit can be produced and assembled more cost-effectively, the motor housing includes a first housing part and a second housing part, which are connectable to each other in a liquid-tight manner and between them form the cooling channel.

Owner:ALFRED KARCHER GMBH & CO KG

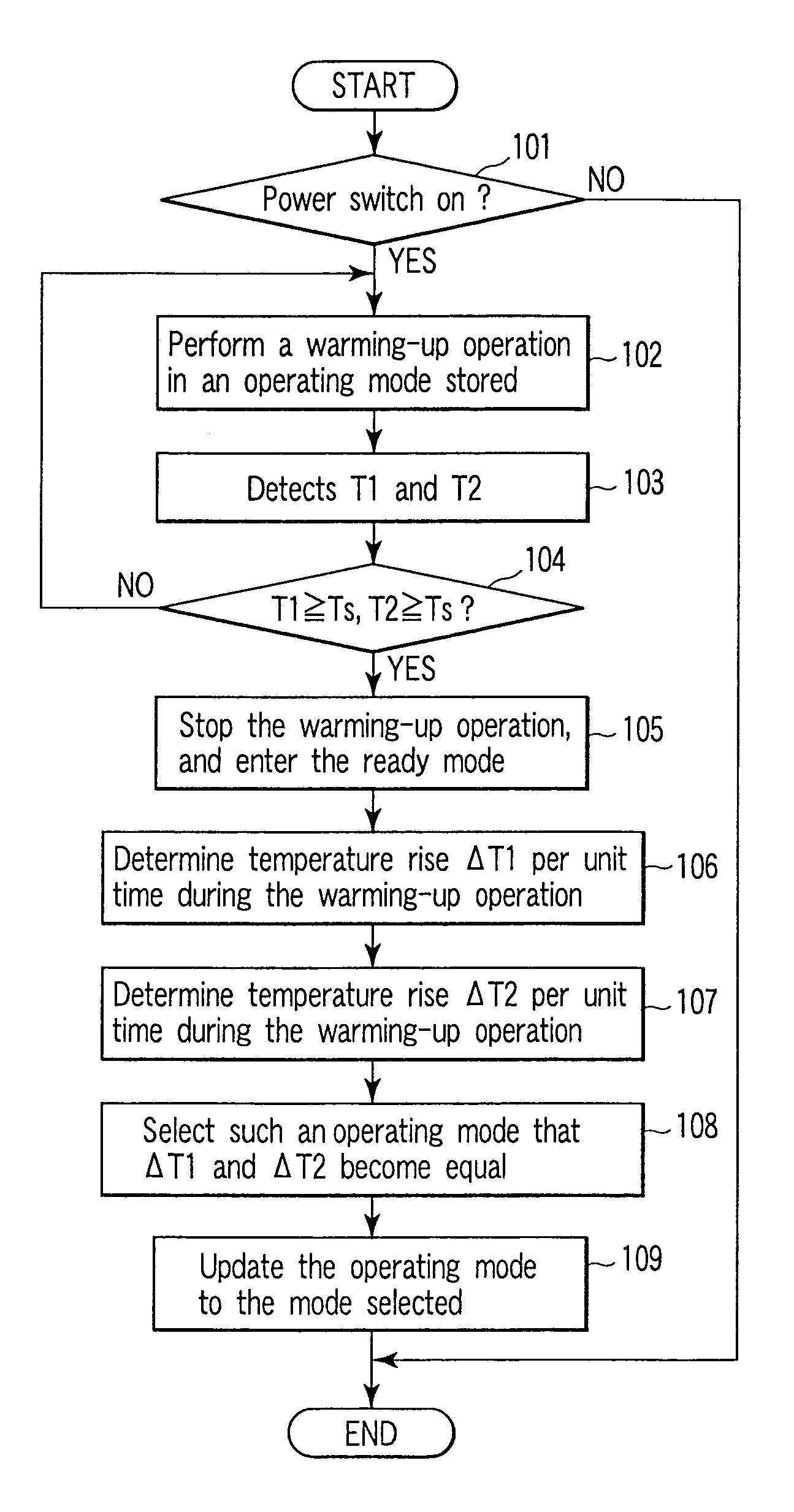

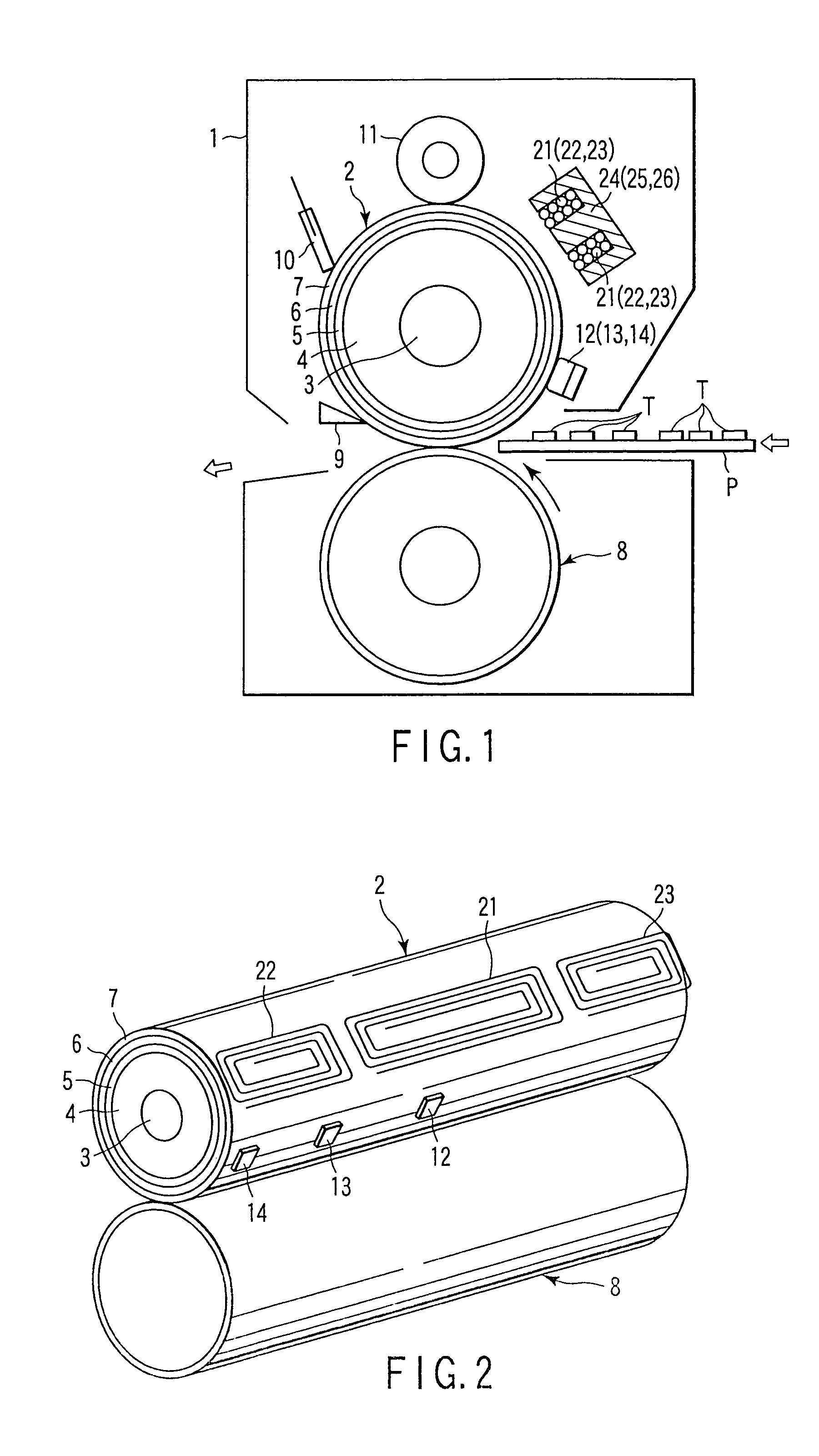

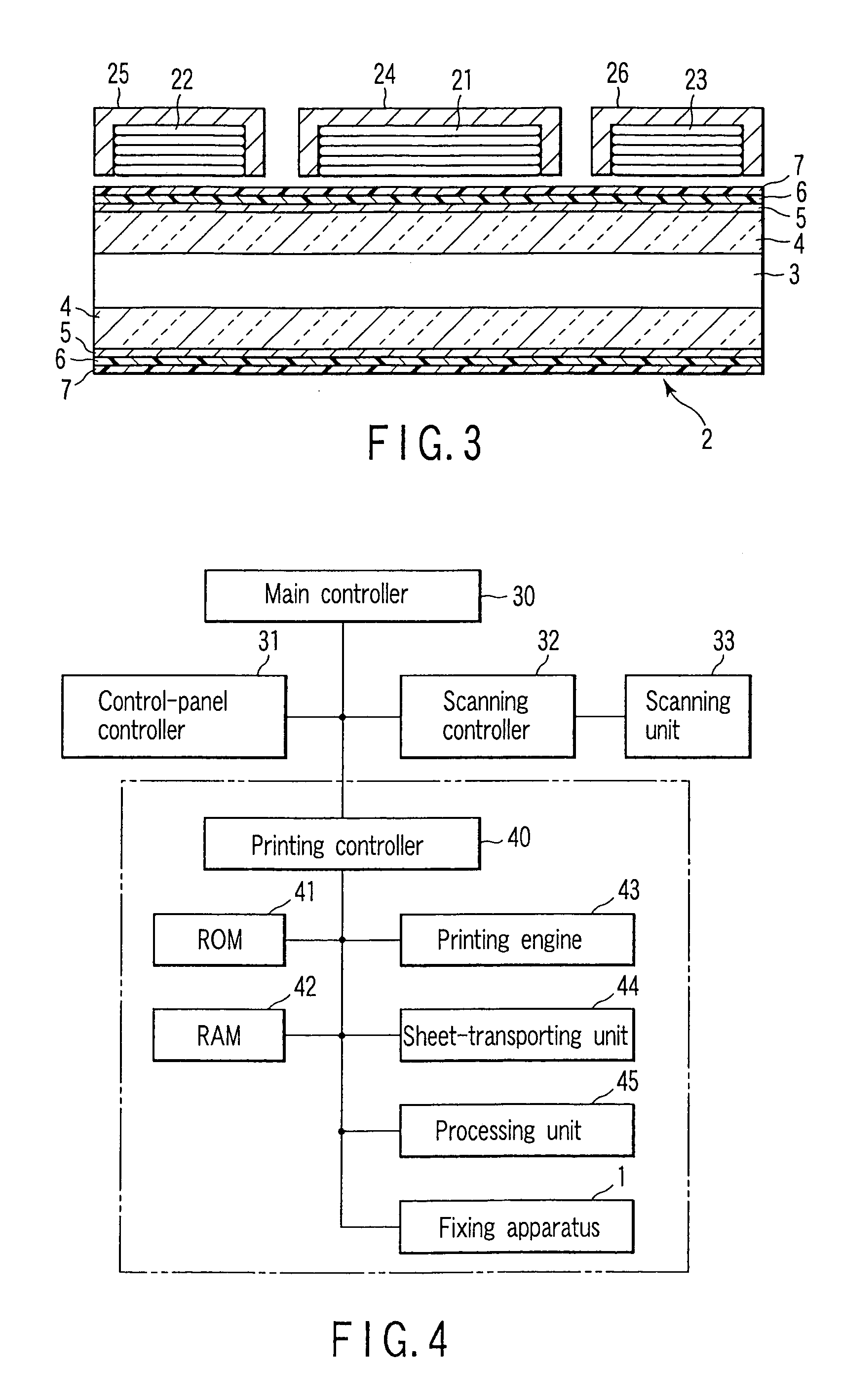

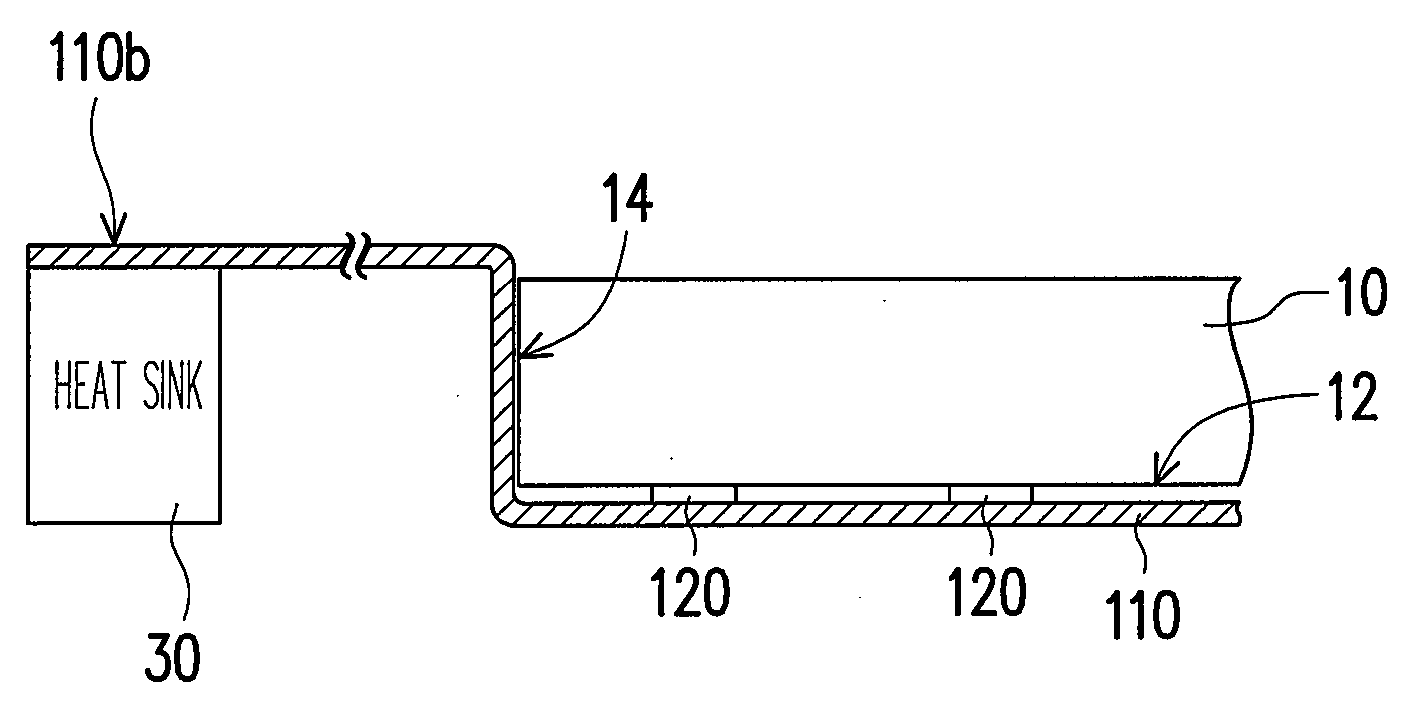

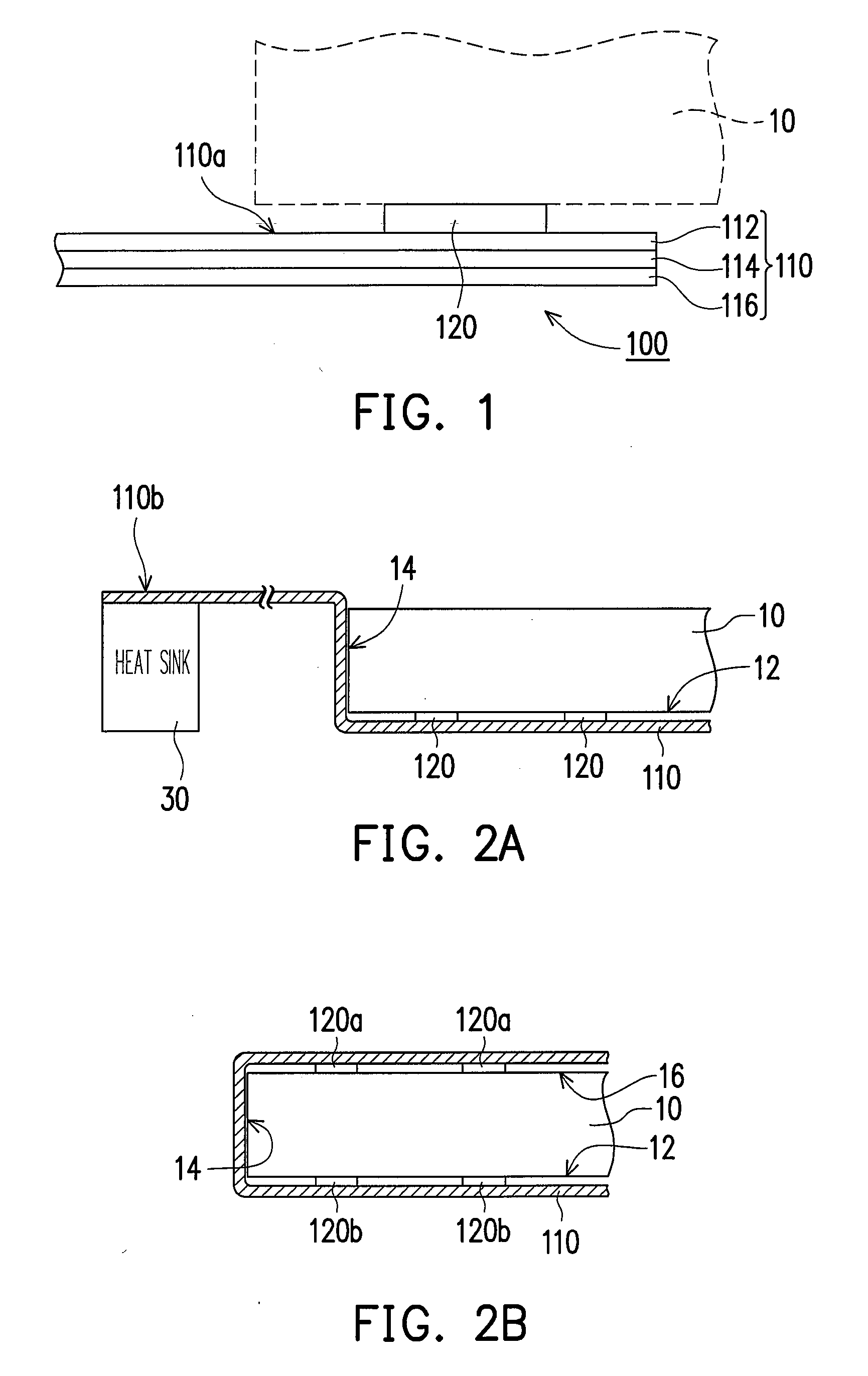

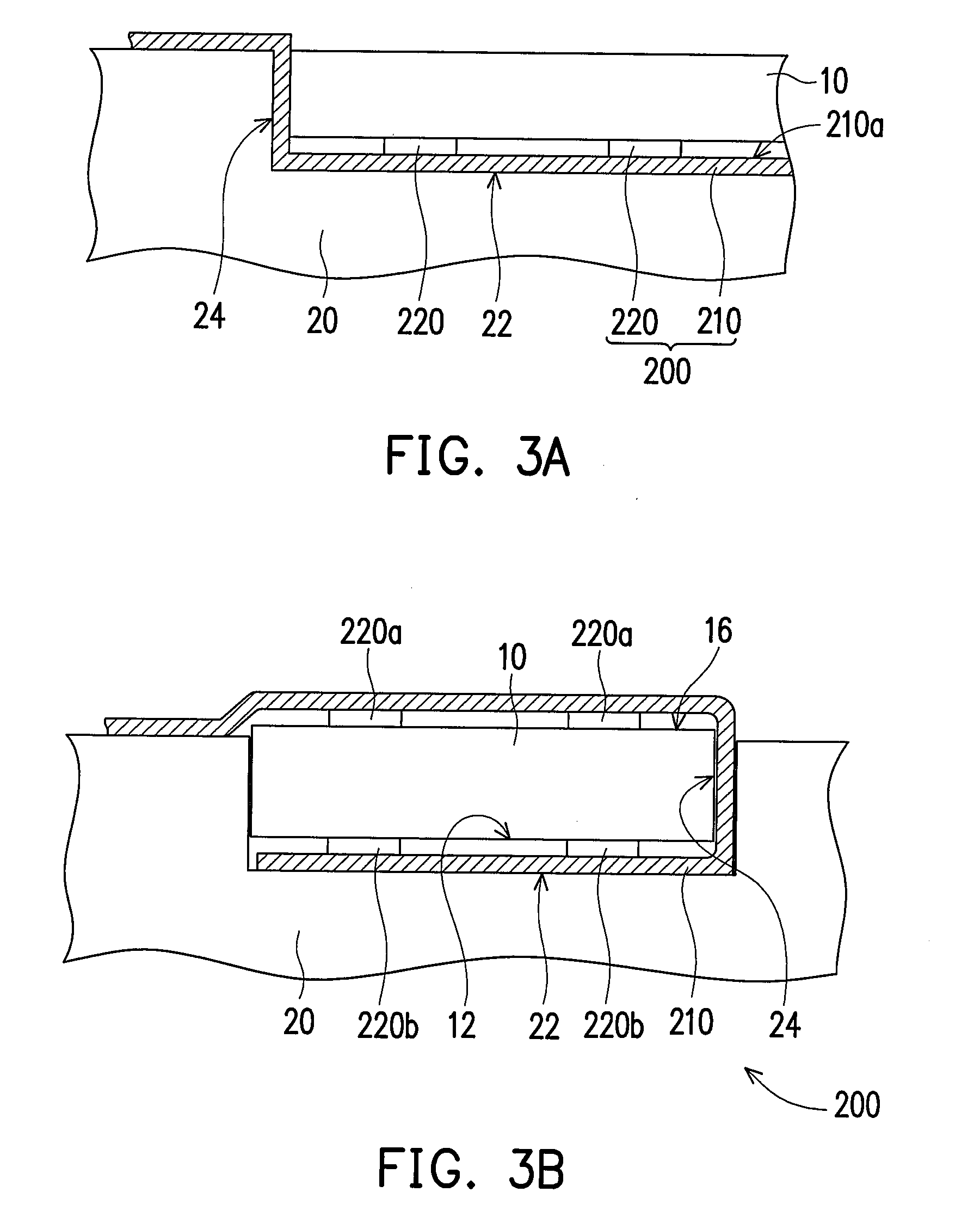

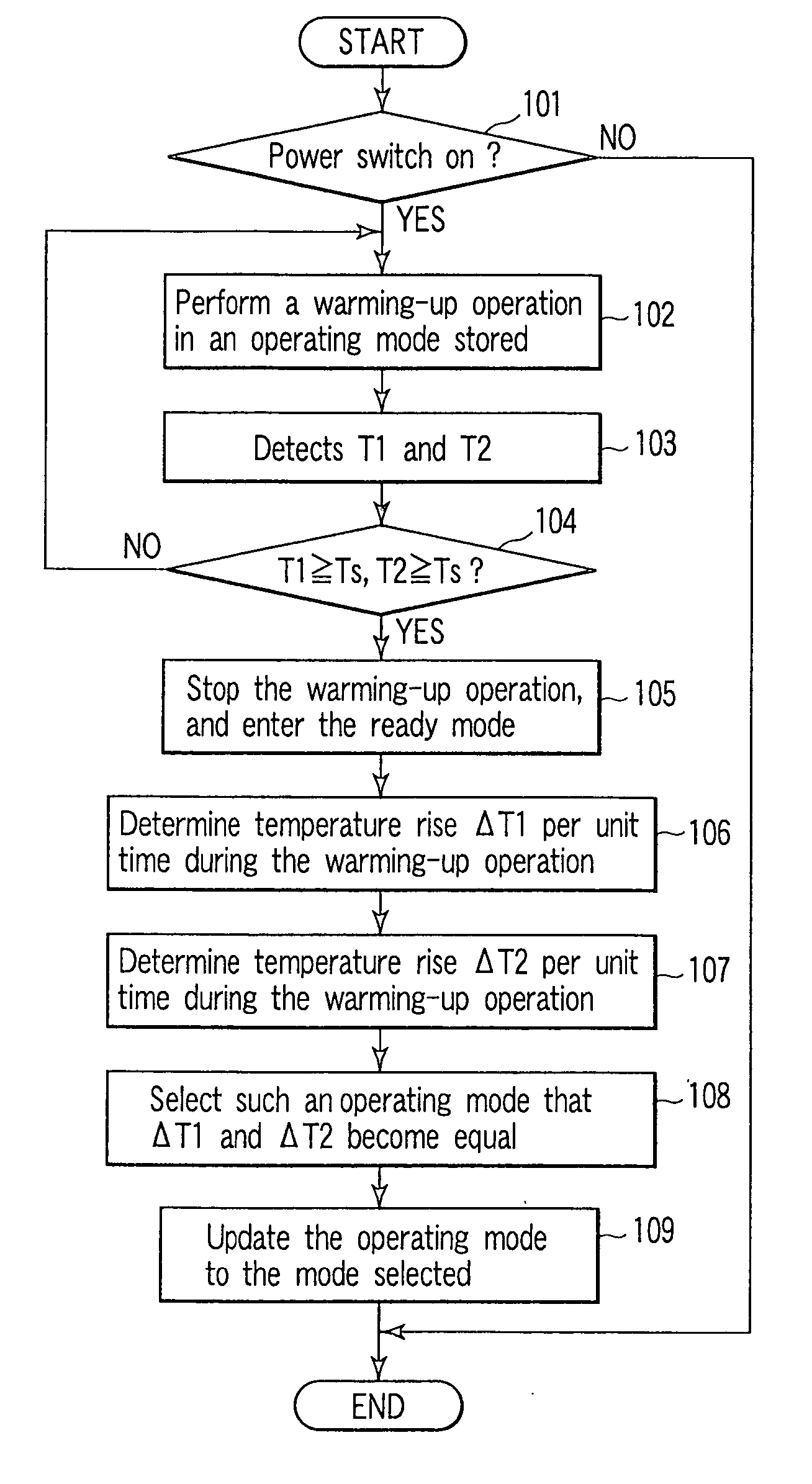

