Unit type heat source system of corn ear dryer

A corn cob and heat source system technology, applied in the direction of dry preservation of seeds, adaptation to climate change, etc., can solve the problems of energy waste, large footprint, high cost, etc., to avoid waste of waste heat, save floor space, and scientific layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

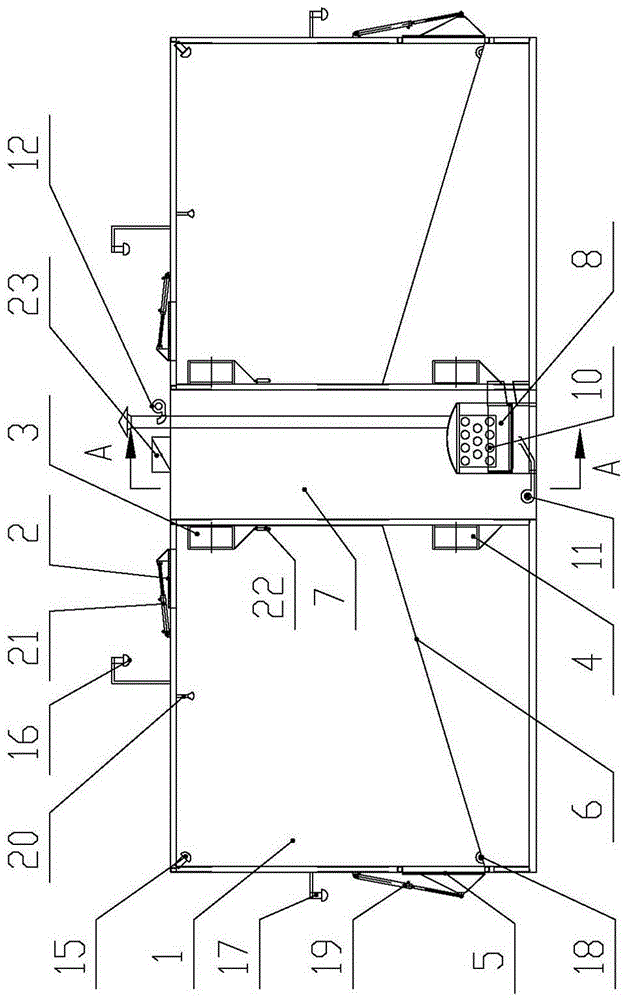

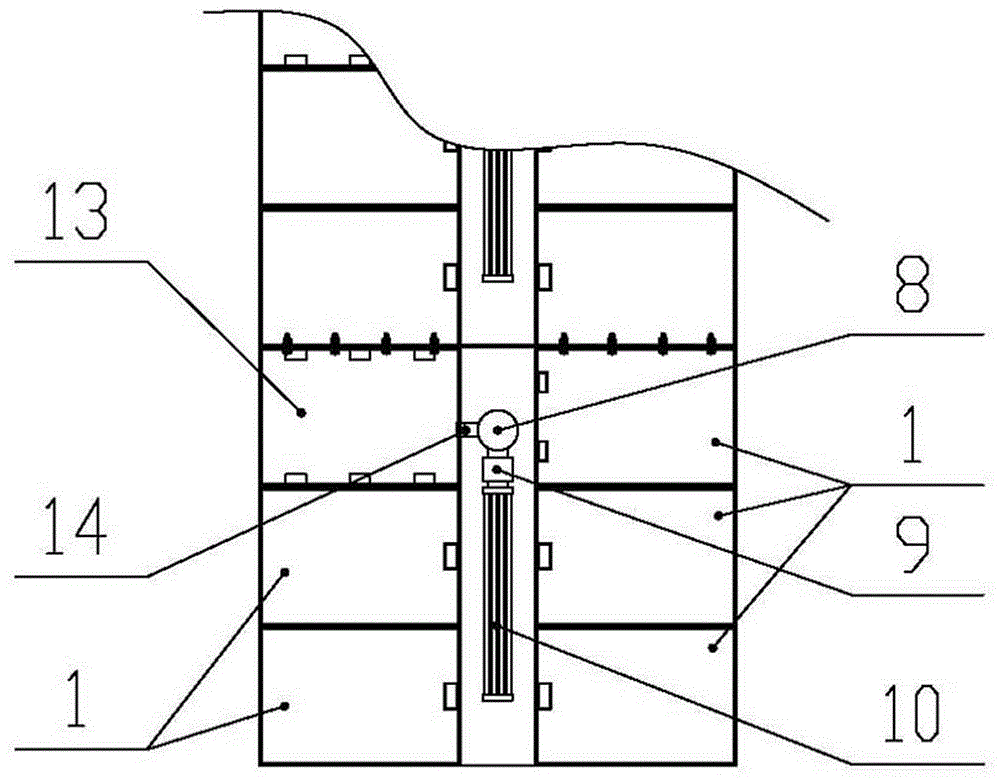

[0023] Example 1, such as figure 1 , 2 As shown, the heat source center is a heat source chamber 7, and the heat source chamber 7 is provided with a hot blast stove 8, a filter 9 and a heat exchanger 10 connected together in sequence; The blower fan 11 and the hot blast stove 8 are equipped with a suction fan 12 outside the heat source chamber 7 through a pipeline passing through the top of the heat source chamber 7 . The hot blast stove 8 can generate heat by burning coal, fuel oil, gas, biomass or by solar energy and electricity conversion, the filter 9 can reduce environmental pollution, and the heat exchanger 10 can accelerate heat exchange.

