Heat pump drying system and control method thereof

A technology of heat pump drying and control method, which is applied in the direction of heat pump, drying, dryer, etc., can solve the problems of energy waste, slow start-up process, and inability to perform constant temperature control, etc., so as to avoid heat waste, improve energy utilization rate, Effect of improving dehumidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described below based on the embodiments, and those skilled in the art should understand that the drawings provided here are for the purpose of illustration, and the drawings are not necessarily drawn to scale.

[0042] Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning.

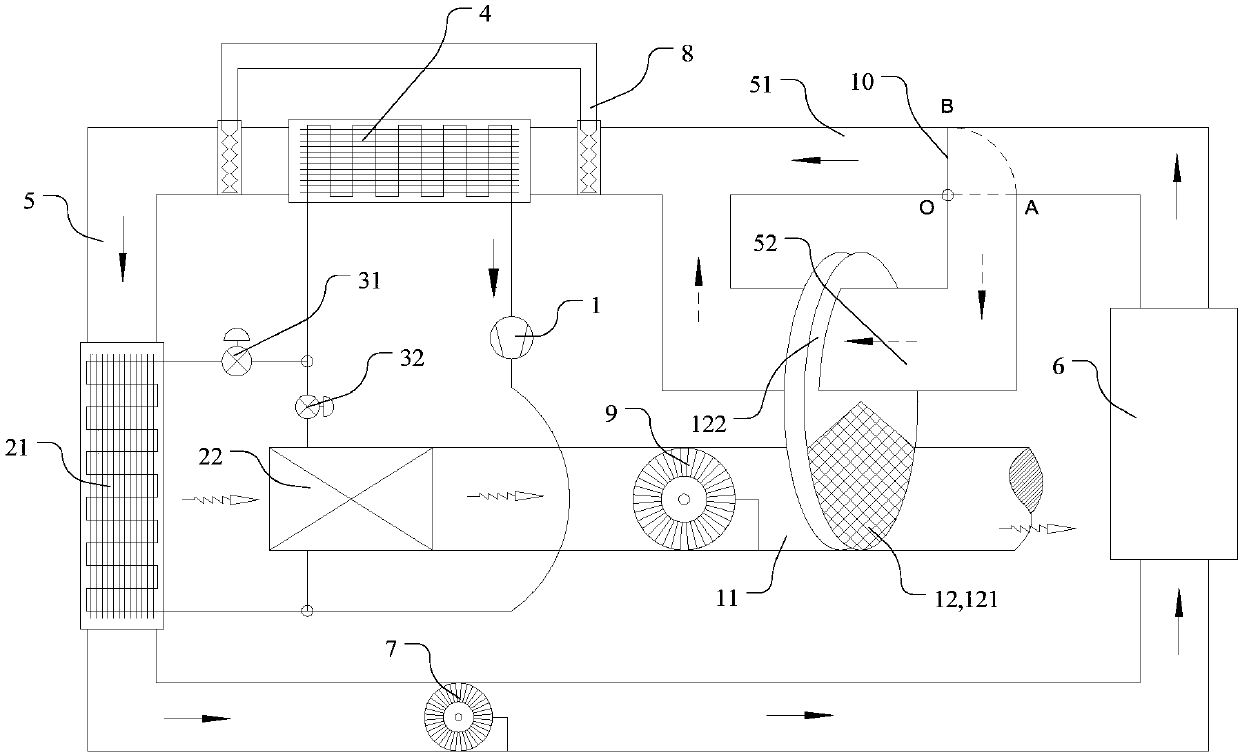

[0043] This application provides a heat pump drying system, such as figure 1 As shown, the heat pump drying system includes a heat pump system and a circulation channel 5 , wherein the circulation channel 5 is used to circulate the circulating working medium in the space to be dried 6 , such as air. A compressor 1 , a condenser, a throttling element and an evaporator 4 are arranged on the refrigerant flow path of the heat pump system, and the evaporator 4 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com