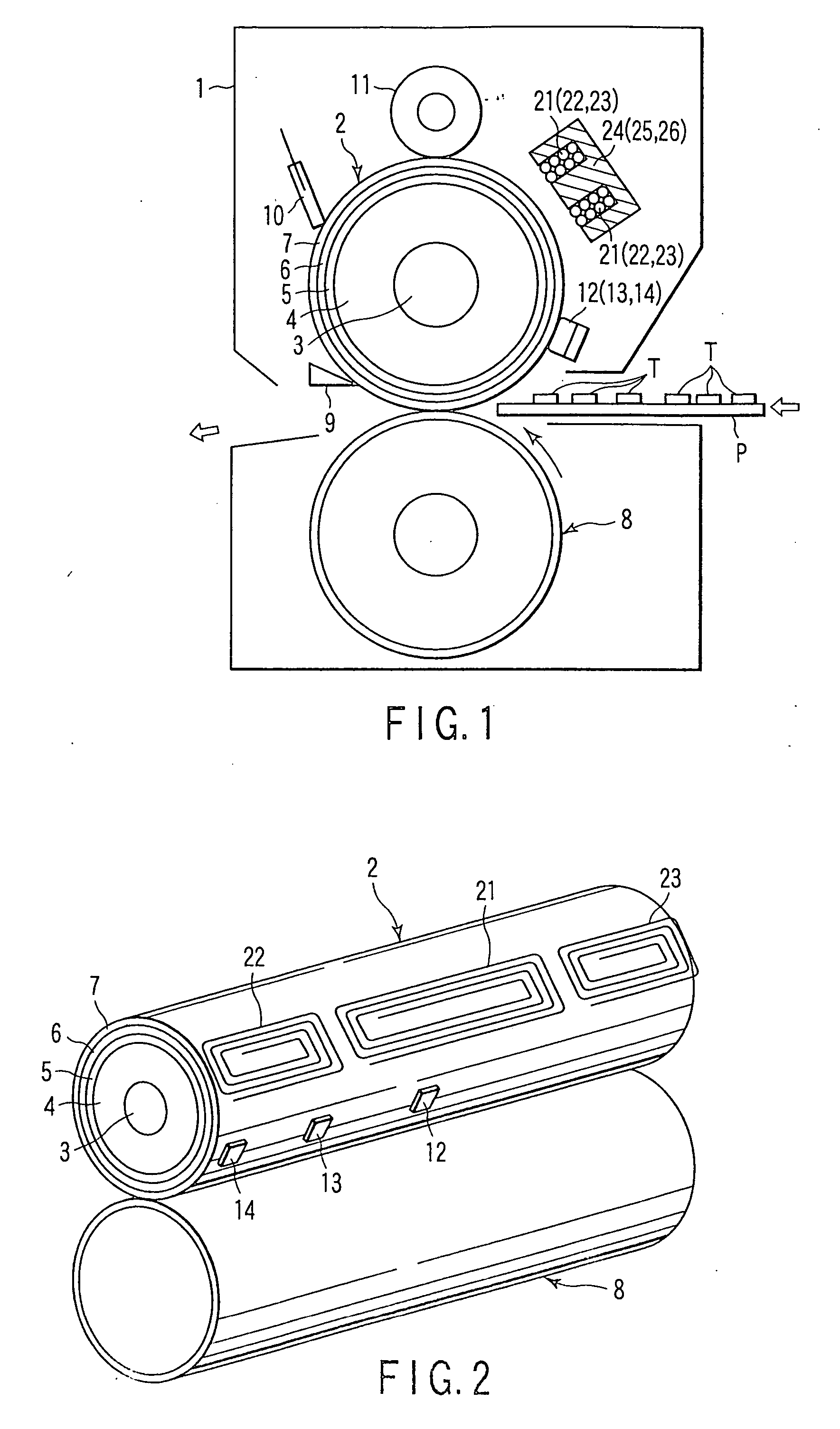

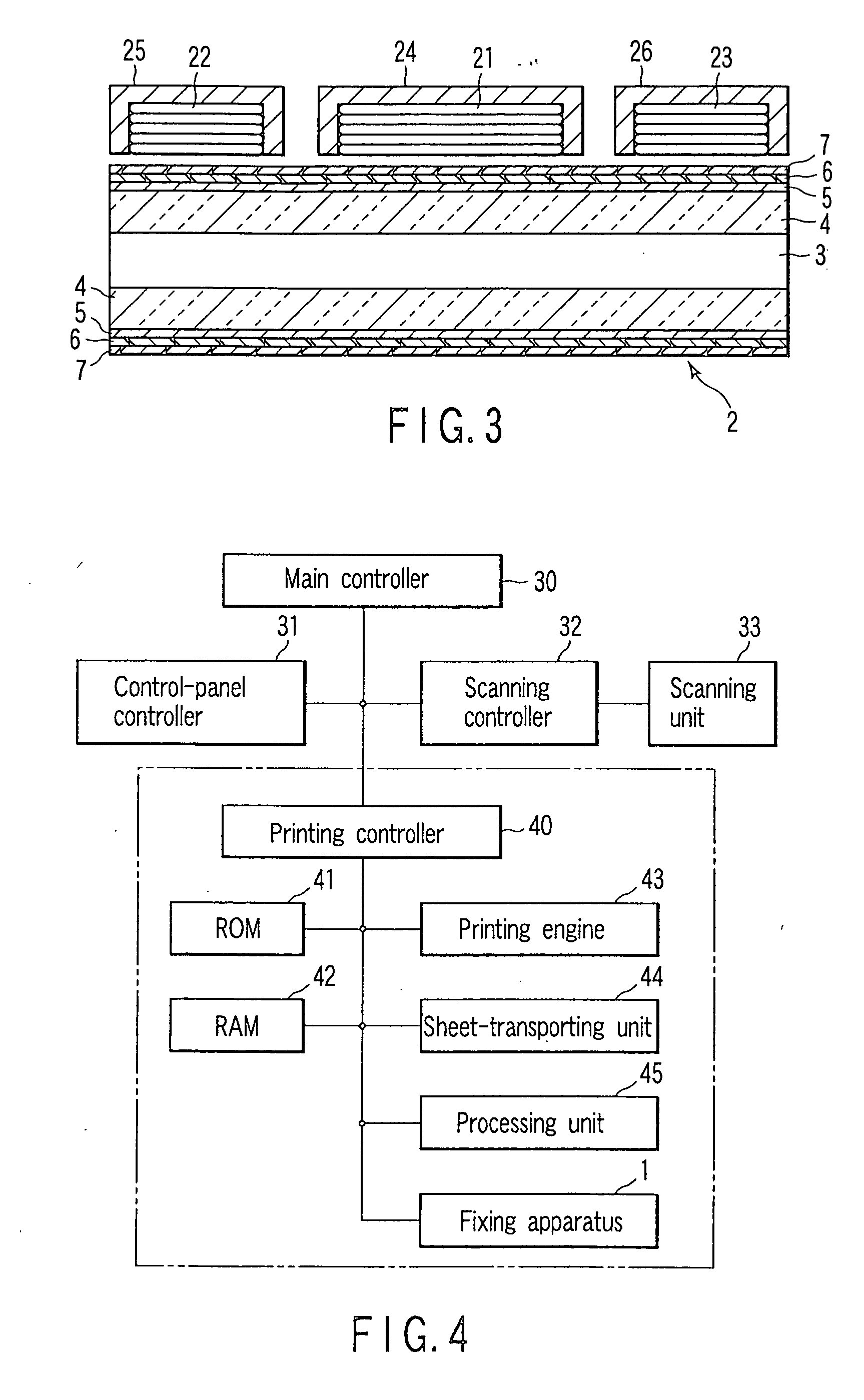

Fixing apparatus and image forming apparatus

ActiveUS7058331B2Short timeHeat wasted during the warming-up operation period can be decreasedElectrographic process apparatusOperation modeEngineering

Owner:KK TOSHIBA +1

Heat-dissipation apparatus for hard disk

InactiveUS20080123291A1Lower operating temperatureExtended service lifeReducing temperature influence on carrierDigital data processing detailsHeat conductingOperating temperature

A heat-dissipation apparatus for a hard disk is provided, which is adapted for being configured on a hard disk or in a hard disk slot, and includes a heat-conducting layer and at least one heat-conducting pad disposed on a surface of the heat-conducting layer corresponding to the hard disk. The heat-conducting pad contacts the hard disk and the waste heat is conducted from the hard-disk to the heat-conducting layer through the heat-conducting pad, and then transferred outside the hard disk or the hard disk slot through the heat-conducting layer. Therefore, the operating temperature of the hard disk in high speed operation is lowered and the service life of the hard disk is prolonged.

Owner:INVENTEC CORP

Fixing apparatus and image forming apparatus

InactiveUS20060188281A1Short timeHeat wasted during the warming-up operation period can be decreasedElectrographic process apparatusImage formationElectrical and Electronics engineering

Owner:KK TOSHIBA +1

Saddle-ride type vehicle

ActiveUS9919756B2Avoid wasting heatWaste heatWeather guardsMotorcyclesCylinder headAutomotive engineering