Embodiment 2

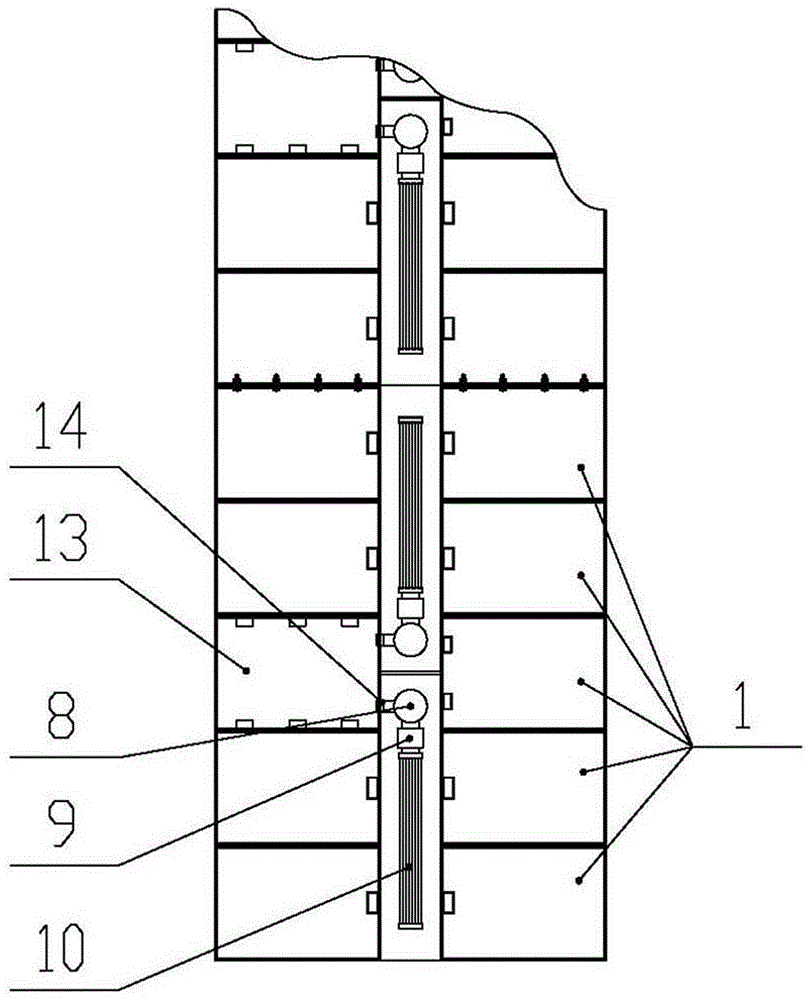

[0024] Example 2, such as figure 1 , 3 As shown, the center of the heat source is two heat source chambers 7 facing each other; each heat source chamber 7 is provided with a hot blast stove 8, a filter 9 and a heat exchanger 10 connected sequentially from the inside to the outside; the hot blast stove 8 A combustion-supporting fan 11 located in the corresponding heat source chamber 7 is installed on the top, and a suction fan 12 located outside the corresponding heat source chamber 7 is installed on the hot blast stove 8 through a pipeline passing through the top of the corresponding heat source chamber 7; the two rows of drying rooms are left and right Symmetrically distributed, each row of drying rooms is five adjacent and independent drying rooms 1 . When applying the present invention on a large scale and in a wide range, the combination of two heat source chambers 7 facing each other and five drying chambers 1 in each row has a compact structure and sufficient heat utili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com