Vacuum refining method for molten steel by using two-tank single-cover type VD refining furnace

A vacuum refining and refining furnace technology, applied in the field of steelmaking VD refining, can solve the problems that the sewage treatment system occupies a large area, is not conducive to the closing and opening of the tank lid, and the structural layout of the VD furnace is unscientific, so as to improve the control stability High performance, compact structure, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

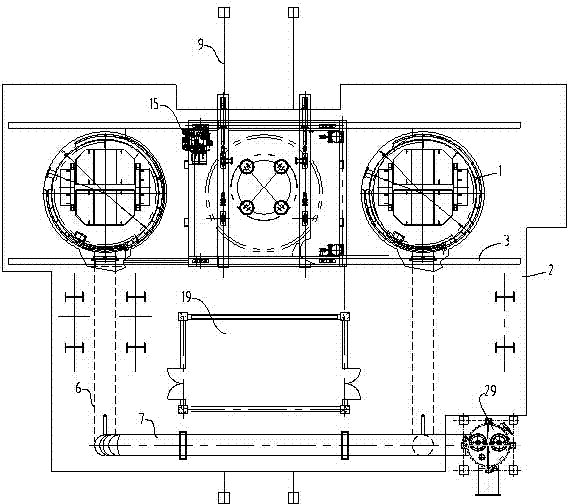

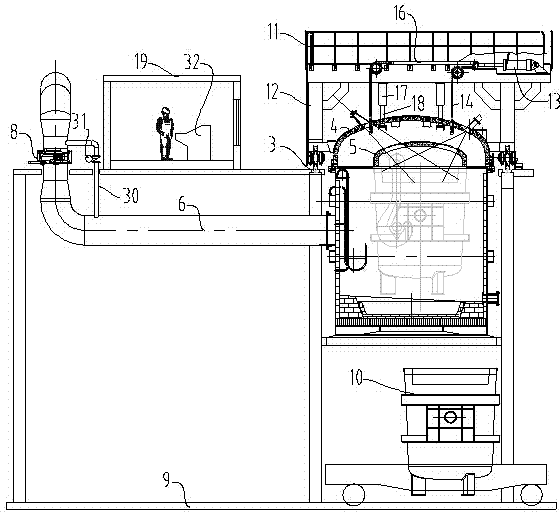

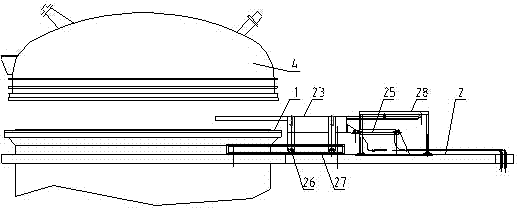

[0040] The present invention will be further described in detail below in conjunction with a double-tank single-cover VD refining furnace and its specific implementation process.

[0041] Specific implementation methods, such as Figure 1-4 As shown, when the present invention is implemented, it is necessary to obtain a double-tank single-lid type VD refining furnace first. Its structure includes two vacuum tanks 1 arranged side by side at intervals. The vacuum tank 1 is provided with an argon blowing device and an air pressure detection probe in the tank. , also includes an operation platform 2 horizontally arranged at the height of the filling mouth of the vacuum tank, a vacuum tank cover truck is also arranged on the operation platform 2, and the rollers under the vacuum tank cover truck are cooperating and installed on the vacuum tanks arranged in parallel on the outside of the two vacuum tanks On the guide rail 3 of the cover car, a vacuum tank cover 4 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com