Owner:HONDA MOTOR CO LTD

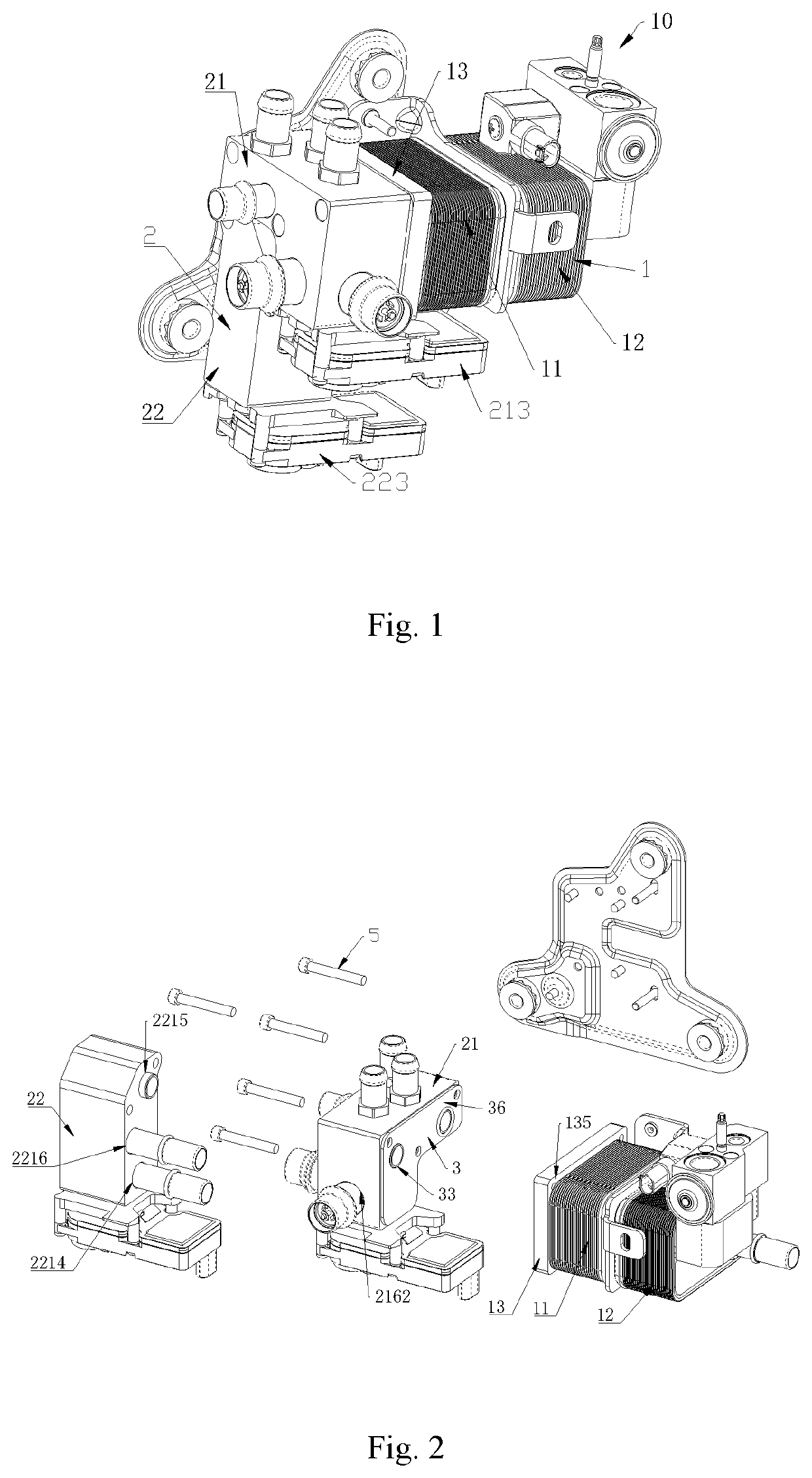

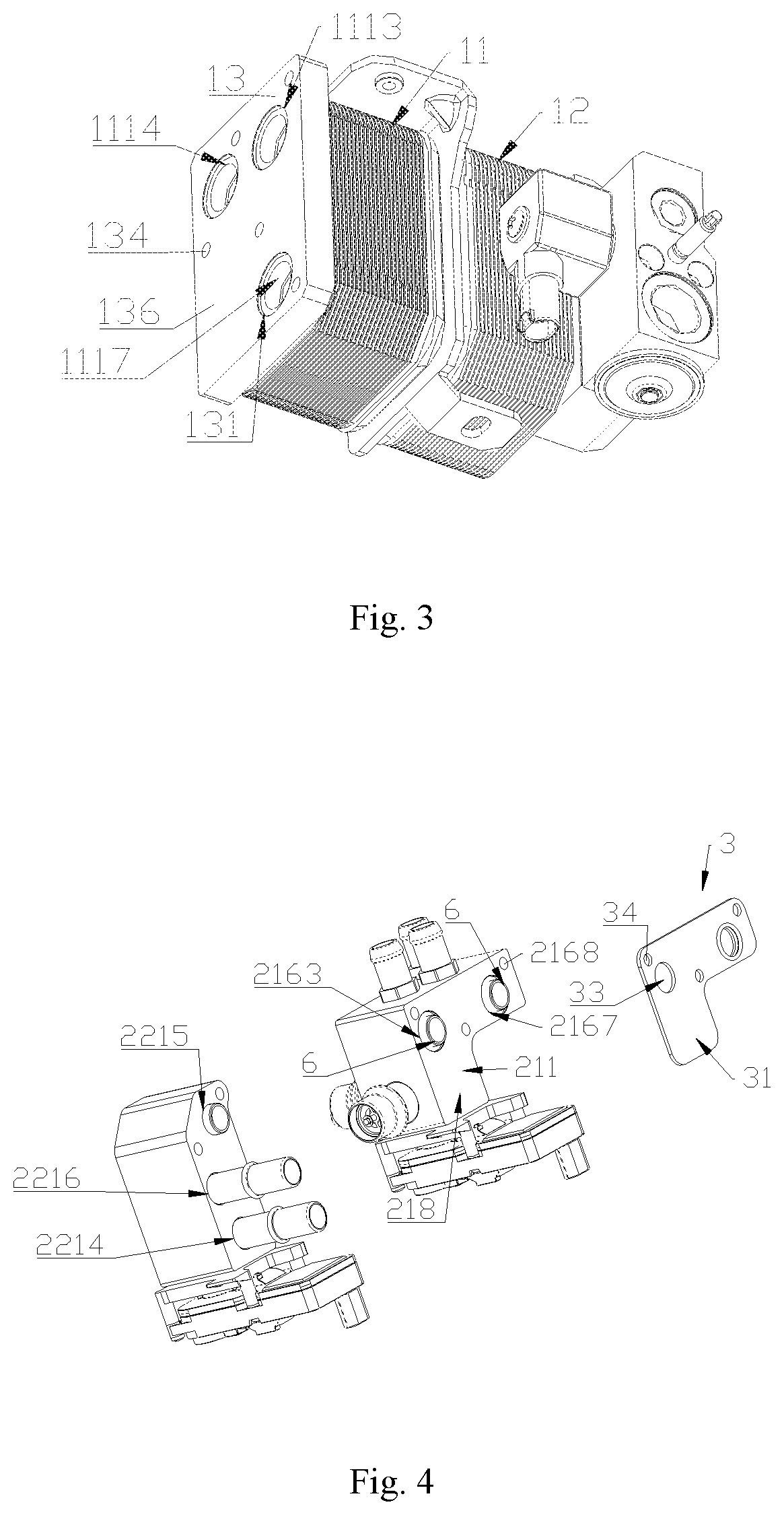

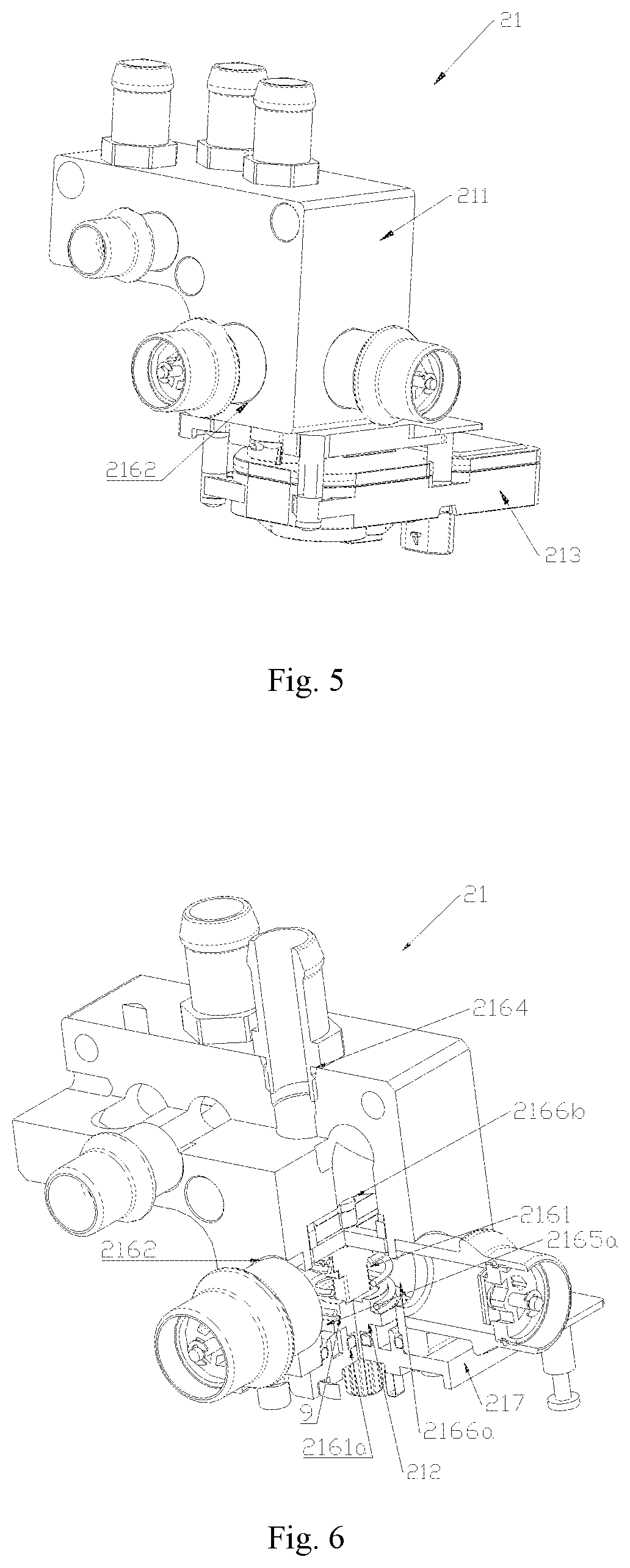

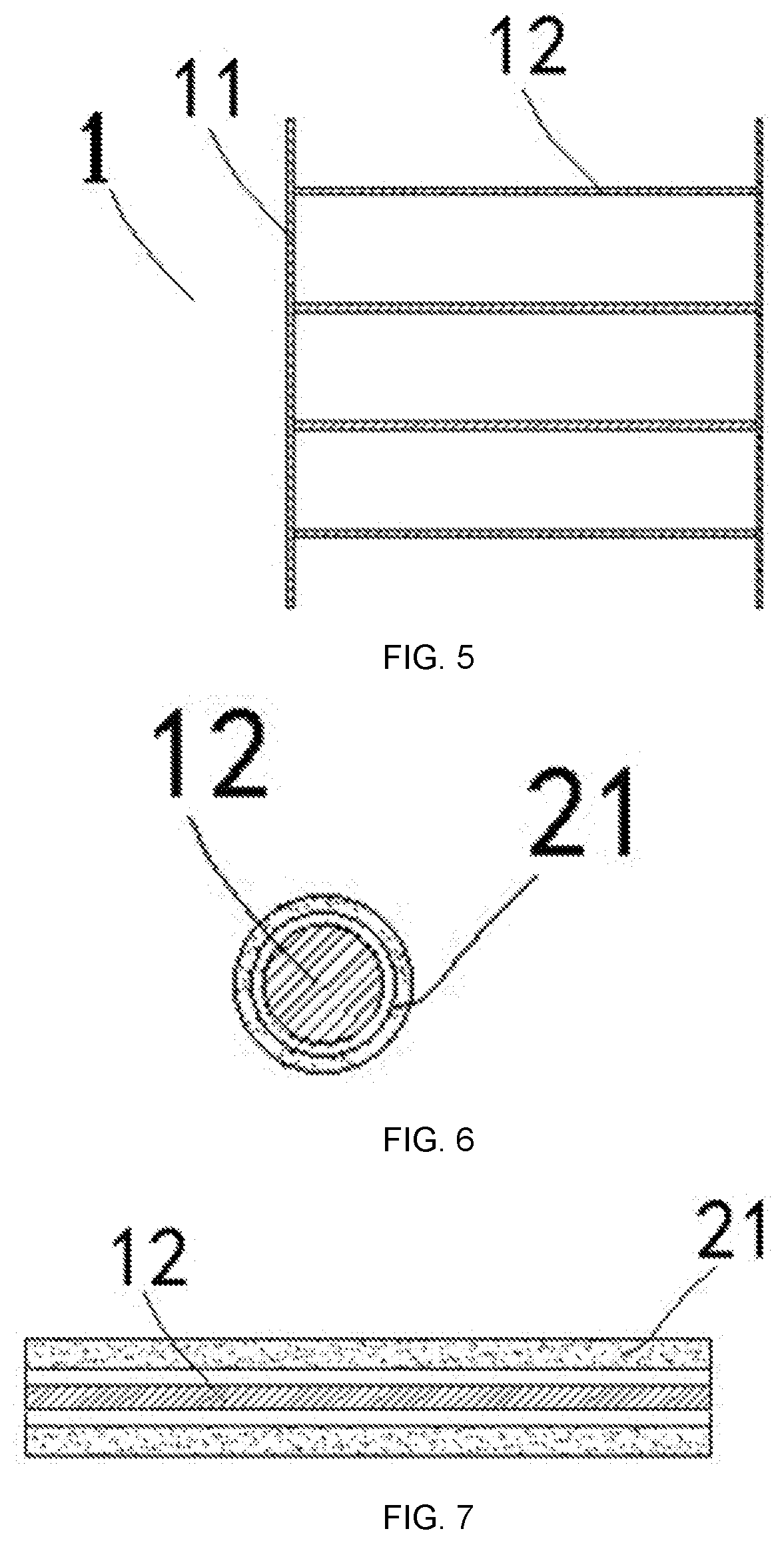

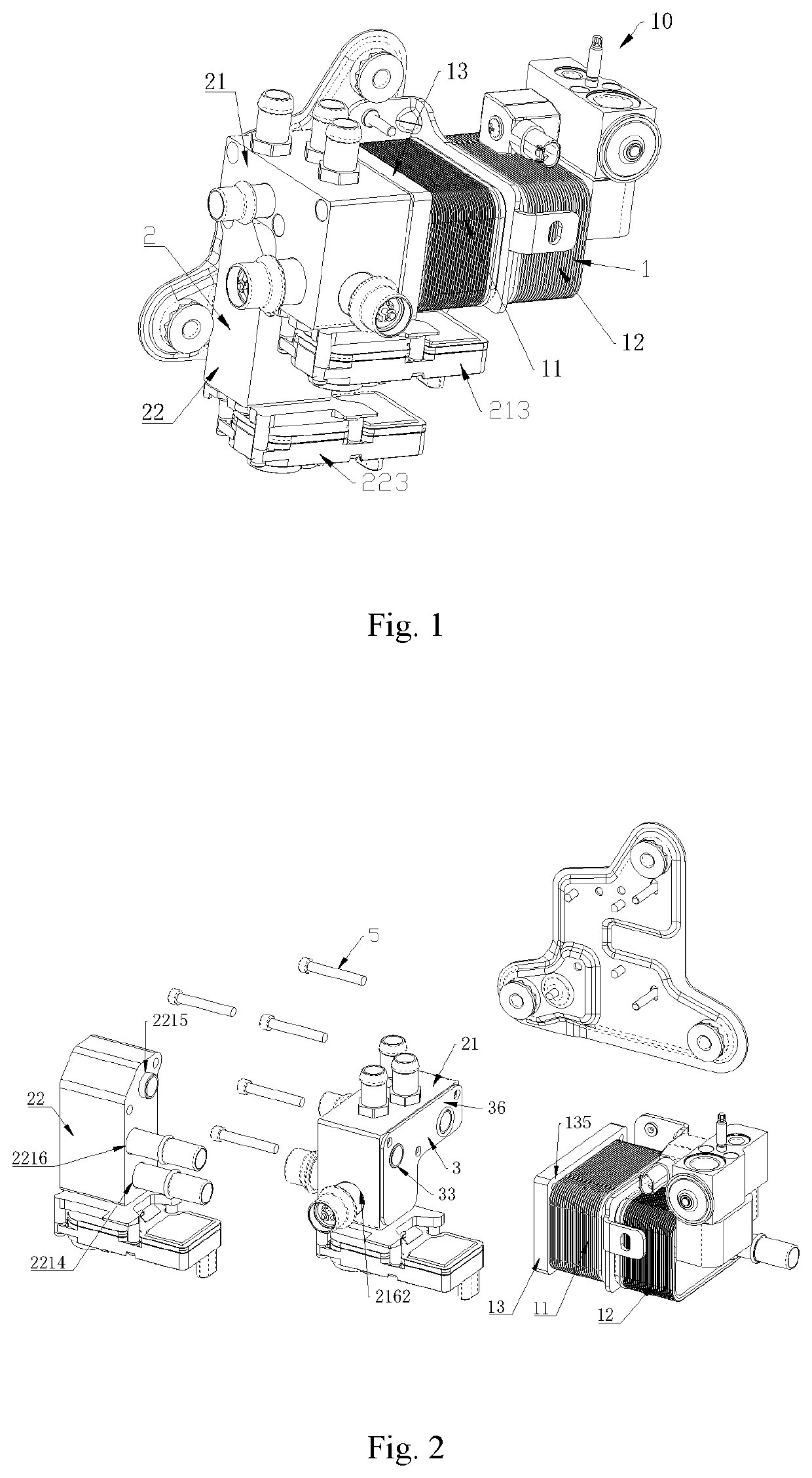

Fluid Heat Exchange Assembly, and Heat Management System of Vehicle

ActiveUS20200031198A1Pipe arrangementSmall and compact structureAir-treating devicesVehicle heating/cooling devicesThermodynamicsFluid control

A fluid heat exchange assembly includes a fluid control module and a fluid heat exchange module, the fluid control module includes a first connecting lateral portion, the fluid heat exchange module includes a second connecting lateral portion; the first connecting lateral portion and the second connecting lateral portion are oppositely and sealingly arranged; the fluid heat exchange module includes a heat exchange core and a connecting component fixed by welding; the fluid control module includes at least a first flow passage and a second flow passage; the fluid heat exchange module includes a first fluid communication cavity, and the second flow passage is in communication