Fuel cell system comprising at least one fuel cell

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, circuits, etc., can solve the problems of insufficient cooling area, ineffective use, poor performance, etc., and achieve the effect of preventing environmental diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

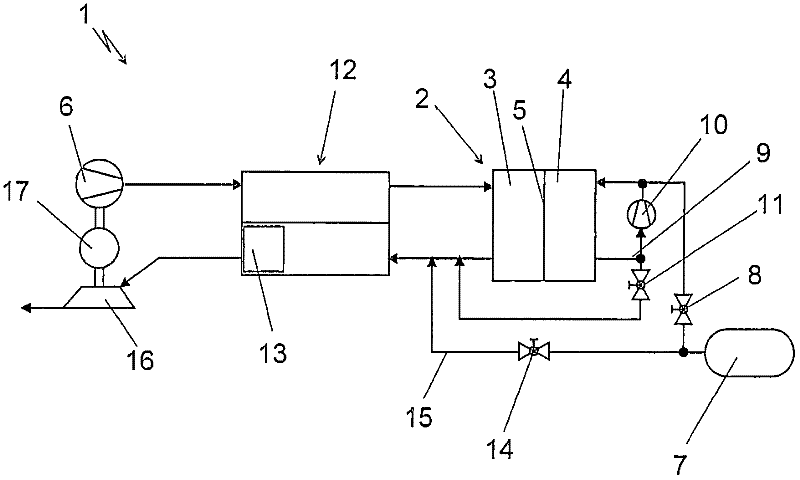

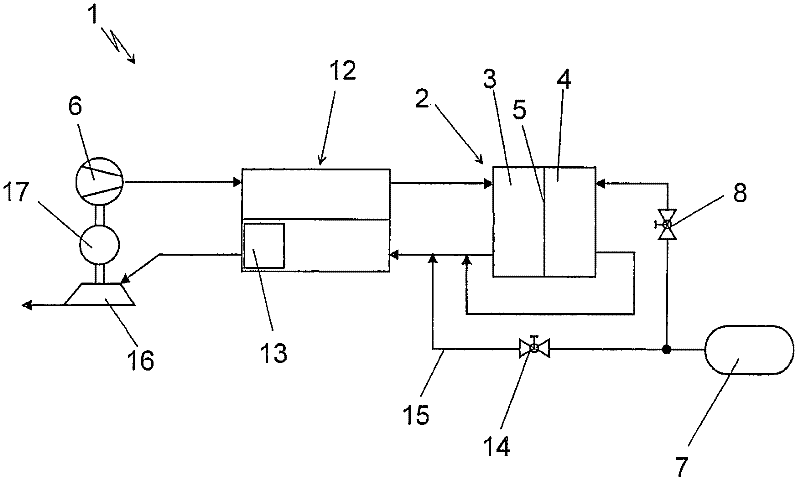

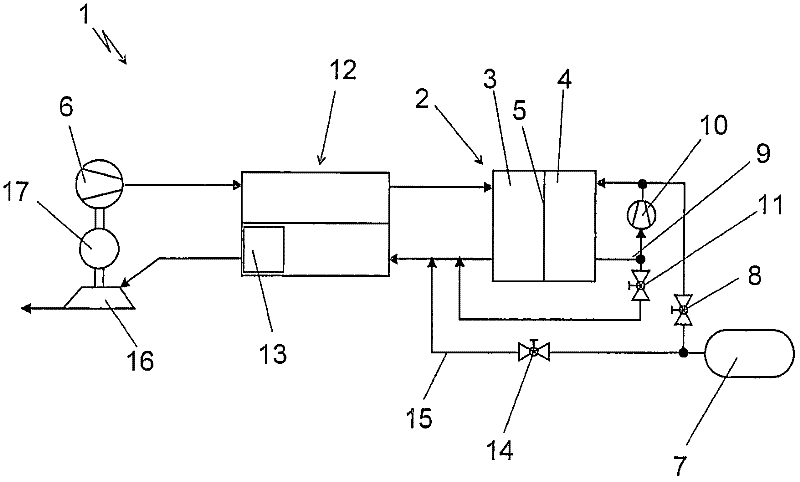

[0019] The illustrations in the following figures show, in very simplified illustrations, only the components necessary to understand the rather complex fuel cell system of the present invention. It is therefore self-evident for the fuel cell system that further components, such as cooling circuits etc., are also provided within the fuel cell system, although they are also not considered in the figures shown below.

[0020] figure 1 A fuel cell system 1 comprising a fuel cell 2 is now shown. The fuel cell 2 thus comprises a stack of individual cells constructed in a conventional manner. A cathode region 3 and an anode region 4 are formed in the fuel cell 2 , and these regions are separated from each other by a PE membrane 5 in the present embodiment. exist figure 1 In the illustrated embodiment, the intake air flow is delivered to the cathode zone 3 by means of a compressor 6 . The compressor 6 can thus be designed, for example, as a screw compressor or as a flow compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com