with the first fluid communication cavity; the connecting component includes a connecting channel, the connecting channel penetrates through the connecting component. The fluid heat exchange assembly reduces pipeline arrangement and is of a small and compact integral structure.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Active vibration isolating support apparatus

ActiveUS7556245B2Waste heatEnhanced inhibitory effectMachine framesLiquid springsDriving currentActuator

When driving an actuator 41 of an active vibration isolating support apparatus M to extend and contract on a predetermined cycle so as to suppress the transmission of vibrations of an engine, since a combined target current ICMDT is calculated by combining a primary target current which cancels a primary vibration of the engine with a secondary target current which cancels a secondary vibration of the engine and furthermore, the actuator 41 is driven with a target driving current ICMD in which a minimum value of the combined target current ICMDT is offset to 0, can the primary vibration and the secondary vibration of the engine be cancelled so as to enhance a vibration isolating function and the inclusion of a direct current component into the target driving current ICMD can be prevented so as to suppress a wasteful heat release of the actuator 41 to a minimum level.

Owner:HONDA MOTOR CO LTD

LED Lamp

InactiveUS20110085339A1Increase temperatureImprove thermal conductivityMechanical apparatusPoint-like light sourceEngineeringHeat sink

A light emitting diode (LED) lamp includes a lamp holder, an LED element installed to the lamp holder, a heat dissipating fin module installed at an external periphery of the lamp holder, and a plurality of heat pipes coupled between the lamp holder and the heat dissipating fin module. The heat pipe is provided for guiding waste heat of the lamp holder to the heat dissipating fin module for the heat dissipation to improve internal and external ambient temperatures of the lamp holder, so as to achieve the effects of maintaining a better thermal conductivity of the lamp holder for a long time, assisting a discharge of the waste heat of the LED, and maximizing an overall working performance of the LED lamp.

Owner:TREND LIGHTING

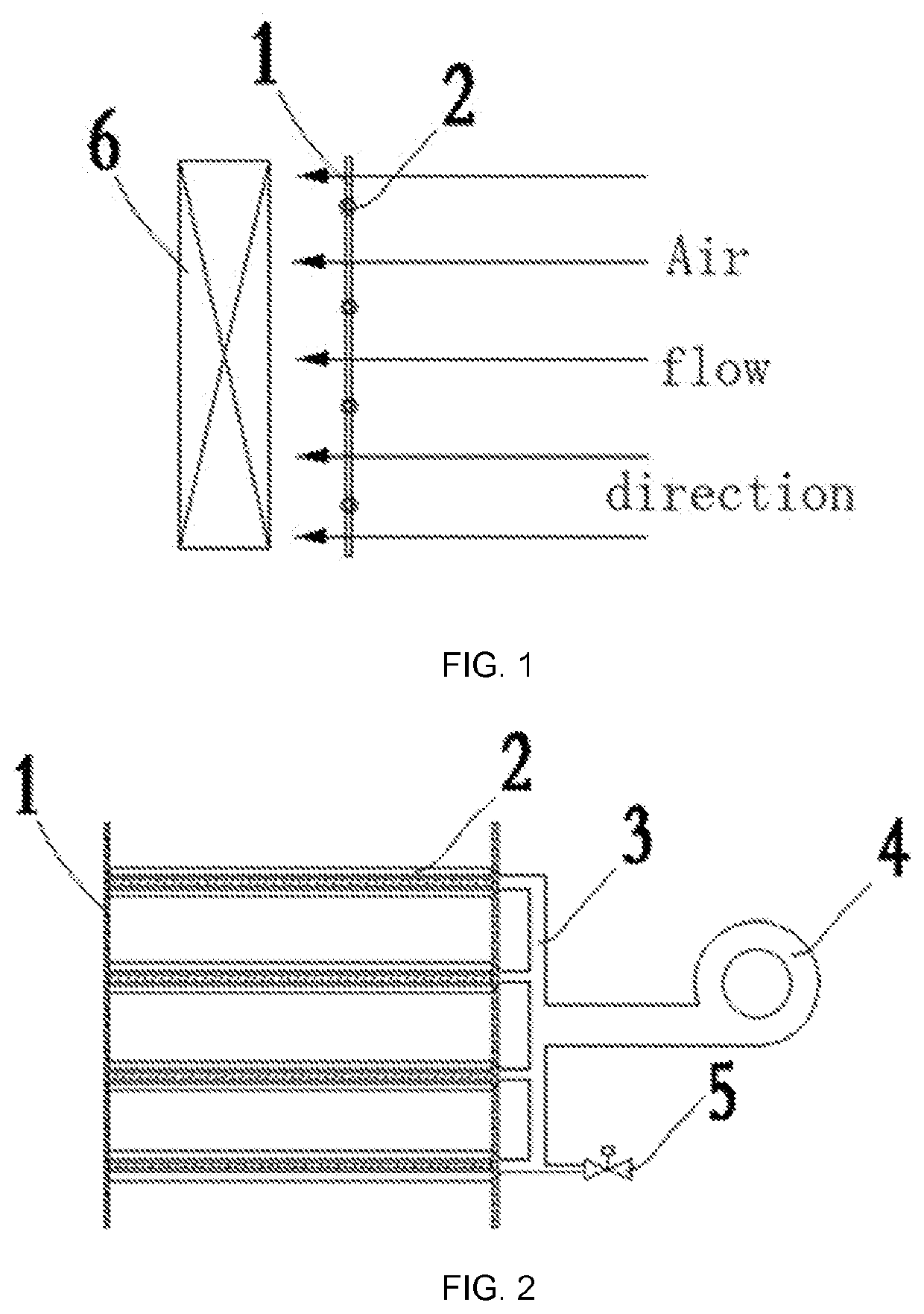

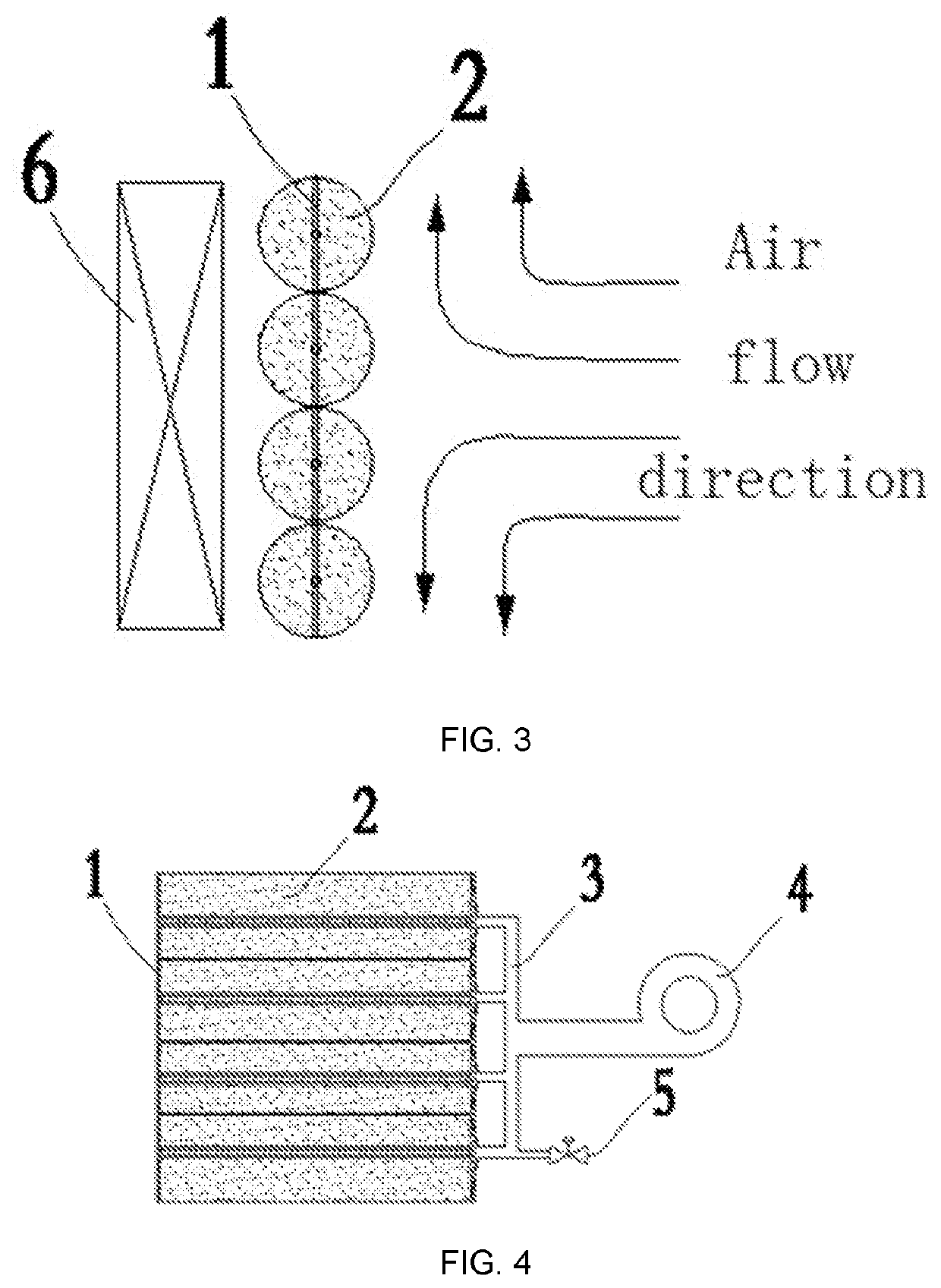

Defrosting control device, air conditioner and defrosting control method therefor

ActiveUS20210078384A1Reducing defrosting heat lossImprove heat lossMechanical apparatusAir-treating devicesAirbag deploymentAutomotive engineering

Provided are a defrosting control device, an air conditioner and a defrosting control method therefor. The device includes an airbag device, wherein the airbag device includes a mounting support (1), an airbag (2) and an inflation mechanism. When an air conditioner to be controlled enters a defrosting mode, the inflation mechanism inflates the airbag (2) such that same forms an airbag layer to isolate an outdoor heat exchanger of the air conditioner to be controlled from flowing air outside the outdoor heat exchanger. The defrosting control device can achieve the beneficial effects of a small defrosting heat loss, a good defrosting effect and a good user experience.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Fluid heat exchange assembly, and heat management system of vehicle

ActiveUS11285781B2Pipe arrangementSmall and compact structureAir-treating devicesVehicle heating/cooling devicesFluid controlHeat management

A fluid heat exchange assembly includes a fluid control module and a fluid heat exchange module, the fluid control module includes a first connecting lateral portion, the fluid heat exchange module includes a second connecting lateral portion; the first connecting lateral portion and the second connecting lateral portion are oppositely and sealingly arranged; the fluid heat exchange module includes a heat exchange core and a connecting component fixed by welding; the fluid control module includes at least a first flow passage and a second flow passage; the fluid heat exchange module includes a first fluid communication cavity, and the second flow passage is in communication with the first fluid communication cavity; the connecting component includes a connecting channel, the connecting channel penetrates through the connecting component. The fluid heat exchange assembly reduces pipeline arrangement and is of a small and compact integral structure.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com